Effects of phase change material (PCM)-based nanocomposite additives on thermal decomposition and burning characteristic of high energy propellants containing RDX

En-fa Fu, Na Sun, Zheng-gang Xiao

Key Laboratory of Special Energy Materials,Ministry of Education,School of Chemical Engineering,Nanjing University of Science and Technology,Nanjing,210094, People’s Republic of China

Keywords:Phase change material Propellants Nanocomposite Thermal decomposition Burning

ABSTRACT A kind of phase change material (PCM)-based nanocomposite was prepared and added into high energy propellants containing RDX as additives to investigate its effect on thermal decomposition and burning characteristic of high energy propellants. The effect of PCM-based nanocomposites on thermal decomposition of high energy propellants is investigated by TG/DSC-FTIR-MS technology. Due to the delayed protection effect(PCM-based nanocomposites can absorb lots of heat at the range of certain temperature when it undergoes structure change or phase transitions) of PCM-based nanocomposites under the thermal decomposition condition, the thermal stability of high energy propellants modified with PCMbased nanocomposites is improved. At the same time, the concentration of N2, NO2, H2O and CO2 is increased during thermal decomposition of high energy propellants whereas NO and CO is decreased.The burning gaseous products and burning characteristic of high energy propellants are studied by the combination of closed bomb test and Fourier transform infrared spectrum. The main burning gaseous products are N2, CO2, CO, H2O, CH4, etc. After the high energy propellant modified with PCM-based nanocomposites, the concentration of CH4 is increased while CO, CO2 and H2O is decreased under the high-pressure burning condition. The progressivity factor of high energy propellants is increased by 22.2% compared with the control sample while the maximum pressure is merely decreased 1.25% after the addition of the PCM-based nanocomposite, thus PCM-based nanocomposites can be used to adjust the burning process and improve the burning progressivity of high energy propellants. This study is expected to boost the practical application of PCM-based nanocomposite to the propellant formulation and effectively control the burning characteristic of high energy propellants.

1. Introduction

High energy propellants have been used nowadays for the artillery to fire farther and more accurately [1]. Cyclotrimethylene trinitramine (RDX), one of high energy energetic materials, is widely used in the high energy propellant formulation for the improvement of energy. Much research [2] indicates that RDX is highly thermally and chemically erosive, which results in the erosion and abrasion of gun barrel and markedly shortens its service life.

Nanocomposites have numerous unique characteristics including good thermal stability, chemical resistance and high specific surface area[3],which have some significant effect on the propellant. Zhang et al. [4] investigated the influence of TiO-3 F nanocomposite in the thermal decomposition of the double-base propellant. They found that the thermal stability of the doublebase propellant was improved after the TiO-3 F nanocomposite was added into the propellant. Wang et al. [5] found that the sensitivity of composite solid rocket propellants was decreased after the addition of nano-Al/nitrocellulose nanocomposite, thus the safety performance of the propellant was improved. Sun et al.[6] studied the migration effect of the addition of TiO-F nanocomposite with low surface energy toward the air/solid interface on the propellant.The TiO-F nanocomposite had low surface energy and could improve the surface hydrophobicity of the propellant,indicating that thereby the surface performance and safety of the propellant is enhanced after the addition of TiO-F nanocomposite.Sun et al. [7] designed a new kind of nanocomposite and added it into the high energy propellants. The results showed that the organic-inorganic nanocomposite had a high specific surface area and could effectively decrease the erosion of high energy propellants on the gun barrel.

Moreover,nanocomposite additives have a significant impact on the burning performance of propellants. Yu et al. [8] discovered that the addition of borane-aluminum nanocomposite can increasingly enhance the burning energy density of liquid propellants. Du et al. [9] investigated the impact of nano-CuO on the combustion performance of double-base propellants. They found that the burning pressure index of the propellant was obvious decreased after the addition of the nano-CuO material. Tian et al.[10] investigated the effect of the addition of fluorinated nanocomposite on the burning performance of double-base propellants.They found that burning rate of double-base propellants was increased after the addition of fluorinated nanocomposite.

Recently, phase change material (PCM)-based nanocomposite has achieved a synergetic combination of nanocomposite and phase change material(PCM nanocomposite can absorb lots of heat at the range of certain temperature when it undergoes structure change or phase transitions). In our previous work [7], the PCMbased nanocomposite was used to reduce the erosion of the propellant.The erosion mass of high energy propellants was decreased by 37.0% after addition of the PCM-based nanocomposite whereas the propellant force was reduced by 5.7%.The results indicated that the PCM-based nanocomposite can be used to effectively solve the erosion problem of the gun barrel. However, the effect of PCMbased nanocomposites on the thermal decomposition and burning process of high energy propellants containing RDX is not clear yet.

The aim of this study is to investigate the effect of the PCMbased nanocomposite on thermal decomposition and burning characteristic of high energy propellants by thermogravimetry/differential scanning calorimetry-Fourier transform infrared spectroscopy-mass spectrum (TG/DSC-FTIR-MS) technology and combination of the closed bomb test and Fourier transform infrared spectrum (FT-IR), respectively. This study is expected to boost the practical application of PCM-based nanocomposite and effectively adjust the burning process of high energy propellants containing RDX.

2. Experiment

2.1. Material

The propellant paste(composed of 57 wt%nitrocellulose,42 wt%nitroglycerine and 1 wt% C) and micro-sized cyclotrimethylene trinitramine(RDX)were purchased from Sichuan Nitrocellulose Co.Ltd.Solid paraffin,nano-BN and nano-TiO(100 nm)were provided by Aladdin Reagent Co., Ltd. Modified zeolitic-67 (ZIF-67, 700 nm)and polymethyl methacrylate(PMMA) were prepared in our lab.

2.2. Preparation of high energy propellants

The phase change material-based nanocomposites (based on solid paraffin as core and PMMA as shell enhanced with nano-BN,nano-TiOand ZIF-67 particles) were prepared by the Pickering emulsion method in our previous work[11]. The high energy propellant samples were prepared as follows process.First,200 g dried propellant paste, 60 g RDX and a certain amount of PCM-based nanocomposites were added in a kneader. Then, a mixed solvent of acetone and ethanol(about 70 ml) with the volume ratio of 1:1 was liberally sprinkled on the above propellant paste. Subsequently, a dough was obtained after gelatinizing the mixture for about 2.5 h. Then the dough was added into a mold with 19-perforation die. A propellant strand with a diameter of 7 mm was extruded from the mold and placed for three days.Finally,it was cut and dried at 45C for 8 h.

