3D direct writing and micro detonation of CL-20 based explosive ink containing O/W emulsion binder

Zhn-xiong Xie ,Chong-wei An ,Bo-yun Ye ,Ji-qing Mu ,Chun-yn Li ,Min-jie Li ,Song-jin Liu

a School of Environment and Safety Engineering,North University of China,Taiyuan,Shanxi,030051,China

b Shanxi Engineering Technology Research Center for Ultrafine Powder,North University of China,030051,Taiyuan,China

c No.55,Research Institute of China North Industries Group Corporation,Changchun,130012,China

Keywords:Direct writing Explosive ink Emulsion binder system CL-20 based energetic composites Micron detonation

ABSTRACT The booming development of DIW technology present an unprecedented prospect in energetic materials field and has attracted great interest due to its relative simplicity and high flexibility of manufacturing.Herein,a novel CL-20 based explosive ink formulation have been developed successfully for MEMS initiation systems via DIW technology.We designed PVA/GAP into an oil-in-water(O/W)emulsion,in the way that the aqueous solution of PVA as water phase,the ethyl acetate solution of GAP as oil phase,the combination of Tween 80 and SDS as emulsifier,BPS as a curing agent of GAP.The ideal formulation with good shear-thinning rheology properties and clear gel point was prepared using only 10 wt% emulsion.The dual-cured network formed during the curing process made the printed sample have good mechanical properties.The printed samples had satisfactory molding effect without cracks or fractures,the crystal form of CL-20 not changed and the thermal stability have improved.Deposition of explosive inks via DIW in micro-scale grooves had excellent detonation performances,which critical detonation size was 1 × 0.045 mm,detonation velocity was 7129 m/s and when the corner reaching 150° can still detonated stably.This study may open new avenues for developing binder systems in explosive ink formulations.

1.Introduction

The advancement of military science and technology promotes the development of modern weapons and the transformation of the new military.More personalized,intelligent,portable,and more destructive weapons will be the mainstream of future military development.The advent of MEMS (Micro Electro-Mechanical Systems) devices that combines miniaturization and intelligence has undoubtedly become the forward-looking weapons in the field of energetic materials.However,it also poses a challenge to the traditional charging process (such as press-fit method,injection method,etc.) while its size is miniaturized [1-3].Besides,the quality consistency of traditional charge is poor,and defects such as holes and cracks are prone to appear,making the performance of explosives unable to be guaranteed.Therefore,there is an urgent need to develop a precise and efficient approach suitable for microcharges in the military field.

Additive manufacturing (AM) has promoted transformation in many industries,and has been widely used in the design and development of products in automobile,machinery,aerospace,electronics,medicine and other fields [4-7].In recent years,researchers have shown great interest in using additive manufacturing technology to prepare energetic materials via inkjet printing [8],electrophoretic deposition [9],photopolymerization[10],melting-extruding [11] and more.Among many methods,direct ink writing(DIW)technology has attracted some interest due to low cost,high processing flexibility and high efficiency[12-15].Advanced military technology countries led by the US invested 40 million dollars to develop direct writing (DW) technology in 1999[16].Brain Fuch has developed a series of explosive ink formulations and successfully loaded the formulation with the best comprehensive performance (EDF-11) on MEMS devices through DIW in 2005.The US can use DIW to realize safe and precisely loading of micro pyrotechnics element and initiation sequence now[16-18].In the recent years,domestic researchers in the field of energetic materials are also actively exploring the use of DIW to realize the charge of MEMS devices and developed many different types of ink formulations which can achieve explosion propagation at the micro-scale [19-24].The binder acts as a skeleton in the explosive ink formulation and is one of its important components.It not only determines the molding process but also plays a vital role in the quality of the molded ink.In order to balance a variety of performances,the existing binder system of explosive inks is generally a hybrid binder system and has two application patterns.One is to dissolve binders,explosive particles and additives in organic solvents to form a all-liquid explosive ink sprayed on the substrate through a piezoelectric nozzle,which explosives crystal forms(CL-20)are prone to change during the printing process,and some safety problems may occur in the application[14].The other is to formulate the binders as a solution,then mix it mechanically with additives and explosives particles to form a suspension ink with a high solid content,which extrude out from the needle relying on an external force to form the predesigned pattern.Most of the binder systems used in suspension inks are composed of water-soluble binders and alcohol-soluble cellulose,which can meet the requirements of micro-scale explosion propagation,but the mixing of the two binder solutions may partially precipitation cause uneven mixing.In 2018,Li cleverly designed the binder system as an emulsion effectively avoiding the problem of uneven mixing of the binder systems [25].Moreover,the binders selected in the ink formulation are mostly inert binder[19,22-24],which is not conducive to further increasing the energy of explosives.With the complexity of the charge structure of MEMS devices,it is also necessary to further explore the explosion transfer capability and mechanical properties of ink formulations at the micro-scale.

Energetic binders are the development direction of binders.The azide energetic binders represented by Glycidyl azide polymer(GAP) have become the frontiers and hotspots of current research due to high energy,insensitive and environmentally friendly advantages,and researching on its curing process are also springing up.Relevant studies shows that GAP and bis-propargyl-succinate(BPS) can obtain good performance through “click chemistry” reaction [26-28].Polyvinyl alcohol (PVA) is a water-soluble binder which has good prospect in application explosive inks due to its aqueous solution have excellent film formation and adhesion[16,19,25].Research has shown that ?-CL-20 has the best overall performance,the reduction of explosive particle size is contribute to reduce the critical detonation size and booster the reliability and stability of detonation wave propagation in micro-sized channels[20,24].

