3D Printing of Next-generation Electrochemical Energy Storage Devices: from Multiscale to Multimaterial

Xi Xu, Yong Hao Tan, Jun Ding*, and Cao Guan*

1. Introduction

Electrochemical energy devices(EESD)such as batteries and supercapacitors have seen significant research interest, driven by a desire to shift from fuel to cleaner energy.[1-3]With the emergence of microelectromechanical systems and wearable electronics, great demands are being placed on EESDs, requiring ever greater energy density with an ever-smaller footprint.[4-5]This is, however, not viable in many 2D designs.[6]Various works have documented the development of a wide range of novel electrode materials showing promising energy and/or power density.[7-10]However, superior performance with these new materials using 2D ultrathin electrodes with low mass loadings (≤1 mg cm-2) is not viable for translation into commercial devices where electrode capacity is typically only 10%of the device capacity.[11-12]Common thick current collector materials such as nickel foam can achieve higher active material mass loading but suffer from heavy mass and charge transport limitations.[13-15]

To realize the full potential of these electrode materials, 3D porous electrodes have therefore been developed to address charge transport limitations in thick electrodes as well as maximizing the usage of given footprint area,with mass loading far beyond the limits of 2D electrodes.[12]Here, we define 3D electrodes as electrodes with nonplanar geometries beyond traditional 2D plates,sheets,and rolls,etc.Such architectures enable an optimal configuration that increase the energy density of the EESD within the areal footprint by efficient use of the vertical dimension.[16]3D porous structures with a continuous conductive network and a fully interconnected hierarchical porosity are believed to be beneficial for electron and ion transport in between the electrodes, but also in the interface of electrolytes and electrodes.[17-21]A major practical consideration for EESDs beyond power and energy density is longevity and safety.[22-25]Interfacial stress is generated during the charge and discharge cycles of the typical EESD which negatively impacts the capacity and cyclability of the device.[17,26-28]Rational design of 3D EESD with multiscale construction can be beneficial to mitigate these stresses.[29-30]Designing new electrode structures may solve the interfacial resistance and stability issues of current EESDs.[31-33]The ubiquity of EESDs and the growing need for long-term sustainability means that EESDs of the future should be made as far as possible,with environmentally benign and nontoxic materials.[34]New electrode materials are required to be chemically stable in the electrolyte and compatible with active materials.Additionally,single/simple fabrication procedures should be utilized where possible for a cleaner and scalable process.[35]

Additive manufacturing (AM), also commonly referred to as 3D printing, has been the integral enabling technology behind research efforts into 3D architectures with a high areal and volumetric capacity.[36-38]AM is being extensively utilized in many areas of electrochemistry to produce electrodes and devices, as this technique allows for fast prototyping and is low cost for short runs. Nowadays, 3D printers can be found not only in many research laboratories, workshops, but also in our homes, highlighting its simplicity and ease of use particularly in comparison with conventional manufacturing. The easy implementation of this new class of manufacturing methods as well as the growing range of processable functional materials promotes the further development of this field to be explored for diverse applications in medicine, arts, and engineering.[39-41]The afore-mentioned challenges in EESD development have being assessed and tackled vigorously by the utilization of 3D printers in many research laboratories and R&D departments.

3D printing has two key value propositions: 1) improved performance through rationally designed geometry and 2) shortening the value chain through the reduction of processing steps.3D printing fabrication processes,such as photopolymerization and material extrusion,have already been shown to be suitable for the EESDs manufacturing,creating controllable/multiscale architectures as well as direct multimaterial device fabrication.Electrochemical energy conversion and storage are facilitated by the transport of mass and charge at a variety of scales.Readily available 3D printing technologies can cover a large range of feature sizes relevant to electrochemistry. 3D printing is also highly flexible in its application for EESDs.It can be easily integrated with different surface modification techniques to induce desired chemistries and morphologies. Its ability to create complex geometry can also be further leveraged to create multiscale templates for materials that may otherwise not be printed with the required properties. The maturation of 3D printing means that researchers and EESD designers have access to a growing library of printable materials using state-of-the-art printers and postprocessing tools. This enables the printing of a larger portion of the electrochemical reactors’ body. Multimaterial printing enables the integration of EESDs and external electronics, thereby reducing the number of steps in device assembly and packaging,potentially realizing cost savings regardless of design and product complexity.

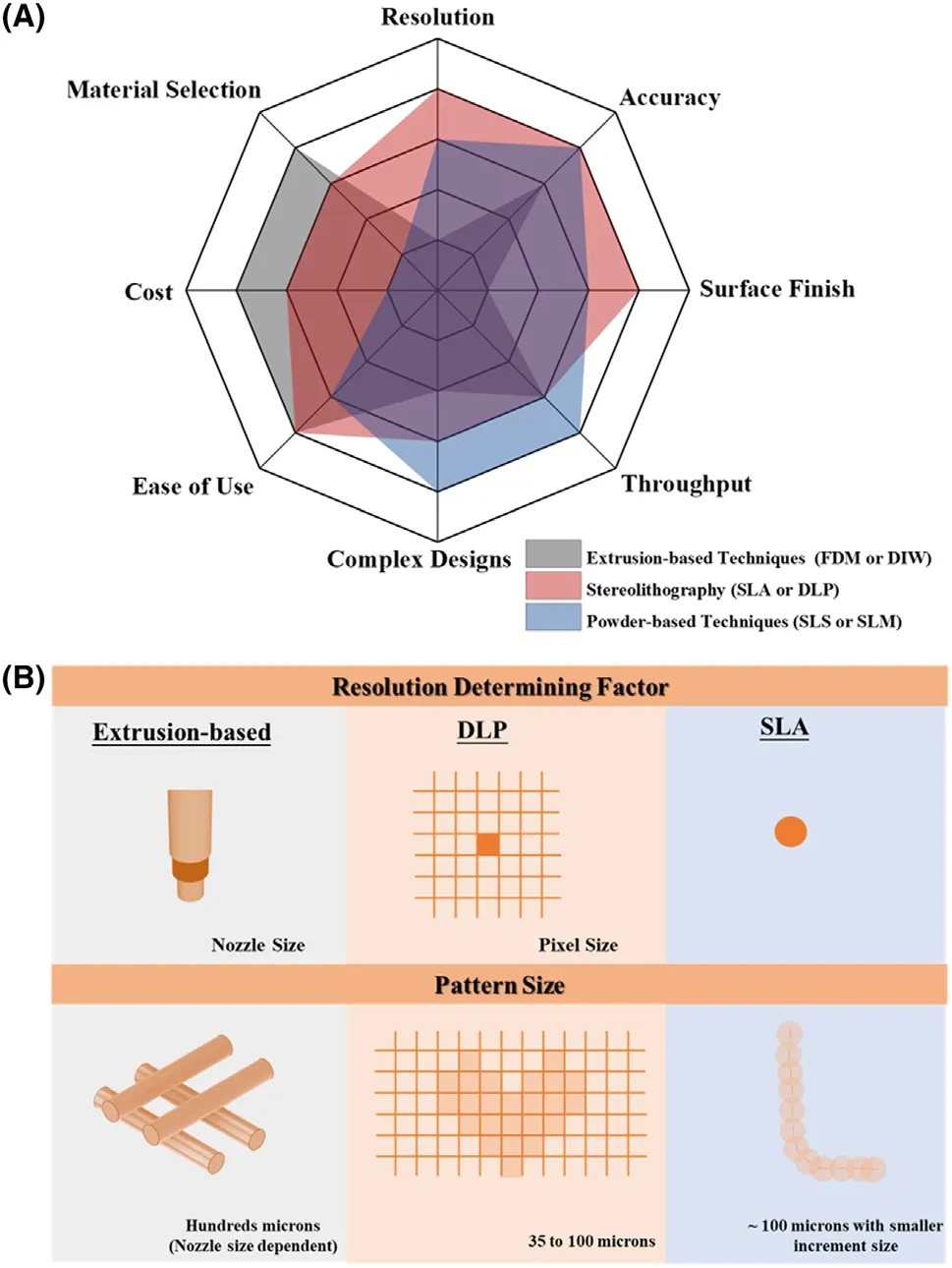

Over the last number of years,a significant amount of research into using 3D printing to create electrodes/devices for electrochemical energy conversion and storage has emerged.[34]There is a variety of 3D-printing technologies available, which include direct ink writing(DIW,or robocasting),fused deposition modeling(FDM),inkjet printing, select laser melting (SLM), and stereolithography (DLP or SLA),making additive manufacturing a highly versatile class of techniques for fabrication in electrochemistry.[42]Figure 1 shows the differences between number of printing techniques. Comparisons among various printing techniques with the consideration in resolution,accuracy,surface finish,throughput,and so on are given.

However, while 3D printing can indeed potentially enable innovations in EESD development, it is a nontrivial task to do so. In order to create the desired hierarchical structures, high-resolution 3D printers are required. However, most 3D printers are typically limited to minimum feature sizes in the range of tens or even hundreds of microns for high-resolution 3D printers. To create the suitable micron and submicron scale features for high-performance EESDs, delicate and precisely controlled postprinting functionalization is generally required.