Five kinds of high energy propellants were prepared by changing the adding content of PCM-based nanocomposites and the adding content of PCM-based nanocomposites(sample 1-5)was 0,0.8,2.3,3.7,5.1 wt%,respectively.Fig.1 shows the photograph of high energy propellant (sample 5) grains.

2.3. Characterization of samples

The morphology and microstructure of high energy propellants were observed by scanning electron microscopy (SEM, Hitachi S-4800, Japan). The glass slides containing samples were covered with a layer of gold,making it conductive under the electron beam.

The thermal decomposition process of high energy propellants was examined by thermogravimetry and differential scanning calorimetry (Netzsch STA409PC, Germany) and Fourier transform infrared spectrum (FT-IR, Nicolet iZ10, America) coupling system(TG/DSC-FTIR-MS) under a Natmosphere with a heating rate of 10C/min.The resolution of Nicolet iZ10 FT-IR was 4 cm.The gas tube of TG/DSC-FTIR-MS system stayed at 220C.The weight of the test sample was approximately 3.0 mg.

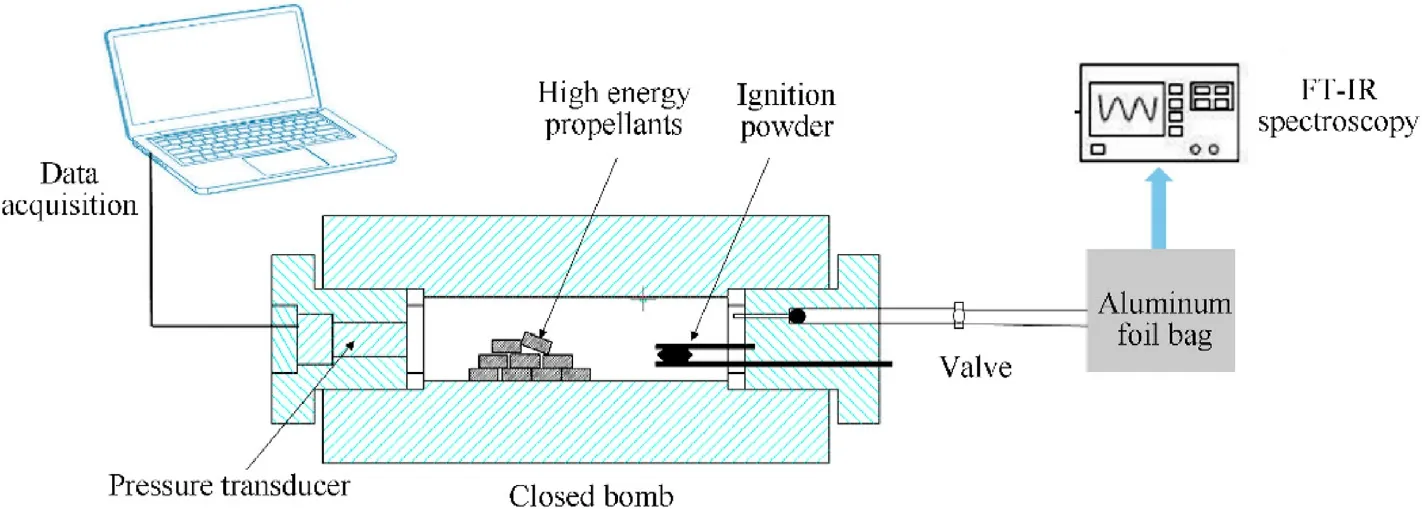

The high-pressure burning of high energy propellant was analyzed by a closed bomb with a volume of 100 cm. The closed bomb test setup was similar to the previous reported device [12].The data sampling interval and experimental loading density were 0.001 ms and 0.2 g/cm, respectively. After each test, the gases products of propellant burning were collected in the aluminum foil bag connecting with Fourier transform infrared spectroscopy.Fig.2 shows the experimental setup for collecting and analyzing the burning gaseous products of high energy propellants.

The gaseous products after closed bomb test were analyzed by Fourier transform infrared spectrum(FT-IR,Nicolet iS10)equipping with a gas cell and a vacuum apparatus in the range of 4000-500 cmat the spectra resolution of 4 cm.

3. Results and discussion

3.1. Morphology and microstructure

Fig.1. Photograph of high energy propellant (Sample 5#) grains.

Fig. 2. An experimental setup for collecting and analyzing burning gaseous products of high energy propellants.

