Cooling Technology for Thrust Chamber of LM-5B LOX/kerosene Engine

HOU Ruifeng,LI Longfei*,LU Gang,CHEN Jianhua

Science and Technology on Liquid Rocket Engine Laboratory,Xi’an Aerospace Propulsion Institute,Xi’an 710100

Abstract: The LM-5B launch vehicle has successfully completed four missions.Eight high-pressure staged combustion LOX/kerosene engines (YF-100) are equipped in the four boosters of the LM-5B,two in each booster.The YF-100 engine adopts various cooling techniques to ensure cooling,including a metal thermal barrier coating,multiple liquid film cooling slots,spiral milled regenerative cooling channels with high aspect ratio,a non-weld forming thrust chamber and an optimal cooling flow path design.In addition,the 480-ton LOX/kerosene engine for China’s future heavy-lift launch vehicle LM-9 will be larger in size,which makes it more difficult to be developed and will have more strict requirements in the cooling process.The main differences between the LM-5B and LM-5 are briefly described in this paper and the development process and working characteristics of YF-100 engines are introduced.The advantages and disadvantages of main cooling methods used in the thrust chambers of high-thrust liquid propellant engines are also described.Finally,the future challenges and countermeasures in cooling technology for China’s high-thrust LOX/kerosene engines and future reusable rocket engines are also presented.

Key words: LM-5B,YF-100,staged combustion LOX/kerosene engine,thrust chamber,cooling technology

1 INTRODUCTION

The LM-5B is a new type of large launch vehicle developed from the heritage of the LM-5 carrier rocket with the concepts of seriation,modularization and combination.It is about 53.7 m long.As China’s first one-and-a-half-stage configuration large launch vehicle,it has been mainly used to launch spacecraft into low Earth orbit.

The core stage of the LM-5B uses two YF-77 liquid oxygen/liquid hydrogen (LOX/LH2) rocket engines with 510 kN of thrust at sea level and can swing in two directions.Attached to the LM-5B core stage are four 3.35 m-diameter boosters,each with two YF-100 LOX/kerosene rocket engines arranged in dual-engine parallel mode.They each produce 120 t of thrust,providing 1200 kN of thrust at sea level.As a result,the LM-5B is currently China’s largest low Earth orbit launch vehicle[1].The YF-100 engine has the characteristics of non-toxic,high reliability and high performance.

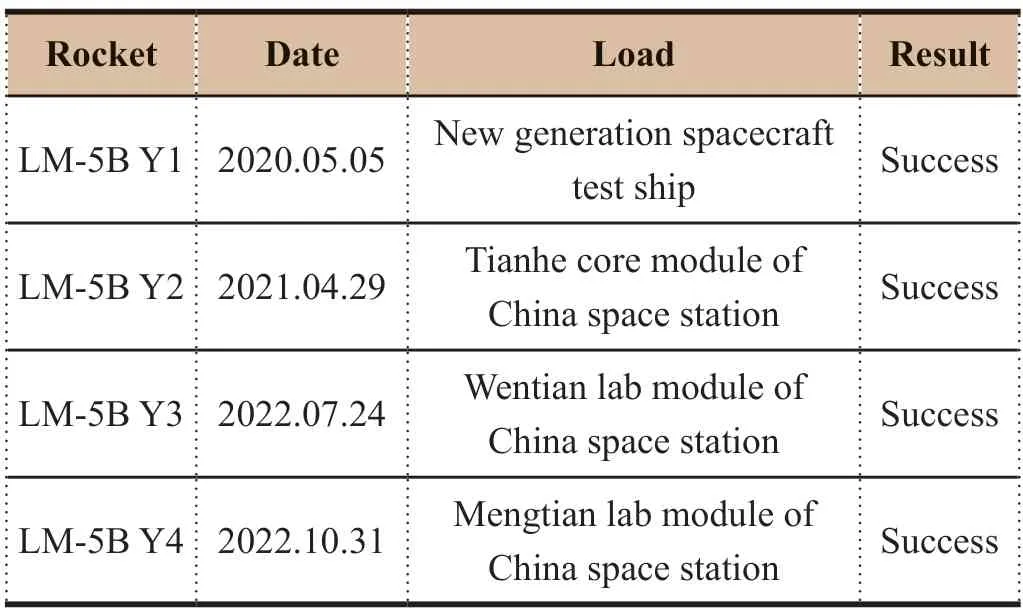

There are three major differences[1]between the LM-5B and LM-5 launch vehicles.Firstly,the LM-5B launch vehicle adopts a one-and-a-half-stage configuration,consisting of a core stage,4 boosters and a module nose cone.Secondly,in order to better meet the mission demands for launching the space station modules,the fairing of LM-5B is 20.5 m long,while the fairing of LM-5 is only 12.3 m long.Thirdly,the LM-5B is mainly used to launch large spacecrafts and modules into low Earth orbit,such as the core module and experimental module of the space station.Benefiting from improvements,the reliability of the LM-5B has been greatly improved.Table 1 shows the launch status of the LM-5B.