EESDs typically have several components,made of different materials to serve different functions. 3D printing to create integrated EESDs is critically dependent on its ability to process these different materials simultaneously in the fabrication process. There are some interesting work demonstrating 3d-printed battery/ supercapacitor and well-reviewed; however, most of the reactor were printed out separately and assembled in a full device.[36,43-46]Different 3D printing techniques have different ways to enable multimaterial processing. Through theappropriate 3D printing techniques, one can realize complex multimaterial structures (with metal–ceramic and ceramic–ceramic combinations). One of the most critical issues in multimaterial printing is the boundary interface, which will inevitably exist between 2 distinct materials. There are two primary concerns regarding boundaries in multimaterial printing. Firstly, physical mixing may occur at the boundaries during the addition of different materials during printing,such as the mixing of different paste mixtures in multinozzle extrusion printing, which may degrade the desired properties. Secondly,the chemical affinity of different materials with each other needs to be evaluated to assess the risk of reaction, compositional changes, and delamination during and after printing. Desired reaction or sintering temperatures of different materials can be tailored using dopants.Matching the desired thermal behavior of distinct materials, combined with a structural design providing maximum adhesion between interfaces, enables the fabrication of high-quality multimaterial/multiscale structures.

Xi Xu is currently pursuing her doctoral degree at the department of Materials Science and Engineering, National University of Singapore, under the supervision of Prof. Jun Ding. She received bachelor degree from Wuhan University of Technology in 2015 and master degree from National University of Singapore in 2017. Her research focuses on the hierarchical design of functional materials for energy- and environmental-related fields using additive manufacturing.

Yong Hao Tan is a PhD candidate from NUS Graduate School for Integrative Sciences& Engineering (NGS). He was graduated from National University of Singapore in 2017 for his BS degree and the joined Prof Jun Ding’s group pursuing his doctoral degree in the field of additive manufacturing of metal materials.

Jun Ding is a professor and deputy head of the department of Materials Science and Engineering,National University of Singapore.He graduated from the School of Physics,Wuppertal University,Germany,in 1986 and completed his PhD study in Ruhr University,Germany,in 1990.He joined the University of Western Australia from 1991 to 1997 and later National university of Singapore.His research has been concentrated on additive manufacturing.His research has been focused on the development of novel 3D printable materials for fabrication of multimaterials and multifunctional devices/structures which have great potential in practical applications.

Cao Guan is Professor and Vice Dean of Frontiers Science Center for Flexible Electronics,Northwestern Polytechnical University.He received his BS degree from the School of Physics,Wuhan University,China,in 2009 and completed his PhD study in the School of Physics and Mathematics Sciences,Nanyang Technological University,Singapore,in 2013.He worked as a Research Fellow in the Department of Materials Science and Engineering,National University of Singapore,from 2014 to 2018.His research focuses on the design of nanostructure materials for flexible energy storage and conversion.

Figure 1. Comparison of different 3D printing techniques. A) A spider web graph showing the key consideration in choosing different 3D printing techniques that will be taken;[98] B) determining factors in resolution limit for different 3D printing techniques.[99-101]

Among the various 3D printing techniques, extrusion-based and photopolymerization-based techniques have garnered much interest due to their ease of operation, relative low cost, and high resolution.For conciseness, this review will be centered on these two techniques.Effort will first be made to highlight the ability of 3D printing to create multiscale structures. This will be holistically assessed from different angles looking at each technique individually, their capabilities, how the printing process can be controlled, modification of the material feedstock preprint as well as modification of the printed material postprint where applicable. Examples of the application of 3D printing to create multiscale structures in EESD research will then be discussed to showcase the applicability of 3D printing for EESDs and how it may be further applied. The multimaterial capability of 3D printing is then assessed in the same manner.

2. Multiscale Structures by 3D Printing

2.1. Direct 3D Printing

2.1.1. Extrusion

There are two extrusion techniques that will be covered in this review,fused deposition modeling(FDM)and robocasting.

FDM, also known as free filament forming (FFF), is a 3D printing process that relies on the extrusion of thermoplastic material from a heated nozzle. The feedstock material is melted and extruded from the hot-end and deposited along the path of the nozzle in a layer by layer fashion as defined by the input CAD file.A variety of polymeric materials ranging from biodegradable polylactic acid (PLA) and polyethylene terephthalate glycol (PETG) blends to engineering grade materials like acrylonitrile butadiene styrene (ABS) and even polyether ether ketone(PEEK). Flexible materials such as thermoplastic polyurethanes (TPU)can also be processed with the same method. The general print speed of FDM can be 50–150 mm/h with highest claimed speed of 500 mm/h.One thing that needs to be kept in mind is that the smaller features are more easily deformed by heat in FDM printing. Structures with high aspect ratio often fail since heating of the molten plastic and nozzle will cause a soften structure.[47]Raul et al have reported a novel work in which supercritical CO2(SCCO2)and the breath figures mechanism(BFs)were combined with FDM to produce internal(pore diameters 80–300 μm) and external pores (with sizes ranging between 2 and 12 μm).[48]For extrusion-based machines like FDM and DIW,minimum feature size is a function of the diameter of the print nozzle.[47]The most common FDM nozzle diameter is 0.4 mm and ergo;the smallest feature that can be printed out is 0.4 mm.[49]And most used commercial nozzles now still have the limitation in providing nozzles with lower diameter especially with FDM printer.Smaller nozzle diameter will inevitably cause clogging.Many printers allow their nozzles tobereplacedandcanbechangedwithdiametersasnarrowas0.15 mmas demonstratedbyE3D.

DIW or robocasting refers to the 3D printing technique where slurry or ink is extruded from a nozzle, building up a part like FDM. The difference is that the feedstock for robocasting is a homogeneous slurry of powder suspended in a fluid aqueous or organic medium, rather than a solid filament. Moreover, the nozzle is more customizable with many advanced technologies and can be downsized to tens of micrometer even nanometer size.[50]However, the requirement in ink formulation can therefore be critical for such process. It is arguably among the simplest, yet efficient process used to fabricate complex and robust structures, while being relatively low cost. Usually, an initial investment of an extrusion-based desktop 3D printer can be around few thousand US dollars. While mechanically straightforward, the technique relies on careful ink formation due to the special rheology behavior (shear thinning) needed for the printing process.[51]Compromising between high solid loading and thixotropic behavior affects significantly material preparation, printing strategy, and architectural design. Robocasting has few fundamental material limitations beyond the requirement on ink rheology, and thus, the resolution is also limited by the nozzle size. It has been widely explored for 3D printing of ceramics, metals, plastics, composites, and even emerging materials such as metal organic framework (MOF), electrospun nanofibers toward applications in energy storage with various postprocessing.[45,52-55]

2.1.2. Photopolymerization

Photopolymerization-based 3DP is a technique that uses light (typically ultraviolet; UV) to initiate and propagate a polymerization reaction to form a cross-linked solid structure. Typical photopolymerization-based 3D printer includes stereolithography (SLA) and digital light processing (DLP) as well as more recent variants such as continuous liquid interface production (CLIP), high-area rapid printing(HARP), two-photon laser lithography, and projection microstereolithography which boasts significant improvements in print speed.[56-59]Such techniques have various advantages, such as highresolution, easy operation, straightforward material change procedure,and less requirement for support structures which is important for more complex 3D electrode designs. Determining factors in resolution limit for different 3D printing techniques are presented in Figure 1B.In DLP 3D printing, XY resolution is defined by the pixel size, the smallest feature the projector can reproduce within a single layer where Z resolution. This depends on the resolution of the projector(commonly being full HD, 1080p), and its distance from the projected window. Therefore, a fixed XY resolution, generally between 35 and 100 microns, will be equipped with many commercial DLP printers. For SLA 3D printers, XY resolution is a result from both the laser’s spot size and the increments how the laser beam can be controlled. An et al. have reported a hybrid 3D printing system that combines DLP and electrohydrodynamic jet (e-jet) printing for the production of transparent and free-form 3D optoelectronic devices in ambient air which is able to print diverse functional materials with high resolutions (minimum linewidth: 2.6 μm), by adjusting the printing speed and position.[60]As a result,photopolymerization-based 3D printing can provide several micrometers printing resolution, continuous scanning production, and large-area projection creating 3D features, which all make it a suitable approach for commercial EESD fabrication. Other than printer setting modification, material-wise manipulation,such as precursor assisted printing, is also a viable route to obtain multiscale structure with higher resolution.[60-62]

