Mechanical properties of thermal aged HTPB composite solid propellant under confining pressure

Zhe-jun Wang, Hong-fu Qiang

206 Staff Room, Xi'an Hi-Tech Institute, Xi'an, 710025, PR China

Keywords:Thermal accelerated aging Confining pressure Hydroxyl-terminated polybutadiene propellant Mechanical properties Strength criterion

ABSTRACT With the purpose of investigating the effects of confining pressure and aging on the mechanical properties of Hydroxyl-terminated polybutadiene (HTPB) based composite solid propellant, tensile tests of thermal accelerated aged propellant samples under room temperature and different confining pressure conditions were performed through the use of a self-made confining pressure device and conventional testing machine. Afterwards, the maximum tensile stress σm and the corresponding strain εm for the propellant under different test conditions were obtained and analyzed. The results indicate that confining pressure and aging can significantly affect the mechanical properties of HTPB propellant, and the coupled effects are very complex.On the one hand,the stress σm increases as a whole when confining pressure becomes higher or thermal aging time rises.Besides, this stress is more sensitive to aging with increasing confining pressure. There are almost three regions in the stress increments (σmP -σm0)/σm0 and thermal aging time curves for HTPB propellant. The maximum value of the stress increment (σmPσm0)/σm0 for the propellant is about 98%at 7.0 MPa and 170 d.On the other hand,the strain εm decreases with increasing thermal aging time under the whole confining pressure conditions. However, the variation of this strain with confining pressure is more complex at various thermal aging time, which is different from that of unaged solid propellant in previous researches. In addition, this strain is slightly less sensitive to aging as the confining pressure increases. Furthermore, there is also a critical confining pressure in this investigation, whose value is between 0.15 MPa and 4.0 MPa. Beyond this critical pressure, the trends of the stress σm and the corresponding strain εm all change. Moreover, there are some critical thermal aging time for the stress increment (σmP-σm0)/σm0 and strain increment(εmP-εm0)/εm0 of HTPB propellant in this investigation, which are about at 35, 50 and 170 d. Finally,based on the twin-shear strength theory, a new modified nonlinear strength criterion of thermal aged HTPB propellant under confining pressure was proposed.And the whole errors of fitted results are lower than 6%. Therefore, the proposed strength criterion can be selected as a failure criterion for the analysis the failure properties of aged HTPB propellant under different confining pressures, the structural integrity of solid propellant grain and the safety of solid rocket motor during ignition operation after long periods of storage.

1. Introduction

It is well known that the reliability of solid rocket motor(SRM)is very important in service and is an important guarantee for its safety during ignition operation. Whereas, the reliability of this motor is mostly dependent on the structural integrity of solid propellant grain [1], because the propellant grain serves as the most prime component and the energy source of SRM.In addition,solid propellant is a typical nonhomogeneous material containing large percentage of energetic components and classified as being in the family of highly particle-filled polymers. In comparison with metal materials, it exhibits more obvious dependence of mechanical properties on the external loading conditions (for example,stress state, etc.) and aging phenomenon [2,3]. During ignition operation, solid propellant is pressurized by hot gases and in a triaxial stress state[4],which is obviously different from that under uniaxial tension or compression. Furthermore, SRM are usually stored for different time before actual ignition operation[5].During this prolonged storage, there is an aging effect on solid propellant because of a combination of chemical reactions and physical processes, which may further influence the properties of solid propellant during ignition operation [6]. Therefore, it is extremely necessary and important to investigate the mechanical properties of solid propellant during ignition after preserving over a long period of time to analyze and ensure the structural integrity of solid propellant grain and the safety of SRM during ignition operation after long periods of storage.

Some researchers as early as Jones and Kruse[7]have attempted to understand the pressure sensitivity of mechanical properties for unaged solid propellants.Subsequently,some progresses about the effects of pressure on the failure resisting capacity of unaged solid propellants were made to investigate the properties of the propellants during ignition operation of SRM, based on mechanical tests under different stress states and a wide temperatures and strain rates by employing various passive confined pressure devices[8-14]. Traissas et al. [4] found that the tensile strength, shear strength and the corresponding failure strain were all improved gradually with increasing confining pressure under loading speeds lower than 1000 mm/min.Moreover,there is a saturation pressure or a threshold value in the effect of confining pressure on the mechanical properties of unaged solid propellants. In general, this critical pressure is about 5.0 MPa[8].When the confining pressure is higher than this critical value, no further significant influence was observed or the failure resisting capacity decreases[4,9].Zhang and Li et al. [10,11] investigated the compressive behaviors of unaged double-base (DB) propellant and Nitrate Ester Plasticized Polyether (NEPE) propellant under confining pressure and loading speeds lower than 1000 mm/min. The triaxial compressive test results indicated that higher pressure could increase the yield strength and compressive strength. Besides, compared with compression, tensile mechanical properties of unaged solid propellants are more sensitive to confining pressure[11].Furthermore,the cohesion and internal friction angle of unaged DB propellant were obtained, according to the Mohr-Coulomb theory [10]. To study the mechanical properties of solid propellant during rapid tensile force, Zhang et al. [12] developed a new experimental system with an upgrade of the convention testing machine. Research shows that there are no parent dewetting points in the unaged propellant stress-strain curves under confining pressure,which are different from the previous researches. Based on the test results made by Liu and Miller et al. [13,14], the reasons for the above performance of mechanical properties for solid propellants are that the crack growth rate changes with increasing confining pressure and the composition of the propellants are different. In addition,confining pressure can usually delay or restrain the microscopic damage inside the propellant, such as dewetting. Compared to compression, the effect of confining pressure on suppressing the development of damage in tension is more obvious.Because of the difficulty of the confining pressure tests,up to now,there are very limited reports that delve into the properties of solid propellants under confining pressure conditions in the open literatures.