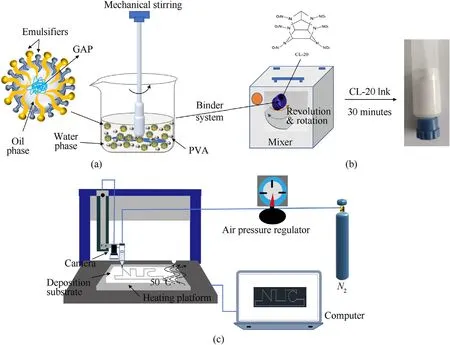

Here,we develop an excellent energetic binder system,which PVA/GAP is designed as an oil-in-water(O/W)emulsion,the aqueous solution of PVA as water phase,the ethyl acetate solution of GAP as oil phase,the combination of Tween 80 and SDS as emulsifier,BPS as a curing agent of GAP.The optimized emulsion is used to prepare explosive ink with different content of submicron CL-20 and an ideal explosive ink formulation for direct writing was selected via testing the ink rheological properties.As shown in Fig.1,we proposed a DIW technology suitable for manufacturing 3D structures,which broke the limitation of traditional charging technology.The properties of printed samples were characterized and analyzed,including the gelation of the ink,the crystal form of the composite,thermal stability,morphology,mechanical properties and its detonation performance in micro-sized channels.

Fig.1.(a) Preparation of emulsion binder system.(b) Preparation of CL-20 Based Explosive Ink.(c) Schematic diagram of ink patterning using DIW.

2.Experimental part

2.1.Materials

Submicron ε-CL-20 was obtained via mechanical ball milling from our own laboratory.PVA 1788(L) was obtained from Youso Chemical Technology Co.Ltd,1.6 g of PVA powders were dissolved in18.4 g water in order to prepare 8 wt% solution in water.Ethyl acetate (AR) was produced by Fuchen Chemical Reagents Factory(Tianjin,China).GAP (Mn=4000,hydroxyl value OH=1.526 mmol g) was provided by Liming Research Institute of Chemical Industry,0.4 g GAP was dissolved in 9.6 g ethyl acetate in order to prepare 4 wt% solution in ethyl acetate.BPS was obtained from Xi'an Institute of Modern Chemistry.SDS was bought from Tianjin Guangfu Chemical Research Institute.Tween80 was bought from Damao Chemical Reagent Factory.

2.2.Preparation of emulsion binder system

Considering the emulsion is prone to delamination and precipitation during storage,in order to further enhance the stable storage time of the emulsion,based on the previous work done by Li on the preparation of emulsion binder [25] and the preliminary experimental exploration,four factors that have greater impact on the stability of the emulsion were selected and the L9 (3)orthogonal experiment (Table S1,Supporting Information) was designed by SPSS software.The optimized experimental conditions(from Table S2 and S3,Supporting Information) are as follows:Tween·80/SDS mass ratio is about 1:3,emulsifier content is 1.5%,concentration ratio of water phase and oil phase is 8%:4%,emulsifying temperature is 25C.

Preparation of optimized emulsion: 0.34 g SDS and 0.12 g Tween80 were added to 20 g 8% PVA aqueous solution,the mixture was stirred at a temperature of 25C and a stirring speed of 450 rpm for 30 min.Then used constant pressure funnel to added 10 g ethyl acetate solution of BPS and GAP(mass ratio 0.3:1)slowly in 15 min,then continuing stirring 30 min an O/W emulsion with a stable time about 144 h was obtained (Fig.1a).The proportions of each component in the optimized emulsion are 5.23% PVA,60.17% water,1.31% GAP,31.39% ethyl acetate,1.5% emulsifier and 0.4% BPS.

2.3.Preparation of CL-20/PVA/GAP/BPS ink and 3D direct writing

In order to obtain the best ink formulation suitable for direct writing,we prepared four different solid content explosives inks containing 88 wt%,90 wt%,92 wt%,94 wt% of submicron CL-20(“88 wt%,90 wt%,92 wt%,94 wt%” refer to the content of CL-20 solids as a percentage of the explosive and binders mass) and tested the inks rheological properties.The ideal ink formulation preparation: 3.6 g ε-submicron CL-20 explosives was added to the 6.15 g emulsion,after mixing the mixture for about 30 min,the ink with desirable stability was obtained (Fig.1b).

The ink was loaded into a 10 cc plastic syringe and degassed in the mixer for 120 s(vacuum can reach 0.2 kPa)and then the syringe was loaded to the direct writing platform.The platform equipped with a camera to capture the pre-designed pattern and plan the deposition track.The syringe is controlled by computer program and extruded at a pressure of 0.30 MPa from the needle (inner diameter ≈0.7 mm).The pattern and 3D structure of the ink are all deposited layer by layer on a preheated glass substrate (50C) by direct writing(Fig.1c).Explosive ink was written into the groove of aluminum plate via layer-by-layer deposition to test the detonation performance.All samples were placed into a constant temperature water bath oven (50C) cured and dried about 12 h after printing for experimental test.

2.4.Characterization and testing

The photographs were taken by a digital camera (Sony,DSCRX10M3).A DX-2700 X-ray diffractometer(XRD,Haoyuan)was used to distinguish the crystal form of CL-20 based composite using a target material(Cu)with a tube voltage of 40 kV,a tube current of 30 mA,a diffraction angle range from 5to 50.Differential scanning calorimetry (DSC) was employed to analyze the thermal stability.Samples mass were all 0.6 mg and measured at heating rates of 5,10,15,20C/min from 30 to 350C.A MZ-220SD electronic densimeter was used to test the density of the composite,test 5 times and take the average value.The rheological properties of explosive inks were tested by a MCR Rheometer.In detail,the rotor diameter is 25 mm and the shear rates range from 0.1 to 100 swith a temperature fixed at 25C.A temperature ramp test was also performed with a 2C/min rate of increase in temperature at 1 rad?sangular frequency.The morphology of the optimized emulsion was characterized by a VHX·2000C digital microscope.A TESCAN Mira 3 Field Emission Scanning Electron Microscope (FESEM) was utilized to characterize the morphology,microstructure of prepared CL-20 explosives and the composite.Mechanical properties (elastic modulus and hardness) were measured by a Nano Indenter G200.

A microchannel detonation experiment [24] was designed to test the detonation performances of the CL-20 based composite.Given the complex structure that MEMS devices may face in future applications,a different angle aluminum plate groove is also designed to test the explosion transfer capability of the sample.