2.2. Post Modification

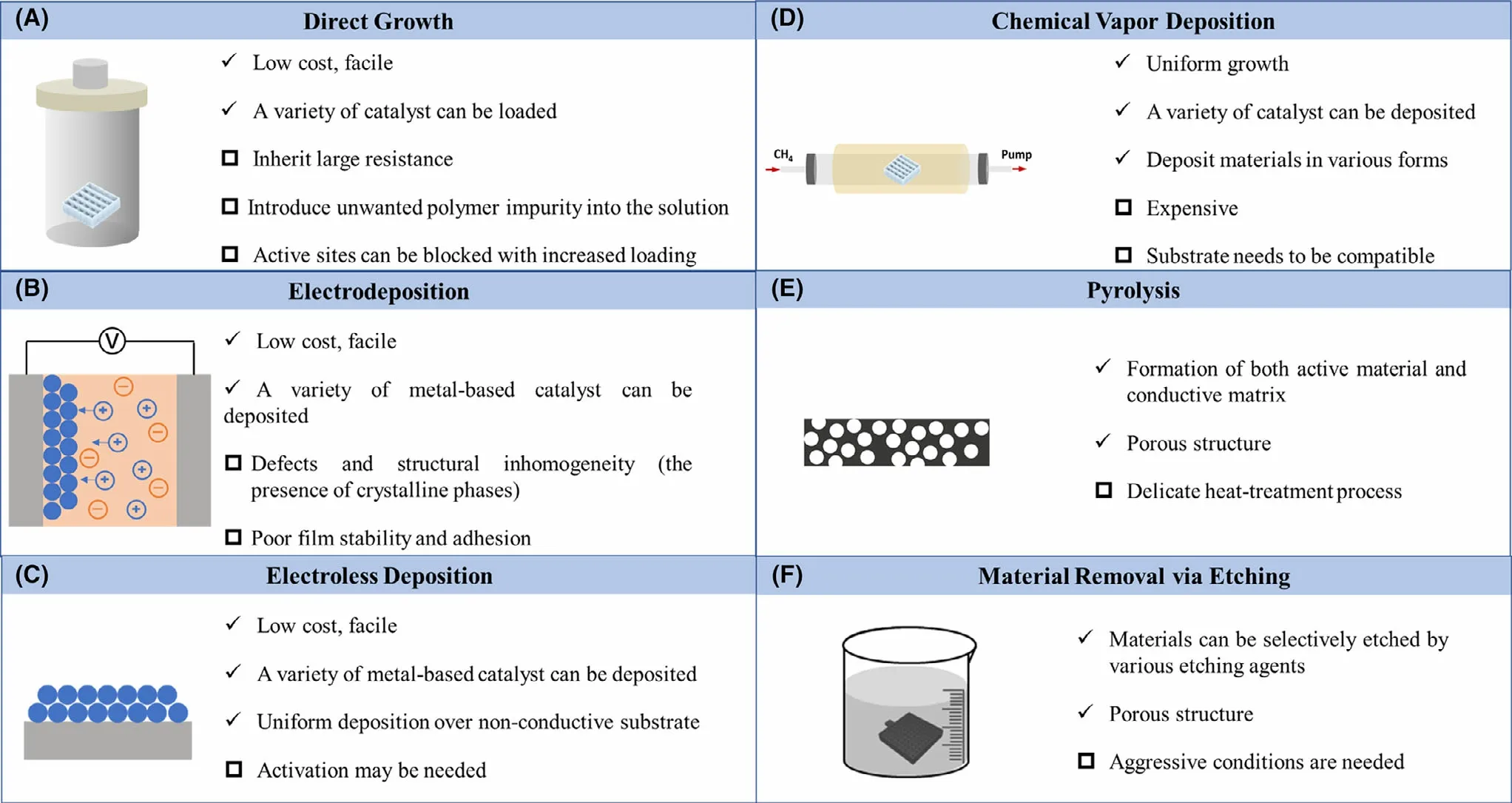

Other than high printing resolution,in order to obtain a multiscale part in 3D EESDs,post-3d-printing surface modification is normally needed to improve the electrode performance for the electrochemical reactions.[63-65]Some commonly used postprocessing methods used for 3d-printed electrodes (including metal-, ceramic-, and polymer-based)are summarized in Figure 2.

Direct attachment of catalysts such as hydrothermal and dip casting can be low-cost methods that can incorporate active materials to electrode surface effectively.Chang et al.have demonstrated that high-performance electrodes with NiCo2S4nanoneedles grown by hydrothermal method on the customized 3D metal architectures can be achieved through a direct 3D printing technique. Such 3D supports,optimized with control over the design, can possess good electrical conductivity, high mechanical strength, and large surface areas, with hierarchical porosity for effective electrolyte circulation and quick removal of bubbles, all contributing to the enhanced electrocatalytic performance.[66]However,large resistance of the catalyst,introduction of unwanted polymer impurity into the solution, the blocking of the active sites at high mass loadings may adverse impact the final electrochemical performance of the electrode as shown in the paper. Electrodeposition is a well-known method to produce a metallic thin-film coating by the action of an electric current.Electroless deposition is also commonly used for the production of metallic thin-film coatings by the chemical reduction of metallic ions onto a substrate,where the uniformity of the plated layer is less dependent on the conductivity of the substrate.Vaneckova et al.have found that by employing fused deposition modeling 3D printing to fabricate electrodes from a polylactic acid/copper composite filament and further surface functionalization by the copper electroplating, can effectively eliminate the kinetic barrier.[67]Xu et al.adopted a combination of two facile techniques,electroless nickel plating,and DIW,for the formation of three-dimensional architectures in a functional hybrid electrode system for electrolysis.Iffelsberger et al and Bui et al. used the similar electroless deposition method and successfully demonstrated a whole electrolyzer which also showed the promising collaboration[52,68-72]Chemical vapor deposition (CVD) is a process in which the substrate is exposed to one or more volatile precursors, which react and/or decompose on the substrate surface to produce the desired thin-film deposit.[73]There are various subclasses of chemical vapor deposition that have been incorporated as postsurface modification methods to generate hierarchical structures, such as ALD.[33,74]Pyrolysis is another commonly used postprinting heat treatment to obtain multiscale architecture as well as a technique for fabricating integrated electrode as both active material and conductive matrix.[75-76]Park et al. have fabricated a novel hierarchical 3D conductive electrode for microsupercapacitors by digital light processing (DLP)-based 3D printing.Photocurable composite resin with silver nanowires was optimized to achieve a design of high aspect ratio and resolution.[77]Additionally, material removal from sacrificial template enables the formation of hierarchically constructed network with micropores, mesopores,and nanopores.[26,33,75]

2.3. 3D printed Multiscale Structures in EESDs

Figure 2. Commonly used postprocessing methods used for 3d-printed metal,ceramic,and polymer-based electrodes.[33,52,66-69,72-76,79,87,102]

