Improvement of the microstructure and magnetic properties of(La,Ce)–Fe–B nanocrystalline ribbons

Li-Yu Lian(連李昱), Xiao-Wei Zhang(張曉偉), Ying Liu(劉穎),2,Jun Li(李軍),?, and Ren-Quan Wang(王仁全)

1School of Materials Science and Engineering,Sichuan University,Chengdu 610065,China

2Key Laboratory of Advanced Special Material&Technology,Ministry of Education,Sichuan University,Chengdu 610065,China

Keywords: (La,Ce)–Fe–B,La/Ce ratio,rare earth content,secondary phases inhibition

1.Introduction

To curb the cost of permanent magnet production, the cost-effective Ce–Fe–B[1–3]and(La,Ce)–Fe–B[4–9]rare earth permanent magnets have attracted wide attention.Herbstet al.[10,11]and Soedaet al.[12]reported the hard magnetic properties of Ce2Fe14B and (La,Ce)2Fe14B compounds, respectively.With the addition of Hf,[13]Ta[14]and Ga[15,16]to Ce–Fe–B type magnets,finer matrix phase grains and good magnetic properties have been obtained.However, the secondary phases (such as CeFe2,β-La phases, etc.) in these magnets result in deterioration of the microstructure and poor magnetic properties.[15,17]Recent investigations have been made on elemental dopants to inhibit secondary phases.Zhanget al.[18]and Rehmanet al.[19]reported that Si and Ge atoms enter into the lattice of the CeFe2phase and suppress the generation of the CeFe2phase.The growth of the matrix phase grains and the formation of the CeFe2phase have been inhibited by the addition of Mo.[20]In comparison,fewer reports have focused on the effect on secondary phase inhibition of light rare earth elements substituted for Ce.

Our previous study investigated the contribution of La to expanding the formation temperature gap between(La,Ce)2Fe14B and metastable Ce2Fe17phases.[21]Recent work on(La,Ce)2Fe14B alloys[22]verified the relationship between phase consistency and magnetic properties.Unlike elemental dopant methods,La atoms may enter into the Ce2Fe14B phase lattice and improve the magnetic properties.[23]Therefore,our understanding of the effect of La on variation of the microstructure and magnetic properties in (La,Ce)–Fe–B ribbons still needs to be clarified.

In this work,(La,Ce)–Fe–B ribbons with different La/Ce ratios and rare earth element contents were prepared.The relationship between the microstructure of ribbons and the magnetic performance was investigated.A fine microstructure was obtained in ribbons with good magnetic properties.

2.Experimental method

Two kinds of cast ingots were prepared by induction melting: Ce–Fe–B type alloy and (La,Ce)–Fe–B type alloy.The Ce–Fe–B type alloy had the nominal compositions of CezFe94?zB6(z= 12, 13, 14, 15, 16) and the (La,Ce)–Fe–B type alloy had nominal compositions of(LayCe100?y)xFe94?xB6(x=12,14,16 andy=0,15,25,35,50).The constituent metals had a purity better than 99.8 wt.%and the whole process of casting took place under an argon atmosphere.The cast ingot was remelted in a quartz tube for the homogenization of alloy composition, followed by rapid quenching at a molybdenum wheel at a speed of 45 m·s?1.The rapidly quenched ribbons were placed in a tube furnace and heated at 525?C for 15 min under a vacuum to ensure their complete crystallization.Standard bonded magnets were prepared to verify the magnetic properties of the ribbons.The mixture,combining the magnetic powder with epoxy resin in the proportion of 100:2.5, was pressed into a cylinder with a density of about 6.0 g·cm?3.These bonded magnets were solidified at 175?C for 90 min.

The phase constitution and structure of Ce–Fe–B type and(La,Ce)–Fe–B type alloys were characterized by an x-ray diffraction(XRD)analyzer with CuKαradiation(λ=1.54 ?A)and CoKαradiation (λ= 1.79 ?A), respectively, over a 2θrange of 20?–70?.The refinement results were calculated by the Rietveld method via general structure analysis system(GSAS)software.[24]Magnetic properties were measured with a vibrating sample magnetometer(VSM;Lakeshore 7410)by applying a maximum magnetic field of 2.5 T.The hysteresis curves were corrected with a demagnetization factor(N)equal to 0.21.[25]Bonded magnets were measured by an automatic measuring instrument for magnetization characteristic(AMT-4).The morphology of the ribbons was investigated by a scanning electron microscope(FEI Inspect F50)and a transmission electron microscope(TEM;FEI Talos F200X)equipped with energy dispersive x-ray spectroscopy (EDX; Super X).The equivalent diameter data were collected via Image Pro Plus(IPP)software with counts of at least 300.

3.Results and discussion

3.1.Phase constitution and magnetic properties of Ce–Fe–B type alloys

To understand the phase variation in Ce–Fe–B alloys,melt ribbons with Ce content changed from 12 at.%to 16 at.%.were prepared.Figure 1(a) shows the XRD pattern of each crystallized ribbon.It is noteworthy that the secondary phase(CeFe2)emerges when the Ce content is 14 at.%.Due to the Curie temperature of the CeFe2phase being much lower than room temperature(about 225 K),[26]this secondary phase exhibits paramagnetism under the working condition of permanent magnets.Meanwhile,the relative intensity of the diffraction peaks of the CeFe2phase in the alloy was enhanced with the growing concentration of Ce,which means that the weight fraction of CeFe2in ribbons grew simultaneously.

Fig.1.XRD patterns of Ce–Fe–B alloys(a)and the magnetic properties of Ce–Fe–B ribbons(b).

