Experimental study on uniaxial ratchetting-fatigue interaction of extruded AZ31 magnesium alloy with different plastic deformation mechanisms

Yu Lei,Hang Li,Yujie Liu,Ziyi Wang,Guozheng Kang

Applied Mechanics and Structure Safety Key Laboratory of Sichuan Province,School of Mechanics and Engineering,Southwest Jiaotong University,Chengdu 610031,China

Abstract The uniaxial ratchetting-fatigue interaction of extruded AZ31 magnesium (Mg) alloy is investigated by uniaxial stress-controlled cyclic tests at room temperature and with addressing the roles of different plastic deformation mechanisms.Different stress levels are prescribed to reflec the cyclic plasticity of the alloy controlled by diverse deformation mechanisms (i.e.,dislocation slipping,deformation twinning and detwinning ones),and then the influence of stress level and stress rate on the ratchetting and fatigue life are discussed.The experimental results demonstrate that different evolution characteristics of whole-life ratchetting and fatigue life presented during cyclic tests with various mean stresses,stress amplitudes and stress rates are determined by the dominated plastic deformation mechanisms.It’s worth noting that the ratchetting can occur in the compressive direction even in the cyclic tests with a positive (tensile) mean stress,and the fatigue life increases firs and then decreases with the increase of mean stress on account of the interaction between dislocation slipping and twinning/detwinning mechanisms.Comparing the fatigue lives obtained in the asymmetric stress-controlled and symmetrical strain-controlled cycle tests,it is seen that the ratchetting deformation causes an additional damage,and then leads to a shortening of fatigue life.

Keywords: Magnesium alloy;Ratchetting;Low-cycle fatigue;Mean stress;Stress amplitude;Stress rate.

1.Introduction

As the lightest structural metallic material [1],magnesium(Mg) alloy has been widely used in automobile,aerospace and other manufacturing field [2,3].It is well known that Mg and its alloys are a kind of materials with a hexagonal closepacked (HCP) crystal structure,so the plastic deformation mechanisms operating in Mg alloys include the dislocation slipping,deformation twinning and detwinning.In particular,thec-axis of extruded Mg alloy crystals is often perpendicular to the extrusion direction in view of the strong basal plane textures formed in the process of extrusion [4].Therefore,extraction twinning can be easily activated during compressive loading when sampling along the extrusion direction of Mg alloy plate,while the non-basal slipping must be activated to coordinate the deformation in the tensile direction.As a result,wrought Mg alloy shows a significan tension-compression asymmetry at room temperature on account of different activated deformation mechanisms;meanwhile,ratchetting (i.e.,the cyclic accumulation of plastic deformation) often occurs in the metals subjected to an asymmetric stress-controlled cyclic loading [5–12],so the ratchetting deformation in Mg alloys should be more complex than that of other metallic materials with face-centered cubic (FCC) and body-centered cubic (BCC) crystal structures when various plastic deformation mechanisms are involved [13–16].

By setting various stress levels,Kang et al.[4] discussed the influence of dislocation slipping and deformation twinning/detwinning mechanisms on the uniaxial ratchetting of extruded AZ31 Mg alloy systematically,which proved the evolution characteristics of uniaxial ratchetting involving various deformation mechanisms.Li et al.[16] further examined the temperature-dependence of the ratchetting produced in extruded AZ31 Mg alloy by conducting cyclic tests at various temperatures.Furthermore,Xiong et al.[17] experimentally investigated the influence of deformation twinning and detwinning on the ratchetting of ZK60 Mg alloy at room temperature from both macroscopic and microscopic observations.In addition,it was found that the ratchetting deformation produced in the stress-controlled cyclic deformation had a remarkable influenc on the fatigue behavior of metallic materials [18–30].For examples,Kang and Liu [20-24] conducted systematic stress-controlled fatigue tests with the occurrence of ratchetting on a variety of metals,and the results showed that the ratchetting would lead to more damage to the materials and then shorten the fatigue lives;Yuan et al.[27] found the fatigue lives of 316LN stainless steel in the asymmetric stress-controlled cyclic tests was much lower than that in the strain-controlled cyclic ones with the same strain amplitudes,which was probably caused by the ratchetting strain promoting the initiation and propagation of cracks.However,very limited studies were reported on the ratchetting-fatigue interaction of Mg alloys: for examples,Chen et al.[31] conducted asymmetrical uniaxial stress-controlled cyclic tests,focusing on the influence of peak stress and stress ratio on the fatigue of AZ91 alloy,and then analyzed the fatigue failure mechanism by considering the interaction of ratchetting damage and fatigue damage and from the fracture morphology;furthermore,Chen et al.[32] researched the interaction among the corrosion,ratchetting and fatigue for AZ31B Mg alloy;recently,Yan et al.[33] discussed the ratchetting deformation and microstructure evolution of hot-rolled AZ31B magnesium alloy.Since only a few of low-cycle fatigue tests were involved in [31,32],the influenc of ratchetting deformation on the fatigue with addressing the contributions of different plastic deformation mechanisms had not been fully reflecte yet.In addition,Lin et al.[34,35] researched the influenc of stress rate on the ratchetting strain and fatigue of AZ91D and AZ31B Mg alloys by the uniaxial stress-controlled cyclic tension and tension-compression tests,respectively,and found that the ratchetting strain of Mg alloys would be reduced and the fatigue life would be prolonged by increasing the stress rate if the plastic deformation was only dominated by dislocation slipping.However,the existing tests were almost performed within the region of plastic deformation dominated by the dislocation slipping.More systematic experimental studies are necessary to reveal the uniaxial ratcheting-fatigue interaction of extruded or rolled Mg alloys comprehensively by addressing the contributions of different plastic deformation mechanisms,which is vital for evaluating the service safety of structural components made by Mg alloys.