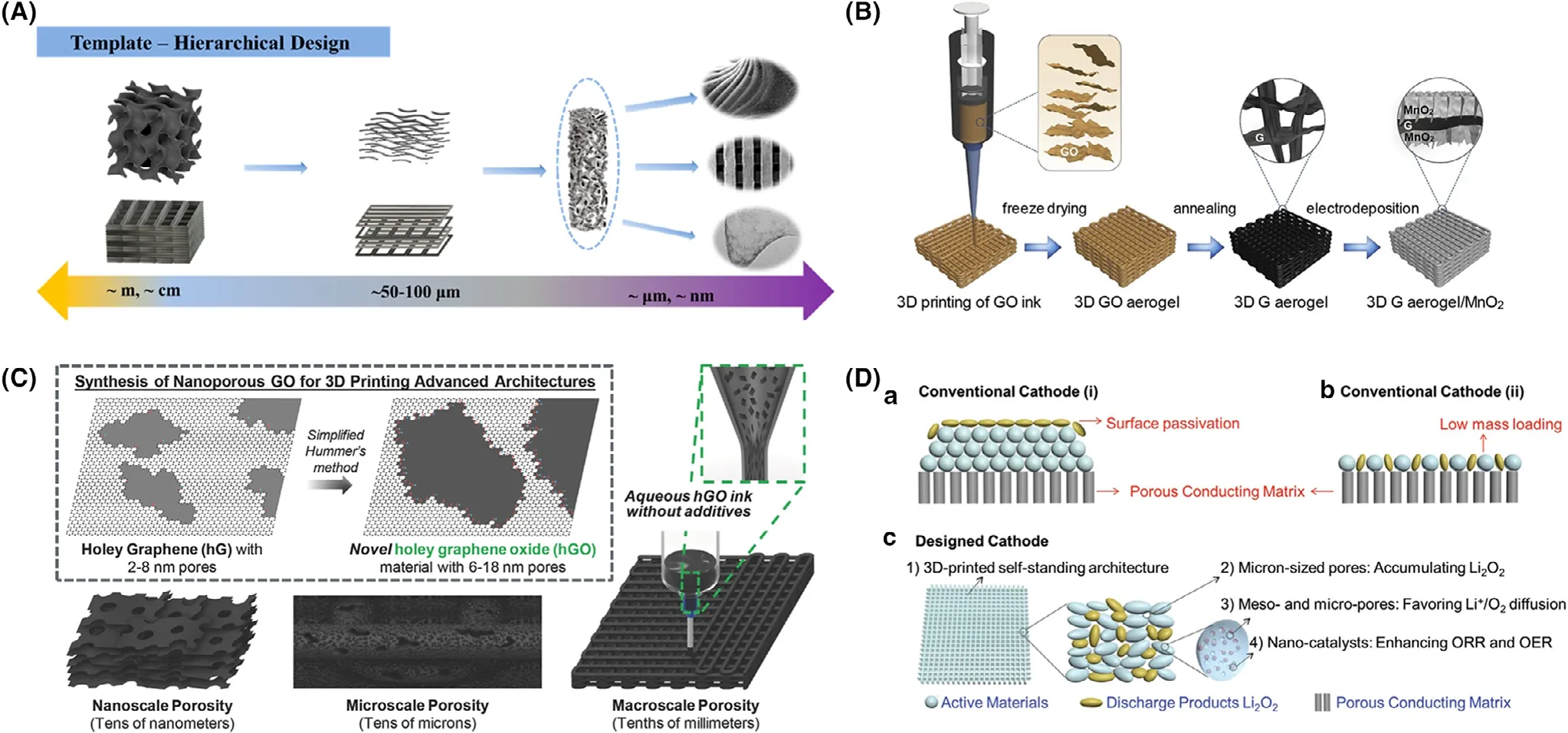

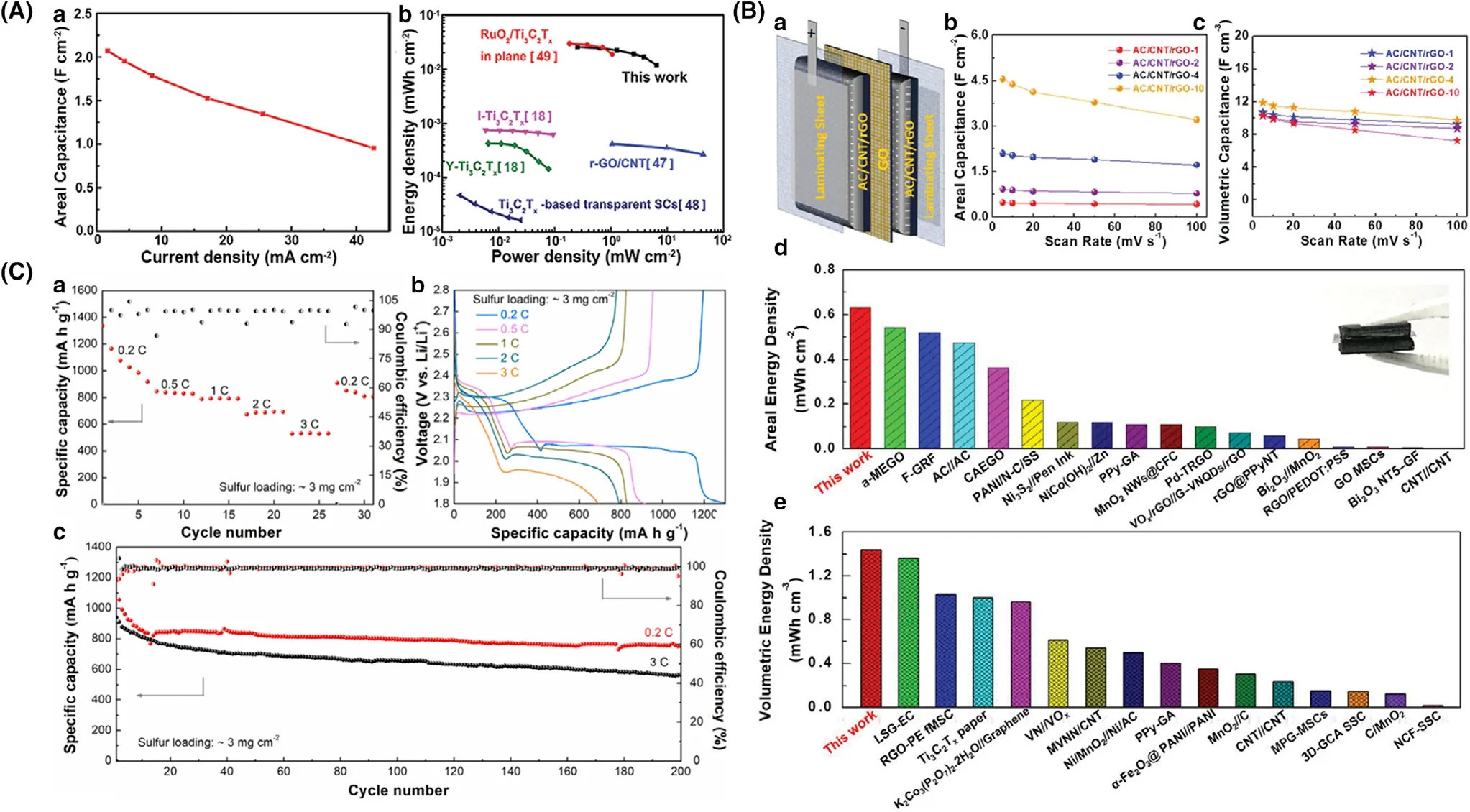

Studies have shown that 3D composite electrodes improve the charge transport and lead to more efficient utilization of the electrode materials at high mass loading. Some of the representative work has been presented in Figure 3 to show the importance of multiscale 3D part and stated that high energy and power density can be achieved as shown in Figure 4.Yang et al have combined 3D printing technology with innovative 2D transition metal carbides material formulations to maximize surface area accessibility and ion transport within electrode. The optimized porosity created more accessible surface area in improving the performance with rational electrode design. The 3D-printed device achieves a high areal capacitance of 2.1 F cm-2at 1.7 mA cm-2and a gravimetric capacitance of 242.5 F g-1at 0.2 A g-1with a capacitance retention rate of above 90% for 10000 cycles. It also exhibits a high energy density of 0.0244 mWh cm-2and a power density of 0.64 mW cm-2at 4.3 mA cm-2. Such high performance benefits from the multiscale and multidimensional architectures.[75]Lim and her collaborators have fabricated a self-standing and hierarchically porous carbon framework with Co nanoparticles embedded as derived from cobalt-based metal–organic framework (Co-MOF) using an extrusion-based printer. The novel self-standing framework possesses good conductivity and necessary mechanical stability. Moreover, the porous framework consists of abundant micrometer-, meso-, and micropores,which together significantly benefit the efficient deposition and decomposition Li2O2within the pores. The self-standing multiscale architecture significantly enhances the cell’s practical specific energy, achieving a high value of 798 Wh kg-1cell.[75]Gao et al. explained in their recently published work that 3D-printed ultrathick AC/CNT/rGO composite electrode (ten layers) can feature high areal and volumetric mass loadings of 56.9 mg cm-2and 256.3 mg cm-3, respectively. The symmetric cell assembled with the 3D-printed thin GO separator and ultrathick AC/CNT/rGO electrodes can possess both high areal and volumetric capacitances of 4.56 F cm-2and 10.28 F cm-3, respectively. Such symmetric cell can also achieve high areal and volumetric energy densities of 0.63 mWh cm-2and 1.43 mWh cm-3, respectively.[78]Yao et al. have confirmed in their work that the hierarchically constructed pores in 3D-printed parts facilitate uniform deposition of MnO2and efficient ion diffusion during charging/discharging even at ultrahigh mass loading of MnO2. A thick graphene aerogel with MnO2loading of 182.2 mg cm-2was fabricated to achieve a high areal capacitance of 44.13 F cm-2.[79]More recently,Gao et al.have demonstrated a homogenous“tri-continuous” phase structure containing micro and nanopores. The “tricontinuous”phase functioned as a continuous network offering the conductive electron paths and interconnected ion channels, which is beneficial for increasing adhesive strength and facilitating electron/ion transport at the nanoscale.[78]

However, as indicated in many works, the increased porosity may also sacrifice the volumetric capacitance and volumetric energy density to some extent and therefore simulation works are needed to be combined with experimental results to develop more rational device architecture.[75]

3. Multimaterial Structures by 3D Printing

While many works have so far explored the benefits of 3D printing for multiscale structures in the field of EESDs, fewer works have investigated the use of multimaterial 3D printing for integrated EESDs.Multiscale structures can be inherently produced from the variety of 3D printing techniques, but multimaterial printing with more complex structure that can be integrated in one step remains a major challenge.[43,80-82]In this section, some documented work using multimaterial printing concept is also reviewed.

3.1. Direct 3D printing

3.1.1. Extrusion (Nozzle Engineering and Ink Formulation)

Commercially available FDM multimaterial printers, such as Raise3D,MakerGear, Robo,gCreate, MAKEiT, and Dremel,include two types of nozzle design:single and multinozzle design according to whether the materials are combined before or after passing through the melting zone. Kim et al. presented fabrication of piezoelectric sensors using BaTiO3(BTO) filler in a poly(vinylidene) fluoride (PVDF) matrix through in situ electric alignment during the FDM printing process.[83]The fabricated free-form single structures maintain uniform alignment of dipoles in the PVDF polymer. However, as limited by its material selection,some of the functional materials cannot be printed.Although such materials can be used as filler to be incorporated into the fused filament, nozzle clogging of the fillers is a serious problem that remains to be solved when being further used to fabricate more complex EESD system.