The magnetic properties of Ce–Fe–B type alloys with rare earth element contents from 12 at.% to 16 at.% were tested with a VSM and are shown in Fig.1(b).The variation of coercivity for the ribbons shared the same trend as the Ce content in the alloys, but a slight lump was found in the magnetic remanence plot.The Ce16Fe78B6ribbon exhibited the best comprehensive properties, withHcj=5.4 kOe and (BH)max=5.22 MGOe, respectively.Grigoraset al.[27]and Liet al.[28]investigated such a phenomenon for the evolution of magnetic properties with variation in the rare earth content, which may be attributed to the phase constitution in alloys.Recent investigations[29,30]reported that the paramagnetic CeFe2phase would effectively isolate and decouple the matrix phase grains.In addition, due to the good wettability of the Ce-rich phase, it would flow into the gap between matrix grains and form grain boundaries (GBs).[31]The exchange coupling effect would be weakened if GBs individually isolated matrix phase grains.Moreover,the relatively low solidification point of the intergranular phase may smooth the edge of hard magnetic phase grains.The regularization of matrix grains in ribbons would lead to a decrease in the effective demagnetization factor(Neff)and improve coercivity.As a result of these factors, the coercivity of Ce–Fe–B type alloy is increased as the Ce content increases.Meanwhile, the proportion of the Ce2Fe14B (2:14:1) phase in Ce–Fe–B type alloys should also be addressed, as this would directly affect the magnetic properties of ribbons.Thus,the increasing concentration of Ce would generate more CeFe2phase and dilute the magnetic remanence of the ribbons.

3.2.Effects of La/Ce ratio on the microstructure and magnetic properties

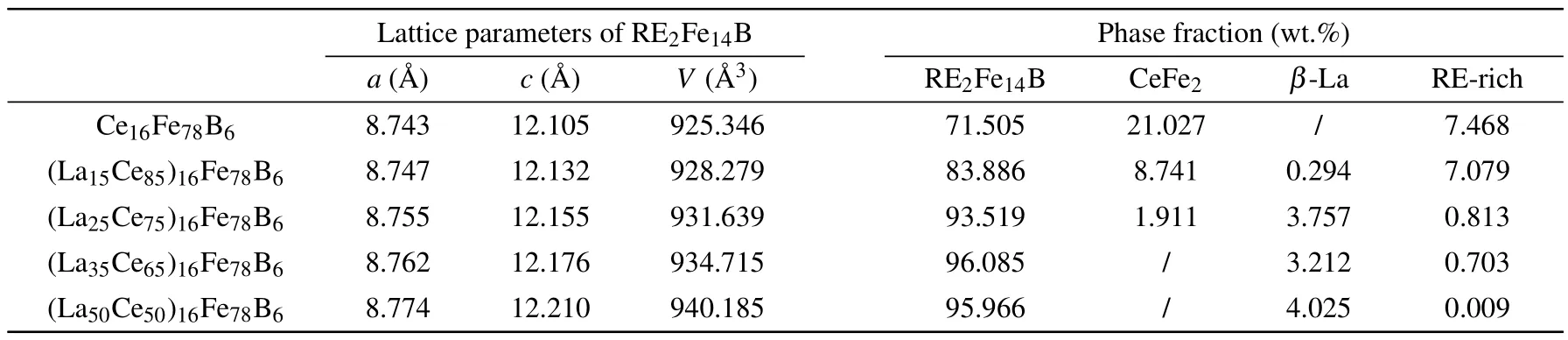

A rare earth element content of 16 at.% was selected for its excellent performance in Ce–Fe–B type ribbons.The Rietveld refinement patterns for differentyvalues in(LayCe100?y)16Fe78B6ribbons are exhibited in Fig.2(a).The lattice parameters of the RE2Fe14B phase (RE=rare earth)and the phase composition of each ribbon are listed in Table 1.Withyincreasing from 0% to 25%, the mass fraction of the CeFe2phase drops from 21.027 wt.% to 1.911 wt.%.Whenyreaches 35%, the 1:2 phase is completely suppressed by La.Due to the instability of the (La,Ce)Fe2phase[32]and the expanded gap in the formation temperature between(La,Ce)2Fe14B and metastable Ce2Fe17phases,[21,33]the CeFe2phase is gradually suppressed with the increasing La/Ce ratio.Given the relatively high temperature(796.75?C)of the invariant reaction(L?α-Fe+β-La),[34]theβ-La phase formed when the La ratio varied from 15% to 50% and the mass fraction of theβ-La phase increased drastically from 0.294 wt.% to 4.025 wt.%.Theγ-Ce phase[35]is a product of a eutectic reaction at about 604?C following the formula L?CeFe2+γ-Ce and was found in(LayCe100?y)16Fe78B6ribbons with a high Ce content.Because La atoms may dissolve into theγ-Ce phase, theγ-Ce phase was named the RE-rich phase in this work.With an increasing La/Ce ratio andβ-La phase generation,the fraction of the RE-rich phase decreased from 7.468 wt.% to 0.009 wt.% in (LayCe100?y)16Fe78B6alloys.

As the substitution of La increased from 0%to 50%,the lattice parameters of(LayCe100?y)16Fe78B6ribbons expanded with a near-linear trend, as shown in Table 1 and Fig.2(b).Because of the larger atomic radius of La compared with Ce,the substitution of La atoms for Ce atoms in the 2:14:1 phase would bring about an expansion of lattice space.Therefore,an increasing La/Ce ratio promotes more La atoms to occupy Ce lattice sites in the Ce2Fe14B tetragonal lattice.