Table 1 Launch missions of the LM-5B

As China’s first basic rocket engine with 120 t thrust,the YF-100 engine adopts a staged combustion cycle technology,where it was necessary to resolve several key technical difficulties including developing high-pressure cooling technology for the thrust chamber.

The YF-100 engines have been used in 9 practical engineering applications including the application in the LM-5 launch vehicle,which demonstrates that the cooling technology for YF-100 engines is very reliable.YF-100 engines adopted dual-engine parallel configuration as shown in Figure 1.Figure 2 shows YF-100 engines du-al-engine parallel configuration used in LM-5.

Figure 1 YF-100 engines adopt dual-engine parallel configuration [2]

Figure 2 YF-100 engines in dual-engine parallel configuration used in LM-5 [3]

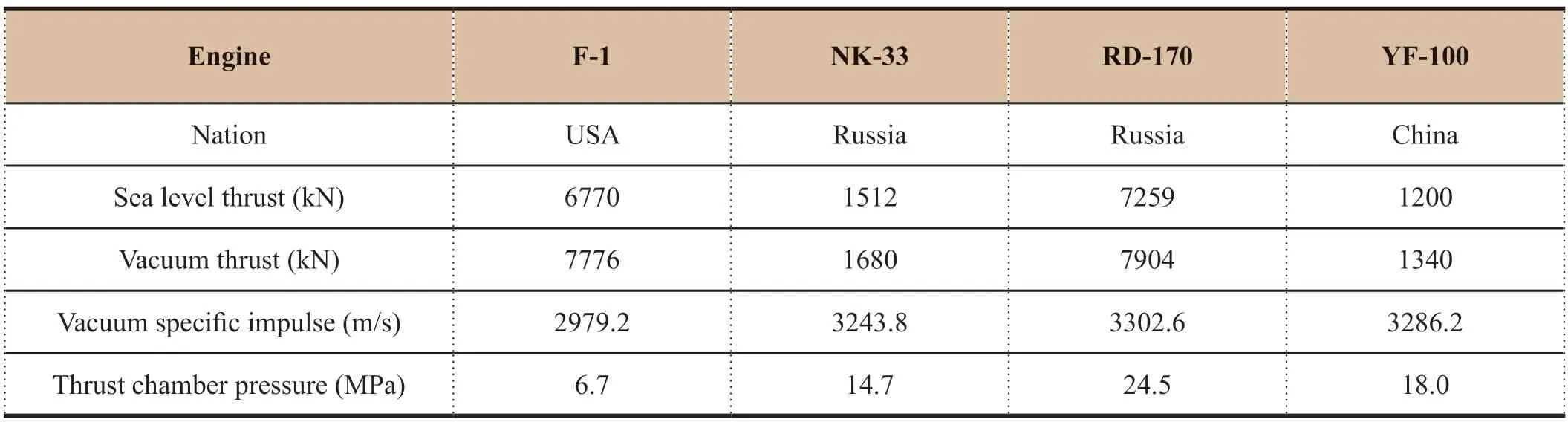

Table 2 shows the parameters of different rocket engines.

Table 2 Comparison of different engine performance parameters

2 DEVELOPMENT AND CHARACTERISTICS OF CHINA’S LOX/KEROSENE ENGINES

The development of the YF-100 engines began 30 years ago,and can be divided into five phases[2-3]: scheme discussion,technology introduction and absorption,research on key technology,engineering development,and for engine application.

In order to meet the future needs for the manned lunar landing,Mars exploration and further deep space exploration,the research and development of China’s heavy-lift launch vehicle has also been on the agenda.Compared to the 5 m-diameter LM-5,the larger-sized LM-9 heavy-lift launch vehicle with higher performance requirements is more difficult to be developed.The LM-9 is designed to produce a thrust of more than 3000 t,providing a carrying capacity to low Earth orbit of more than 100 t and to the Earth-moon transfer orbit of more than 50 t[4-8].