3.Results and discussion

3.1.Emulsion optimization and rheological behavior

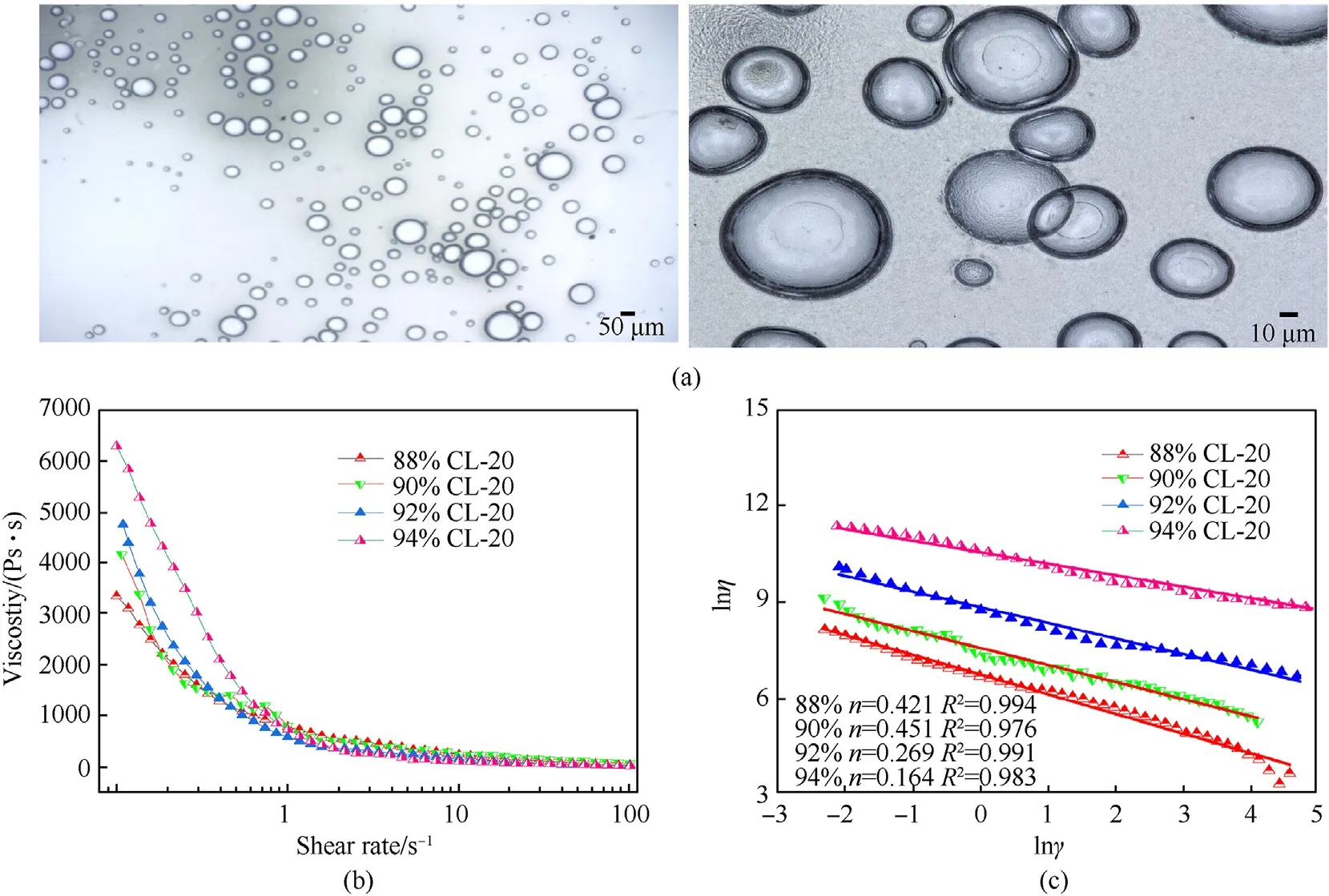

Evaluating the emulsion with the time that emulsion remains stable without phase separation or separation as an indicator,the results of orthogonal experiment was analyzed by SPSS software.According to the analysis methods often used in orthogonal experiment data processing [29,30],the best conditions for preparing emulsion were obtained as above described.The VHX-2000C digital microscope was used to observe the dispersion of oil droplets in the optimized emulsion and it could be seen from Fig.2a that the particle size of oil droplets is mainly about 20-120 μm,have a homogeneous distribution and no obvious flocculation.The emulsion can be stable stored for a period of time without delamination or precipitation in that the emulsifier (SDS/Tween80) adsorbed at the interface between two phases,which reduced the interfacial tension and formed an energy barrier on the surface of oil droplets (as shown in Fig.1a) to prevent the oil droplets from gathering together [31].

The viscosity of the slurry used in DIW directly affects the printability,so it is of great importance to be properly designed to have a homogeneous particle distribution and suitable rheology for flow.In order to get an ideal explosive ink formulation for direct writing,we prepared four different solid content explosives inks containing 88 wt%,90 wt%,92 wt%,94 wt% of submicron CL-20 and tested the inks rheological properties.As is shown in Fig.2b,all the inks showed a shear-thinning behavior in the shear-rate range of 0.1-100 swhich conformed to the typical characteristics of a pseudoplastic fluid,this behavior can be described by Ostwald-de Wale equation.

Fig.2.(a) Emulsion optical micrographs.Plot (b) and Ln-Ln plot (c) of viscosity as a function of shear rate.

where η is apparent viscosity,K is consistency coefficient,n is fluidity index,γ is shear rate.The rheological parameter n was calculated by linear fitting and the results are shown in Fig.2c.Rrefers to the correlation coefficient of fitting line,when it is more than 0.95,it means the Ostwald-de Wale equation can describe rheological properties of the explosive ink.The closer the value of n is to 1,the less the external environment will affect the fluid [22].Meanwhile,it can be seen from Fig.2b that the viscosity raise with the increase of the explosive content.Excessive viscosity reduces fluidity,which is easy to cause needle blockage during direct writing.Therefore,explosive ink with 90 wt% submicron CL-20 was selected for micro scale charge.Specifically,the proportion of each components in the ideal explosive ink formulation was 90 wt% submicron CL-20,7.7 wt% PVA,1.9 wt% GAP and 0.4 wt% BPS(Emulsifier was added additionally,2.2 wt%).