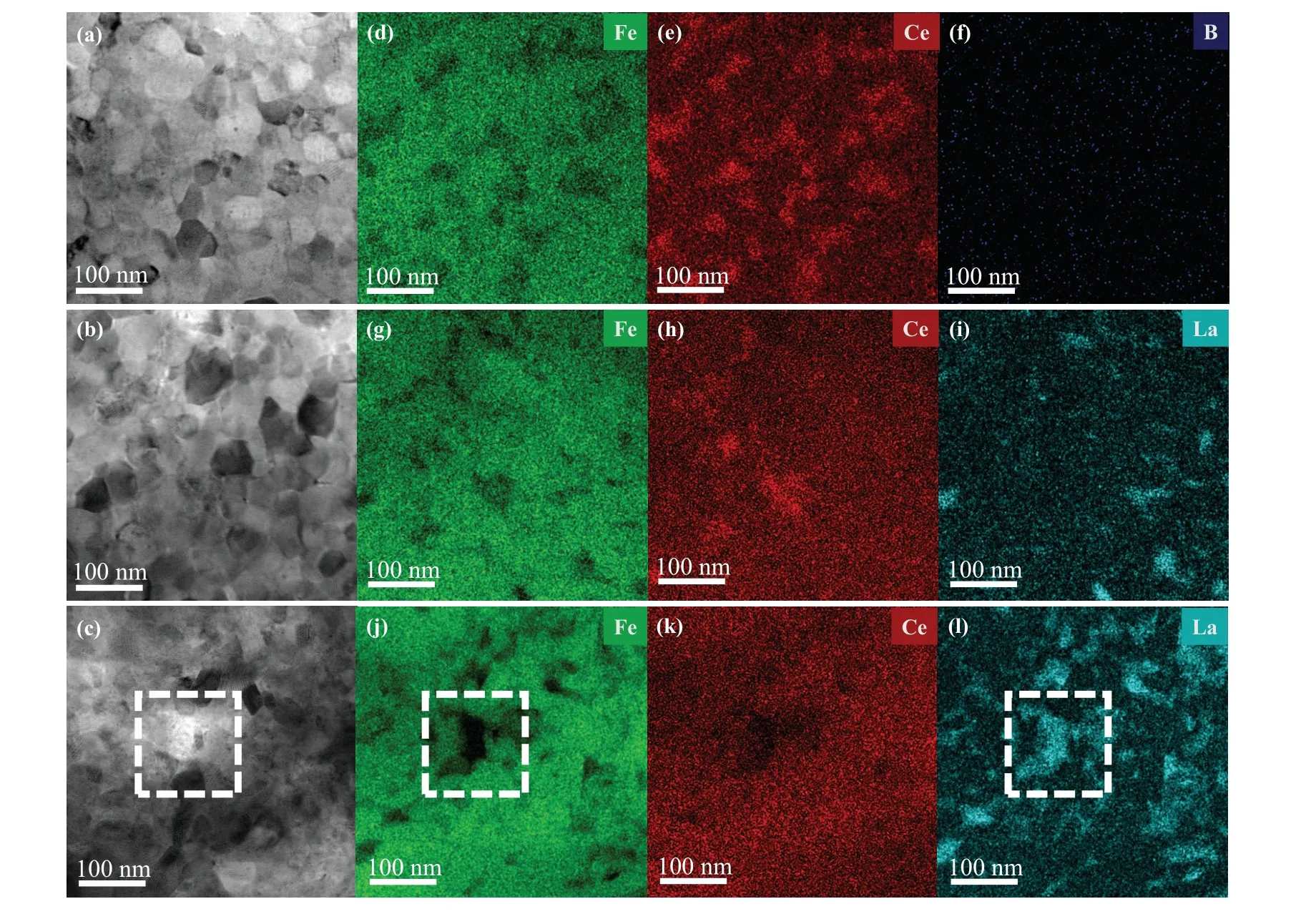

To clarify the elemental distribution in ribbons,TEM and EDX mapping studies for different La/Ce ratios were performed,as shown in Fig.3.The bright-field TEM images for Ce16Fe78B6,(La15Ce85)16Fe78B6and(La35Ce65)16Fe78B6are demonstrated in Figs.3(a),3(b)and 3(c),respectively.Fe,Ce,B and La were selected for mapping scanning and the detected regions are exhibited in Figs.3(d)–3(l).The concentration of rare earth elements in (LayCe100?y)16Fe78B6alloys is excessive for formation of the matrix phase.Hence,the aggregation of rare earth elements is inevitable, as reflected in Figs.3(e),3(h), 3(i), 3(k) and 3(l).With the La/Ce ratio increased, the aggregating areas of La expanded.The positive formation energy[36]of La2Fe14B may induce more serious segregation of La than Ce.Notably,a large area of La segregation(with a length of about 112.16 nm)is found in Fig.3(l).This critical aggregation may accelerate the consumption of excessive rare earth atoms in the(La35Ce65)16Fe78B6ribbon.

Fig.2.XRD patterns of(LayCe100?y)16Fe78B6 alloys(a)and the refined lattice parameters for(La?Ce100?y)16Fe78B6 alloys(b).

Table 1.The refined lattice parameters and phase fractions of(LayCe100?y)16Fe78B6 alloys.

Fig.3.Bright-field (BF) TEM images for the rapidly quenching ribbons: Ce16Fe78B6 (a), (La15Ce85)16Fe78B6 (b) and (La35Ce65)16Fe78B6(c).The TEM-EDX elemental mappings of each ribbon are shown in(d)–(l).