In the process of upgrading the LOX/kerosene engine from the current 120 t thrust to 480 t thrust,the technical difficulty is geometrically increasing rather than simply scaling up.The increase of thrust greatly increases the propellant flow,thrust chamber pressure and heat flux.This brings great challenges in terms of structural design,thermal protection technology and heat transfer technology,and generates extremely high requirements for material properties,sealing processes and engine operational reliability.At present,the 480 t thrust LOX/kerosene engine has successfully completed testing through all its operational phases under realistic operating conditions[9].

3 KEY COOLING TECHNOLOGIES FOR HIGH-PRESSURE THRUST CHAMBER

The thrust chamber is a key component of the YF-100 engine,which needs to operate over a long duration at a high temperature of about 3500°C.It is very difficult to achieve perfect cooling in the thrust chambers of staged combustion rocket engines,with high pressure and high heat flux.Primitive regenerative cooling is unable to cope with the ablation problem caused by higher pressure in the chamber.Especially for engines using liquid oxygen/hydrocarbon propellant,which use fuel as the coolant (such as kerosene),the coking property of the fuel at high temperature will seriously deteriorate the heat transfer capacity in the regenerative cooling channel.This will negatively impact the heat dissipation performance.Figure 3 shows the liquid film cooling slot burned during its hot test.

Figure 3 Burned liquid film cooling slot in the thrust chamber body

In addition,the heat flux of the high-temperature gas also increases rapidly in the high-pressure environment.Due to these factors,under the dual action of the sharp increase of internal temperature and the associated reduced efficiency of external heat dis-sipation,local ablations occur in the thrust chamber,which causes unstable operation of the engine.In order to ensure the reliability of the cooling process,LOX/kerosene engines adopt a combination of various cooling methods,including metal thermal barrier coatings,multiple liquid film cooling slots,spiral milled regenerative cooling channels of high aspect ratio,non-weld formed thrust chambers and a reasonable cooling flow path design[2,10].

3.1 Regenerative Cooling Technology

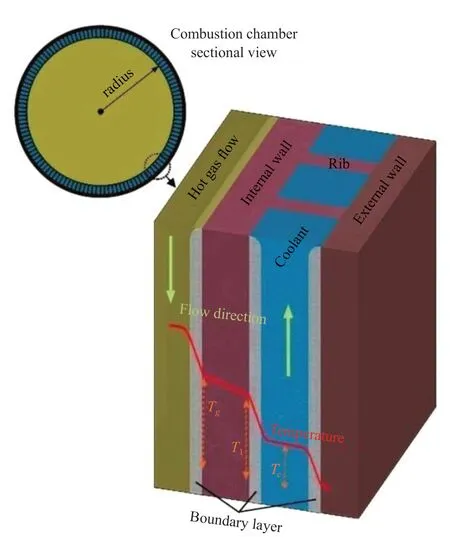

Regenerative cooling is widely used in liquid propellant rocket engines.For regenerative cooling,the propellant is forced to flow close to the outside of the thrust chamber wall and then injected into the combustion chamber to participate in combustion process.The advantage of this cooling technology is that it can transfer heat dissipated from the wall back to the thrust chamber through the conduction of the regenerative coolant.This not only effectively protects the thrust chamber wall from being damaged by high temperature,maintaining it below the permitted temperature,but also reduces heat produced by combustion being lost to the outside environment[11].Figure 4 shows the schematic diagram of the flow of regenerative coolant.

Figure 4 Flow of regenerative coolant [10]

The process of calculating the convective heat transfer density between liquid-side wall and regenerative coolant can be obtained from the turbulent forced heat transfer formula for the tube.The calculation method of convection heat transfer coefficient is as follows:

whereh1is convective heat transfer coefficient,Nuis Nussel number determined by Mikheyev’s modified formula,λis thermal conductivity of regenerative coolant,dis equivalent diameter of regenerative cooling channel.

On the basis of original simple vertical flow regenerative cooling,spiral milled slot regenerative cooling,regenerative cooling using artificial roughness to enhance heat transfer,high aspect ratio channel regenerative cooling have been gradually developed.Spiral regenerative cooling can be applied to the area with high heat flux in the thrust chamber.It can effectively improve the flow rate of the coolant,increase the heat transfer coefficient between the wall and the coolant,keep the circumferential temperature of the same section wall in a uniform state,which can avoid the local ablation caused by uneven gas with high temperature[12].