Figure 3. Construction consideration of multiscale electrodes obtained by 3D printing. A) Design consideration of hierarchical templates. A large surface area and hierarchically constructed porous structure can be essential to retain outstanding electrochemical performance with high mass loading for energy conversion and storage reactions.Reproduced with permission.[33]Copyright 2020,ACS publication.B)Schematic illustration of a 3D printed graphene aerogel/MnO2.With the consideration of retaining a good capacitive performance at high loading of active material,a multiscale graphene aerogel was printed to be used as current collector. Reproduced with permission.[79] Copyright 2019, Cell. C) Schematic representation of extruding complex 3D architectures with hierarchical porosity(macroscale →nanoscale). Reproduced with permission.[103] Copyright 2018, Wiley-VCH. D) Comparison of three schematic Li–O2 cathodes. (a) Conventional cathode (i) with powdered active materials coated on the porous conducting matrix. (b) Conventional cathode (ii) with active materials directly grown on the matrix with a low mass loading. (c) The novel cathode designed with 3D-printed self-standing and hierarchically porous catalyst framework without employing the porous matrix.Reproduced with permission.[75]Copyright 2018,Wiley-VCH.

Challenges also existed in the multimaterial assembly as in DIW: 1)rapid drying and clogging issues in the nozzle during printing, 2)cracking and mismatch during the co-sintering process,and 3)elemental leaching through boundaries during sintering.As mentioned before,aqueous/nonaqueous homogenous slurry of powder particles based on the conventional colloidal processing depends on a solvent-evaporation step. Such step is important in solidification of as-printed structure but may not be ideal for multimaterial printing as it may cause unwanted nozzle clogging and during the long printing process which might involve the changing of the nozzle.Shrinkage mismatch may also cause significant cracks, delamination, and structural failures when handling multimaterial printing. Lastly, chemical leaching across the boundaries between two different materials is inevitable if close contact is made.[84]

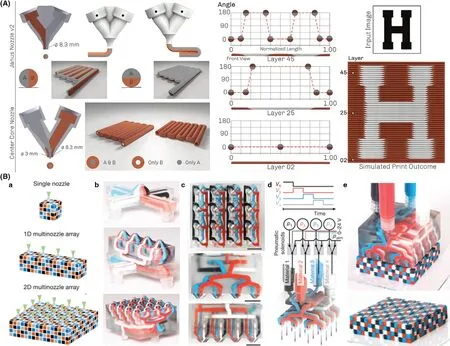

To solve the problems existed in the multimaterial printing,different multimaterial printers and various nozzle designs were fabricated. One direct setting can multinozzle printer,the presence of a second extruder will eat into the area that would be available for printing with a single extruder.[85]The artifacts of multinozzle printing can be divided into two main types.Horizontally printed tile and vertically printed tile.Horizontally layering maintains a fixed nozzle height for each layer while vertically printing allows more flexibility in printing multigradient throughout layers.Warping and cracking during drying were observed on some of horizontally printing tile due to the nonuniform drying.However, as for the vertically printing pattern, delamination can be a big limitation.The chances of oozing and stringing become higher and layer-shifting defects will exist if one of the extruders causes material deposited by the other to warp. More specifically, several customized nozzle designs were also developed in response to the material and process constraints described above,by combining material flows not only from two separate extruders to fulfill the multimaterial printing.Bechthold et al. have proposed two unique types of extrusion nozzles. The nozzles produced two distinct configurations of material within a single print bead, a bifurcated “Janus” bead and a concentric “Center-core”bead(Figure 5).For the Janus Nozzle,the end of the two linear extruders was merged into a single nozzle. Figure 5 summarizes the design affordances of the nozzle. The center-core nozzle used the same 45 degree angle configuration of two linear extruders as the Janus nozzle,but encapsulated one nozzle inside of the other.This novel type of nozzle is capable of producing three printing patterns which are not restricted multimaterial printing but also hollow structures that can be used for further infiltration/multiscale printing. Potential design affordances of the center-core nozzle need to be verified by further study,but initial tests show promising results. Apart from design and implementation of mixing and switching nozzles,allowing multiple materials to be co-printed continuously, the frequency or resolution at which they can switch materials is limited.Specifically,the large dead volume in mixing nozzles results in long material transitions, causing nozzle clogging.More recently,Lewis et al.reported the design and fabrication of voxelated soft matter using multimaterial multinozzle 3D (MM3D)printing,in which the composition,function,and structure of the materials are programmed at the voxel scale with enhanced build speed.[86]Moreover,Studart et al.proposed multimaterial magnetically assisted 3D printing platform(MM-3D printing)opened the way toward the manufacturing of functional heterogeneous materials with exquisite microstructural features.Further shape change required for reconfiguration can also be achieved using a much wider range of chemistries and external triggering stimuli.[87]

Figure 4. Multiscale electrodes with superior performance for EESDs. A) Electrochemical performance of 3D-printed few-layer large-flake Ti3C2Tx interdigitated electrodes integrated into current-collector-free symmetric MSCs (finger diameter of 326 μm and gap distance of 187 μm). A) Reproduced with permission.[104] Copyright 2019, Wiley-VCH. B) Electrochemical performance of the assembled AC/CNT/rGO symmetric supercapacitors. B) Reproduced with permission.[78] Copyright 2018, Wiley-VCH. C) Cycling performance of Li-S cells assembled with 3D-printed freeze-dried electrode.[105] Copyright 2019,Elsevier B.V.

From material-wise consideration,a universal formulation applicable to a variety of materials may be able to mitigate such clogging problem. Moreover, to overcome shrinkage problem, it is important to make sure a similar ligand removal and comparable sintering condition to minimize the shrinkage disparity.The suspensions can also be reformulated to consider the different shrinkage rates while retaining similar viscoelastic response to minimize printing defect. Zhang et al. have covered a self-curable epoxide–amine ink formulation to print a wide range of ceramics (metal oxides, nitrides, and carbides) and metals without the need for an external curing source.[88]Such ink system needs no extra solvent-evaporation step and effectively solved the challenges such as high energy requirements, limitations of materials with high refractive index, tedious postprocessing heat treatment processes,uneven drying shrinkages, and brittleness of green bodies which current curing techniques may encountered. Through this technique,complex multimaterial structures can be printed.[50]Otherwise,another feasible route which has been successfully demonstrated for copper-and graphene-based electrode materials by Rocha et al is using nonionic thermosensitive hydrogel (i.e., Pluronic F127).[89]Pluronic F127 with inherent reversible viscoelastic properties and shear-thinning behavior is suitable to be mixed with different material and forms printable inks.[90]As hydrogel can preserve water better than anionic/cationic-polymeric additives in the conventional colloidal ink formulations and may help to minimize the cracks problem during drying step. Although some of the proposed formulation are demonstrated for only ceramic materials, it is also applicable in many other combinations such as metal/metal, metal/ceramic. Another possible solution to minimize the sintering cracks and delamination is to increase the solid loading while using same aqueous colloidal paste via surface modification of the starting powder.

3.1.2. Photopolymerization (Printer Setup and Ink Formulation)

Similar to the many other desktop printers, projection stereolithography-based printer can incorporate with external setup to be used in the multimaterial and multiscale 3D printing.This allows the fabrication of multifunctional polymer composites with localized control of particle distribution, geometric flexibility, and fast build speed. Such modified process enables the design complexity, the range of polymer composites material, and a higher degree of functionality. Printing parameters of the resin in curing and patterning can be investigated easily to provide a guideline for printing composites for real application. However,because a whole tank of resin is prepared and is used for printing layers,the filler concentrations and patterns are difficult to control among layers. Although in situ particle-polymer blending can partially solve the problem, such premixing manufacturing method lacks flexibilities in producing composites with heterogeneous properties/multimaterial combination with less boundary defects,greatly limiting applications in smart machines/fast manufacturing. Pan et al. approaches for fabrications of multifunctional particle-polymer composites using external field-assisted projection-based stereolithography processes.Additionally,particle alignment mechanisms using an external magnetic field and an external acoustic field were investigated separately.[91-92]The proposed particle manipulation techniques outperform the existing particle manipulation methods on localized particle distribution control, broad filler material selection in terms of size and type, and various gradient patterns.

Figure 5. Multimaterial electrodes by 3D printing. A) Diagram showing the various nozzle prototypes produced. The large travel distance of the Janus Nozzle v1 prevented clay from extruding. Janus Nozzle v2 oriented extruders at a 45 degree angle to one another in order to reduce the travel distance from the end of the clay cylinder to the tool tip. Center-core nozzle retained the general form of Janus Nozzle v2 but adjusted material flow to provide a concentric extrusion. A) Reproduced with permission.[85] Copyright 2019, ACADIA. B) (a) Schematic of voxelated architectures printed using a single (0D) nozzle (top)and the 1D (middle) and 2D (bottom) MM3D printheads. (b) Photographs of the corresponding 0D, 1D, and 2D four-material MM3D printheads. (c)Photographs showing the top (top) and side (middle and bottom) views of a 4 × 4-nozzle, four-material, 2D MM3D printhead. Scale bars, 10 mm. (d)Schematic of MM3D printhead operation, where V1–V4 represents the voltage waveforms controlling the extrusion pressures p1–p4 for materials 1–4, and patm denotes the atmospheric pressure. (e) Voxelated matter produced by MM3D printing using a 4 × 4-nozzle, four-material, 2D printhead. B) Reproduced with permission.[86] Copyright 2019, Nature.