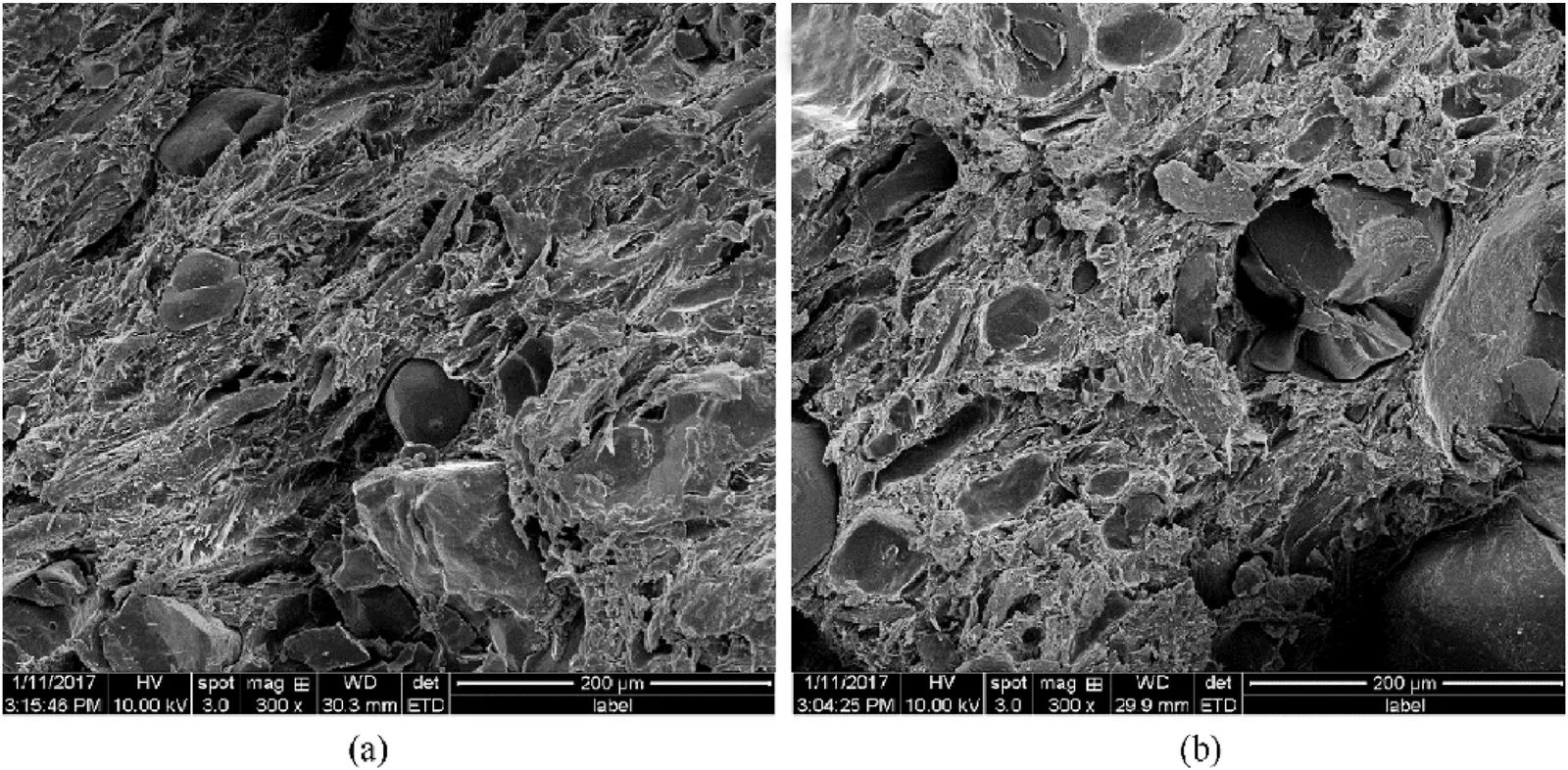

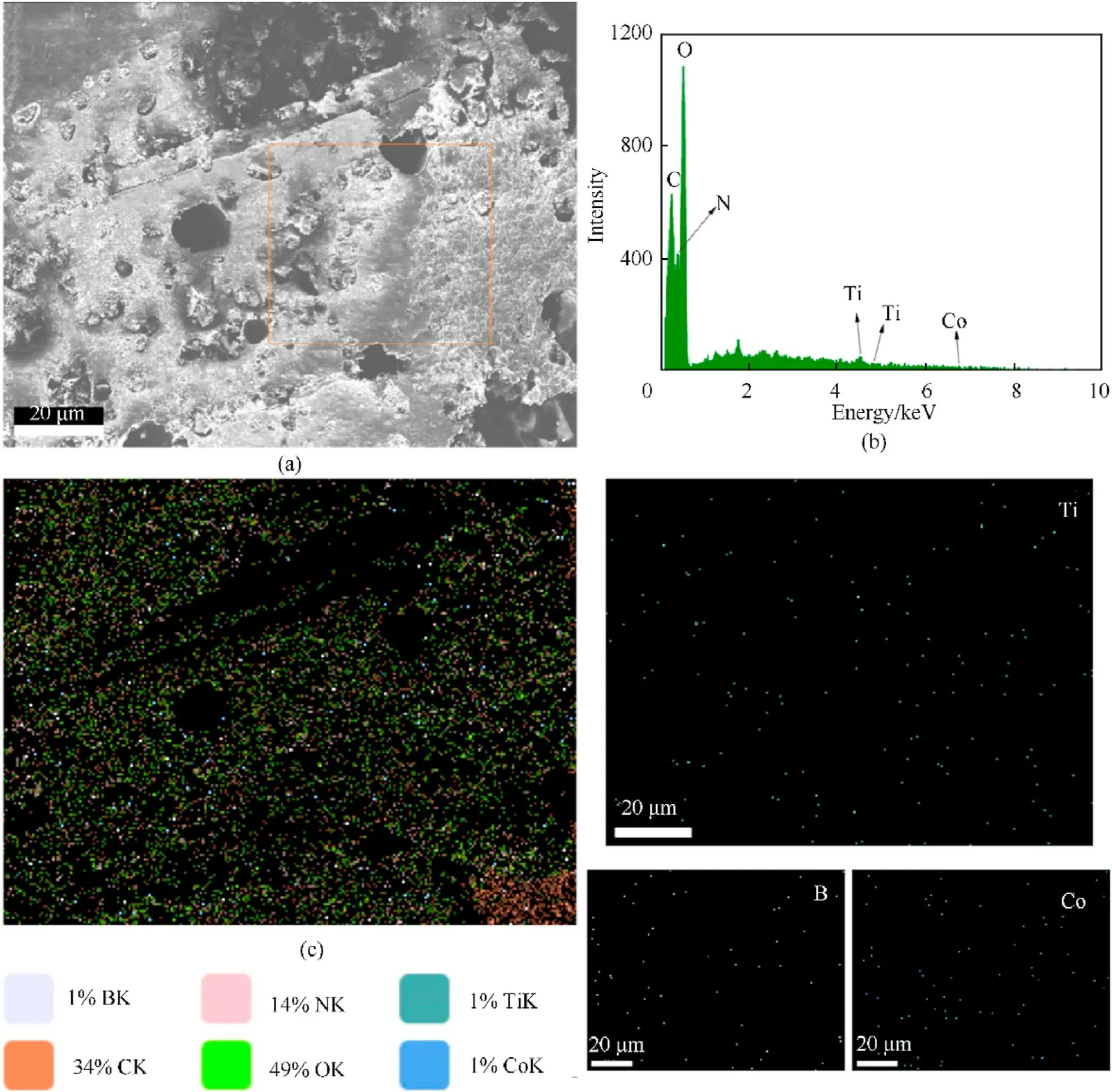

The effect of PCM-based nanocomposite filler on the high energy propellant matrix was investigated by SEM.Fig.3 shows the SEM image of the microstructure of samples. As shown in Fig. 3a,the high energy propellant (sample 1) presents a homogenous network structure with irregular appearance.There are no obvious interspace or holes on the surface of high energy propellants(sample 5), indicating that the modified high energy propellant has a similar network structure. The SEM results indicate that the microstructure of high energy propellants has little change after the addition of PCM-based nanocomposite since the content of PCM-based nanocomposite inside the bulk is very low.