Compared to simple vertical flow regenerative cooling,regenerative cooling using artificial roughness can effectively increase the heat transfer time between the coolant and the thrust chamber wall,even the temperature distribution of near and far coolant in the regenerative cooling channel,and increase the thermal conductivity of the coolant[7,13].However,the use of regenerative cooling channels with artificial roughness increases the flow resistance of the channels and increases the possibility of coking of the regenerative coolant.Therefore,this technique can be applied in localized regions with high heat flux density.In addition,the regenerative cooling using a high aspect ratio channel can enable the channel number to increase,increase the side surface area of regenerative cooling channel,reduce the pressure drop of coolant,and thus extend the life of regenerative cooling channel.Therefore,this technology is very beneficial for improving the reliability of reusable engines.

On the other hand,the regenerative cooling structure greatly increases engine mass despite its significant enhancement of cooling capacity,high-thrust liquid propellant rocket engines cannot cancel the regenerative cooling structures at present.

3.2 Liquid Film Cooling Technology

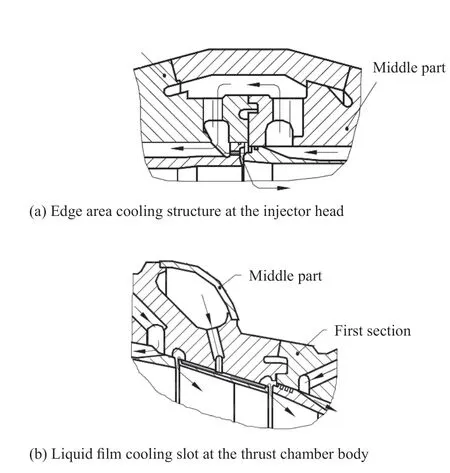

Liquid film cooling in combination with regenerative cooling is used to accomplish thrust chamber cooling in many advanced liquid propellant rocket engines like the RD-170.Employed at different locations,liquid film cooling structures can be divided into an edge area cooling structure at the injector head and a liquid film cooling slot at the thrust chamber body[14].The liquid film cooling slot refers to ring holes or narrow cracks machined in the circumferential direction on the thrust chamber wall.Coolant is injected in the thrust chamber through slots to form a relatively low-temperature fluid layer adjacent to the inner wall,which separates the inner wall from high-temperature gas,reducing temperature of the chamber wall and the regenerative cooling channel.Figure 5 is a schematic diagram of RD-170 injection structure.

Figure 5 Injection structures of liquid film cooling of RD-170 [15]

High-thrust liquid propellant rocket engines often use liquid film cooling for high-pressure thrust chamber cooling.Despite the remarkable cooling effect liquid film cooling suffers from a complicated manufacturing process and high cost.In addition,in order to achieve a better cooling effect,multiple liquid film cooling slots have to be used simultaneously in the thrust chamber for practical engineering applications.The location,flow rate and structures of each cooling slot have a significant nonlinear influence on the final cooling effect.

In some high-pressure thrust chambers,one cooling slot is not enough to protect the thrust chamber.For example,in the RD-170 engine,a total of three cooling slots are used.The location of each cooling slot is designed according to temperature distribution of the thrust chamber wall.The first cooling slot is designed to protect the thrust chamber body from damage,the second to protect the third one from destroying the high-speed hot gas flow,while the third one to reduce the thermal protection pressure in the thrust chamber throat section.

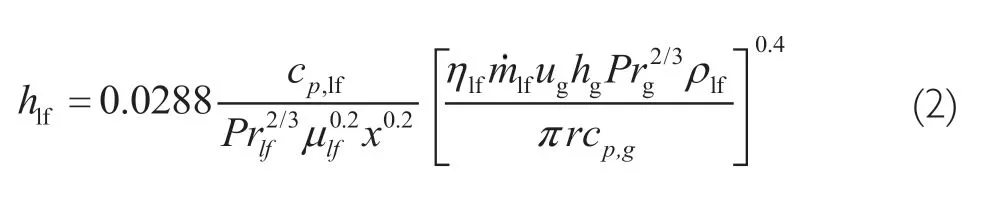

The convective heat transfer density between gas-side wall and liquid film coolant can be calculated by Stechman’s method:

wherehlfis convective heat transfer coefficient between the gas-side wall and liquid film coolant,cpis constant pressure specific heat,Pris Prandtl number,μis dynamic viscosity coefficient,

xis axial distance,ηis cooling efficiency,m˙is mass flow rate,μis velocity,hgis convective heat transfer coefficient between the hot gas flow and liquid film,ρis density,ris temperature recovery coefficient of the hot gas flow,lfis the liquid film,gis the hot gas flow.