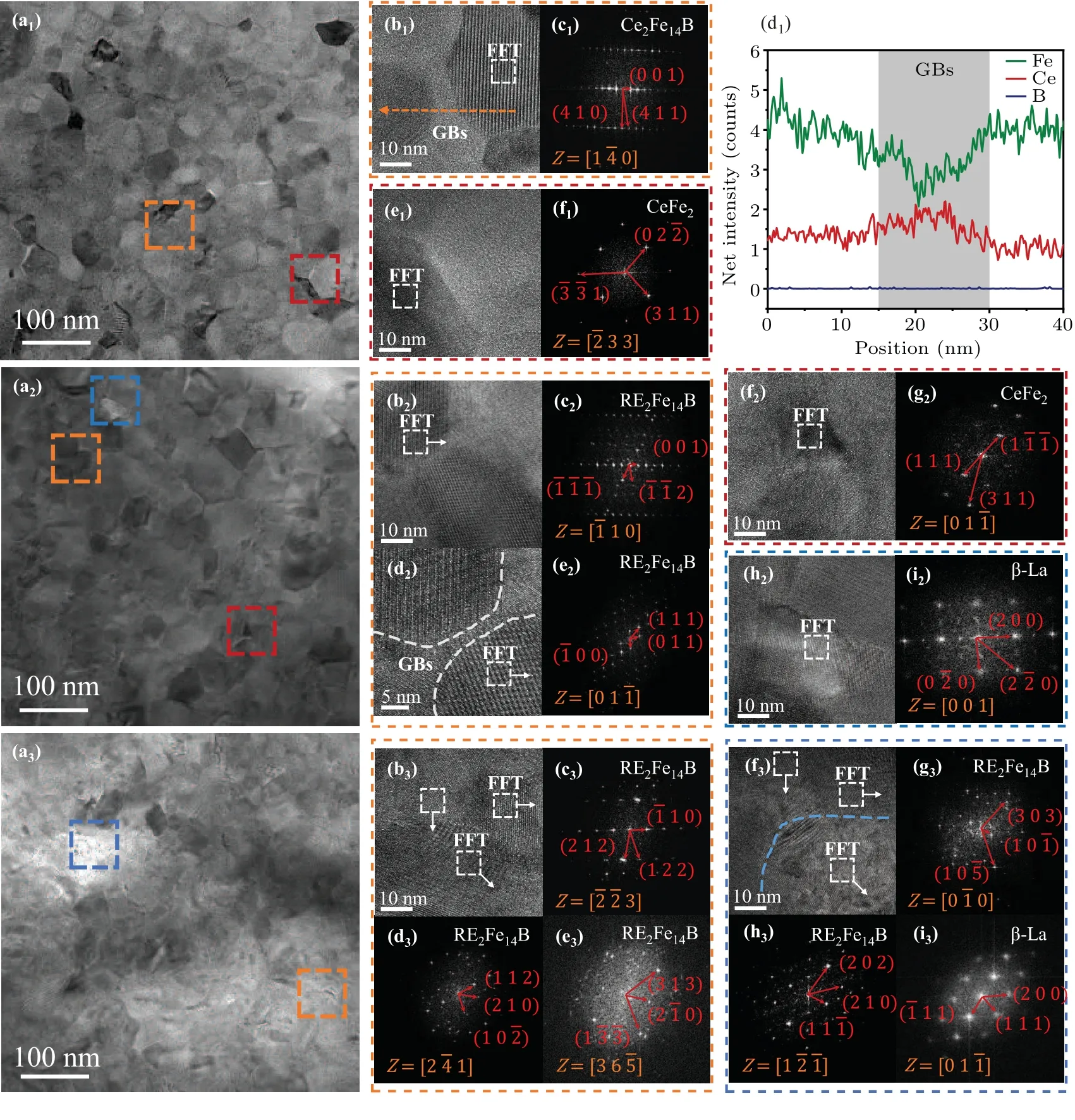

The TEM images of ribbons for Ce16Fe78B6,(La15Ce85)16Fe78B6and (La35Ce65)16Fe78B6are exhibited in Figs.4(a1), 4(a2) and 4(a3).Figure 4(b1) shows the highresolution TEM(HRTEM)image of the orange square area in Fig.4(a1).It shows the region far from the secondary phase in the Ce16Fe78B6ribbon.A 2:14:1 phase grain was confirmed via a fast Fourier transformation (FFT) pattern, as shown in Fig.4(c1).By virtue of the high fraction of rare earth-rich phase in the Ce16Fe78B6alloy,rare earth atoms were gathered in this region, and GBs (with a thickness of about 7.62 nm)were formed between 2:14:1 phase grains.The EDX line scanning results for the GBs are exhibited in Fig.4(d1).This further proved that the composition of GBs is enriched with rare earth elements.Figure 4(b2)shows a similar area remote to the secondary phase in the(La15Ce85)16Fe78B6ribbon and is marked with an orange square in Fig.4(a2).The adjacent matrix grains were confirmed via FFT patterns in Figs.4(c2)and 4(e2).Clear GBs (with a thickness of about 3.53 nm)were formed between them and are exhibited in an enlarged image in Fig.4(d2).The orange square in Fig.4(a3) is the area far from the secondary phase in the (La35Ce65)16Fe78B6ribbon.In the HRTEM image(Fig.4(b3))of this area,matrix grains were confirmed by FFT patterns in Figs.4(c3)–4(e3).However, there is no obvious GB around these matrix phase grains.

The CeFe2phase exists in regions marked with red squares in Figs.4(a1) and 4(a2), these being TEM images for the Ce16Fe78B6ribbon and the (La15Ce85)16Fe78B6ribbon, respectively.HRTEM images of these areas are shown in Figs.4(e1)and 4(f2),respectively.The CeFe2phase grains were verified from the FFT images in Figs.4(f1) and 4(g2).These 1:2 phase grains are distributed in the triple junctions among matrix grains that directly contact each other,as shown in Figs.S1(a1–f1)and(a2–d2).

Theβ-La phase grains were found in(La15Ce85)16Fe78B6and are marked with a blue square in Fig.4(a2).Figure 4(h2)shows the HRTEM image of this blue square, and theβ-La phase grains were confirmed by the FFT pattern in Fig.4(i2).The large segregation area of La in (La35Ce65)16Fe78B6ribbons is marked with a blue square in Fig.4(a3).The HRTEM and FFT images of the segregation area are shown in Figs.4(f3)and 4(i3).It is noticeable that aβ-La phase grain formed in this segregation region.Figures 4(g3)and 4(h3)are FFT images for neighboring 2:14:1 phase grains.However,there is no apparent intergranular phase between adjacent matrix phase grains that are next to theβ-La phase,as shown in Figs.S1(e2)–(k2).