However, mixing of particles and liquid resin remains the primary challenge, as agglomeration or undesired particle dispersion patterns occur when the particles are not blended properly before the printing or when the 3D printing process takes a long time. Magdassi et al.reported a family of highly stretchable elastomers that are suitable for the DLP-based 3D printing technology.[93]By mixing monomers at various ratios, such DLP printed elastomers can be stretched by up to 1100%. It enables the direct creation of complex 3D lattices or hollow structures for multimaterial combination and multiscale architecture where extremely large deformation is needed.

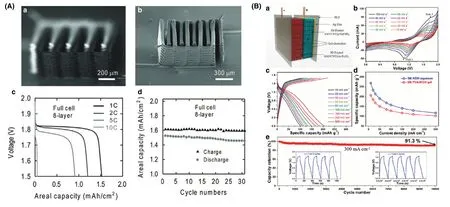

Figure 6. 3D printed Multimaterial EESDs.A)(a)Optical and(b)SEM images of printed and annealed LTO-LFP architectures.(c)Full-cell voltage as a function of areal capacity for 8-layer interdigitated LTO-LFP electrodes. (d) Areal capacity of full cell composed of 8-layer interdigitated LTO-LFP electrodes measured as a function of number of cycles tested.Reproduced with permission.[50]Copyright 2013,Wiley-VCH.B)Electrochemical properties of the single 3D-printed QSS-NFB devices. (a) Schematic illustration, (b) CV curves, (c) galvanostatic charge–discharge (GCD) curves, (d) rate properties, (e) cycling properties of the 3D-printed QSS-NFB device.Reproduced with permission.[96]Copyright 2020,ACS publication.

One advantage over extrusion-based printing is the as-formed solid products enables one-step assembly. Not many works have been explored the possibility of fabricating EESDs using photopolymerization-based 3D printing techniques although the high printing quality and fast speed have been proven.However,restriction in material selection limited the further application.The formulation manipulation techniques need to be carried out to outperform the existing particle manipulation methods on localized particle distribution control, broad filler material selection in terms of size and type. Fantino et al. have coupled the photoreduction of a metal precursor with 3D-printing technology and showed the possibility of the fabrication of conductive 3D hybrid structures consisting of metal nanoparticles and organic polymers shaped in complex multilayered architectures.[93]3D conductive structures were fabricated incorporating silver nitrate into a photocurable oligomer in the presence of suitable photoinitiators and exposing them to a digital light system.Similar skills are foreseeable to be broad to other metal electrodes. Wang et al. demonstrated that by mixing the conductive filler with polymer matrix, the printed conductive complex structures can be used as hollow capacitive sensor,electrically activated shape memory composites, stretchable circuits, showing the versatility of photopolymerization-based 3D printing for conductive complex structures.[94]Yin et al.presented a work in alternative digital light processing 3D printing of two photocurable precursors: hydrogel and water-dilutable polyurethane acrylate (WPUA), in which the ionically conductive hydrogel layers serve as soft,transparent electrodes and the electrically insulated WPUA as flexible, transparent dielectric layers.[95]Moreover,the effects of process parameters on the particle-resin mixture curing and particle patterning can be easily investigated to provide a guideline for printing composites thus is suitable for practical application.

3.2. 3D printed Multimaterial EESDs

Sun et al.have carefully designed concentrated LFP and LTO viscoelastic inks enabled printing of these thin-walled anode and cathode structures in one batch (Figure 6). Using this LFP-LTO combination, they have achieved a high areal energy density of 9.7 J cm-2at a power density of 2.7 mW cm-2.[50]Other demonstrated work mainly focuses on planar mesh integration without taking complex structures into consideration. Kong et al. have demonstrated a printing with multicomponents as quasi-solid-state nickel iron battery (QSS-NFB), two electrodes consisting of ultrathin Ni(OH)2nanosheet array cathode and holey α-Fe2O3nanorod array anode are achieved with a ultrahigh active material loading over 130 mg cm-3and excellent compressibility up to 60% (Figure 6). The compressible QSS-NFB exhibited an excellent cycling stability (~91.3% capacity retentions after 10 000 cycles) and ultrahigh energy (28.1 mWh cm-3at a power of 10.6 mW cm-3).[96]Integrated EESDs in the form of complete devices hold the promise of simplified production and real applications. There have, however, been major strides made toward the realization of multimaterial printing with more complex and compact design which has been discussed in detailed in the previous section and below as outlook.[97]

4. Summary and Outlook

Compared with traditional 2D electrodes and planar EESD structures,the synthesis of 3D thick porous electrodes/3D EESD has proven to be promising in addressing charge transport limitations in commercial EESDs. The realization of improved electron, ion transport, and mechanical properties through the construction of continuous 3D structures with hierarchical porosity is essential. 3D structures have also demonstrated excellent structural stability,being able to withstand stresses caused by volume change during charge/discharge. One of the major benefits in using 3D printing technique is the design flexibility and having that advantage not only promotes the energy density and power density but also enables the development of EESDs for wearable devices. Complex 3D structures, with hierarchically constructed architecture,are beneficial to improve electrochemical performance therefore need to be printed with high resolution, accuracy, and surface finish.From the technique’s perspective,optimized printer setting is a prerequisite to achieve high-resolution 3D architectures. Presently, various works have demonstrated good results, showing the promise of 3D printing.However,there does not seem to yet be a standard metric by which authors report performance, for example, areal versus volumetric.Standardization of performance metrics will provide a better framework for comparison, against other works as well as commercial systems. There also remains much untapped potential in the free-form shaping afforded by 3D printing, with many current works so far still experimenting with relatively simple shapes such as flat rectangular meshes.Developments in modeling and simulation tools such as generative design have combined advanced computational tools and 3D printing for structures with designed mechanical properties. This can potentially be leveraged for optimization of EESDs,for robust structures that can undergo large deformation to power flexible wearable devices.Other tools like computational fluid dynamics can be utilized to optimize flow in new complex 3D electrodes for further improved performance.

The next major challenge of 3D printed EESDs is the realization of viable integrated electronic devices. While many works have so far showed the possibility of utilizing 3D printing for multiscale structures toward EESDs with enhanced performance,fewer works have been documented the realization of multimaterial 3D printing for integrated EESDs. Integrated EESDs in the form of complete devices with all the benefits of complexity afforded by 3D printing hold the promise of simplified production and real applications.Multiscale structures can be inherently produced from the variety of 3D printing techniques, but multimaterial printing remains highly challenging. Challenges and efforts in multimaterial printing have been reviewed in this article. For multimaterial printing,major issues include nozzle clogging,crack/delamination, as well as elemental leaching. Material-wise modification can potentially mitigate such boundary defects,among the many other possibilities in fabricating postprocessing-free 3D-printed EESDs without sacrificing their electrochemical performance. Meanwhile, new innovative printer designs regarding the printer setup such as the introduction of an ultrasound nozzle, oxygen-embedded print chamber are expected to be developed.

Together with fast development in active material chemistry and structural flexibility in 3D-printed parts, effective/optimized electrode architecture modeling will be necessary to realize EES systems with superior energy and power density and to meet the insatiable demand for more energy and power. Ex situ and in situ characterization techniques (e.g., high-resolution TEM, atomic force microscopy, NMR spectroscopy,cryo-electron microscopy,and transmission X-ray microscopy) are helpful to understand and even monitor the real-time electrochemical performance and serve as a better guideline for nextgeneration 3D EESDs design.

Acknowledgments

The authors acknowledge the financial supports by National Natural Science Foundation of China (grant no. 51902265), Fundamental Research Funds for the Central Universities, Key Research and Development Program of Shaanxi (no.2020KWZ-001), and Project for graduate Innovation team of Northwestern Polytechnical University.

Conflict of Interest

The authors declare no conflict of interest.

Keywords

3d printing, electrochemical energy storage devices, multimaterial, multiscale

Received: October 5, 2020

Revised: November 14, 2020

Published online: December 6, 2020

[1] R.Raccichini,A.Varzi,S.Passerini,B.Scrosati,Nat.Mater.2015,14,271.

[2] P.Alstone,D.Gershenson,D.M.Kammen,Nat.Clim.Chang.2015,5,305.

[3] X. Li, M. Rui, J. Song, Z. Shen, H. Zeng, Adv. Func. Mater. 2015, 25,4929.

[4] Y. Gogotsi, P. Simon, Science 2011, 334, 917.

[5] P. Forouzandeh, S. C. Pillai, Mater. Today Proc. 2020, 5, 233.