3.2.Direct writing and gelation of explosive ink

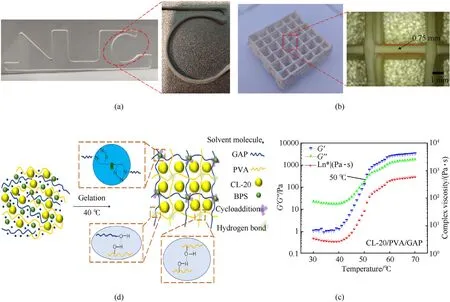

Two patterns were employed to evaluate the printing effect of ink and the important factors of pattern formation was also studied.One is a “NUC” pattern (length and width:80 mm × 20 mm,4 layers,Fig.3a) and the other is a 3D multi-layer cubic grid (length and width: 30 mm × 30 mm,10 layers,Fig.3b).The ink was extruded through a 19G needle (inner diameter≈0.7 mm) according to the pre-designed pattern and directly written on the preheated (≈50C) glass plate.The obtained 3D structure is selfsupported without obvious collapse,printing linewidth can reach about 0.75 mm and the printed pattern does not fracture even under certain bending conditions.This heat treatment is implemented to induce the gelation of emulsion system in the ink,and evaporation of the solvent (ethyl acetate and water) as much as possible to form a dry layer before a second layer is deposited.Gelation refers to the critical point where the slurry changes from a liquid-like to a solid-like state and the viscosity dramatically increases[32].The storage modulus Gand loss modulus Grepresent the elastic and viscous behavior of the material,respectively,and characterize the solid-like and liquid-like properties of the material.Near the gel point,the material changes from liquid-like to solid-like,Gsuddenly increases,so the gel point can be determined according to the change of G'.In Fig.3c,it is observed that Gincreases to greater than Gat 50C,the ink begins to denote a more solid-like property,which can be defined as the gel point.Gelation is a physical state corresponding to the formation of a crosslinking network in the initial stage of the curing reaction,which is of great significance for the application period and curing temperature of propellant and explosive formula processing.The dual-cured network structure formed during the curing process of the explosive ink is shown in Fig.3d.One is through “click chemistry” reaction to form a chemical cross-linking network,that is,GAP was cured by reaction of the azide group with BPS through a 1,3-dipolar cycloaddition reaction to form 1,2,3-triazole network [26].PVA containing numerous -OH can easily form intermolecular and intramolecular hydrogen bonds.The physical entanglement between PVA chains also contributes to the formation of physical cross-linking network during heat treatment[33].In addition,part of -OH in the PVA can also form crosslinks with -OH terminated GAP through hydrogen bonds.The ink can manufacture the distortion-free and self-supported 3D structures,which probably attributed to the composite cured by dual-cured network's excellent mechanical properties.

Fig.3.(a)“NUC”pattern.(b)3D multilayer cubic grid.(c)storage modulus(G′),loss modulus(G′′),and complex viscosity(?)as a function of temperature.(d)Gelation process in 3Dprinting.

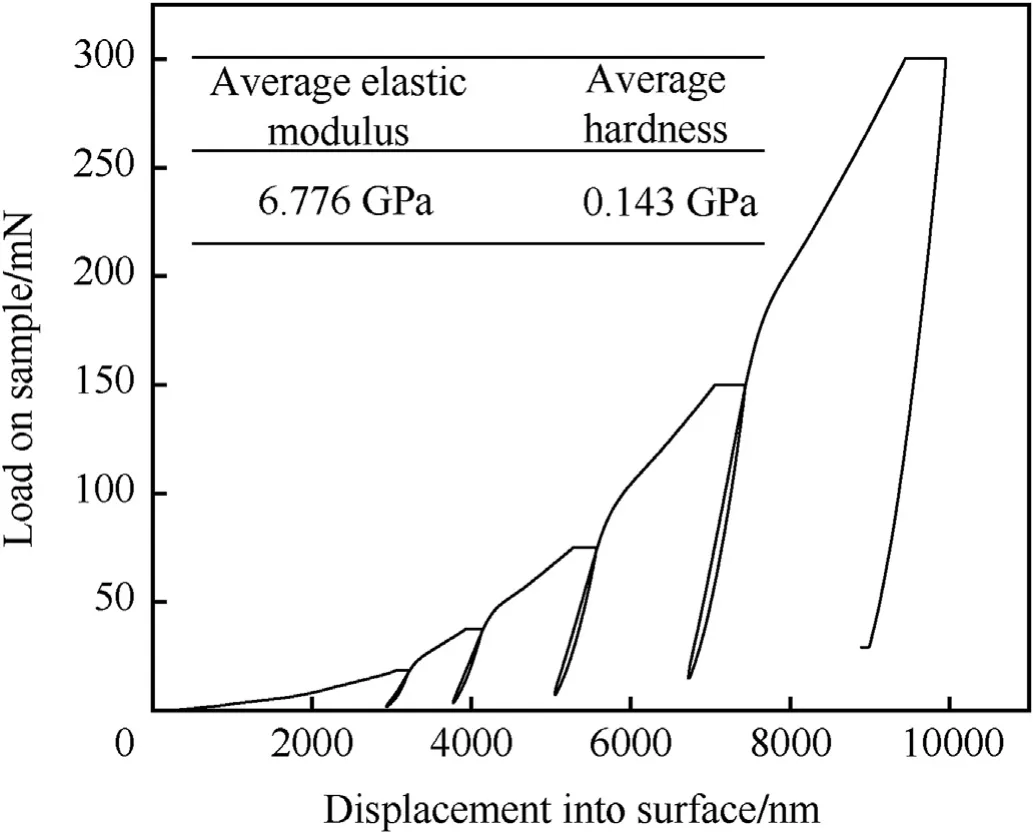

Energetic materials with good mechanical properties are more conducive for field troops to deal with complex external environments.Elastic modulus and hardness are two important parameters that characterize the mechanical properties of material.The former reflects the difficulty of elastic deformation about the material,and the latter refers to the material's ability to resist local deformation,especially plastic deformation or indentation.A nanoindentation tester is used to test the mechanical properties of printing samples after curing,based on the obtained indentation curve(load-displacement curve),elastic modulus and hardness are calculated,the results (average value of 5 measurements) are shown in the table in Fig.4.The elastic modulus and hardness of the printed sample are 6.776 GPa and 0.143 GPa,respectively,which implies that the 90 wt% CL-20 based composite is mechanically sound.