The element compositions of high energy propellant surface were analyzed by energy disperse spectroscopy. The EDX spectra and the atomic percentage of high energy propellant sample are presented in Fig. 4. Fig. 4a shows that some particles distribute in the propellant surface and the area of red border is used to determine the element dispersion.The intensive peak of C(0.25 keV),O(0.53 keV), Ti (4.5 keV) and Co (6.9 keV) is shown in Fig. 4b, indicating that TiOand ZIF-67 are dispersed in the propellant surface.However,the element of B(BN) is not detected in the EDX spectra due to the intensive peak is weak.The element mapping is used to clearly analyze the dispersion of BN on the propellant surface.Fig.4c shows the resulting images of the detected elements on the propellant surface. As shown in Fig. 4c, the contents of Ti (from TiO), Co (from ZIF-67) and B (from BN) elements are all 1% and three elements have a homogenous distribution in the propellant surface, indicating the PCM-based nanocomposite has good dispersion in the propellant matrix.

In summary, the SEM and EDS results both indicate that the PCM-based nanocomposite has good dispersibility in the propellant formulation.

3.2. Thermal decomposition behavior

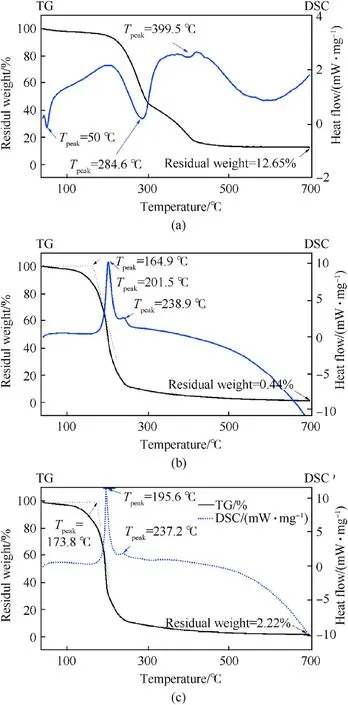

The TG/DSC curves of PCM-based nanocomposite, the control propellant (sample 1) and the high energy propellant modified with PCM-based nanocomposite(sample 4)are shown in Fig.5.In our previous research [7], the effect of PCM-based nanocomposite content on the erosion performance and force of high energy propellants was investigated.The results indicated that sample 4was optimal formula to decrease the erosive performance (reduce by 22.22%)of high energy propellants whereas the propellant force of high energy propellants was only decreased by 5.7%.Therefore,the sample 4is selected as an experiment sample to compare with the control sample to investigate the effect of PCM-based nanocomposite on the performance of high energy propellants.

As shown in Fig. 5a, the PCM-based nanocomposite has two mass loss stages in the TG curve.The first stage exhibits due to the evaporation and decomposition of the solid paraffin [13] with about 56.3% mass loss in a temperature range of 176-323C. The second stage exhibits with about 25.2%mass loss in a temperature range of 323-446C due to the decomposition of PMMA [14].When the temperature increases to 500C,12.65%residue remains due to the existence of some nanoparticles in the PCM-based nanocomposite. As shown in Fig. 5b-c, the thermal decomposition of high energy propellants (sample 1and sample 4) both have one mass loss process and the final residual weight of high energy propellant is increased from 0.44% to 2.22% after the addition of PCM-based nanocomposite. Moreover, there is no obvious decomposition peak of PCM-based nanocomposite in Fig.5c due to the lower content of PCM-based nanocomposite in the high energy propellants (sample 4).

Fig. 3. SEM image of high energy propellants (sample 1# and sample 5#).

Fig. 4. EDS spectra and element mapping images of the high energy propellant after the addition of PCM-based nanocomposite (sample 5#).

As shown in Fig. 5a, the DSC curve of the PCM-based nanocomposite has three endothermic peaks that locate at 50.0C(phase change peak of solid paraffin), 284.6C and 399.5C,respectively. As can be seen from Fig. 5b-c, the high energy propellant (sample 1and 4) releases a lot of heat in a temperature range of 150-230C that corresponds to the decomposition of the propellant paste [13], and it releases a little heat in a temperature range of 230-262C that corresponds to the pyrolysis of RDX[14].The DSC curve of the high energy propellant has two exothermic peaks that locate at 201.5C and 238.9C, and the modified high energy propellant has two endothermic peaks that locate at 195.6C and 237.2C, indicating that PCM-based nanocomposite affects the decomposition stage of high energy propellants.Due to the higher thermal stability of inorganic particle (BN, nano-TiOand ZIF-67) and phase change endothermic reaction of solid paraffin in the high energy propellants grain,the onset temperature of thermal decomposition is increased. With the temperature increased,the polymer chain(PMMA)starts to move or decompose and the structure of propellant samples may be destroyed to accelerate the decomposition of the propellant paste,thus the DSC peak temperature is decreased after the addition of PCM-based nanocomposites.

It is obviously observed in Fig. 5b-c that the initial decomposition temperature of high energy propellants is increased from 164.9 to 173.8C after the addition of PCM-based nanocomposite.Due to the existence of the PCM-based nanocomposite before 176C, the PCM-based nanocomposite in the high energy propellants can absorb a lot of heat and the thermal decomposition of the propellants is delayed. The results indicate that the thermal stability of high energy propellants is improved after the addition of PCM-based nanocomposites.