[6] T.S.Arthur,D.J.Bates,N.Cirigliano,D.C.Johnson,P.Malati,J.M.Mosby,E.Perre,M.T.Rawls,A.L.Prieto,B.Dunn,MRS Bull.2011,36,523.

[7] S. C. Pang, M. A. Anderson, T. W. Chapman, J. Electrochem. Soc. 2000,147, 444.

[8] K. Shen, X. Chen, J. Chen, Y. Li, ACS Catalysis 2016, 6, 5887.

[9] S. Chen, L. Ma, S. Wu, S. Wang, Z. Li, A. A. Emmanuel, M. R. Huqe, C.Zhi, J. A. Zapien, Adv. Func. Mater. 2020, 30, 1908945.

[10] X. Cheng, J. Pan, Y. Zhao, M. Liao, H. Peng, Adv. Energy Mater. 2018,8, 1702184.

[11] Z. Kang, G. Yang, J. Mo, Y. Li, S. Yu, D. A. Cullen, S. T. Retterer, T. J.Toops, G. Bender, B. S. Pivovar, Nano Energy 2018, 47, 434.

[12] H. Sun, J. Zhu, D. Baumann, L. Peng, Y. Xu, I. Shakir, Y. Huang, X.Duan, Nat. Rev. Mater. 2019, 4, 45.

[13] N. Nitta, F. Wu, J. T. Lee, G. Yushin, Mater. Today 2015, 18, 252.

[14] H. Chen, J. Jiang, L. Zhang, D. Xia, Y. Zhao, D. Guo, T. Qi, H. Wan, J.Power Sources 2014, 254, 249.

[15] Z.-H. Huang, Y. Song, D.-Y. Feng, Z. Sun, X. Sun, X.-X. Liu, ACS Nano 2018, 12, 3557.

[16] J. Werner, G. Rodr′?guez-Calero, H. Abru~na, U. Wiesner, Energy Environ.Sci. 2018, 11, 1261.

[17] Q. Zhang, H. Wan, G. Liu, Z. Ding, J. P. Mwizerwa, X. Yao, Nano Energy 2019, 57, 771.

[18] Z. Yu, D. G. Mackanic, W. Michaels, M. Lee, A. Pei, D. Feng, Q. Zhang,Y. Tsao, C. V. Amanchukwu, X. Yan, Joule 2019, 3, 2761.

[19] S. Yang, S. Wang, X. Liu, L. Li, Carbon 2019, 147, 540.

[20] J.Dai,L.Wang,A.Xie,J.He,Y.Yan,ACS Sustain.Chem.Eng.2019,8,739.

[21] F. Zhang, P. Xiong, X. Guo, J. Zhang, W. Yang, W. Wu, H. Liu, G.Wang, Energy Storage Mater. 2019, 19, 251.

[22] A. Ahmadiparidari, R. E. Warburton, L. Majidi, M. Asadi, A. Chamaani,J. R. Jokisaari, S. Rastegar, Z. Hemmat, B. Sayahpour, R. S. Assary, Adv.Mater. 2019, 31, 1902518.

[23] K. A. Severson, P. M. Attia, N. Jin, N. Perkins, B. Jiang, Z. Yang, M. H.Chen, M. Aykol, P. K. Herring, D. Fraggedakis, Nat. Energy 2019, 4, 383.

[24] H. Jiang, J. Sun, L. Wei, M. Wu, W. Shyy, T. Zhao, Energy Storage Mater.2020, 24, 529.

[25] Y. He, C. Lu, S. Liu, W. Zheng, J. Luo, Adv. Energy Mater. 2019, 9,1901810.

[26] Z. Li, K. Jiang, F. Khan, A. Goswami, J. Liu, A. Passian, T. Thundat, Sci.Adv. 2019, 5, eaav2820.

[27] F. Hao, W. Wang, P. P. Mukherjee, Phys. Rev. Appl. 2019, 11, 034038.

[28] X. Song, Y. Lu, F. Wang, X. Zhao, H. Chen, J. Power Sources 2020, 452,227803.

[29] K. Li, Z. Hu, J. Ma, S. Chen, D. Mu, J. Zhang, Adv. Mater. 2019, 31,1902399.

[30] Y. Chen, X. Ke, Y. Cheng, M. Fan, W. Wu, X. Huang, Y. Liang, Y.Zhong, Z. Ao, Y. Lai, Energy Storage Mater. 2020, 26, 56.

[31] C.Sun,Y.Ruan,W.Zha,W.Li,M.Cai,Z.Wen,Mater.Horizons 2020,7,30.

[32] Y. Zheng, H. Seifert, H. Shi, Y. Zhang, C. K¨ubel, W. Pfleging, Electrochim. Acta 2019, 317, 502.

[33] X. Xu, C. Guan, L. Xu, Y. H. Tan, D. Zhang, Y. Wang, H. Zhang, D. J.Blackwood, J. Wang, M. Li, ACS Nano 2019, 14, 937.

[34] X. Gao, X. Yang, Q. Sun, J. Luo, J. Liang, W. Li, J. Wang, S. Wang, M. Li,R. Li, Energy Storage Mater. 2020, 24, 682.

[35] Z. Lv, W. Li, L. Yang, X. J. Loh, X. Chen, Acs Energy Lett. 2019, 4, 606.

[36] F. Zhang, M. Wei, V. V. Viswanathan, B. Swart, Y. Shao, G. Wu, C.Zhou, Nano Energy 2017, 40, 418.

[37] C. Sun, S. Liu, X. Shi, C. Lai, J. Liang, Y. Chen, Chem. Eng. J. 2020, 381,122641.

[38] T. S. Wei, B. Y. Ahn, J. Grotto, J. A. Lewis, Adv. Mater. 2018, 30,1703027.

[39] W. Shi, M. Sun, X. Hu, B. Ren, J. Cheng, C. Li, X. Duan, X. Fu, J. Zhang,H. Chen, Adv. Mater. 2017, 29, 1701089.

[40] Y. Yang, Z. Chen, X. Song, Z. Zhang, J. Zhang, K. K. Shung, Q. Zhou, Y.Chen, Adv. Mater. 2017, 29, 1605750.

[41] D. G. Moore, L. Barbera, K. Masania, A. R. Studart, Nat. Mater. 2020,19, 212.

[42] A. T. Kutbee, R. R. Bahabry, K. O. Alamoudi, M. T. Ghoneim, M. D.Cordero, A. S. Almuslem, A. Gumus, E. M. Diallo, J. M. Nassar, A. M.Hussain, NPJ Flexible Electronics 2017, 1, 1.

[43] S. M. H. Hashemi, U. Babic, P. Hadikhani, D. Psaltis, Curr. Opin. Electrochem. 2020, 20, 6.

[44] P. Chang, H. Mei, S. Zhou, K. G. Dassios, L. Cheng, J. Mater. Chem. A 2019, 7, 4230.

[45] X. Tian, J. Jin, S. Yuan, C. K. Chua, S. B. Tor, K. Zhou, Adv. Energy Mater. 2017, 7, 1700127.

[46] Y. Pang, Y. Cao, Y. Chu, M. Liu, K. Snyder, D. MacKenzie, C. Cao, Adv.Func. Mater. 2020, 30, 1906244.

[47] J. S. Chohan, R. Singh, Rapid Prototyp. J. 2017, 23, 495.

[48] R. Sanz-Horta, C. Elvira, A. Gallardo, H. Reinecke, J. Rodr′?guez-Hern′andez. Nanomaterials 2020, 10, 1080.

[49] V. Mazzanti, L. Malagutti, F. Mollica, Polymers 2019, 11, 1094.

[50] K. Sun, T.-S. Wei, B. Y. Ahn, J. Y. Seo, S. J. Dillon, J. A. Lewis, Adv.Mater. 2013, 25, 4539.

[51] J. A. Lewis, J. Am. Ceram. Soc. 2004, 83, 2341.

[52] X. Xu, C. Li, J. G. Lim, Y. Wang, A. Ong, X. Li, E. Peng, J. Ding, ACS Appl. Mater. Interfaces. 2018, 10, 30273.

[53] C. Zhu, T. Liu, F. Qian, W. Chen, S. Chandrasekaran, B. Yao, Y. Song, E.B. Duoss, J. D. Kuntz, C. M. Spadaccini, M. A. Worsley, Y. Li, Nano Today 2017, 15, 107.

[54] Y. Zhao, B. Liu, L. Pan, G. Yu, Energy Environ. Sci. 2013, 6, 2856.

[55] Y. Yan, X. Liu, J. Yan, C. Guan, J. Wang. Energy Environ. Mater, 1.

[56] X. Kuang, Z. Zhao, K. Chen, D. Fang, G. Kang, H. J. Qi, Macromol.Rapid Commun. 2018, 39, 1700809.

[57] D. A. Walker, J. L. Hedrick, C. A. Mirkin, Science 2019, 366, 360.

[58] S. K. Saha, D. Wang, V. H. Nguyen, Y. Chang, J. S. Oakdale, S.-C. Chen,Science 2019, 366, 105.