Compared with the insufficient confining pressure tests,during the past few decades,a considerable amount of work has been done to studying the effect of aging on the properties of solid propellants at ambient pressure[15-17].The most common method is thermal accelerated aging of a propellant at elevated temperatures higher than ambient temperature to reduce the time scale, then mechanical experiments were conducted on the aged propellant samples in a reasonable aging time[18].The previous experimental findings obtained reveal that the properties of solid propellant are significantly dependent on aging. Furthermore, the elasticity modulus and tensile strength of aged solid propellants usually increase overall at ambient pressure,whereas the failure strain has a significant decline [17]. Furthermore, some failure criteria have been constructed with the measured mechanical parameters of aged solid propellants at ambient pressure[19].It is obviously that there is almost no current work on the coupled effects of aging and confining pressure on the mechanical properties of solid propellants,and the related failure criteria is sorely lacking.Thereby,it is impossible to provide an accuracy analysis of the structural integrity of solid propellant grain and the safety of SRM during ignition operation after long periods of storage,which provokes the requirement of the new test methods and analysis theories.

In the presented paper, tensile tests of solid propellant were conducted under a wide thermal-accelerated aging time and different confining pressure conditions, firstly. Afterwards, the effects of confining pressure and aging time on the typical mechanical properties of the propellant were investigated. Finally,according to the twin-shear strength theory, a modified strength criterion was constructed and selected as a failure criterion to further describe the coupled effects of confining pressure and aging on the failure resisting capacity of the propellant.

2. Experiments

2.1. Materials and sample preparation

The widespread triple-component Hydroxyl-terminated polybutadiene(HTPB,binder and fuel)based composite solid propellant was selected as experimental material for this study, and its compositions are as follows: 66.5 mass-% of ammonium perchlorate(AP, oxidizer),17.5 mass-% of Aluminium (Al) powder (metal fuel),16 mass-%of HTPB and other additives(such as plasticizer,bonding agent and curing agent). According to the Chinese aerospace industry standard of P. R. C, QJ 2328A-2005, the freshly mixed and cured propellant samples were cut into blocks with dimensions of 120 mm × 130 mm × 30 mm.

2.2. Accelerated ageing experiments

Temperature-controlled (±0.5 K, stability) commercial air circulating aging ovens LR016 was applied for conducting the thermalaccelerated aging experiments of HTPB propellant blocks in loadfree condition (no pre-strain). Then, according to the Chinese aerospace industry standard of P. R.C, QJ 2328A-2005 and the previous work [19], the thermal-accelerated aging temperature was selected as 343.15 K with RH<10%.In addition,the total aging time is over 188 days. Furthermore, at the scheduled intervals of time during the aging period, the propellant blocks were removed to measure the mechanical properties of HTPB propellant.