Therefore,in this paper,a variety of uniaxial fatigue tests of extruded AZ31 Mg alloy with the occurrence of ratchetting deformation are conducted at room temperature so that the evolution characteristics of uniaxial whole-life ratchetting and the fatigue life of the Mg alloy with different plastic deformation mechanisms can be researched,and then the influ ences of mean stress,stress amplitude and stress rate on the uniaxial ratchetting-fatigue interaction are investigated.Accordingly,the obtained results here will provide basic experimental data for the construction of constitutive law and fatigue life-prediction model in future work.

2.Experimental materials and procedure

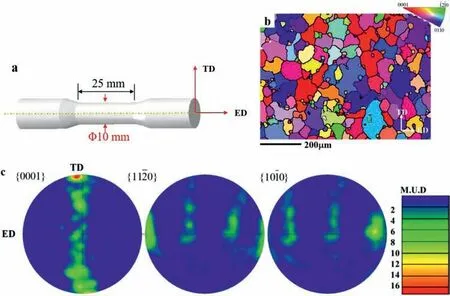

The extruded AZ31 Mg alloy plate was used in this work.Dumbbell-shaped samples with a section diameter of 10 mm and a gage length of 25 mm were manufactured from the plate,and the samples’ axial directions were set to be parallel to the extrusion direction (ED) of the plate to emphasis the role of the texture,as demonstrated in Fig.1a,where TD represents the traverse direction of the sample.In addition,initial microstructure and corresponding pole figure of the AZ31 alloy characterized by electron back scattered diffraction (EBSD) are presented in Fig.1b and c,and the EBSD examination is conducted on the polished TD-ED plane.It can be seen from Fig.1c that the alloy has a typical {0001}texture with a high density of 17.07.

RPL100 test machine was used,and the axial strain was obtained by a uniaxial extensometer.A sequence of fatigue tests was performed at room temperature and a triangular wave form was adopted.Various strain amplitudes with an identical strain rate (0.002/s) were prescribed in the symmetrical strain-controlled cyclic tests to reveal the cyclic softening/hardening feature of the AZ31 alloy.Besides,the ratchetting during the uniaxial whole-life cycles and fatigue behavior of the alloy was researched by conducting the stresscontrolled cyclic tests with a variety of mean stresses and stress amplitudes and at two stress rates (i.e.,20 and 100 MPa/s),respectively.

3.Results and discussions

3.1.Monotonic deformation

At first monotonic tensile and compressive tests were performed to understand the fundamental mechanical properties of the AZ31 alloy at room temperature and choose suitable loading conditions for the cyclic tests.Then,Fig.2 provides the obtained stress-strain (in absolute value) curves of the monotonic tension and compression.It is demonstrated in Fig.2 that the tensile yield stress of extruded AZ31 Mg alloy is about 200 MPa,while the compressive one is only 70 MPa.The monotonic deformation of AZ31 alloy is remarkably asymmetric at room temperature,which is related to the diverse plastic deformation mechanisms involved during the monotonic compressive and tensile deformations,and related to the textures formed during the manufacture of Mg alloy[4].

3.2.Uniaxial strain-controlled deformation

Fig.1.The initial macro and micro figure of extruded AZ31 Mg alloy specimen: (a) dimensions and orientation of the specimen;(b) the initial microstructure;(c) corresponding pole figures

Fig.2.Monotonic stress-strain curves of extruded AZ31 Mg alloy.

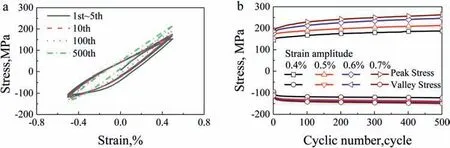

Then,the typical cyclic stress-strain curves of AZ31 alloy and the evolution of peak stress (PS) and valley stress (VS)obtained in uniaxial symmetric strain-controlled cyclic tests(with the strain amplitudes of 0.4,0.5,0.6 and 0.7%) are illustrated in Fig.3.Obviously,as demonstrated in Fig.3a,the hysteresis loops show apparent asymmetry because of the formation of tension twins during compression.Moreover,as shown in Fig.3b,obvious cyclic hardening occurs in both the tensile direction and compressive direction,and it should be noted that the cyclic hardening in the tensile direction is more significan than that in the compressive direction.