[59] R. M. Hensleigh, H. Cui, J. S. Oakdale, C. Y. Jianchao, P. G. Campbell, E.B. Duoss, C. M. Spadaccini, X. Zheng, M. A. Worsley, Mater. Horizons 2018, 5, 1035.

[60] B. Ren, J. Liu, Y. Wang, Y. Chen, K. Gan, Y. Rong, J. Yang, J. Am. Ceram.Soc. 2019, 102, 6498.

[61] B. Elder, R. Neupane, E. Tokita, U. Ghosh, S. Hales, Y. L. Kong, Adv.Mater. 2020, 32, e1907142.

[62] J. T. Muth, P. G. Dixon, L. Woish, L. J. Gibson, J. A. Lewis, Proc. Natl Acad. Sci. USA 2017, 114, 1832.

[63] B. Yao, S. Chandrasekaran, H. Zhang, A. Ma, J. Kang, L. Zhang, X. Lu, F.Qian, C. Zhu, E. B. Duoss, C. M. Spadaccini, M. A. Worsley, Y. Li, Adv.Mater. 2020, 32, 1906652.

[64] Z. Liang, Y. Pei, C. Chen, B. Jiang, Y. Yao, H. Xie, M. Jiao, G. Chen, T.Li, B. Yang, L. Hu, ACS Nano 2019, 13, 12653.

[65] G. Ercolano, T. Zambelli, C. van Nisselroy, D. Momotenko, J. V¨or¨os, T.Merle, W. W. Koelmans, Adv. Eng. Mater. 2019, 22, 1900961.

[66] S. Chang, X. Huang, C. Y. Aaron Ong, L. Zhao, L. Li, X. Wang, J. Ding,J. Mater. Chem. A 2019, 7, 18338.

[67] E. Van?e?ckov′a, M. Bou?sa, R. Sokolov′a, P. Moreno-Garc′?a, P. Broekmann,V. Shestivska, J. Rathousk′y, M. G′al, T. Sebechlebsk′a, V. Kolivo?ska, J.Electroanal. Chem. 2020, 858, 113763.

[68] J. Xue, L. Gao, X. Hu, K. Cao, W. Zhou, W. Wang, Y. Lu, Nano-Micro Lett. 2019, 11, 1.

[69] X. Su, X. Li, C. Y. A. Ong, T. S. Herng, Y. Wang, E. Peng, J. Ding, Adv.Sci. 2019, 6, 1801670.

[70] C. Iffelsberger, S. Ng, M. Pumera, Appl. Mater. Today 2020, 20,100654.

[71] J. C. Bui, J. T. Davis, D. V. Esposito, Sustain. Energy Fuels 2020, 4, 213.

[72] S. Ng, C. Iffelsberger, Z. Sofer, M. Pumera, Adv. Func. Mater. 2020, 30,1910193.

[73] P. C. Sherrell, C. Mattevi, Mater. Today 2016, 19, 428.

[74] C. Marichy, M. Bechelany, N. Pinna, Adv. Mater. 2012, 24, 1017.

[75] Z. Lyu, G. J. H. Lim, R. Guo, Z. Kou, T. Wang, C. Guan, J. Ding, W.Chen, J. Wang, Adv. Func. Mater. 2019, 29, 1806658.

[76] Z. Lyu, G. J. Lim, R. Guo, Z. Pan, X. Zhang, H. Zhang, Z. He, S. Adams,W. Chen, J. Ding, Energy Storage Mater. 2020, 24, 336.

[77] S. H. Park, M. Kaur, D. Yun, W. S. Kim, Langmuir 2018, 34, 10897.

[78] T. Gao, Z. Zhou, J. Yu, J. Zhao, G. Wang, D. Cao, B. Ding, Y. Li, Adv.Energy Mater. 2019, 9, 1802578.

[79] B. Yao, S. Chandrasekaran, J. Zhang, W. Xiao, F. Qian, C. Zhu, E. B.Duoss, C. M. Spadaccini, M. A. Worsley, Y. Li, Joule 2019, 3, 459.

[80] G. D. O’Neil, Curr. Opin. Electrochem 2020, 20, 5.

[81] P. Wu, Z. Fang, A. Zhang, X. Zhang, Y. Tang, Y. Zhou, G. Yu, Research 2019, 2019, 8393085.

[82] V. G. Rocha, E. Saiz, I. S. Tirichenko, E. Garc′?a-Tu~n′on, J. Mater. Chem.A 2020, 8, 15646.

[83] H. Kim, F. Torres, D. Villagran, C. Stewart, Y. Lin, T. L. B. Tseng, Macromol. Mater. Eng. 2017, 302, 1700229.

[84] E. Peng, D. Zhang, J. Ding, Adv. Mater. 2018, 30, 1802404.

[85] Z. Seibold, S. Mhatre, J. L. G. del Castillo, M. Bechthold.presented at Proceedings of the Annual Conference of the Association for Computer-Aided Design in Architecture (ACADIA) 2019.

[86] M. A. Skylar-Scott, J. Mueller, C. W. Visser, J. A. Lewis, Nature 2019,575, 330.

[87] D. Kokkinis, M. Schaffner, A. R. Studart, Nat. Commun. 2015, 6, 8643.

[88] D. Zhang, E. Peng, R. Borayek, J. Ding, Adv. Func. Mater. 2019, 29,1807082.

[89] V.G.Rocha,E.Garc′?a-Tu~n′on,C.Botas,F.Markoulidis,E.Feilden,E.D’Elia,N.Ni,M.Shaffer,E.Saiz,ACS Appl.Mater.Interfaces.2017,9,37136.

[90] E. Feilden, E. G.-T. Blanca, F. Giuliani, E. Saiz, L. Vandeperre, J. Eur.Ceram. Soc. 2016, 36, 2525.

[91] L. Lu, Dissertation/Thesis ProQuest Dissertations Publishing 2019.

[92] L. Lu, P. Guo, Y. Pan, J. Manuf. Sci. Eng. 2017, 139.

[93] B. Zhang, S. Li, H. Hingorani, A. Serjouei, L. Larush, A. A. Pawar, W. H.Goh, A. H. Sakhaei, M. Hashimoto, K. Kowsari, S. Magdassi, Q. Ge, J.Mater. Chem. B 2018, 6, 3246.

[94] Q. Mu, L. Wang, C. K. Dunn, X. Kuang, F. Duan, Z. Zhang, H. J. Qi, T.Wang, Additive Manufacturing 2017, 18, 74.

[95] X. Y. Yin, Y. Zhang, J. Xiao, C. Moorlag, J. Yang, Adv. Func. Mater.2019, 29, 1904716.

[96] D. Kong, Y. Wang, S. Huang, B. Zhang, Y. V. Lim, G. J. Sim, P. Valdivia y Alvarado, Q. Ge, H. Y. Yang, ACS Nano 2020, 14, 9675.

[97] M. Rafiee, R. D. Farahani, D. Therriault, Adv. Sci. 2020, 7, 1902307.

[98] E. E. Petersen, J. Pearce, Technologies 2017, 5, 7.

[99] A. Blaeser, D. F. Duarte Campos, U. Puster, W. Richtering, M. M. Stevens, H. Fischer, Adv. Healthcare Mater. 2016, 5, 326.

[100] M. Mao, J. He, X. Li, B. Zhang, Q. Lei, Y. Liu, D. Li, Micromachines 2017, 8, 113.

[101] J. Stringer, B. Derby, J. Eur. Ceram. Soc. 2009, 29, 913.

[102] L. F. Arenas, N. Kaishubayeva, C. Ponce de Le′on, F. C. Walsh, Transactions IMF 2020, 98, 48.

[103] S. D. Lacey, D. J. Kirsch, Y. Li, J. T. Morgenstern, B. C. Zarket, Y. Yao, J.Dai, L. Q. Garcia, B. Liu, T. Gao, S. Xu, S. R. Raghavan, J. W. Connell, Y.Lin, L. Hu, Adv. Mater. 2018, 30, 1705651.

[104] W. Yang, J. Yang, J. J. Byun, F. P. Moissinac, J. Xu, S. J. Haigh, M.Domingos, M. A. Bissett, R. A. W. Dryfe, S. Barg, Adv. Mater. 2019, 31,1902725.

[105] X.Gao,Q.Qian,X.Yang,J.Liang,A.Koo,W.Li,J.Wang,R.Li,F.Holness,A.Price,S.Yang,T.Sham,X.Sun,Nano Energy,2018,56,595.

Energy & Environmental Materials2022年2期

Energy & Environmental Materials2022年2期

- Energy & Environmental Materials的其它文章

- Editor’s Note on “Frontier Outlook” Column

- Graphite Anode for Potassium Ion Batteries: Current Status and Perspective

- Green Synthesis of Nitrogen-to-Ammonia Fixation: Past,Present, and Future

- Photo-assisted Rechargeable Metal Batteries for Energy Conversion and Storage

- The Transference Number

- Recent Advances on the Development of Functional Materials in Microbial Fuel Cells: From Fundamentals to Challenges and Outlooks