3.3. Effect of PCM-based nanocomposite on gaseous products evolved during thermal decomposition

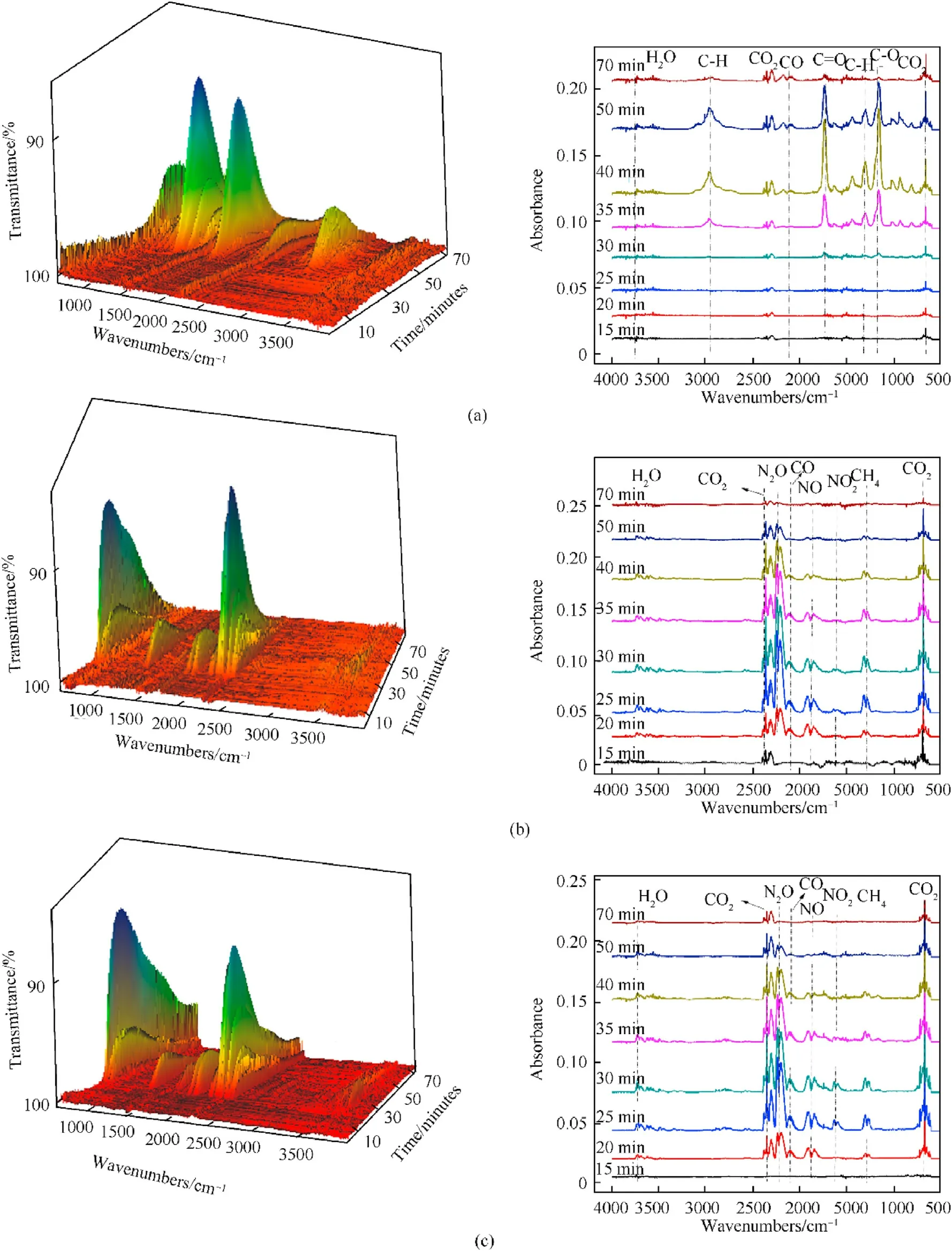

In this section,the 3D FT-IR is used to detect the composition of gaseous products evolved during the thermal decomposition of high energy propellants and to obtain the evolution of gaseous products as a function of temperature.The 3D FT-IR spectrogram of gaseous compounds evolved during thermal decomposition of PCM-based nanocomposite,the control sample(sample 1)and the high energy propellant modified with PCM-based nanocomposite(sample 4) are shown in Fig. 6.

Fig. 5. TG/DSC curves of (a) PCM-based nanocomposite, (b) the control sample(sample 1#) and (c) the modified high energy propellant (sample 4#).

As shown in Fig.6a,the characteristic peaks appear in the FT-IR spectra at 3760 cm,2947(1325)cm,1940 cm,2359(2305 and 664)cm,1182 cm,which correspond to the stretching vibration of H-O(HO),C-H,C=O,COand CO,respectively.The PCM-based nanocomposite is consisted of the PMMA, solid paraffin and inorganic nanoparticles.The inorganic nanoparticles hardly decompose at 700C. As known in References [15,16], gaseous compounds of PCM-based nanocomposite are HO, COand volatile small molecule alkanes or unsaturated olefins,aldehydes,alcohols,carboxylic acids, etc.

As shown in Fig.6b-c,the onset stage of thermal decomposition of the high energy propellant (sample 1and sample 4) are both the decomposition reaction of nitrates. At the same time, the gaseous products are CH(1250 cm), NO(1590 cm), NO(1910 cmand 1846 cm),NO(2236 cmand 1300 cm),CO(2248 cm,2195 cmand 743 cm).The concentration of NO is significantly increased due to the thermal decomposition of the RDX after 230C. When the temperature increases to 250C, the decomposition reaction is completed and the concentration of NOand NO is significantly increased whereas CHis decreased.

Compared Fig. 6b with Fig. 6c, it is obvious to be seen that the concentration of NOand HO gas is significantly increased while NO, NO and CO gas is reduced after the addition of PCM-based nanocomposite under thermal decomposition condition.