There are two disadvantages of liquid film cooling slot structures.Firstly,the annular slot structure for internal cooling will increase the mass of the engine,which is unfavorable to a launch vehicle.Secondly,when the liquid film coolant flow rate is too large,the combustion efficiency will be reduced,which is not conducive to improving engine performance.

3.3 Thermal Barrier Coating Technology

Thermal barrier coating technology is one of the internal cooling technologies.Thermal barrier coatings have been widely used in thrust chamber walls of liquid propellant rocket engines and blades of aero engine gas turbines.For a high-pressure thrust chamber,high-temperature and high-speed gas flows have a very intense erosion effect on the thrust chamber wall.Thermal barrier coatings are an important and indispensable means to ensure the thrust chamber wall will not being destroyed by burning and meet the strict cooling requirements despite their complex manufacturing process.

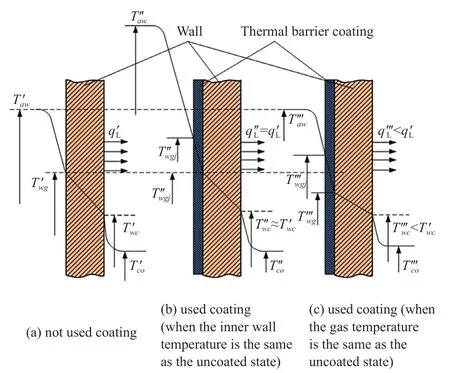

Figure 6 is a schematic diagram of the temperature distribution on the thrust chamber wall of a liquid propellant rocket engine after using thermal barrier coatings.Comparison between Figure 6(a) and Figure 6(c) indicates that the temperature and heat flux of the inner and external walls with thermal barrier coatings are lower significantly at similar gas temperatures near the walls.As a result,the coolant required is relatively less.By comparing Figure 6(a) and Figure 6(b),it can be seen that at similar inner wall temperature and heat flux,the thrust chamber with thermal barrier coatings can operate in the environment with higher gas temperature.

Figure 6 Temperature distribution after application of thermal barrier coatings [16]

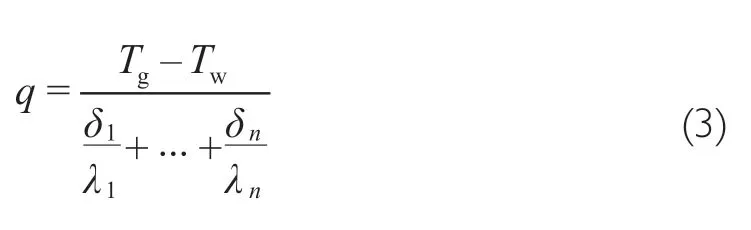

The convective heat transfer density between the gas-side wall and hot gas flow can be calculated by the heat conduction formula:

whereTis the temperature,gis the hot gas flow,wis the gasside wall,δis the thickness of coatings,λis the thermal conductivity of coatings,1,…nis coating number.

In the thrust chambers of high pressure staged combustion LOX/kerosene engines,the combustion chamber inner wall and part of nozzles are coated with metal thermal barrier coatings,whose low thermal conductivity is employed to protect the thrust chamber wall.In addition,thermal barrier coatings with a double-layer design have both effects of heat insulation and anti-erosion.The inner surface of the combustion chamber wall is only electroplated with nickel coatings.However,the inner surface of the nozzle wall is plated with chromium coatings on nickel-based coatings.

Due to fast gas flows in converging-diverging nozzles,the double-layer coating design was adopted.The erosion effect of gas flows on the wall surface is very intense.Chromium metals are characterized by superior heat resistance and strong scour resistance.With double layered coatings,despite the occurrence cracks in localized areas due to the scouring action of gas flows,gas flows only touch the nickel layer below,rather than the copper wall of the thrust chamber[12].The RD-170 engine has the similar coating structure.

4 CHALLENGES AND COUNTERMEASURES OF FUTURE COOLING TECHNOLOGY

In addition to the increase of thrust chamber pressure mentioned earlier,another trend of future rocket engines is the ability to reuse.The reuse of a launch vehicle can greatly reduce the cost of the rocket launch and improve the economy of a launch vehicle.SpaceX’s Raptor engine is reported to have a thrust chamber pressure of 30 MPa.At present,China’s rocket engine cannot reach this pressure,so it is necessary to resolve the relevant problems in this process.