Fig.4.The load-displacement curve of CL-20 based samples.

3.3.Microscopic morphology analysis

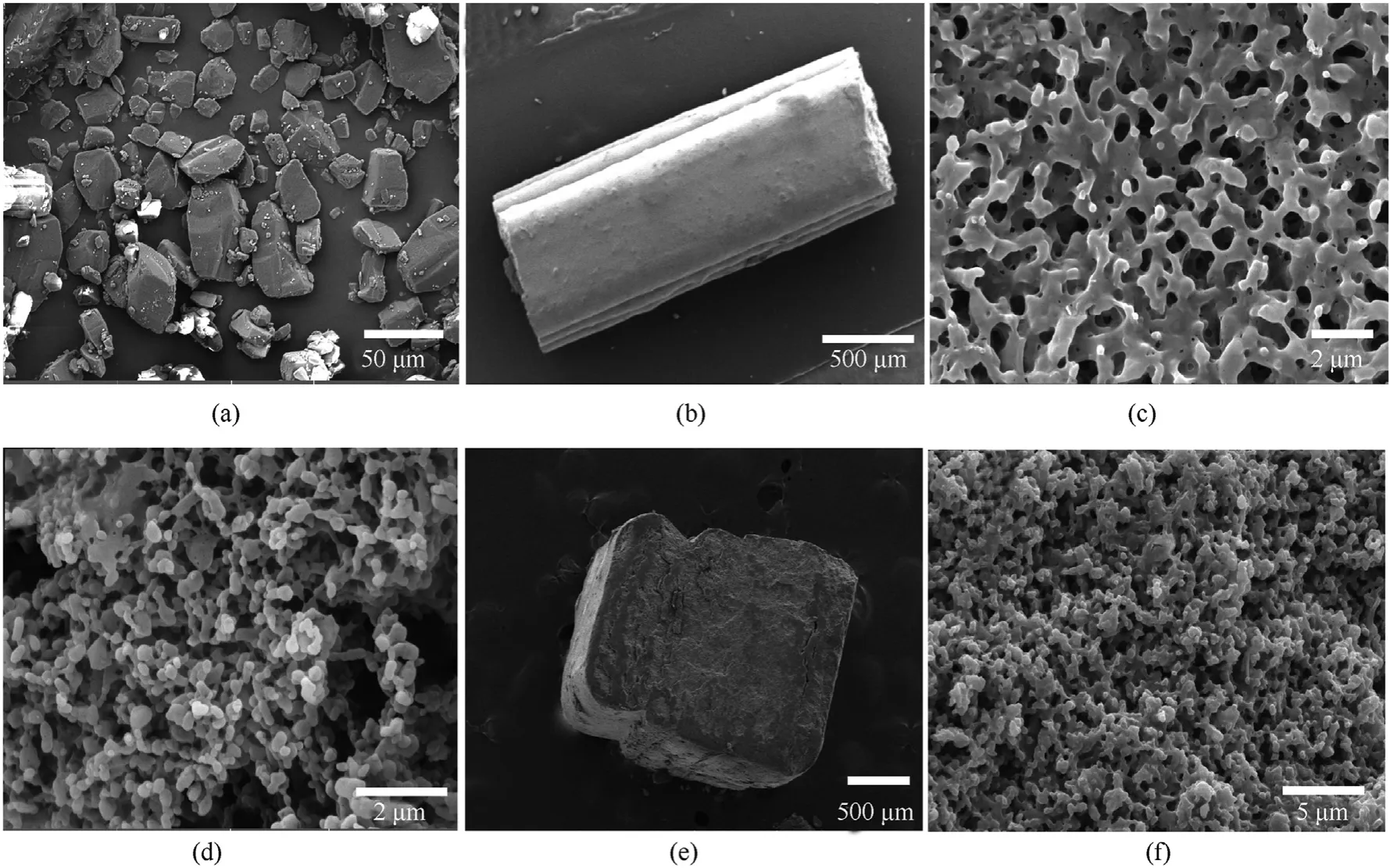

The morphology of the CL-20 explosives and printed samples were observed by SEM Fig.5a,d are the raw CL-20 and the submicron CL-20 respectively.It can be seen that the submicron CL-20 obtained by mechanical ball milling has great changes in morphology and particle size compared to the CL-20.The shape changes from a spindle shape to a nearly spherical shape and the size is reduced from about 50 μm to 300 nm.Fig.5 b,c are the surface morphologies of the printed samples at different magnifications.The molded samples have a good molding effect on the whole,and the surface is smooth and flat without cracks.The holes observed at higher magnifications may be caused by solvent volatilization.Fig.5 e,f are the cross-sections of the printed sample.It can be seen that the printed sample have a uniform compact crosssection and the stacked layers of explosive ink are compact without cracks or voids.The density of CL-20 based explosive ink with 90 wt% solid content is 1.627 g/cm,and the theoretical maximum density(TMD)is about 1.881 g/cm.The dual-cured network structure formed during the curing process of the explosive ink make CL-20 particles and emulsion binders are connected together to form a honeycomb structure.

Fig.5.SEM photos of raw CL-20 (a) and submicron CL-20 (d).Surface (b,c) and Cross-section (e,f) of CL-20 based composite after curing.