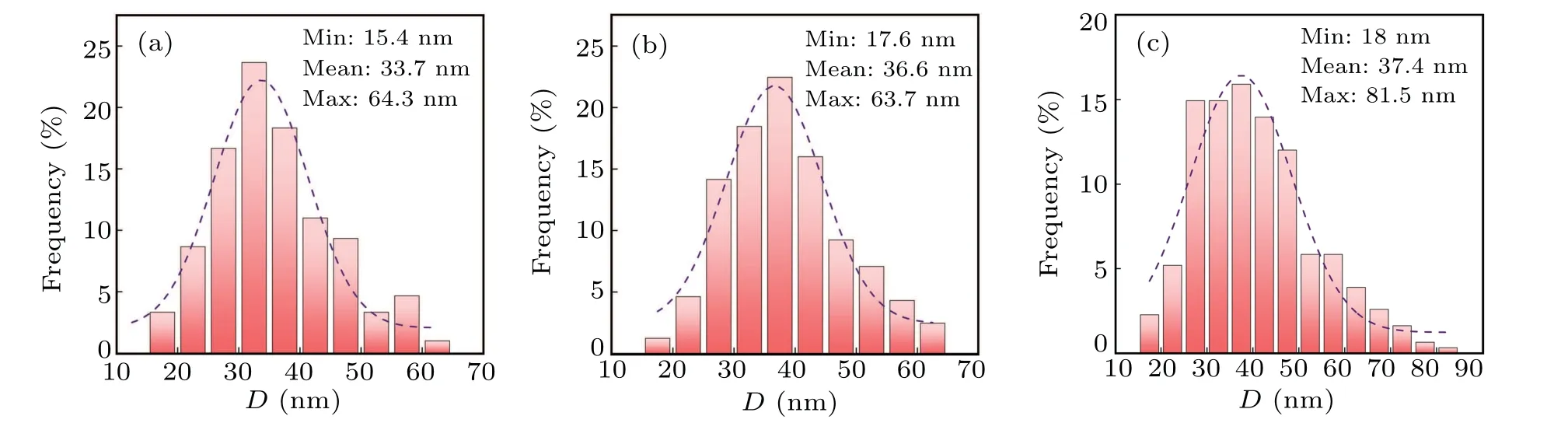

Statistical graphs of the equivalent diameter (D) of matrix phase grains for Ce16Fe78B6, (La15Ce85)16Fe78B6and(La35Ce65)16Fe78B6ribbons are exhibited in Figs.5(a)–5(c),respectively.When the La/Ce ratio changed from 0%to 35%,the mean equivalent diameter of the matrix grains increased from 33.7 nm to 37.4 nm.

Fig.4.Bright-field TEM images for the rapidly quenching ribbons Ce16Fe78B6 (a1),(La15Ce85)16Fe78B6 (a2)and(La35Ce65)16Fe78B6 (a3).Areas remote to secondary phases are marked as orange squares in (a1), (a2) and (a3).The high-resolution TEM (HRTEM) and fast Fourier transformation (FFT) images for the orange squares are shown in (b1) and (c1), (b2) and (e2) and (b3) and (e3), respectively.The EDX line scanning result for the grain boundaries of(b1)is shown in(d1).The CeFe2 phase exists in areas marked as red squares in(a1)and(a2).The HRTEM and FFT images for the red squares are shown in(e1)and(f1)and(f2)and(g2),respectively.The β-La phase exists in areas marked as blue squares in(a2)and(a3).The HRTEM and FFT images for blue squares are shown in(h2)and(i2)and(f3)and(i3),respectively.

Fig.5.Statistical graphs of the equivalent diameter of matrix phase grains in Ce16Fe78B6(a),(La15Ce85)16Fe78B6(b)and(La35Ce65)16Fe78B6(c)ribbons.

Figure S2 shows the results of EDX mapping studies of areas containing rare earth-rich andβ-La phases, respectively.For the area where a rare earth-rich phase is present(Fig.S2(a)), the elements are homogeneously distributed, as shown in Figs.S2(b)–(d).Benefiting from the good mobility of the rare earth-rich phase, the length of the segregation area of Ce is as little as 12.6 nm.Therefore, in Ce16Fe78B6and (La15Ce85)16Fe78B6ribbons, the relatively high fraction of the rare earth-rich phase would promote sufficient rare earth atoms to form GBs.For(La35Ce65)16Fe78B6ribbons,in comparison,the rare earth-rich phase fraction(0.703 wt.%)is too low to enclose matrix grains.Moreover, the formation of theβ-La phase consumed excessive rare earth atoms and was aggregated in the junctions among matrix phase grains,as shown in Figs.S2(e)–(h).Both factors are responsible for the deterioration of ribbon microstructure,especially on the GBs.

Fig.6.The hysteresis loops of(LayCe100?y)16Fe78B6 alloys(a)and the magnetic parameters for(LayCe100?y)16Fe78B6 alloys(b).

The magnetic properties of ribbons are closely related to their phase composition and microstructure.Figures 6(a)and 6(b)show the hysteresis loops and magnetic properties of(LayCe100?y)16Fe78B6(y=0, 15, 25, 35, 50) ribbons.The maximum magnetic energy product of 6.5 MGOe was obtained in (La15Ce85)16Fe78B6ribbon.During the increase in La ratio,theBrof the ribbons grew from 5.2 kG to 6.0 kG,but theHcjvalue dropped from 5.5 kOe to 3.3 kOe.

Due to the suppression of CeFe2by La in (La,Ce)–Fe–B ribbons, the relative content of the matrix phase and the magnetic remanence are improved.Furthermore, referring to the density functional theory results calculated by Alamet al.[37]the valence of the Ce element is sensitive to the environment of atoms in the crystal lattice.The expansion of the Ce2Fe14B lattice space would promote the valence to a +3 state, which means the magnetic moment of a single crystal would be enhanced.[38]As a result, the ribbon’s magnetic remanence was improved after La substituted for Ce in the alloy.

The size of matrix phase grains increased with increase in the La/Ce ratio, leading to the deterioration of coercivity.Meanwhile, based on the results of theoretical calculations, the anisotropy field (HA) of the La2Fe14B compound(20 kOe)[10]is lower than that of the Ce2Fe14B compound(26 kOe).When La atoms entered the Ce2Fe14B lattice structure,the(La,Ce)2Fe14B matrix phase would be formed with a relatively lowerHAthan Ce2Fe14B.[21]In addition, as the La content increased,fractions of the rare earth-rich phase and the CeFe2phase decreased, strengthening the exchange coupling effect between matrix phase grains.[17]The large segregation area of theβ-La phase would generate poor GBs between matrix grains,[4]and they may act as nucleation sites for the reverse magnetization domains and worsen theHcjof ribbons.In summary, all these factors would induce the deterioration of coercivity in(La,Ce)16Fe78B6.