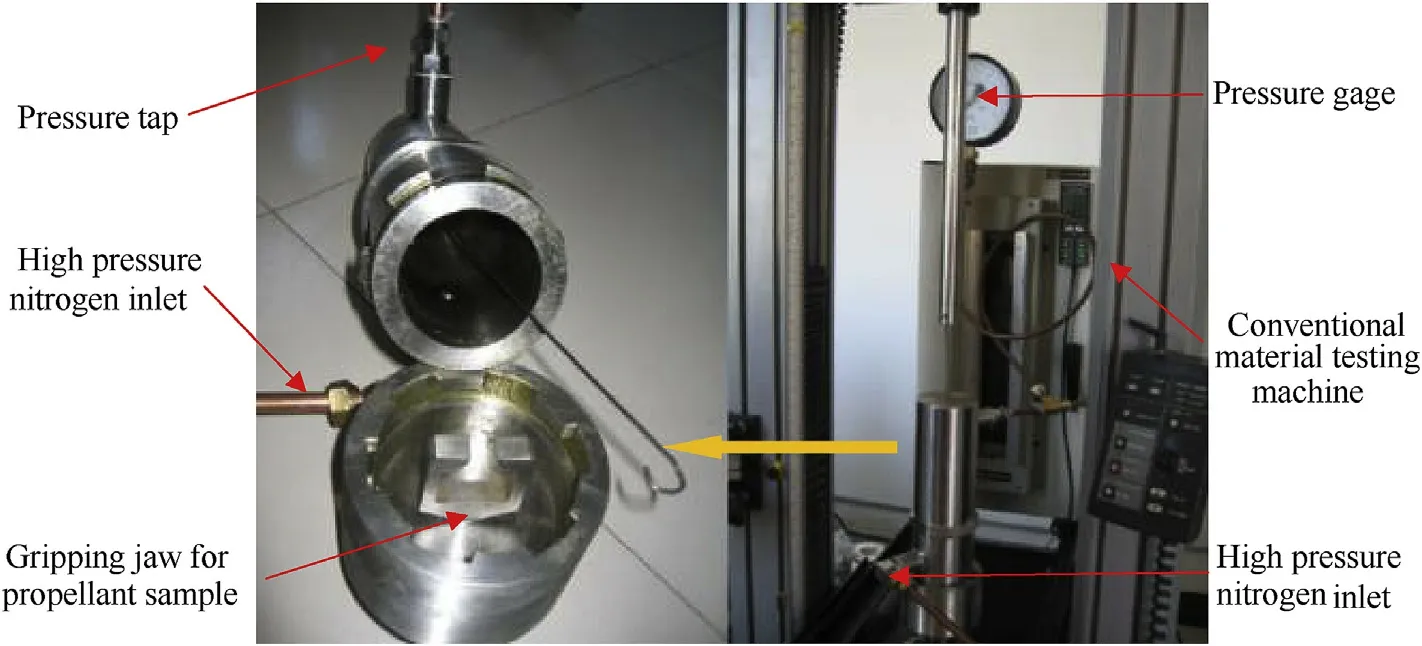

2.3. Tensile tests under confining pressure

To avoid the effects of moisture and viscoelastic recovery on the mechanical behaviors of the propellant, the aged HTPB propellant blocks were firstly put into a dryer until they no longer shrunk,and the geometrical dimensions were constant.Then these blocks were further cut into individual dumbbell-slat samples for tensile tests according to the Chinese national standard of P. R. C, GJB 770B-2005,and the dimensions of the samples are consistent with that in our previous work[20].Tensile tests under confining pressure and room temperature 298.15 K were performed through using a selfmade passive confining pressure device and conventional material testing machine (as shown in Fig.1), which can guarantee the triaxial loading condition required in this investigation.Because the maximum pressure on the internal surface of triple-component HTPB propellant grain is usually regarded as 4.0-10.0 MPa during ignition operation of SRM [21], four groups of confining pressure conditions with relative atmospheric pressure 0.0 MPa (namely,absolute pressure 0.10 MPa), 0.15 MPa, 4.0 MPa and 7.0 MPa were applied using nitrogen gas when conducting the tensile tests.During testing, the variation of confining pressure with time was monitored by the pressure gage,whose accuracy is up to 0.01 MPa.Moreover,when the confining pressure reached its scheduled value in the test chamber, the test was conducted. Finally, the aged propellant samples were pulled to failure at the scheduled confining pressure and a constant loading speed of 100 mm/min. And the corresponding load and displacement were recorded with the testing machine software.

Fig.1. Confining pressure test system.

To guarantee the reliability of test results,the test was repeated for five times at each loading condition (confining pressure and aging time) in this paper. The sample test matrix is shown in Table 1.All experimental data investigated in the following sections were the average of the five replicas after excluding the outlier ones according to the Chinese national standard of P. R. C, GJB 770B-2005.

3. Results and discussion

Based on the load-displacement curves of HTPB propellant for each test,the corresponding engineering stress σ and strain ε were calculated. Afterwards the stress-strain curves of the propellant were obtained. In general, the maximum tensile stress σand the corresponding strain εwere determined to analyze the failure resisting capacity of solid propellant. Therefore, these two mechanical parameters of HTPB propellant were directly obtained from the stress-strain curves in this investigation.

3.1. Effect of confining pressure on the mechanical properties

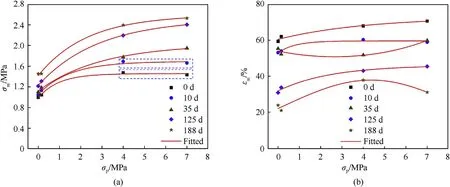

The variation of the maximum tensile stress σand the corresponding strain εfor HTPB propellant with confining pressure at typical thermal aging time are shown in Fig. 2. As seen, confining pressure has a pronounced effect on the mechanical properties of HTPB propellant.On the one hand,the stress σis obviously larger when the pressure is higher than the atmospheric pressure at all thermal aging time(as shown in Fig.2(a)).It means that the tensile strength of unaged and aged HTPB propellant under confining pressure is all greatly improved. Moreover, the stress σwith confining pressure is in an increasing tendency as a whole at all thermal aging time. However, there is a critical confining pressure between 0.15 MPa and 4.0 MPa.In addition,this critical value is the same for unaged and aged HTPB propellant, which indicates that thermal aging has no obvious effect. Before the pressure reaches this critical value, the increasing amplitude of the stress σwith confining pressure is higher at all thermal aging time.Whereas,the variation of the stress σwith confining pressure is complex when the pressure is higher than 4.0 MPa.At the initial stage of thermal aging(0 and 10 d),the stress σdecreases slightly from 4.0 MPa to 7.0 MPa (as marked by dashed boxes in Fig. 2(a)). Nevertheless, a continuous increment in this stress is found for a longer aging time of 35-188 d.On the other hand,the variation trend of the strain εwith confining pressure at different thermal aging time is complex(as shown in Fig. 2(b)), compared with that of the corresponding stress σ.Firstly,this strain continuously increases with an increase in confining pressure at the thermal aging time of 0 and 125 d.However, there is also a critical confining pressure between 0.15 MPa and 4.0 MPa. Before the pressure is up to 4.0 MPa, a continuous decreasing in the strain εat the thermal aging time of35 d,beyond which this strain increases with confining pressure.At the thermal aging time of 10 and 188 d,the strain all increases as a whole when the confining pressure is lower than 4.0 MPa. Then it drops at the higher confining pressure.