3.3.Uniaxial whole-life ratchetting

3.2.1.Effect of mean stress

As mentioned in Section 1,Lin et al.[35] indicated the ratchetting strain (the average value of peak strain and valley strain) and its rate of Mg alloy increased with increasing the stress amplitude and mean stress during the stresscontrolled cyclic loading,resulting in the shortening of fatigue life.However,they merely focused on the cyclic tests where the plastic deformation was dominated by dislocation slipping.Therefore,to research the influenc of mean stress on the whole-life ratchetting of extruded AZ31 alloy by addressing the roles of various plastic deformation mechanisms,a variety of cyclic tests with an identical stress amplitude and various mean stresses were conducted at first so that the stress-strain responses and the evolution of peak strain (PE)and valley strain (VE) can be discussed under various loading conditions.Kang et al.[4] researched the dependence of uniaxial ratchetting of AZ31 Mg alloy on the prescribed mean stress,and revealed that the ratchetting strain could not fully reflec the ratchetting evolution of the alloy during the cyclic deformation due to the different accumulating directions of PE and VE occurred in some loading cases.Thus,the evolution characteristics of the whole-life ratchetting of extruded AZ31 alloy are revealed here by addressing the variations of PE and VE,respectively.

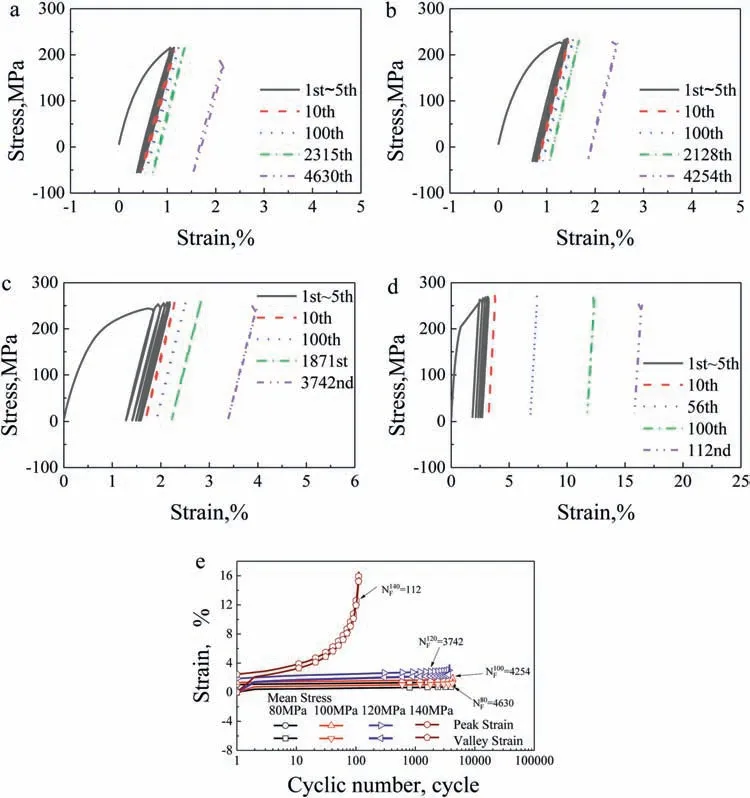

Fig.4 gives some typical stress-strain hysteresis loops(i.e.,for 1–5th,10th,100th,half-life and whole-life cycles) of the Mg alloy and the evolution curves of PE and VE with an identical stress amplitude of 140 MPa and different mean stresses of 80,100,120 and 140 MPa.In these cases,the prescribed PS is greater than the tensile yield stress of the alloy,while the applied VS is far less than the compressive yield stress,so that the plastic deformation during the cyclic tests is mainly controlled by dislocation slipping.It can be found from Fig.4a,b,c and d that the hysteresis loops obtained from cyclic tests always present a slender and symmetrical shape in the whole life due to only the contribution of dislocation slipping to the plastic deformation.Moreover,as illustrated in Fig.4e,the PE and VE always accumulate towards the identical tensile direction with increasing the cycles when the cyclic deformation of AZ31 alloy is only dominated by dislocation slipping,and the ratchetting of AZ31 alloy here is similar to that of FCC and BCC metals [7,36].Furthermore,the PE and VE of the alloy increase dramatically if the prescribed stress level is high enough (e.g.,with the stress level of 140±140 MPa).

Fig.3.Cyclic responses of extruded AZ31 Mg alloy in symmetric strain-controlled cyclic tests: (a) typical hysteresis loops for the strain amplitude of 0.5%;(b) evolution curves of PS and VS vs.number of cycles.

Fig.4.Cyclic responses of extruded AZ31 Mg alloy with various mean stresses (80,100,120 and 140 MPa) and constant stress amplitude (140 MPa): typical hysteresis loops for (a) 80±140 MPa,(b) 100±140 MPa,(c) 120±140 MPa and (d) 140±140 MPa;(e) evolution curves of PE and VE.

Fig.5.Cyclic responses of extruded AZ31 Mg alloy with various mean stresses (0,?10,?20 and ?30 MPa) and constant stress amplitude (130 MPa):typical hysteresis loops for (a) ?30±130 MPa,(b) ?20±130 MPa,(c) ?10±130 MPa and (d) 0±130 MPa;(e) evolution curves of PE and VE.