3.4.XRD characterization

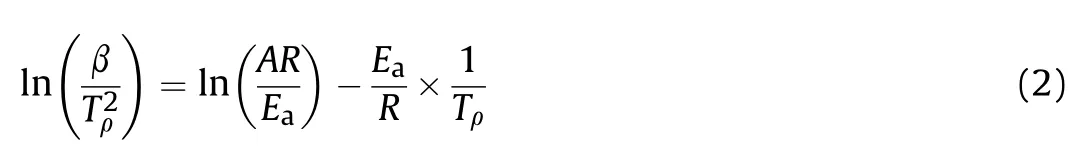

CL-20 is a typical polycrystalline explosive and the dissolution of CL-20 by the solvent during ink preparation will make its crystal form change [14].The defects formed by the crystal structure change may become a potential hot spot and affect the stability of the explosive.XRD was used to distinguish whether the crystal form of CL-20 based composite has changed.Fig.6 shows the CL-20 based composite has three strong characteristic peaks at the diffraction angles of 12.58,13.76and 30.3,which are basically consistent with ?-raw CL-20 and submicron CL-20(via mechanical ball milling).All the XRD patterns are consistent with the standard PDF card (00-050-2045) of ε-CL-20.This results indicate that neither the ink preparation process nor the CL-20 based composite sample involves the transformation of CL-20 crystal form.

3.5.Thermal properties

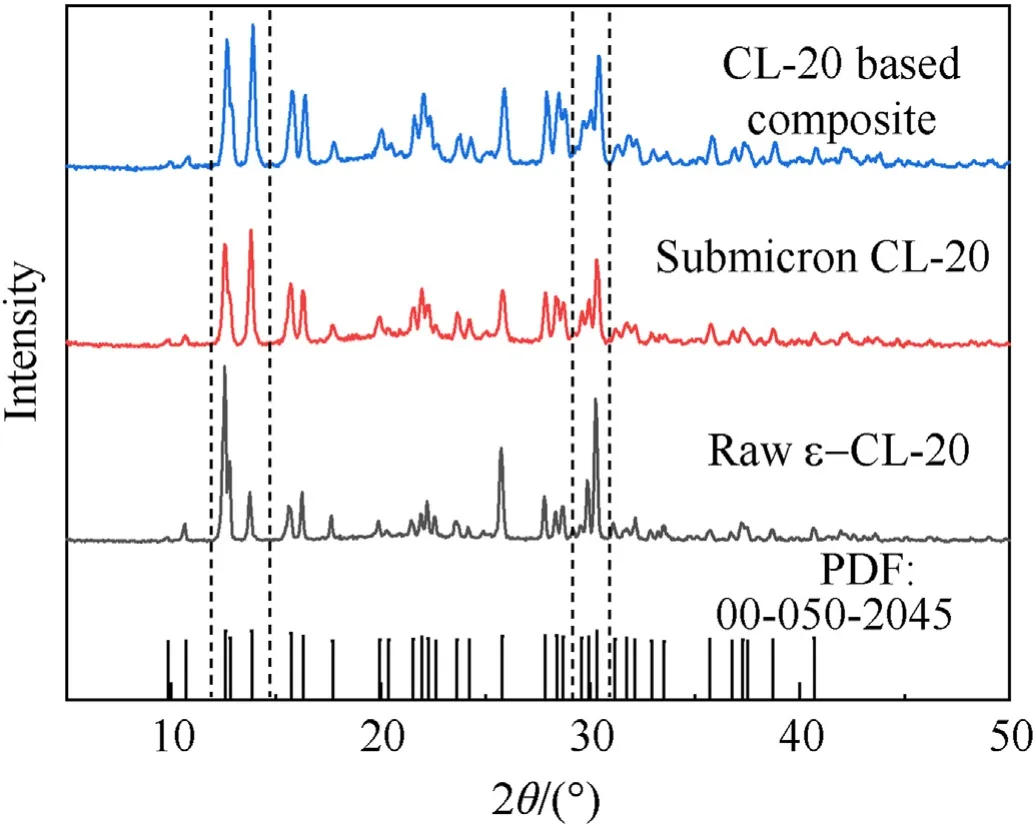

Energetic materials tend to undergo uncontrolled reactions when heated,that is,thermal explosions.This behavior may occur during its transportation and storage,which cannot meet the requirements of the application of explosives.We studied the thermal safety properties of submicron CL-20 and CL-20 based composite samples by DSC.Fig.7 a,b show the DSC curves of submicron CL-20 and CL-20 based composite samples,respectively.It can be seen that the thermal decomposition peak temperature of the samples increases with the heating rate.The curves of submicron CL-20 are smooth before the decomposition peak temperature,while the curves of ink molding samples have a smaller exothermic peak around 200C-240C.The reason is that PVA in the CL-20 based composite samples would be a molten state at 200C and thermally decomposes in advance [22].