Table 1 Sample test matrix.

Fig. 2. Mechanical parameters of HTPB propellant vs. confining pressure at typical thermal aging time (a) Maximum tensile stress; (b) strain at maximum tensile stress.

3.2. Effect of thermal aging on the mechanical properties

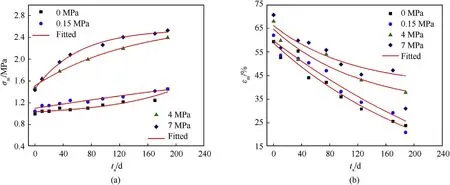

The variation of the maximum tensile stress σand the corresponding strain εfor HTPB propellant with thermal aging time at different confining pressures are shown in Fig.3.It can be seen that thermal aging still remarkably influences the mechanical properties of HTPB propellant under confining pressure.On the one hand,the stress σhas a significant increase as a whole when thermal aging time continuously increases,as shown in Fig.3(a).Moreover,the increasing amplitude of this stress for the propellant is higher at the initial stage of thermal aging and the higher confining pressure of 4.0 and 7.0 MPa, which indicates that the stress σis more sensitive to aging with increasing confining pressure.On the other hand, the strain εdecreases as a whole with increasing thermal aging time,as shown in Fig.3(b).In addition,the trend of this strain decreasing with thermal aging time is slightly less obvious at higher confining pressure, which indicates that the strain εis slightly less sensitive to aging with increasing the confining pressure.

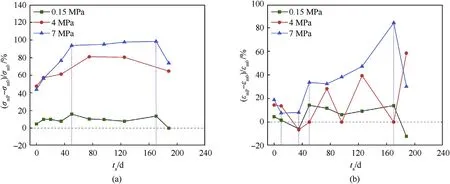

Compared with mechanical properties of HTPB propellant at the atmospheric pressure, the increasing amplitude of the stress σand the increasing amplitude of the strain εwith the coupled effects of confining pressure and thermal aging time are shown in Fig. 4. As observed in Fig. 4(a), the characteristics of the stress increments(σ-σ)/σand thermal aging time curves for HTPB propellant are quite similar under different confining pressure levels. Moreover, there are almost distinct three regions in the curves.Firstly,continuously increasing thermal aging time can lead to a rise in the stress increment (σ-σ)/σ. And then a plateau region presents,beyond which the stress increment(σσ)/σdrops again with thermal aging time. In addition, the maximum value of the stress increment(σ-σ)/σfor HTPB propellant is about 98% at 7.0 MPa and 170 d. Fig. 4(b) shows that the characteristics of the strain increments (ε-ε)/εand thermal aging time curves for HTPB propellant are complex and different from each other under various confining pressure levels.At the lower confining pressure of 0.15 MPa,there are four regions in the curve, which is similar to that of the stress increment(σ-σ)/σ. Nevertheless, there are five ones for that at the highest confining pressure of 7.0 MPa. Furthermore, obvious fluctuation appears in the curve at the middle confining pressure of 4.0 MPa.The maximum value of the strain increment(ε-ε)/εfor HTPB propellant is about 84%at 7.0 MPa and 170 d.Finally,it can be concluded from Fig. 4 that there are some critical thermal aging time for the stress increment(σ-σ)/σand the strain increment(ε-ε)/εof HTPB propellant,which are about at 35,50 and 170 d.

Fig. 3. Mechanical parameters of HTPB propellant vs. thermal aging time under different confining pressures (a) Maximum tensile stress; (b) strain at maximum tensile stress.

Fig. 4. Mechanical parameters of HTPB propellant vs. thermal aging time under different confining pressures (a) Increasing amplitude of maximum tensile stress; (b) increasing amplitude of the strain at maximum tensile stress.