As can be illustrated from Fig.5,with an identical stress amplitude of 130 MPa and different negative mean stresses(i.e.,compressive ones of ?30,?20 and ?10 MPa),as well as zero mean stress,the prescribed PS is far less than the tensile yield stress of AZ31 alloy,while the VS is higher than the compressive yield stress;thus,the plastic deformation here is mainly controlled by deformation twinning and detwinning.It should be noted that when the mean stress is negative,the cyclic loading is set to be directly started from a compressive loading stage in the firs cycle,rather than from a tensile loading stage as shown in Fig.5,so that the instability can be avoided in the subsequent cycles.Since the prescribed PSs in these conditions are all less than the tensile yield stress,such a change cannot influenc the cyclic response of AZ31 alloy,which can be taken as the same as that started from the tensile loading to the PS and then experienced the subsequent cyclic deformation.Then,as mentioned by Kang et al.[4],the AZ31 alloy presents cyclic hardening feature because of the residual twin and its accumulation.Therefore,as demonstrated in Fig.5,due to the main contributions of deformation twinning and detwinning to the cyclic deformation,the shapes of the hysteresis loops are symmetrical and convex,and become narrower and narrower with the increase of cyclic number,on account of the accumulation of residual twin in the cyclic deformation,which leads to a cyclic hardening characteristic of AZ31 alloy.Besides,as demonstrated in Fig.5e,the PE and VE accumulate simultaneously towards the compressive direction with increasing the cycles.Furthermore,with the increase of mean stress (in absolute value),the PE and VE accumulate more remarkably and the ratchetting becomes more significantl .

Moreover,the stress-strain responses of the alloy and the curves of PE and VE with an identical stress amplitude of 190 MPa and different mean stresses (20,30,40,50,60,70 and 80 MPa) are illustrated in Fig.6.Due to such a high stress amplitude,the PS and VS exceed the yield stresses of the alloy in the tensile direction and compressive direction,respectively,hence the cyclic deformation is simultaneously controlled by dislocation slipping,twinning and detwinning.So,the hysteresis loops are obviously asymmetric,especially in the cases with low mean stresses(e.g.,20,30,40,50 MPa),where a host of twins are formed in the compressive loading stage and these twins are just partially detwinned within the subsequent reverse tensile loading stage.After the completion of the detwinning,the plastic deformation becomes to be controlled by the dislocation slipping again.Consequently,the hysteresis loops are intensely asymmetric,as shown in Fig.6a,b,c and d.As demonstrated by Kang et al.[4],when the cyclic deformation is dominated simultaneously by the three deformation mechanisms,the PE and VE of extruded AZ31 Mg alloy will have distinctive evolution trends with increasing the cycles in view of the participations of different deformation mechanisms.By contrast,as illustrated in Fig.6a and b,although a positive mean stress is prescribed in the performed cyclic tests with the mean stresses of 20 and 30 MPa(also in Fig.6h),the responding PE always evolves cyclically towards the compressive direction,while the VE firs cyclically accumulates towards the tensile direction and then accumulates towards the compressive direction.This is because a multitude of twins are formed in the initial compressive loading stage and can just be partially detwinned during the subsequent cycles,leading to a gradual accumulation of residual twins which makes the VE evolve cyclically towards the tensile direction but the PE evolve towards the compressive direction.After certain cycles,the VE becomes to be accumulated cyclically in the compressive direction due to the further development of residual twins,which was not found in Kang et al.[4].Also,when the prescribed mean stress is increased to 40 MPa,the PE still obviously accumulates towards the compressive direction,but the VE only slightly accumulates towards the tensile direction during the whole-life cyclic test,as demonstrated in Fig.6c.Afterwards,with the further increase of mean stress,the contribution of dislocation slipping to the plastic deformation becomes more significant and the PE and VE accumulate cyclically towards the tensile direction simultaneously,even if the hysteresis loops are more or less asymmetric,as illustrated in Fig.6d.Nonetheless,when the positive mean stress is greater than 50 MPa,the hysteresis loops gradually become to be symmetrical and both the PE and VE cyclically accumulate towards the tensile direction (i.e.,the direction of mean stress) as demonstrated in Fig.6e,f and g as well as Fig.6i,since the plastic deformation changes to be dominated only by the dislocation slipping again.

Fig.6.Cyclic responses of extruded AZ31 Mg alloy with various mean stresses (20,30,40,50,60,70 and 80 MPa) and a constant stress amplitude(190 MPa): typical hysteresis loops for (a) 20±190 MPa,(b) 30±190 MPa,(c) 40±190 MPa,(d) 50±190 MPa,(e) 60±190 MPa,(f) 70±190 MPa and (g)80±190 MPa;(h) (i) evolution curves of PE and VE.

Fig.7.Evolution curves of PE and VE of extruded AZ31 Mg alloy with various stress amplitudes (120,140,160 and 180 MPa) and a constant mean stress (i.e.,100 MPa).

3.2.2.Effect of stress amplitude

To explore the effect of stress amplitude on the wholelife ratchetting of extruded AZ31 alloy with varied plastic deformation mechanisms,some cyclic tests with an identical mean stress and different stress amplitudes are performed for AZ31 alloy,and then the cyclic responses of the alloy and the evolution of PE and VE are discussed.