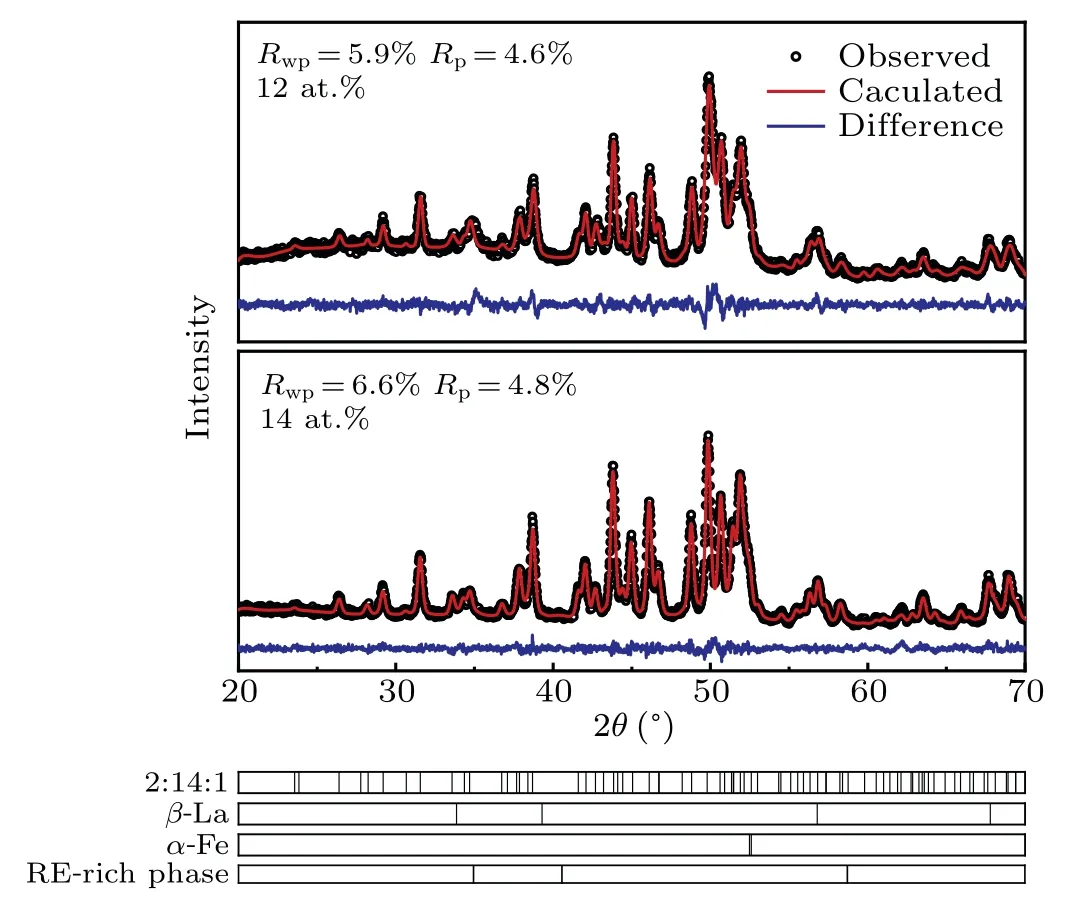

3.3.Effects of rare earth content on microstructure and magnetic properties

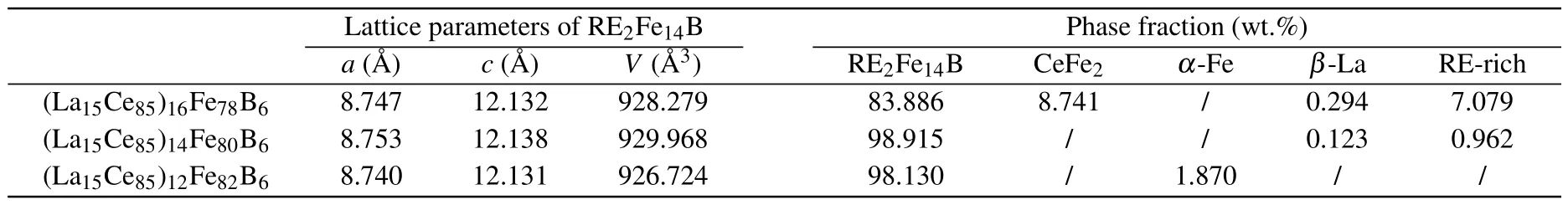

Due to the inhibitory effect on the CeFe2phase and the relatively low fraction of theβ-La phase,a proportion of 15%of La in(La,Ce)–Fe–B alloy was selected as the optimal La/Ce ratio.The Rietveld refinement results for(La15Ce85)12Fe82B6and (La15Ce85)14Fe80B6ribbons are given in Fig.7 and Table 2.The paramagnetic CeFe2and theβ-La phases are faded in (La15Ce85)14Fe80B6and (La15Ce85)12Fe82B6alloys.The CeFe2phase was wholly suppressed in (La15Ce85)14Fe80B6alloy shown by the low relative intensity of CeFe2in the XRD pattern of Ce14Fe80B6.With the reducing content of La, the formation of theβ-La phase was suppressed in the(La15Ce85)14Fe80B6ribbon with a low fraction of 0.123 wt.%.With the smaller rare earth content in the(La15Ce85)14Fe80B6ribbon than in the (La15Ce85)16Fe78B6ribbon, the fraction of the rare earth-rich phase declined from 7.079 wt.% to 0.962 wt.%.However, because of the repulsion between La and Fe[39,40]in forming a compound,theα-Fe phase forms in(La15Ce85)12Fe82B6ribbon with a phase fraction of 1.87 wt.%.

Fig.7.XRD pattern of(La15Ce85)12Fe82B6 and(La15Ce85)14Fe80B6 alloys.