Since solid propellant is highly particle-filled elastomer,namely,its mechanical properties(such as the maximum tensile stress and the related strain)under various loading conditions are dependent on not only the changes of its properties due to physical and chemical mechanisms, but also the occurrence and propagation of microcracks inside itself. Therefore, the analysis of the aging mechanism and the microscopic damage is the key to understand the mechanical properties of aged HTPB propellant under confining pressure conditions. According to the previous researches[19,22,23], the chemical mechanism of composite solid propellant during thermal accelerated aging mainly includes oxidative crosslinking, chain scission and consecutive reactions. In addition, the dominating fracture mechanism of aged and unaged solid propellant under room temperature and quasistatic tensile loading conditions are generally all the adhesive interface failure between AP particles and the matrix, namely dewetting phenomenon [19,24].Besides, because the matrix hardens and the interface adhesive stress decreases as thermal aging time increases, the interface failure phenomenon is much more likely to occur, which further causes the decline of the strain εat the maximum tensile stress.However, on the one hand, the movement of the macromolecules for solid propellant in the transverse direction was restricted by confining pressure [13,25]. On the other hand, the interface adhesive stress remarkably increases under confining pressure condition, because the adhesive interfaces of solid propellant are under hydrostatic compression[8,14].In addition,confining pressure can prevent the propagation of microcracks inside the propellant.Thus,the microscopic damage of solid propellant is usually slighter under confining pressure conditions.Due to the above reasons,the value of the maximum tensile stress σand the related strain εare all higher than that at the atmospheric pressure as a whole in this investigation, as shown in Figs. 2 and 4.

From the above analysis and Fig.3,oxidative cross-linking may be still the dominant chemical mechanism of HTPB propellant during thermal accelerated aging in this investigation, which results in a whole rising trend of the maximum tensile stress σfor aged HTPB propellant under different confining pressure conditions (as shown in Fig. 3(a)), while a decline of the corresponding strain ε, as shown in Fig. 3(b). It can be concluded that confining pressure can't change the effect of thermal aging chemical mechanism on the mechanical properties of HTPB propellant. Because the effect of thermal aging on the adhesive interface failure of HTPB propellant is more obvious in the initial stage of thermal aging,the increasing amplitude of the stress σwith thermal aging time for the propellant is higher,and the stress σis more sensitive to aging with increasing confining pressure,as shown in Figs.2(a),3(a)and 4(a). With continuously increasing thermal aging time, the adhesive interface failure of HTPB propellant is very serious,namely the effect of thermal aging time on the microscopic damage of the propellant is slighter. Moreover, there are no further significant influence of confining pressure on the interface adhesive stress and microscopic damage of HTPB propellant with the pressure up to its critical value. Therefore, the failure resisting capacity of the propellant remains constant or decreases when the confining pressure is higher than 4.0 MPa, as shown in Fig. 2. Furthermore, the variation of mechanical properties for aged HTPB propellant under different confining pressure conditions, as shown in Fig. 4, results from the coupled effects of thermal aging and confining pressure,as stated above. Because the coupled effects are complex, further studies should be made.

4. Strength criterion of aged propellant under confining pressure

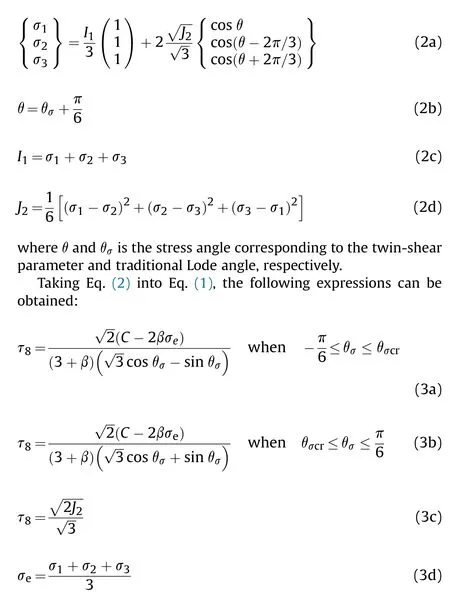

With the measured data in laboratory, the failure criterion of materials is usually developed to provide a criterion for evaluating its damage or the related structural integrity under other loading conditions. In general, the failure criterion of materials includes strength criterion and fracture criterion[2],and the former one was only studied in this investigation because there are no pre-existing cracks in the propellant samples.In the past decades,considerable attention has been given by scientists to formulate the strength theory and the corresponding failure criterion. Under triaxial loading condition, it is necessary to describe the influence of the intermediate principal stress (σ) on the determination of the strength for materials [26]. Compared with other models, such as von Mises, Drucker-Prager, Mohr-Coulomb, the advantage of the twin-shear strength theory proposed by Yu is that it effectively takes into account the influence of the intermediate principal stress and is appropriate for materials with unequal tension and compression strengths [27]. The mathematical expressions for the twin-shear strength criterion with the principal shear stresses and normal stresses are as follows (σ≥σ≥σ) [28]:

where τ,τand τare the three principal shear stresses,which can be calculated with Eq. (1c), σ, σand σare the three principal normal stress, which can be calculated with Eq. (1d), σ,σand σare the three principal stresses,β represents the effect of the normal stress on the failure of materials, C is the strength parameter of materials.

In cylindrical coordinates, the principal stresses can also be expressed in terms of the first invariant Iof the stress tensor and the second invariant of the deviatoric stress Jas follows(σ≥σ≥σ) [29]:

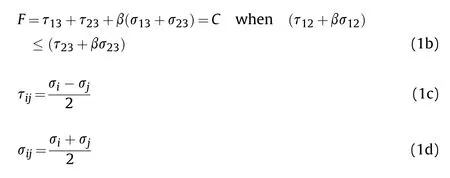

Fig.5. The variation of the octahedral shear stress τ8 with the average principal stress σe at typical thermal aging time.

where τand σis the octahedral shear stress and the average principal stress,respectively.