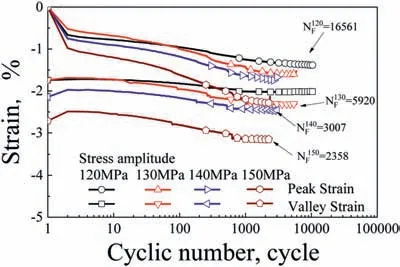

Figs.7 and 8 give the responses of PE and VE of the Mg alloy with the identical mean stresses of 100 and ?20 MPa,respectively.As demonstrated in the figures since the plastic deformation is controlled by a single plastic deformation mechanism (i.e.,in the cases with a mean stress of 100 MPa,it is dominated by dislocation slipping;while in the cases with a mean stress of ?20 MPa,it is dominated by deformation twinning and detwinning),both the PE and VE cyclically accumulate towards the direction of mean stress within the whole-life cyclic deformation and their absolute values increase with increasing the stress amplitude.

Fig.8.Evolution curves of PE and VE of extruded AZ31 Mg alloy with various stress amplitudes (120,130,140 and 150 MPa) and a constant mean stress (i.e.,?20 MPa).

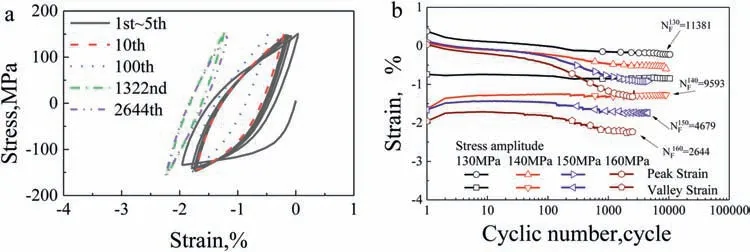

As demonstrated in Fig.9,it is clearly that the ratchetting of extruded AZ31 alloy still occurs obviously even in the symmetrical stress-controlled cyclic tests due to the tensioncompression asymmetry.Furthermore,it can be found from Fig.9b that,within the whole-life cycles,the responding PE and VE basically evolve towards the compressive direction with the increase of cyclic number,since the prescribed PS is lower than the tensile yield stress and no dislocation slipping occurs in the tensile direction during the plastic deformation.Similar to that shown in Fig.5b,c,6a and b,the responding VE of the Mg alloy with the stress amplitudes of 130,140 and 150 MPa evolves towards the tensile direction in the initial several cycles,which is also mainly on account of the cyclic hardening caused by the residual twins and their accumulation,as mentioned by Hazeli et al.[37],Kang et al.[4] and Xiong et al.[17].

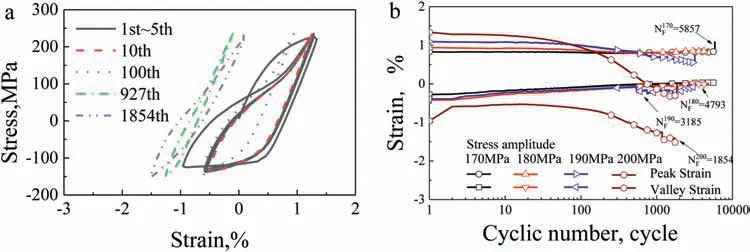

Fig.10 illustrates the typical hysteresis loops of AZ31 alloy and the curves of PE and VE with an identical mean stress of 40 MPa and a variety of stress amplitudes (i.e.,170,180,190 and 200 MPa,higher than the cases illustrated in Figs.8 and 9).As can be found from the figure the hysteresis loops are obviously asymmetric on account of the interaction between dislocation slipping and twinning/detwinning mechanisms.Also,as demonstrated in Fig.10b,the curves of PE and VE with various stress amplitudes are not identical each other since different mechanisms dominate the cyclic plastic deformation.With larger stress amplitudes (e.g.,190 and 200 MPa),both the PE and VE basically accumulate towards the compressive direction with increasing the cycles(except for the VE during the firs beginning of cyclic deformation) and a significan compressive ratchetting occurs.This is mainly because the compressive yield stress is relatively lower,and the influenc of increasing the stress amplitude on the compressive plastic deformation is more remarkable than that on the tensile one.Consequently,a compressive ratchetting will occur in the cyclic tests of the Mg alloy as long as the stress amplitude is high enough,even if the mean stress is positive (tensile).However,if the prescribed stress amplitude is not so large (e.g.,170 and 180 MPa),only a very weak ratchetting is observed in the tensile direction from Fig.10b,due to small plastic deformations in both tensile and compressive directions.

Fig.9.Cyclic responses of extruded AZ31 Mg alloy with various stress amplitudes (130,140,150 and 160 MPa) and a constant mean stress (i.e.,0 MPa):(a) typical hysteresis loops for 0±160 MPa;(b) evolution curves of PE and VE.

Fig.10.Cyclic responses of extruded AZ31 Mg alloy with various stress amplitudes (170,180,190 and 200 MPa) and a constant mean stress (40 MPa): (a)typical hysteresis loops for 40±200 MPa;(b) evolution curves of PE and VE.