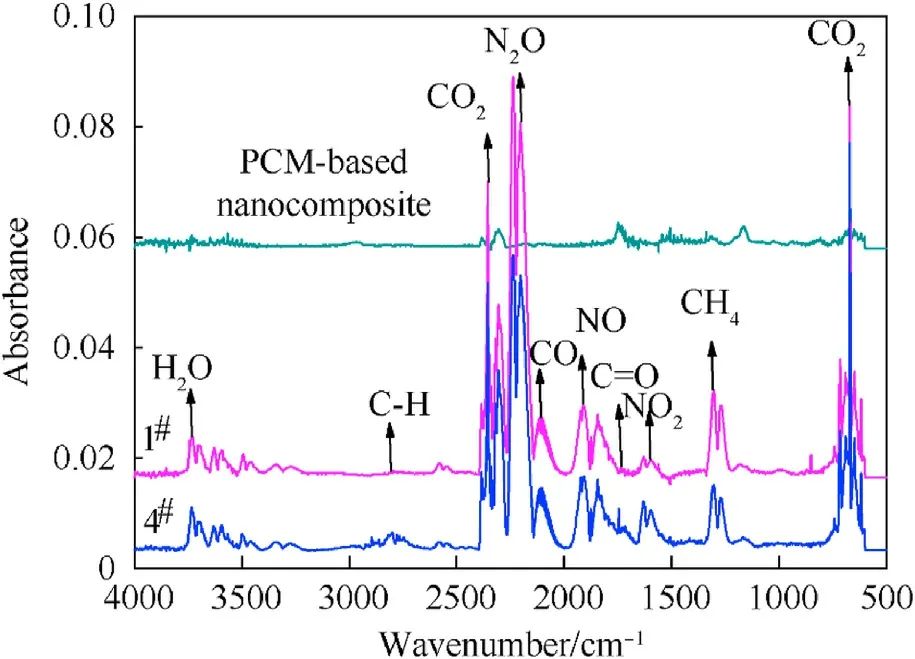

The Fourier transform infrared spectroscopy of gaseous compounds evolved during thermal decomposition of PCM-based nanocomposite, the control sample (sample 1) and high energy propellants modified with PCM-based nanocomposites(sample 4)at the maximum mass loss rate is shown in Fig.7.The spectrogram of gaseous compounds evolved at 230C is selected to investigate the decomposition of high energy propellants during the maximum mass loss rate. As shown in Fig. 7, the PCM-based nanocomposite has little thermal decomposition at 230C. The detected gaseous products (sample 1) are HO (3721 cm), CO(2248 cm, 2195 and 743 cm), NO (1910 and 1845 cm), NO(1590 cm), and NO(2236 cm).The result indicates that NO gas is produced due to the reaction of NOgas and the aldehydes.The detected gaseous products (sample 4) are the same as that of the control sample(sample 1). It is obviously observed in Fig. 7 that the absorption peak intensity of CO, NO and CHproduced by modified high energy propellants is reduced whereas NO, COHO and aldehyde(C=O) gas is increased in comparison with that of the control sample.The result indicates that the concentration of NO,HO and aldehyde (C=O) is increased after addition of PCM-based nanocomposite under thermal decomposition. PCM-based nanocomposite are enriched on the surface of high energy propellants,and it has opposite effect on the reaction of NOand aldehyde to produce NO and CO [4]. Thus, the concentration of NO and CO is reduced whereas NO, COand aldehyde (C=O) gas is increased evolved during thermal decomposition of high energy propellants after the addition of PCM-based nanocomposites.

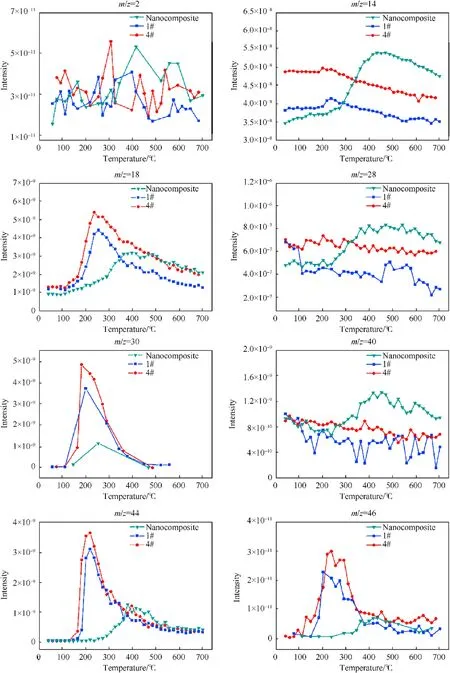

The mass spectra of gaseous products of m/z signals at different temperature regions are given in Fig.8.As shown in Fig.8,signal at m/z 2,14,18, 28, 30, 40, 44, and 46 correspond to [H](m/z = 2),[CH](m/z = 14), [HO](m/z = 18), [N/CO](m/z = 28), [NO/CHO](m/z = 30), [CH](m/z = 40), [CO/NO](m/z = 44) and[NO](m/z=46),respectively.With the temperature increase,the ion current intensity of HO,NO,and NOis increased before 237C and then decreased after 237C,indicating that the temperature of maximum thermal decomposition rate of high energy propellants is around 237C and it is consistent with DSC results (the second Tpeak of high energy propellants in the DSC curve are both around 237C). It is obvious to be seen in Fig. 8 that the ion current intensity of NOand HO gas is increased after the addition of PCMbased nanocomposite. As can be seen from Fig. 8, the ion current intensity of [N/CO](m/z = 28) is increased after the addition of PCM-based nanocomposites. Therefore, the concentration of Nis increased(CO is reduced which has been known in the above FT-IR analysis)after the addition of PCM-based nanocomposites.

The concentration of NOand HO is increased under the thermal decomposition condition after the addition of PCM-based nanocomposites, because PCM-based nanocomposites are enriched on the surface of high energy propellants and it has opposite effect on the reaction of NOand aldehyde to produce NO and CO in the fizzing zone of high energy propellants (in Ref. [4]).The PCM-based nanocomposite can suppress the generation of NO and CO under the thermal decomposition condition.Moreover,the decomposition of PCM-based nanocomposites can produce lots of[CH], HO and CO, and [CH]can react with NOto produce more HO.Therefore,the concentration of HO and COis improved under the thermal decomposition of high energy propellants after addition of PCM-based nanocomposites.

Fig.6. 3D FT-IR spectrogram of gaseous compounds evolved during thermal decomposition of(a)PCM-based nanocomposite,(b)the high energy propellant(sample 1#)and(c)the high energy propellant modified with PCM-based nanocomposites (sample 4#).

3.4. Effect of PCM-based nanocomposite additives on burning gaseous products

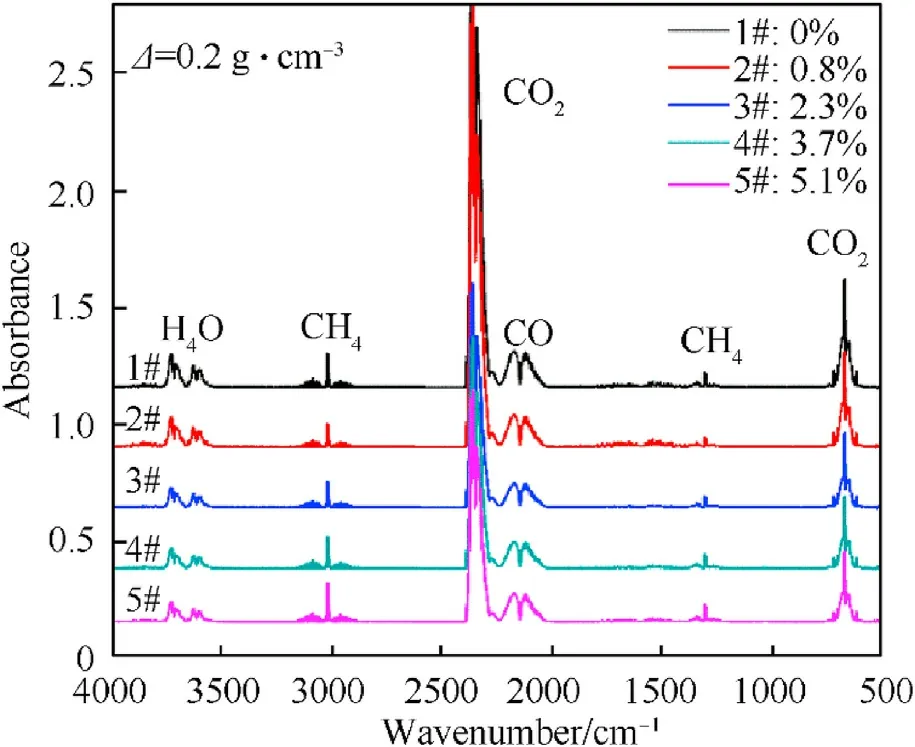

The burning gaseous products of high energy propellants are analyzed by Fourier transform infrared spectroscopy under the same experimental condition. Fig. 9 shows the Fourier transform infrared spectroscopy of the burning gaseous products.