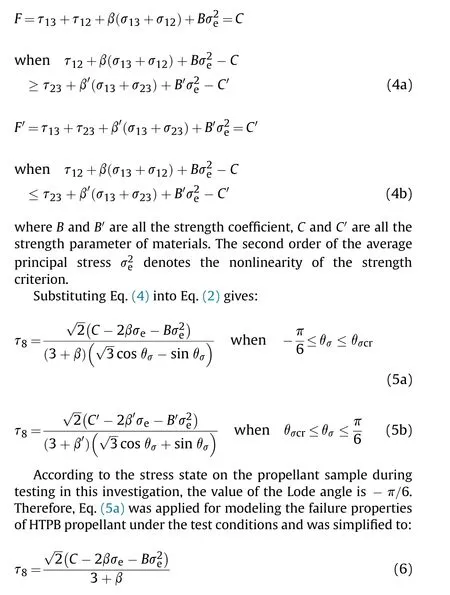

Eq.(3)shows that the relationship of the octahedral shear stress τwith the average principal stress σis linear,which indicates that the conventional twin-shear strength criterion can only study linear relationships.However,the variation trend of the stress τis nonlinear as the stress σincreases in this investigation, as shown in Fig. 5. To overcome the shortcoming of the conventional twinshear strength criterion, the following new modified nonlinear strength criterion was proposed (σ≥σ≥σ):

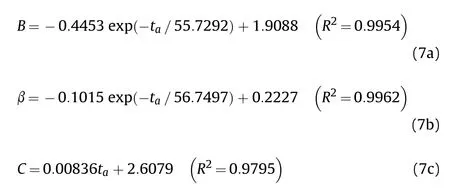

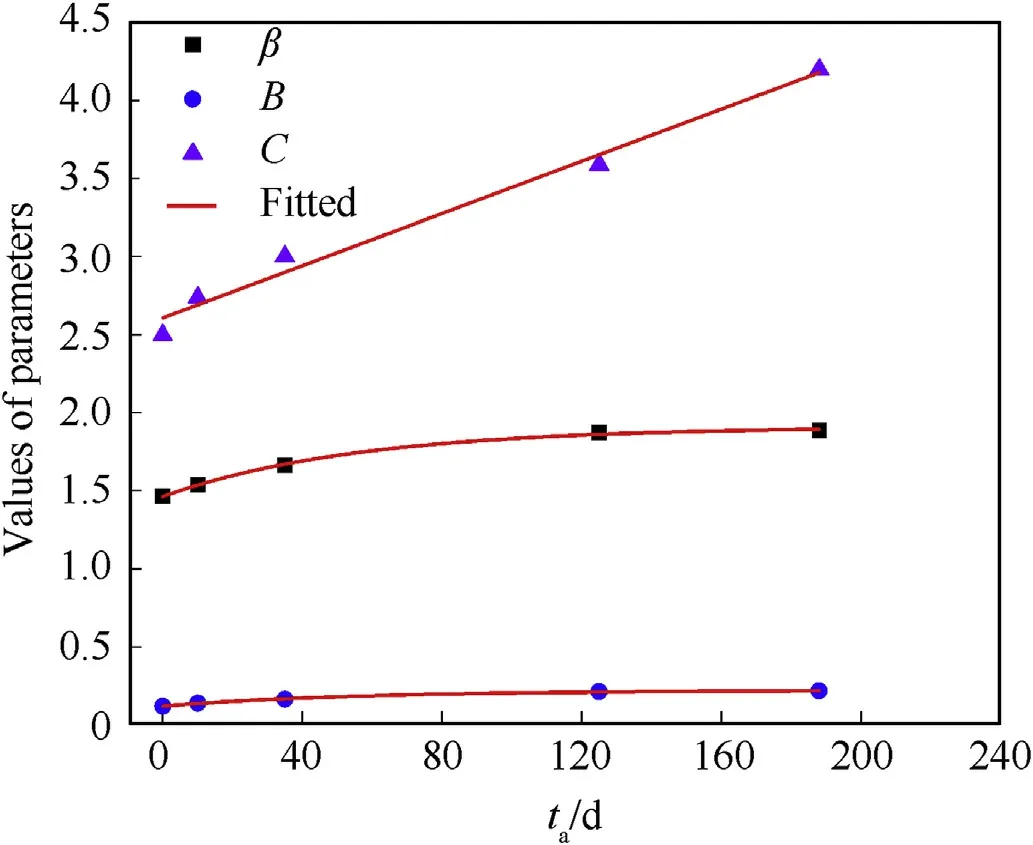

Based on the test data of aged HTPB propellant under different confining pressures,the corresponding parameters in Eq.(6)can be fitted with the genetic algorithm-based optimization method. The values of these parameters under various loading conditions are shown in Fig.6,which reveals that these parameters are obviously influenced by thermal aging time.Furthermore,the corresponding fitted results are also shown in Fig. 6 and the expressions are as follows:

where tis thermal aging time.