3.2.3.Effect of stress rate

Previous study had emphasized that the ratchetting of metals is remarkably time-dependent (or rate-dependent) even at room temperature [38].In addition,Duan et al.[39],Chen et al.[40] and Wu et al.[41] indicated that high strain rate favors deformation twinning and restricts dislocation slipping.However,in the stress-controlled cyclic tests,Lin et al.[35] found that the change of stress rate has little effect on the generation of twins.Furthermore,Meng et al.[42] experimentally studied the influenc of stress rate on the ratchetting of the AZ31B alloy with a changing history of stress rate.Therefore,it is indispensable to research the effect of stress rate on the whole-life ratchetting of extruded AZ31 Mg alloy.As demonstrated by Lin et al.[34,35],the ratchetting strain of the Mg alloy increases with the decrease of stress rate when the cyclic deformation is only attributed to the dislocation slipping mechanism,resulting in shorter fatigue life;however,when the prescribed mean stress and stress amplitude are both low,the Mg alloy shows rate-independence,so the stress rate has little impact on both ratchetting and fatigue.As mentioned in the previous subsections,the ratchetting of AZ31 alloy within the whole-life cyclic deformation is remarkably dependent on the prescribed stress level.Thus,the influenc of stress rate on the whole-life ratchetting is necessary to be researched by addressing the roles of various plastic deformation mechanisms.

Fig.11 provides the evolution of PE and VE obtained within the cyclic tests of AZ31 alloy at different stress rates.To be sure,the plastic deformation in the prescribed three loading conditions demonstrated in Fig.11 is dominated only by dislocation slipping.It can be found from Fig.11 that at the two stress rates (i.e.,20 and 100 MPa/s),all the PE and VE accumulate cyclically in the tensile direction in view of a higher positive mean stress (100 or 120 MPa),and the tensile ratchetting of the alloy is apparently dependent on the stress rate and becomes more prominent at lower stress rate.

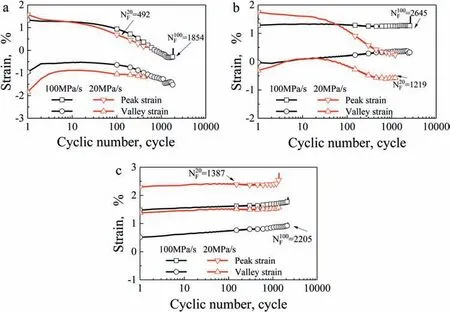

Similarly,Fig.12 provides the corresponding results at different stress rates but with a smaller positive mean stress (40,50 or 60 MPa),where the cyclic deformation is attributed to the contributions of both the dislocation slipping and twinning/detwinning mechanisms.On account of the complex plastic deformation mechanisms,the evolutions of PE and VE with the increase of the cycles are different at different stress rates.It can be seen from Fig.12a and c that with the same stress levels,the evolutions of PE and VE are similar at different stress rates within the whole-life cycles,since the plastic deformations during the cyclic tests with these two stress levels are mainly dominated by the deformation twinning/detwinning and dislocation slipping,respectively;on the other hand,the ratchetting of the alloy within the whole-life cycles at lower stress rate is more remarkable than that at higher one if the cyclic deformation is controlled by the dislocation slipping(in Fig.12c),but it is a little bit more significant than that at higher stress rate if the plastic deformation is dominated by the twinning/detwinning (in Fig.12a).However,from Fig.12b,it is illustrated that with a stress loading of 50±190 MPa,the evolution trends of PE and VE are obviously different at different stress rates: when the stress rate is 100 MPa/s,the PE and VE increase gradually towards the tensile direction with the increase of cyclic number;on the contrary,when the stress rate is 20 MPa/s,the PE always accumulates in the compressive direction,but the VE firs evolves towards the tensile direction and then accumulates towards the compressive direction after about 10 cycles.Such a kind of varied rate-dependence is caused by the different ratedependences of dislocation slipping and twinning/detwinning.That is,the cyclic deformation dominated mainly by dislocation slipping presents significan rate-dependence,and more significan ratchetting occurs within the cyclic deformation at lower stress rate,as illustrated in Fig.12c;while,the cyclic deformation controlled mainly the twinning/detwinning is not so rate-dependent,and the corresponding whole-life ratchetting is only slightly influence by the variation of stress rates,as demonstrated in Fig.12a;when both the contributions of dislocation slipping and twinning/detwinning become activated during the cyclic deformation,the whole-life ratchetting presents a varied and complicate rate-dependence,as shown in Fig.12b.

Fig.11.Evolution curves of PE and VE of extruded AZ31 Mg alloy at diverse stress rates for: (a) 100±140 MPa;(b) 120±140 MPa;(c) 100±160 MPa.

Fig.12.Evolution curves of PE and VE of extruded AZ31 Mg alloy at different stress rates for: (a) 40±200 MPa;(b) 50±190 MPa;(c) 60±190 MPa.

Fig.13.Evolution curves of PE and VE of extruded AZ31 Mg alloy at different stress rates for: (a) ?20±140 MPa;(b) ?30±130 MPa.