Fig. 7. Fourier transform infrared spectrogram of gaseous compounds evolved during thermal decomposition of PCM-based nanocomposite,the control sample(sample 1#)and the modified high energy propellant (sample 4#) at 230 °C.

As shown in Fig. 9, the burning products are HO (3770 and 3550 cm), CO(2250 and 670 cm), CO (2171 cm), and CH(3019 and 1303 cm). It is obvious to be seen that species of burning gaseous products (sample 1-5) have little change, and the detected gaseous products still are CO, CO, HO, CH, etc.,indicating there is no secondary reaction in the burning process of high energy propellants [4]. The high energy propellants are a mixture which mainly consisted of nitroglycerin, RDX and nitrocellulose.Thus,the gaseous products of high energy propellants are consisted of one or several elements of C,H,O and N.As shown in Fig. 10, the burning gaseous products of high energy propellants have almost no nitrogen-containing gas detected in the FT-IR spectrum. The reaction in the flame zone is dominant comparing with that of other flame region during burning process of high energy propellants [17], so the main nitrogen-containing burning gaseous products is N(The Ngas is non-infrared active and it is not detected by FT-IR).

The relation between the absorbance A and transmittance T can be described by Lambert-Beer’s law, are shown in Eq. (1).

According to the Lambert-beer laws, it can be used for estimating the concentration of gases when A is less than 0.5. The absorption of gas is saturated and it can not be used as the method to analyze the concentration of gaseous products if A is great than 0.5[4].The value of absorbance of COgas at 2250 cmis greater than 0.5, thus its concentration is discussed only at 670 cm.Compared with the high energy propellant, the relative concentration of CHgas of the modified high energy propellants(sample 2-5) is decreased (the relative peak area of CO and COgas is reduced while that of CHgas is increased)and this trend increases as the content of the PCM-based nanocomposite increases. Solid paraffin is the main component of the PCM-based nanocomposite and it is a mixture of hydrocarbons with a carbon number of about 18-30.Under the high-temperature and high-pressure condition,it is cracked into small molecular alkanes and small molecular alkanes react with NOto produce more CHgas. Moreover, a large amount of CHis also produced in the burning process of the PCMbased nanocomposite, thus the concentration of CHis increased evolved during burning process of high energy propellants.

In summary,the main burning gaseous products of high energy propellants are N,CO,CO,HO,CH,etc.,and the concentration of CHgas is increased while CO, CO and HO gas are reduced after the addition of PCM-based nanocomposite under the high-pressure condition.

3.5. Effect of PCM-based nanocomposite additives on burning characteristic

The burning characteristic of high energy propellant is studied by the closed bomb test. The obtained pressure-time curves for each propellant sample are plotted in Fig.10a.As shown in Fig.10a,it can be found that with the increasing of PCM-based nanocomposite contents, the burning time increases from 5.1 to 6.0 ms and the value of maximum pressure decreases from 297.3 to 286.0 MPa.The pressure of high energy propellants(sample 2-5)reaches their maximum value by longer time than that of the control sample,and the value of maximum pressure of high energy propellants(sample 2-5)is lower than that of the control sample.Furthermore, this trend becomes more evident with increasing of PCM-based nanocomposite contents in the propellant matrix because PCM-based nanocomposite is non-energetic material which is unable to produce huge amounts of gases and releases a lot of heat during their burning.

The dynamic vivacity, L, can be calculated using Eq. (2). It is.

W and B are calculated using following two equations [18],respectively.

where the pis the maximum pressure in the closed bomb test.

Fig. 10b shows the derivative curves of pressure for each propellant sample. As shown in Fig. 10b, the initial burning rate of sample 2-5is decreased comparing with the control sample.Fig. 10c shows the burning rate-versus pressure curves of each propellant sample.As shown Fig.10c,the maximum burning rate of sample 2-5has no obvious change comparing with that of control sample. The result indicates that PCM-based nanocomposites can effectively inhibit the initial burning of propellants.

The W-B curve has been used to assess the geometric progressivity of propellants[19],and it is shown in Fig.10d.When the value of B is in the range of 0-0.3,the value of W(sample 2-5)are significantly less than that of the control sample, demonstrating that PCM-based nanocomposite could effectively decrease the initial generation rate of burning gas and this trend increases as the content of the PCM-based nanocomposite increases.

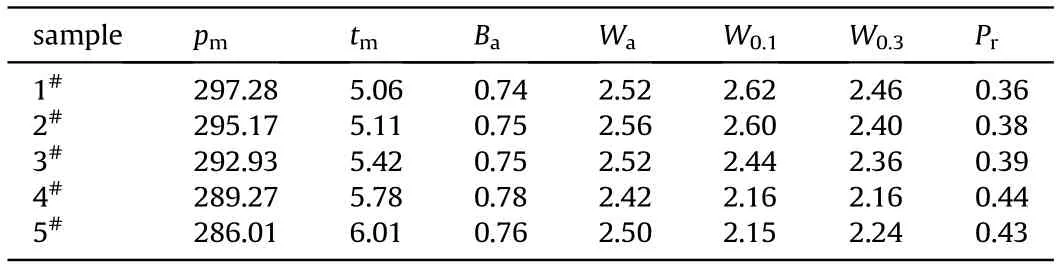

The burning progressivity factor(P)is usually used to evaluate the burning progressivity of high energy propellants [7], and it is shown in Eq. (4). Table 1 shows the value of Pof high energy propellants.

where the Bis the value of relative pressure of the inflection point in Fig.10b.