For (La15Ce85)14Fe80B6alloy, the La content is higher than in (La15Ce85)12Fe82B6alloy.This may promote more La atoms to enter into the matrix phase lattice and generate a greater lattice space.In comparison,the lattice parameters are much closer forx=14 at.%and 16 at.%alloys,in agreement with a previous report.[23]

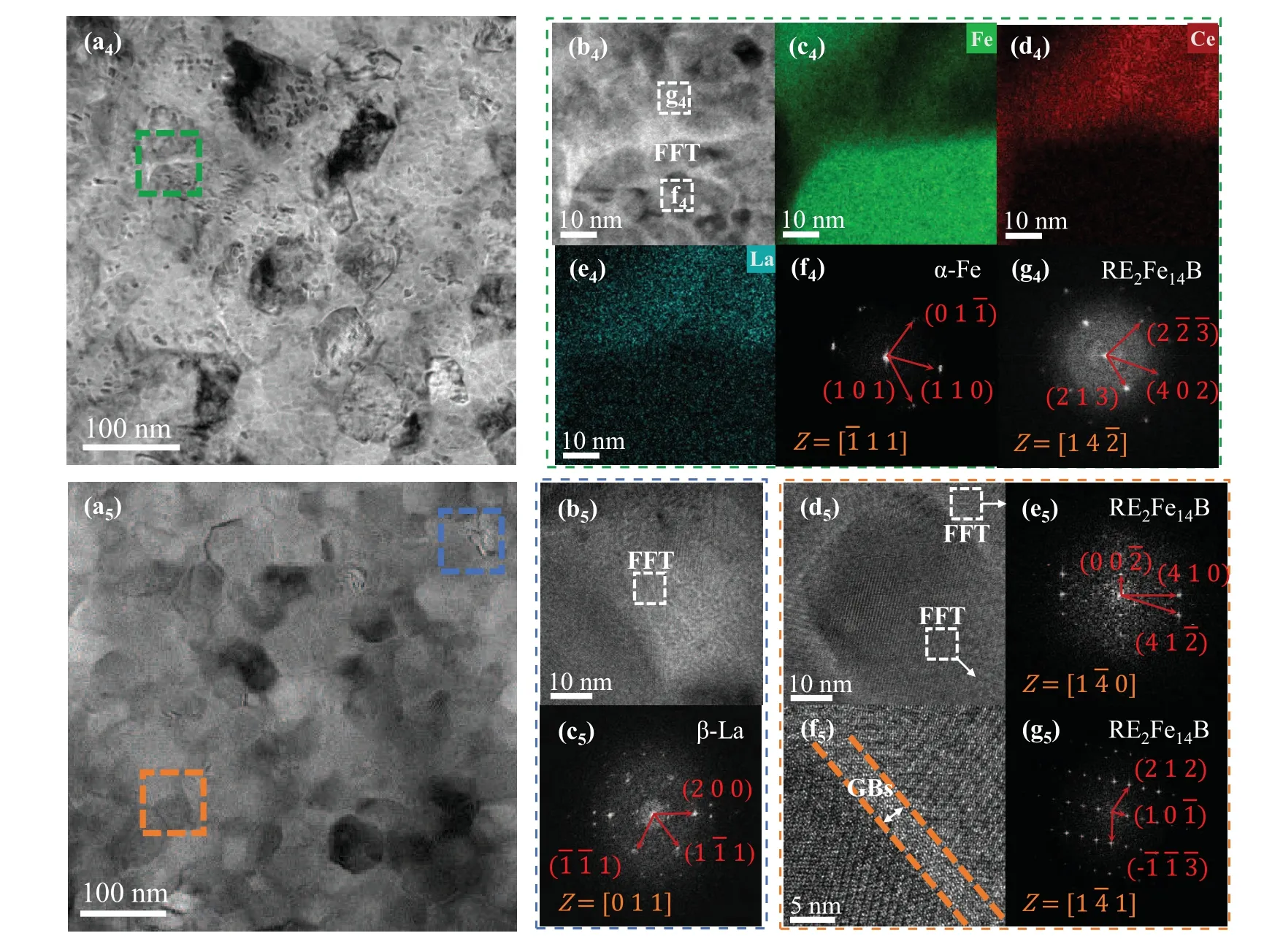

The TEM results for (La15Ce85)12Fe82B6and(La15Ce85)14Fe80B6ribbon are shown in Fig.8.Figure 8(b4)is the enlarged bright-field TEM image for the area marked with a green square in Fig.8(a4).An EDX mapping study for Fe,Ce and La in this area was done and the results are shown in Figs.8(c4)–8(e4).In (La15Ce85)12Fe82B6ribbon, a large Fe segregation region (with a length of about 65.13 nm) was found,and theα-Fe phase was confirmed via the FFT pattern(Fig.8(f4))in this region.The 2:14:1 phase next to this region was verified by the FFT image in Fig.8(g4).

Table 2.The refined lattice parameters and phase fractions of(La15Ce85)16Fe78B6,(La15Ce85)14Fe80B6 and(La15Ce85)12Fe82B6 alloys.

Fig.8.Bright-field TEM images for the rapidly quenching ribbons (La15Ce85)12Fe82B6 (a4) and (La15Ce85)14Fe80B6 (a5).The α-Fe phase exists in the area marked as the green square in(a4).The bright-field TEM images and the TEM-EDX elemental mappings of the green square are shown in(b4)and(e4).Parts(f4)and(g4)show FFT images for areas marked with white squares in(b4).The β-La phase exists in the area marked with a blue square in(a5).The HRTEM and FFT images for the blue square are shown in(b5)and(c5).The area remote to the β-La phase is marked as an orange squares in(a5).The HRTEM and FFT images for the orange square are shown in(d5)and(g5).