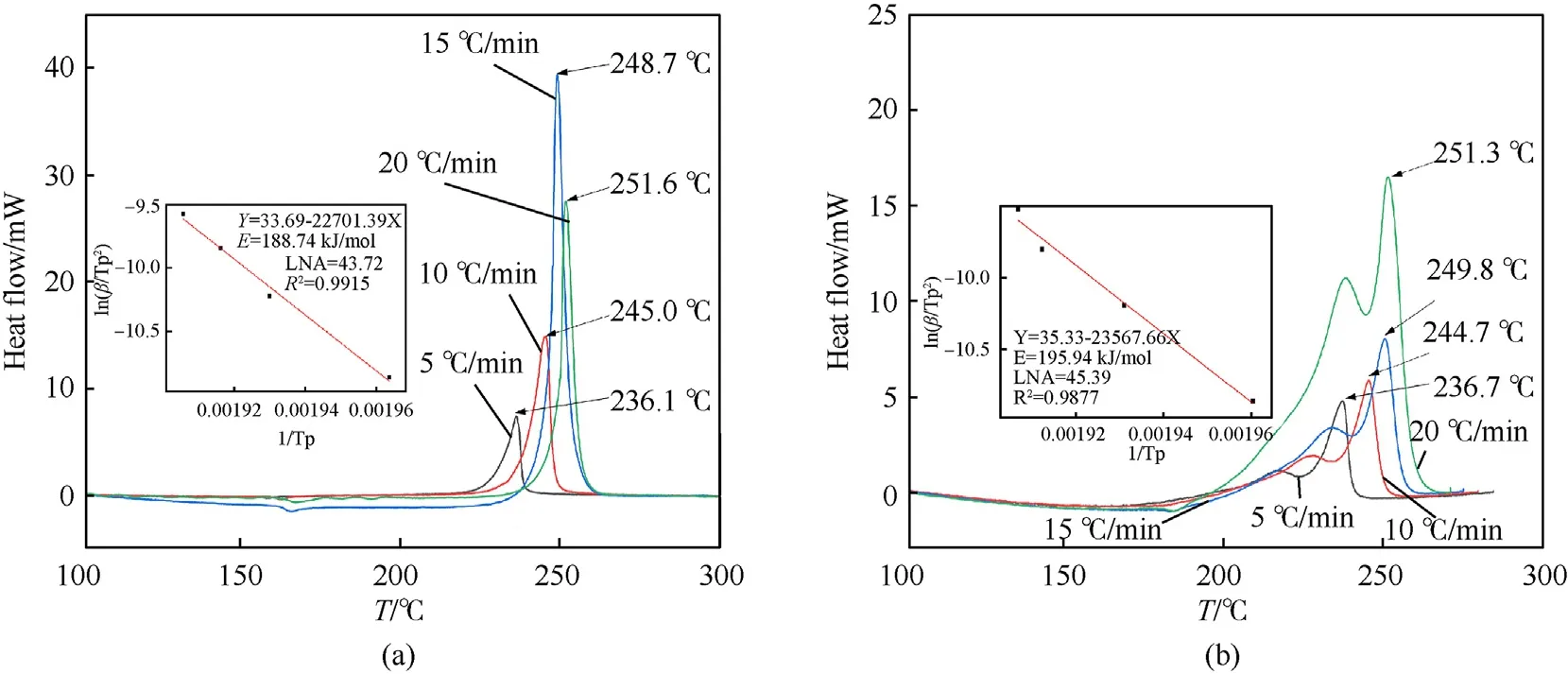

The DSC thermokinetic parameters were processed by the Kissinger equation (2) [24,34],

Fig.6.X-ray diffraction spectra of raw ?-CL-20,submicron CL-20 and CL-20 based composite.

Where β is the heating rate,C/min;Tp is the decomposition peak temperature at heating rate of β,K;A is the pre-exponential factor;Eis the apparent activation energy,kJ/mol;R is the gas constant(8.314 J/mol?K).Substituting the corresponding decomposition peak temperatures of the samples at different heating rates (5,10,15,20C/min) into Eq.(2),the linear relationship between ln(β)and 1/Tp is obtained by fitting.The apparent activation energy of submicron CL-20 and CL-20 based composite samples were calculated respectively.It can be seen that the apparent activation energy of CL-20 based composite samples is slightly higher than submicron CL-20,which is increased by about 7.2 kJ/mol,implying that the CL-20 based composite samples have better thermal stability.This is ascribed to GAP that was cured with BPS by “click chemistry”reaction can form triazole crosslinks[27],which confers higher thermal stability to the CL-20 based composite.

Fig.7.The DSC curves of sub-CL-20(a),CL-20-based composite ink(b).

3.6.Micro scale detonation performance

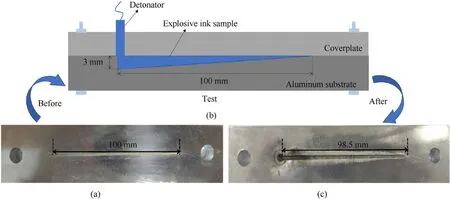

Detonation is a crucial indicator that determines the destructive capability and application prospects of explosives.Understanding the detonation performance of explosive charges is of great realistic significance for the design of weapon systems.Due to the tendency of microminiaturization weapons system,the critical size and detonation velocity of explosives on micro scale are preferred and universally approved parameters of characterizing explosives.We utilize DIW technology to deposit explosive ink layer by layer in a pre-designed micro-channel experimental assembly to test detonation performance of CL-20 based composite.The critical size of detonation was test via a wedge-shaped charge method[35],which can be calculated by formula(3)and the test assembly can be seen in Fig.8b.

It can be seen from Fig.8 that the values of A,B,and C are 100 mm,98.5 mm,and 3 mm respectively.From this,the critical size of detonation can be calculated as 0.045 mm,which implies the CL-20 based explosive composite can reliably detonate above 1 × 0.045 mm.It is observed from the photo after detonation in Fig.8c that the CL-20 based composite can achieve stably and reliably detonation transmission in the micro-scale groove,and left obvious detonation traces on the aluminum plate,which make the groove significantly widened.