Table 1 shows the value of Pr of high energy propellants. The burning progressivity factor(sample 2-5)are greater than that of the control sample (sample 1), demonstrating that PCM-based nanocomposite could efficiently improve progressive burning of high energy propellants. Fig. 10d and Table 1 show that the Pof sample 4are the highest,indicating that burning characteristic of high energy propellants can be controlled by changing the PCMbased nanocomposite content.

Fig.8. Mass spectrometry ion current intensity-temperature curves of gaseous products evolved during thermal decomposition of PCM-based nanocomposite,the control sample and the high energy propellant modified with PCM-based nanocomposite (sample 1# and sample 4#).

Fig. 9. Fourier transform infrared spectrogram of burning gaseous products.

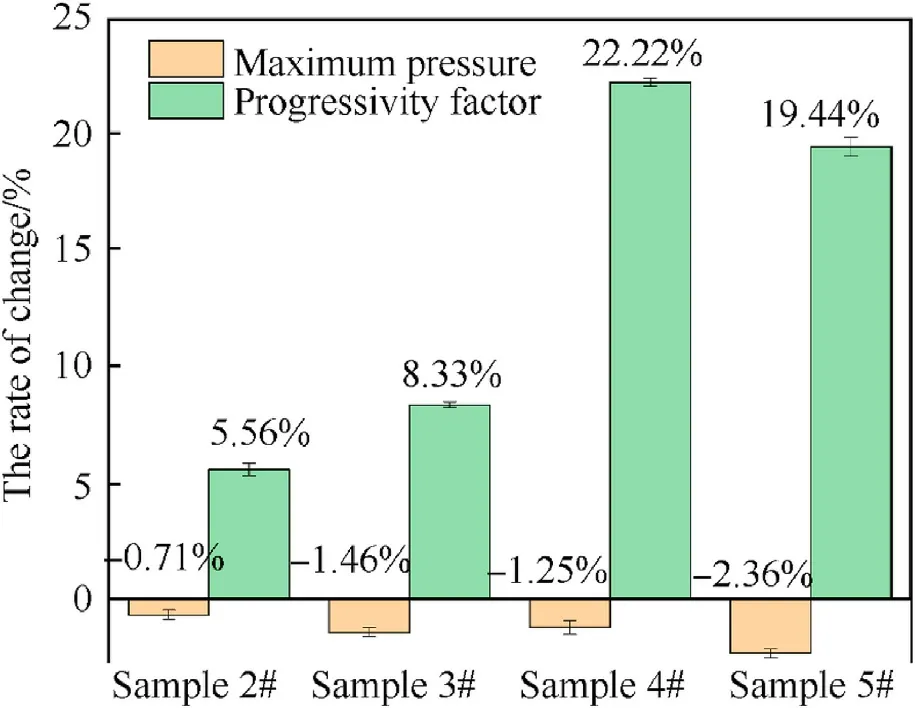

Fig. 11. Effect of the PCM-based nanocomposite on the maximum pressure (yellow histogram) and progressivity factor (green histogram) of high energy propellants.

Fig.10. The pressure-time (a), derivative pressure-time (b), burning rate-versus pressure (c) and dynamic vivacity (d) curves of high energy propellants.

Table 1 Characteristic parameters and Pr value of high energy propellants.

Fig.11 shows the effect of the PCM-based nanocomposite on the maximum pressure and progressivity factor of high energy propellants. It is obviously observed in Fig. 11 that the maximum pressure of high energy propellants is decreased and the progressivity factor is increased after the addition of the PCM-based nanocomposite. As shown in Fig.11, the P(sample 4) is extreme increased by 22.22% compared with the control sample while the maximum pressure is merely decreased by 1.25%, demonstrating that the PCM-based nanocomposite can effectively improve the burning performance and less reduce its power of high energy propellants. The results indicate that the PCM-based nanocomposite may be used in the high energy propellant formation.

In summary, the PCM-based nanocomposite can be used to adjust the burning process and improve its progressive burning of high energy propellant.

4. Conclusion

High energy propellants containing RDX modified with PCMbased nanocomposites were prepared and its characterization was studied. The SEM and EDS results indicate that PCM-based nanocomposites have good compatibility in the propellant formulation. The effect of PCM-based nanocomposites on the thermal decomposition of high energy propellants was investigated by TG/DSC-FTIR-MS technology. Due to the delayed protection effect of PCM-based nanocomposite(PCM nanocomposite can absorb lots of heat at the range of certain temperature when it undergoes structure change or phase transitions)on thermal decomposition of high energy propellants, the thermal stability of high energy propellants is improved after the addition of PCM-based nanocomposite.At the same time,the concentration of CO,NO and CHis decreased while the concentration of N, NO, HO and COis increased evolved during thermal decomposition of high energy propellants.

The burning gaseous products and burning characteristic of high energy propellant are studied by the closed bomb test and Fourier transform infrared spectroscopy. The main burning gaseous products evolved during the burning process of high energy propellants are N, CO, CO, HO, CH, etc., and the concentration of CHis increased while CO,COand HO gas is reduced after the addition of PCM-based nanocomposites under the high-pressure condition.The progressivity factor of high energy propellants increased by 22.22% comparing with the control sample while the maximum pressure is merely decreased 1.25%after the addition of PCM-based nanocomposite, so PCM-based nanocomposite can be used to improve the burning progressivity of high energy propellants.

In summary, the addition of PCM-based nanocomposite does not only improve the thermal stability and decrease the erosion performance, but also adjusts the burning process and improves the progressive burning of high energy propellants containing RDX.

We declare that we have no financial and personal relationships with other people or organizations that can inappropriately influence our work,there is no professional or other personal interest of any nature or kind in any product, service and/or company that could be construed as influencing the position presented in,or the review of, the manuscript entitled, “Effects of phase change material (PCM)-based nanocomposite additives on thermal decomposition and burning characteristic of high energy propellants containing RDX”.

The authors would like to acknowledge the National Natural Science Foundation of China(Grant No.22075146)to provide fund for conducting experiments.

- Defence Technology的其它文章

- Research on DSO vision positioning technology based on binocular stereo panoramic vision system

- Dynamics of luffing motion of a hydraulically driven shell manipulator with revolute clearance joints

- Blast performance of layered charges enveloped by aluminum powder/rubber composites in confined spaces

- Chemical design and characterization of cellulosic derivatives containing high-nitrogen functional groups: Towards the next generation of energetic biopolymers

- Applicability of unique scarf joint configuration in friction stir welding of AA6061-T6: Analysis of torque, force, microstructure and mechanical properties

- Multi-area detection sensitivity calculation model and detection blind areas influence analysis of photoelectric detection target