Fig.14.Relationship between fatigue lives obtained under different stress levels and: (a) stress amplitudes;(b) mean stresses.

With negative mean stresses (?20 and ?30 MPa) and relatively lower stress amplitudes (e.g.,140 and 130 MPa,correspondently),since the prescribed PSs are all lower than the tensile yield stress of AZ31 alloy (about 200 MPa),no cyclic deformation is produced in the firs tensile loading stage,the cyclic deformation here is controlled by only deformation twinning within the compressive loading stage and the relative detwinning in the reverse tensile loading stage;further,the obtained curves of PE and VE in the two loading conditions and at diverse stress rates are demonstrated in Fig.13.The figur illustrates that both the PE and VE of the Mg alloy accumulate cyclically towards the compressive direction at diverse stress rates,and the compressive ratchetting presents relatively obvious rate-dependence,in other words,the compressive ratchetting at lower stress rate is more obvious than that at higher one,even if the twinning/detwinning deformation mechanism does not present so remarkable ratedependence like the dislocation slipping does.

3.3.Fatigue life with ratchetting

3.3.1.Fatigue lives under various stress levels

First,the fatigue lives of extruded AZ31 Mg alloy obtained in the uniaxial stress-controlled low-cycle fatigue tests with different stress levels (i.e.,different prescribed mean stresses and stress amplitudes) are discussed.Then,the obtained results with varied stress levels are demonstrated in Fig.14.As illustrated in Fig.14a,the increase of prescribed stress amplitude will significantl shorten the fatigue life of AZ31 Mg alloy,but the nonlinear relationship between the prescribed stress amplitudes and fatigue lives is obviously connected with the prescribed mean stress,because the variation of mean stress (if the stress amplitude is prescribed to be a certain value) can result in the change of dominated plastic deformation mechanism involved during the cyclic deformation,as discussed in Section 3.2.1.However,as shown in Fig.14b,different from that of stress amplitude,the influenc of varied mean stresses on the fatigue lives is not monotonic.That is,in some cases,the increase of mean stress elongates the fatigue life,but in some cases,it obviously shortens the fatigue life as illustrated in Fig.14b,which is connected with the different cyclic deformation mechanisms involved.In details,when the plastic deformation is attributed to the contribution of a single dislocation slipping or twinning/detwinning mechanism (i.e.,the results shown in Fig.14b for the cases with stress amplitudes of 140 or 130 MPa),the increase of the absolute mean stress results in the decrease of fatigue life,which is also obtained by Lin et al.[34,35] and Chen et al.[32];on the contrary,when the plastic deformation is attributed to the contributions of both the dislocation slipping and twinning/detwinning mechanisms,the fatigue life increases firs and then decreases with the increase of the mean stress (i.e.,the results illustrated in Fig.14b for the cases with the stress amplitude of 190 MPa).To sum up,the fatigue lives of extruded AZ31 Mg alloy are dramatically dependent on the prescribed stress levels and activated plastic deformation mechanism,which should be reasonably addressed in the construction of life-prediction models in the future work.

Fig.15.Fatigue life with different stress rates vs.prescribed stress levels for: (a) 40±200,(b) 50±190,(c) 60±190,(d) 100±140,(e) 100±160,(f)120±140,(g) ?20±140,(h) ?30±130.

As for the influenc of stress rate on the fatigue lives of the AZ31 Mg alloy,Fig.15 illustrates that the decrease of stress rate gives rise to the shortening of the fatigue life,no matter whether the cyclic plastic deformation is dominated by only one deformation mechanism (dislocation slipping or twinning/detwinning) or all of them.When the plastic deformation is dominated by dislocation slipping (e.g.,(d)100±140,(e) 100±160 and (f) 120±140 MPa),the experimental results are similar to that obtained by Lin et al.[34].However,Lin et al.[35] found that under the cyclic loading cases with relatively lower stress levels,the effect of stress rate on fatigue is very weak.By contrast,as the cases shown in Fig.15 (i.e.with the stress levels of (g) ?20±140 and (h)?30±130 MPa),when the cyclic deformation is controlled by twinning/detwinning mechanism,the fatigue lives are shortened with decreasing the stress rate.That is,although the stress rate has little impact on the twinning/detwinning,the decrease of stress rate makes the absolute ratchetting strain increase obviously,which leads to the shortening of fatigue life.

Fig.16.Relationship between responding half-life strain amplitude and (a) prescribed stress amplitudes;(b) prescribed mean stresses.

3.3.2.Effect of ratchetting on fatigue life

Fig.17.Fatigue lives obtained in the strain-controlled and stress-controlled cyclic tests vs.strain amplitude.