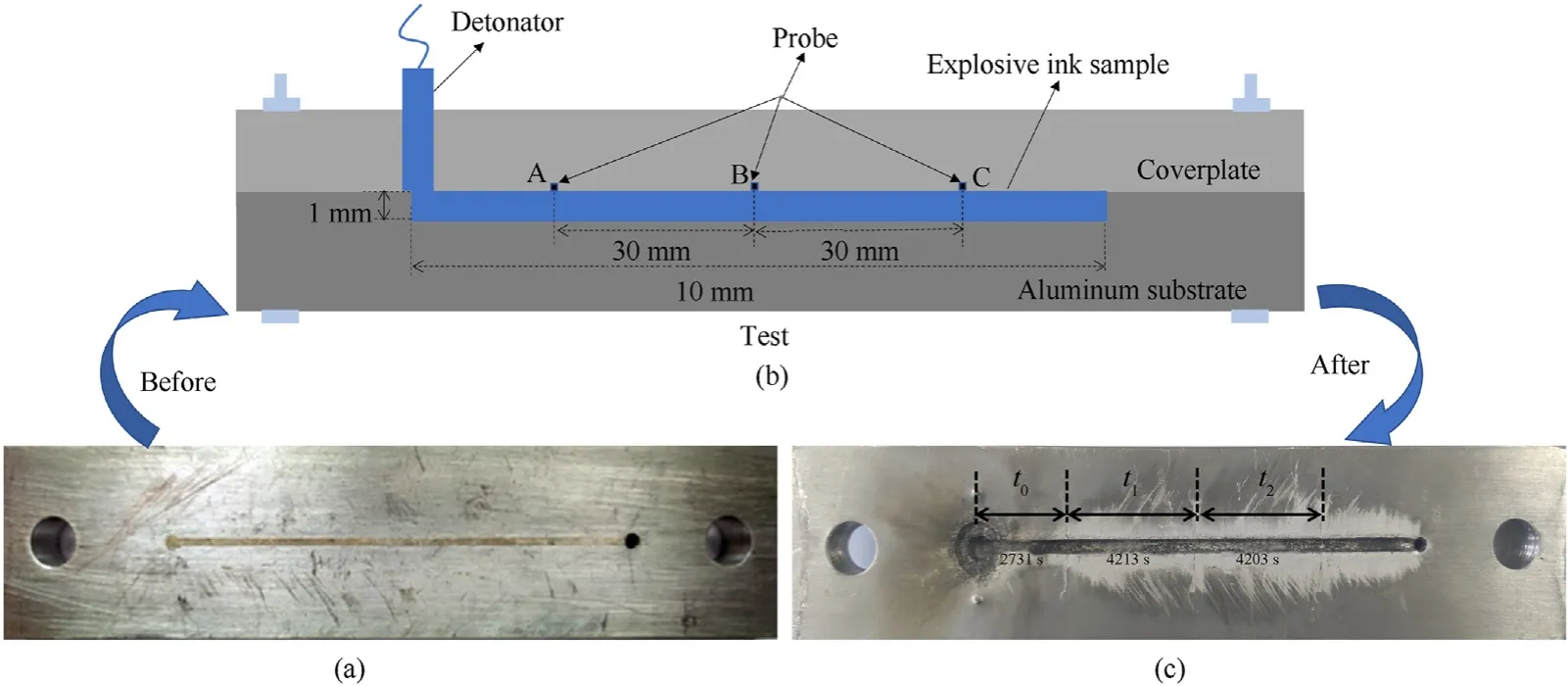

Use the same method to deposit the explosive ink into a rectangular section groove (length,width and depth:1 mm×1 mm×1 mm)to test detonation velocity via an electrical signal probe method[40].The probes are employed to record the transmission time of the detonation wave from A to B,B to C,that is tand t.The distance between the detonation wave from the initiation end to A belongs to unstable detonation zone which can influenced by the detonation energy of the detonator.Therefore,the average of detonation velocity in latter two distances is often taken as the final detonation velocity for the accuracy of the data.It can be seen from Fig.9 that the CL-20 based composite is detonated completely in the micro-scale channel,the values of tand tare 4213 ns and 4203 ns,respectively.The detonation velocity of CL-20 based composite is calculated to be 7129 m/s and the destructive capability carried by the highspeed detonation wave makes the charging groove significantly widened.

Fig.8.The measurement of critical detonation thickness of explosive Ink.(a)photograph of wedge charge of explosive ink before detonation.(b)assembly diagram of the critical detonation size test.(c)photograph of substrate after detonation.

Fig.9.Measurement of detonation velocity of explosive ink.(a)photograph of rectangular explosive charge before detonation.(b)assembly diagram for detonation velocity test.(c)photograph of substrate after detonation.

Fig.10.(a) Photo of charge substrate before detonation.(b) photo of charge substrate before detonation.

Given the complex structure that MEMS devices may face in future applications,the research on whether energetic materials can still detonate reliably and stably in complex circuits cannot be ignored.Related researchers have proposed the corner tuning effect of explosives[36],which coincides with the complex charge circuit in the application of MEMS devices.Based on this concept,we designed a different angle aluminum plate groove (length,width and depth: 1 mm × 1 mm × 1 mm) to test the explosion transfer capability of the CL-20 based composite as shown in Fig.10a.We could see from Fig.10b that the detonation transfer capacity of CL-20 based composite in micro-scale grooves gradually weaken with the angle increase.The detonation energy attenuates when reaching a certain angle,which is not enough for the detonation wave to continue transmission.The detonation wave can still transfer when the corner is as high as 150,and the detonation traces left on the aluminum plate can be clearly observed.When the detonation wave reach at 160,the transmission failed as shown in the circle mark of Fig.10b.This implies that the explosive ink formulation will have a promising application prospect in smart weapon systems.

4.Conclusion

In summary,we have broken through the limitations of traditional suspension explosive ink design method,successfully introduced the energetic binder GAP into the CL-20 based mixtures system via designing the binder system as an O/W emulsion,and adopted a novel reaction route as the curing method of GAP.In the way that GAP was cured via “click chemistry” by reaction of the azide group with BPS through a 1,3-dipolar cycloaddition reaction to form 1,2,3-triazole network.An ideal formulation of submicron CL-20 based explosive ink was selected with only 10 wt% emulsion.The explosive ink have good shear thinning characteristic,which can be combined with DIW technology to print desired patterns and self-supported 3D structures,and can maintain a stable shape after curing without fracture or obvious collapse.The explosive ink had a clear gel point during the curing process and formed a dualcured network,which made the CL-20 based composite mechanically sound.Through the test and analysis of the curing process,microstructure,crystal form and thermal properties of the direct writing ink,it was concluded that the ink formulation had a satisfactory molding effect after curing.The surface was smooth and had a compact cross-section,and charge density could reach 1.627 g/cm.The crystal form of CL-20 in printed samples did not change and the thermal stability have improved.The explosive inks were deposited in micro-scale grooves via DIW technology,having excellent detonation performance,which critical detonation size was around 1×0.045 mm,detonation velocity was around 7129 m/s and when the corner reach as high as 150it could still detonated stably.This study may open new avenues for developing binder systems in explosive ink formulation and would offer a technical reference for the application of explosive inks in micro-scale sequences.

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

This work was supported by the Graduate Education Innovation Project of Shanxi Province (2020SY401) and No.55 Research Institute of China North Industries Group Corporation Open Innovation Fund(WDZC2020JJ017).

Supplementary data to this article can be found online at https://doi.org/10.1016/j.dt.2021.09.007.

- Defence Technology的其它文章

- Experimental study on propagation characteristics of rotating detonation wave with kerosene fuel-rich gas

- Adaptive robust control for triple avoidance -striking -arrival performance of uncertain tank mechanical systems

- Experimental study on WFeNiMo high-entropy alloy projectile penetrating semi-infinite steel target

- Numerical investigation of a muzzle multiphase flow field using two underwater launch methods

- Shock wave and bubble characteristics of underwater array explosion of charges

- A micro-chip exploding foil initiator based on printed circuit board technology