For reusable launch vehicles,engine thrust chambers are one of the most problematic components,requiring additional attention.When a reusable launch vehicle re-enters the atmosphere,the problem of heat flux increase caused by air friction will seriously affect the thermal protection process of engines.Especially after multiple reuses,the repeated cycle of cooling and heating will cause fatigue stress concentration of the thermal protection structures such as regenerative cooling channels,so that the mechanical performance of the structures will be reduced and the operational requirements for the engines will not be satisfied.Therefore,the ability to reuse the cooling structure is very important to judge the number of reuse times for a launch vehicle.In the process of reusing the rocket engine,it is necessary to strengthen the integrity inspection and the cooling capacity margin of thrust chambers.

In order to ensure the reliability of the engine and the safety for reuse,in addition to further optimizing the cooling structure of the thrust chamber,the performance of the related engineering materials should be further improved.Engineering materials with high mechanical strength and high thermal conductivity can effectively alleviate the thermal protection problem of the thrust chamber when it is reused,and greatly improve the reliability of the reusable launch vehicle.

In addition to the above mentioned regenerative cooling structures,liquid film cooling slots and thermal barrier coatings,the selection of inner wall materials and the layout of coolant flow path should be considered[17-19].For the future advanced LOX/kerosene engines,the cooling structures of thrust chambers can be proposed using the following methods:

1) The regenerative cooling channels adopt a milled process,and adopt a spiral design with high aspect ratio in the area with high heat flux.

2) Multiple liquid film cooling slots should be set at different thrust chamber locations in the axial direction at the same time,so as to reduce the heat flux.

3) Some rough structures are artificially created in the regenerative cooling channels,so as to enhance the heat transfer ability in the local area.

4) Materials with good thermal conductivity,such as copper alloy,should be used for thrust chamber inner wall.

5) For the surface of the thrust chamber wall we should choose a reasonable heat insulation layer,such as carbon layer,ceramic coatings or metal coatings.

6) The flow path of coolant should be optimized.For example,kerosene ought to be introduced to thrust chambers from upstream of the throat,where heat flux is high,to take full advantage of kerosene’s better cooling properties at low temperature.

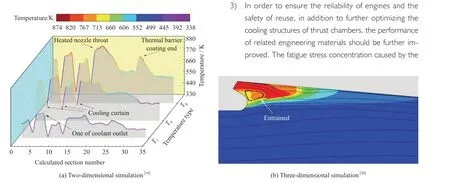

In the process of development,a variety of methods are used to estimate the cooling capacity of a high-pressure staged combustion LOX/kerosene rocket engine,such as two-dimen-

2) For the future advanced 480 t-thrust staged combustion LOX/kerosene rocket engines,the pressure of the thrust chambers will be more than 20 MPa.Therefore,a reliable cooling method for thrust chambers will be more difficult to find.It is proposed to further study the flow mechanism,heat transfer mechanism and active mechanism of liquid films using annular slot for internal cooling.

3) In order to ensure the reliability of engines and the safety of reuse,in addition to further optimizing the cooling structures of thrust chambers,the performance of related engineering materials should be further improved.The fatigue stress concentration caused by the sional simulation of heat flux and three-dimensional simulation of temperature.Figure 7 shows the schematic diagram of the simulation method adopted.

Figure 7 Schematic diagram of the simulation

5 CONCLUSION

This paper introduces the LM-5B and LOX/kerosene rocket engines.In addition,the cooling structures used in thrust chambers of high-pressure staged combustion LOX/kerosene engines were discussed comprehensively.Finally,the following conclusions have been reached:

1) Due to stage reduction and cooling structure optimization,the reliability of the LM-5B has been greatly improved.The future LM-9 will use more advanced LOX/kerosene engines.Therefore,the requirements for thrust chamber cooling performance will be more stringent.After discussing the advantages and disadvantages of main cooling methods,the regenerative cooling using artificial roughness is expected to be used to enhance heat transfer and improve cooling capacity.repeated cycle of cooling and heating in the process of engine reuse determines the service life of re-usable launch vehicles to a great extent,so needs to be carefully monitored.

- Aerospace China的其它文章

- Application of Artificial Intelligence in Outer Space Dispute Resolution

- Structural Analysis and Life Prediction of Thrust Chambers For Hydrogen-Oxygen Rocket Engines

- Dynamic Analysis of Launch Vehicle Piping Systems

- 12-Point Leveling Systems for Mobile Platforms and Emergency Plans

- Design of A Hot Redundant Communication Network for Drive Control Systems of Mobile Launch Platforms

- Research on Frequency Improvement for LOX/kerosene Rocket Engine-Servo Loop