Figure 8(b5) is the HRTEM image of the region marked with a blue square in Fig.8(a5).Theβ-La phase in this region was confirmed by the FFT pattern(Fig.8(c5)).In this region,the GBs between neighboring matrix grains are obscure.The area far from theβ-La grains is marked with an orange square in Fig.8(a5).Clear GBs have been formed with a thickness of 2.75 nm,as displayed in Fig.8(d5)and enlarged in Fig.8(f5).Both grains were confirmed as the matrix phase via FFT images in Figs.8(e5) and 8(g5).The reduction of the rare earth content inhibits the formation of secondary phases(the CeFe2andβ-La phases)and curbs the consumption of excessive rare earth elements.Thus, the rare earth-rich phase remained in(La15Ce85)14Fe82B6ribbon with a fraction of 0.962 wt.%,and clear GBs can be generated between the matrix phase grains.

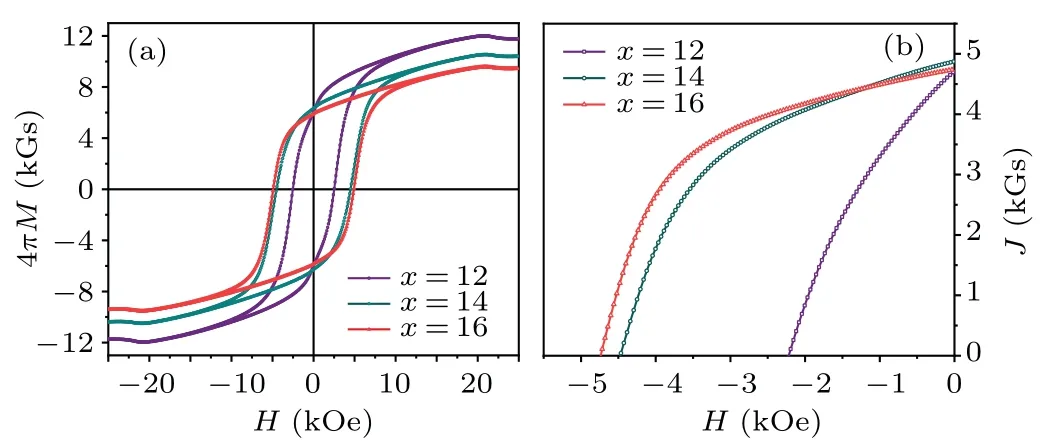

The variation of magnetic properties and the hysteresis loops of (La15Ce85)xFe94?xB6(x= 12, 14, 16) ribbons are shown in Fig.9(a).As the rare earth element content decreases, the coercivity of the melt-spun ribbons dropped from 4.9 kOe to 2.5 kOe.On the contrary, theBrof stripes attained a peak of 6.29 kG whenx= 14 at.%.The magnetic remanence of the (La15Ce85)12Fe82B6ribbon is lower than that of the (La15Ce85)14Fe80B6ribbon by 0.2 kG.Compared with the (La15Ce85)16Fe78B6ribbon, theHcjvalue of the(La15Ce85)14Fe80B6ribbon decreased slightly by 0.4 kOe.This may be due to the contribution of the inhibition of secondary phases and the formation of GBs in the (La15Ce85)14Fe80B6ribbon.The optimal (BH)max(6.81 MGOe) was achieved in (La15Ce85)14Fe80B6ribbons withHcj= 4.51 kOe.A best (BH)maxof 4.5 MGOe for(La15Ce85)14Fe80B6bonded magnet was obtained, as shown in Fig.9(b).

Fig.9.The hysteresis loops of(La15Ce85)xFe94?xB6 ribbons(a)and the demagnetization curves of bonded(La15Ce85)xFe94?xB6 magnets(b).

In the(La15Ce85)12Fe82B6ribbon,the exchange coupling effect exists between hard–soft magnetic grains and hard magnetic grains.[41]The large size of theα-Fe phase grain prevented complete exchange hardening of the soft magnetic phase.[42]Furthermore,the large soft magnetic area in the ribbon weakened the exchange coupling effect between matrix grains.[43]Thus,the(La15Ce85)12Fe82B6ribbon had lower coercivity and magnetic remanence than the(La15Ce85)14Fe80B6ribbon.Thinner GBs and a lower fraction of secondary phases were obtained in they=14 ribbon, which could explain the slightly lower coercivity and stronger remanence than for they=16 one,which had a more robust exchange interaction.To sum up, a declining rare earth content decreases the weight of secondary phases and heightens the intergranular exchange coupling between the matrix phase grains.

4.Conclusion

In this work,the phase composition and microstructure of(La,Ce)–Fe–B rapidly quenching ribbons have been modified via a reasonable composition design.The solute behavior of La atoms entering into the matrix phase lattice has been discussed.An increasing ratio of La in (La,Ce)–Fe–B induces a near-liner expansion of lattice parameters and variation of the intrinsic properties in the matrix phase.Due to the decline ofHAand the enhancement of magnetic moment that occurred in the 2:14:1 phase lattice,the magnetic properties of ribbons would be affected.In the alloy with a relatively high rare earth content(16 at.%),the formation of secondary phases(the CeFe2andβ-La phases)is hard to avoid and would result in microstructural deterioration.Reducing the rare earth content suppressed the formation of these secondary phases and strengthened the exchange coupling effect between grains.A fine microstructure with a shallow secondary phase fraction was obtained in the (La15Ce85)14Fe80B6ribbon.Good magnetic properties with(BH)max=6.81 MGOe,Hcj=4.51 kOe andBr=6.29 kG were found for the(La15Ce85)14Fe80B6ribbon.A bonded magnet with (BH)max=4.5 MGOe was prepared.

Acknowledgement

Project supported by the fifth batch of major scientific and technological research projects in the Panxi Experimental Zone of Sichuan Province, the new functional materials and applications of rare earth vanadium titanium (Grant No.2020SCUNG201).

- Chinese Physics B的其它文章

- First-principles calculations of high pressure and temperature properties of Fe7C3

- Monte Carlo calculation of the exposure of Chinese female astronauts to earth’s trapped radiation on board the Chinese Space Station

- Optimization of communication topology for persistent formation in case of communication faults

- Energy conversion materials for the space solar power station

- Stability of connected and automated vehicles platoon considering communications failures

- Lightweight and highly robust memristor-based hybrid neural networks for electroencephalogram signal processing