Chen et al.[32] indicated that ratchetting strain occurs in the stress-controlled cyclic tests had a certain impact on the fatigue behavior of Mg alloy,but they had not carried out enough tests to verify it.Based on the systematic tests in this study,the effect of ratchetting deformation on the fatigue lives of extruded AZ31 Mg alloy is discussed by comparing the fatigue lives obtained in the symmetric strain-controlled (where no ratchetting occurs) and asymmetric stress-controlled cyclic tests.As illustrated in Fig.16,the responding strain amplitude of AZ31 alloy at half-life obviously depends on the magnitude of prescribed stress.Similarly,the evolution of responding strain amplitudes with applied mean stresses and stress amplitudes is relatively complex,corresponding to that of fatigue lives in Fig.14.That is,the responding strain amplitudes increase with increasing the stress amplitude,while decrease with increasing the mean stress (except for that the cyclic deformation is attributed to both dislocation slipping and twinning/detwinning).

In conclusion,the evolution of the fatigue lives of the alloy obtained in both the strain-controlled and stress-controlled cyclic tests with strain amplitude is illustrated in Fig.17,where the strain amplitude for the stress-controlled tests represents the responding strain amplitude at the half-life cycle as demonstrated in Fig.16.It is illustrated in Fig.17 that the fatigue lives obtained in almost all the stress-controlled cyclic tests are significantl lower than that in the symmetric straincontrolled cyclic tests,which implies that the ratchetting deformation produced in the stress-controlled cyclic deformation causes more damage to the Mg alloy and then reduces the fatigue lives.Accordingly,whether the plastic deformation is controlled by a dislocation slipping,twinning/detwinning mechanism or both of them,the occurrence of ratchetting deformation may reduce the fatigue life of AZ31 Mg alloy.

However,in this paper,only the uniaxial whole-life ratchetting and fatigue life of extruded AZ31 Mg alloy are investigated macroscopically at room temperature;hence,a systematic microscopic observation should be further performed in the future work to reveal the micro-mechanism of ratcheting-fatigue interaction in the Mg alloy.Also,the multiaxial ratchetting-fatigue interaction of extruded AZ31 alloy should be addressed at room and elevated temperatures in the future work.

4.Conclusion

From the monotonic deformation tests and the systematic uniaxial cyclic tests of extruded AZ31 Mg alloy at room temperature,the obtained conclusions can be listed as follows:

(1) The extruded AZ31 alloy shows a significan tensioncompression asymmetry in monotonic deformation tests at room temperature in view of the different deformation mechanisms (i.e.dislocation slipping,twinning and detwinning)involved in the tension and compression.Similarly,the hysteresis loops obtained in the symmetrical strain-controlled cyclic tests present apparent asymmetry on account of the contributions of diverse deformation mechanisms.Moreover,a cyclic hardening occurs because of the accumulation of twins;also,the hardening in the tensile direction is more prominent than that in the compressive direction.

(2) In view of diverse plastic deformation mechanisms,the whole-life ratchetting of the alloy is obviously dependent on the stress level;also,the evolution feature of PE and VE with the increase of cycles is quite different from each other in some loading cases.Especially,when the cyclic deformation is controlled by multiple deformation mechanisms,the compressive ratchetting will occur in the whole-life cycles even though the mean stress is positive (tensile).

(3) Fatigue lives of the alloy significantl depend on the prescribed mean stresses and stress amplitudes.Generally,increasing the stress amplitude and mean stress gives rise to the shortening of fatigue life;but it should be noted that the fatigue life firs increases and then decreases with the increase of mean stress when the dislocation slipping,twinning and detwinning mechanisms control the cyclic deformation,simultaneously.

(4) The effect of stress rate on the whole-life ratchetting of the Mg alloy extremely depends on the mechanism that controls the plastic deformation.That is,when the cyclic deformation is controlled by only a single mechanism (e.g.,dislocation slipping or twining/detwinning),the ratchetting is closely related to the stress rate and becomes more prominent at lower stress rate;however,when the deformation is attributed to both dislocation slipping and twinning/detwinning,the change in the evolution trends of ratchetting with the stress rate depends greatly on which mechanism mainly controls the cyclic deformation.Nonetheless,the effect of stress rate on the fatigue life of extruded AZ31 alloy can be basically summarized as that the lower the stress rate,the shorter the fatigue life is.

(5) The ratchetting deformation produced during the asymmetric stress-controlled cyclic deformation can give rise to a remarkable reduction of the fatigue life of AZ31 alloy.

Declaration of Competing InterestThe authors declared that they have no conflict of interest to this work.

Acknowledgements

Financial support from National Natural Science Foundation of China (11532010) is gratefully acknowledged.

Journal of Magnesium and Alloys2023年1期

Journal of Magnesium and Alloys2023年1期

- Journal of Magnesium and Alloys的其它文章

- Formation of carbon and oxygen rich surface layer on high purity magnesium by atmospheric carbon dioxide plasma

- Local hardening and asymmetric twin growth by twin-twin interactions in a Mg alloy

- Brittle and ductile characteristics of intermetallic compounds in magnesium alloys: A large-scale screening guided by machine learning

- Assessment of Mg(OH)2/TiO2 coating in the Mg-Ca-Zn alloy for improved corrosion resistance and antibacterial performance

- Simultaneous refinemen of α-Mg grains and β-Mg17Al12 in Mg-Al based alloys via heterogeneous nucleation on Al8Mn4Sm

- Unveiling the influenc of dendrite characteristics on the slip/twinning activity and the strain hardening capacity of Mg-Sn-Li-Zn cast alloys