Based on Eqs. (6) and (7), the strength criterion of aged HTPB propellant under different confining pressures was developed.According to Eqs.(3d)and(6),the parameter β in Eq.(6)represents the effect of principal stress(σ,σand σ)on the failure properties of HTPB propellant. Fig. 6 and Eq. (7b) show that this parameter increases at a continually decreasing rate of increase as thermal aging time increases,which indicates that the failure properties of the propellant are more sensitive to the principal stress with longer thermal aging time.It can be seen from Fig.6 and Eq.(7a)that the longer thermal aging time can lead to the higher value of the parameter B. In other words, the effect of the average principal stress σon the failure properties of HTPB propellant is more remarkable with an increase in thermal aging time.In addition,the strength parameter C (in Eqs. (6) and (7c)) of the propellant also continuously increases with longer thermal aging time, which is consistent with the results from the previous work on the mechanical properties of aged solid propellants [17,19].

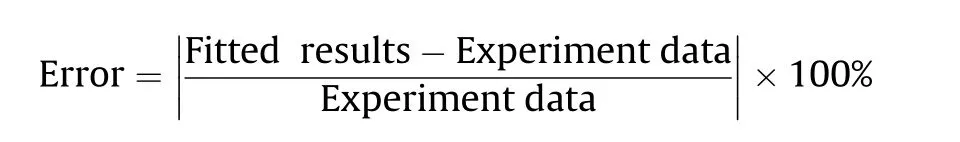

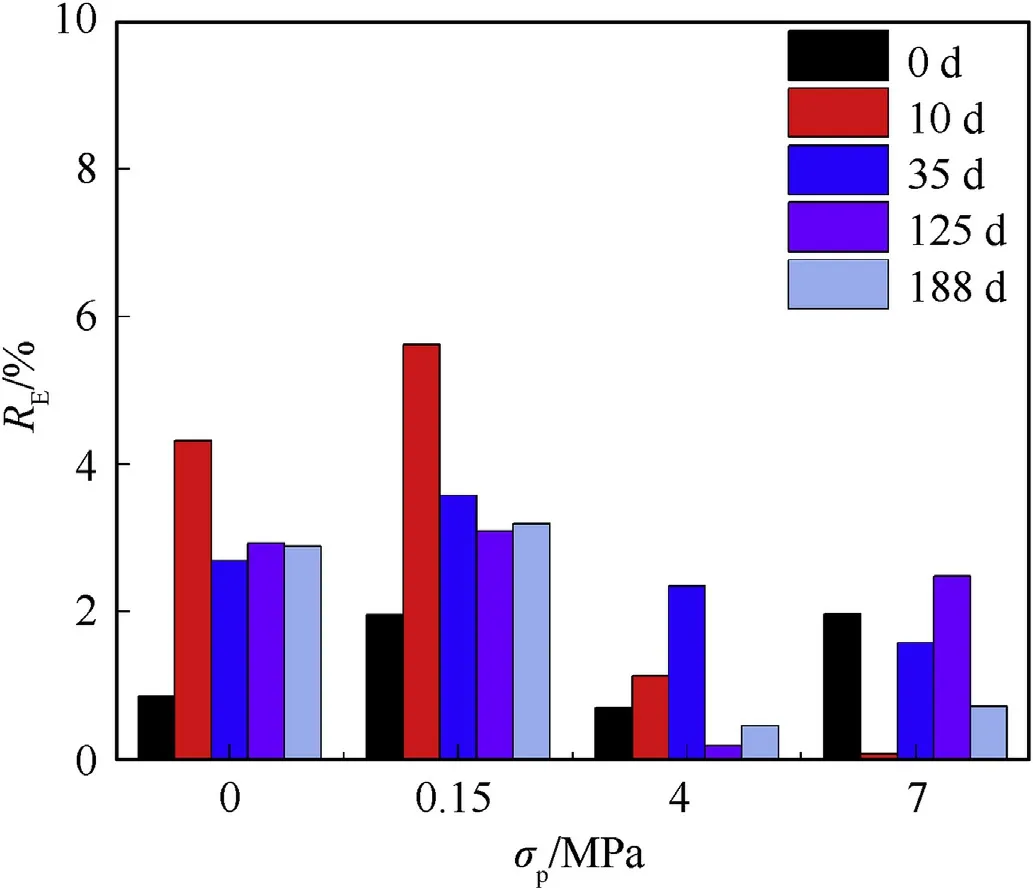

The comparisons of experimental data and fitted results for the stress τwith variation of the stress σby the proposed strength criterion are shown in Fig. 5. Moreover, the error is defined as follows and the related values are given in Fig. 7.

Fig. 6. The fitted curves of the strength criterion parameters.

Fig. 7. The errors on the fitted results by the proposed strength criterion with experimental data.

It can be seen from Figs. 5 and 7 that the overlap between experimental data and fitted results are generally good, the whole errors of fitted results are lower than 6%. It demonstrates that the proposed modified nonlinear twin-shear strength criterion(namely Eqs.(6)and(7))can offer a good description of mechanical properties of aged HTPB propellant under different confining pressures. In addition, the strength of HTPB propellant in a wide range of thermal aging time and confining pressure conditions can be also predicted with this proposed modified nonlinear strength criterion. Therefore, this strength criterion can be selected as a failure criterion for the further analysis the failure properties of aged HTPB propellant under different confining pressures, the structural integrity of solid propellant grain and the safety of SRM during ignition operation after long periods of storage.

5. Conclusion

Mechanical properties of aged triple-component HTPB-based composite solid propellant under confining pressures were successfully investigated for the first time by means of the thermal accelerated aging test method, a self-made confining pressure device and conventional testing machine. Based on the test results,the effects of confining pressure and thermal aging were analyzed and discussed.Moreover,a failure criterion was proposed with the twin-shear strength theory. The following conclusions can be drawn.

(1) As confining pressure increases (relative atmospheric pressure from 0.0 MPa to 7.0 MPa) or thermal aging time rises(from 0 to 188 d),the maximum tensile stress σincreases as a whole. However, the corresponding strain εdecreases with increasing thermal aging time under all confining pressure conditions. Besides, the variation of this strain εwith confining pressure at various thermal aging time is not the same and very complex, which is different from that of unaged solid propellant under confining pressure.Secondly,there is a stronger dependence of the stress σon thermal aging when confining pressure becomes higher. Whereas,the strain εis slightly less sensitive to thermal aging with increasing confining pressure.Thirdly,there are almost three regions in the stress increments (σ-σ)/σand thermal aging time curves for HTPB propellant. Whereas,more regions or obvious fluctuation appears in the strain increments (ε-ε)/εand thermal aging time curves.Moreover, the maximum value of the increment(σ-σ)/σand (ε-ε)/εfor the propellant is about 98% and 84% at 7.0 MPa and 170 d, respectively.Fourthly, there is also a critical confining pressure in this investigation,whose value is between 0.15 MPa and 4.0 MPa.In addition, this critical value is the same for unaged and aged HTPB propellant, which indicates that thermal aging has no obvious effect. Beyond this critical pressure, the trends of the stress σand the corresponding strain εall change. Furthermore, there are some critical thermal aging time for the stress increment (σ-σ)/σand strain increment (ε-ε)/εof HTPB propellant in this investigation,which are about at 35,50 and 170 d.The above properties reveal that thermal aging have a significant influence on the mechanical properties of HTPB propellant under confining pressure, and the coupled effects of confining pressure and thermal aging are very complex and different from that in previous researches.Therefore,the test data and the mechanical properties of HTPB propellant obtained in this investigation can provide the basis for further effectively investigate the mechanical properties of solid propellant during ignition after preserving over a long period of time to analyze and ensure the structural integrity of solid propellant grain and the safety of SRM during ignition operation after long periods of storage.

(2) Oxidative cross-linking may be still the dominant chemical mechanism of HTPB propellant during thermal accelerated aging in this investigation.It can be concluded that confining pressure can't change the effect of thermal aging chemical mechanism on the mechanical properties of HTPB propellant.In addition,rising thermal aging time can lead to a much more obvious interface failure phenomenon of solid propellant. However, confining pressure can suppress the initiation and evolution of microcracks inside the propellant before the pressure is up to its critical value, thus the microscopic damage of solid propellant is usually slighter.Beyond the critical pressure,the effect of confining pressure is less remarkable. Therefore,mechanical properties of aged HTPB propellant under confining pressures in this investigation mainly result from the above chemical mechanisms and the variation of the microscopic damage for the propellant. Due to the complexity of microscopic damage for aged HTPB propellant under confining pressures, further study should be made.

(3) Through employing the twin-shear strength theory, a new modified nonlinear strength criterion of thermal aged HTPB propellant under confining pressures was proposed and verified. Good agreements were observed between the test data and fitted results.The whole errors of the fitted results are lower than 6%.Therefore,the proposed strength criterion can be selected as a failure criterion for the analysis the failure properties of aged HTPB propellant under different confining pressures, the structural integrity of solid propellant grain and the safety of SRM during ignition operation after long periods of storage.

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

The authors gratefully acknowledge the financial support of the National Natural Funds in China (No. 11772352) and the Science project of Shaanxi Province (Nos.20190504 and 2019SZS-09).

- Defence Technology的其它文章

- Research on DSO vision positioning technology based on binocular stereo panoramic vision system

- Dynamics of luffing motion of a hydraulically driven shell manipulator with revolute clearance joints

- Blast performance of layered charges enveloped by aluminum powder/rubber composites in confined spaces

- Chemical design and characterization of cellulosic derivatives containing high-nitrogen functional groups: Towards the next generation of energetic biopolymers

- Applicability of unique scarf joint configuration in friction stir welding of AA6061-T6: Analysis of torque, force, microstructure and mechanical properties

- Multi-area detection sensitivity calculation model and detection blind areas influence analysis of photoelectric detection target