The effect of strain rate on compressive behavior and failure mechanism of CMDB propellant

Heng-ning Zhang,Hai Chang,Xiao-jiang Li,Xiong-gang Wu,Qi-wen He

Xi’an Modern Chemistry Research Institute,Xi’an,Shaanxi,710065,China

Keywords:CMDB propellant Mechanical response Strain-rate dependence Failure mechanisms

ABSTRACT The compressive mechanical behavior of composite modi fied double base(CMDB)propellant was investigated across a wide scope of strain rates ranging from 10-3 s-1 to 4210 s-1 at room temperature,by applying a conventional universal testing machine and a split Hopkinson tension bar(SHPB),respectively.The derived stress-strain curves at different strain rates show a strong rate dependence,indicated that yield stress,ultimate stress and strain energy density of CMDB propellant all increase with strain rate by following a power law function,while the ampli fication of increase are different.The deformation and damage modes of CMDB propellant has changed from a typical ductile manner(cracking along the axial direction)to a brittle manner(maximum shear failure)with increasing of strain rate.Scanning electron microscopy(SEM)was employed to explore the microscopic failure characteristics of CMDB propellant.Under quasi-static loading,the nearly parallel micro-cracks propagating along the axial direction and the debonding of RDX particle without particle crushing can be observed.While under dynamic loading,the micro-crack is 45°angle to the axial direction,and multiple cracking modes of RDX particles appeared.Finally,the correlation between strain energy density and failure mechanisms of CMDB propellant was revealed by developing four characteristic failure modes.The findings of this study is very important to evaluate the structural integrity of CMDB propellant.

1.Introduction

As a class of high-energy solid propellant,Composite modi fied double base propellant(CMDB)has been widely used as fuel in various types of solid rocket motors(SRMs),owing to its excellent advantages,such as low characteristic signal,good combustion performance and mature processing technology[1-3].In terms of constituent,CMDB propellant can be classi fied as a typical composite material,which contains nitrocellulose(NC)as binder matrix,nitroglycerin(NG)as plasticizer,and high explosive particles such as cyclotrimethylene trinitramine(RDX)are incorporated as solid filler.Speci fically,as the binder of CMDB propellant,NC has a rigid molecular con figuration with relative high glass transition temperature(usually much higher than room temperature),which leads to the brittle manner under high strain rate loading.On the other hand,the linear molecular con figuration of NC can result in the creeping effect of CMDB propellant,a typical stress relaxation behavior under quasi-static loading[4,5].

Generally,the proper functionality of SRMs depends largely on the mechanical behaviors of solid propellant.Take CMDB propellant as an example,multiple types of compressive loadings are imposed upon CMDB propellant during its service life.Not only suffer low strain rate stimulation,such as transportation and storage,but also be exposed to high strain rate circumstance,such as launch overload and blast wave caused by sympathetic detonation et al.[6-11].These quasi-static and dynamic loadings may lead to different characteristic damage of CMDB propellant grain,thus affecting the reliability and safety of SRMs[12].

In recent years,much work has been documented on the mechanical response of solid propellants at various strain rate,which corresponds to the different loading circumstance.To study the impact fracture toughness of a triple base gun propellant consisting of NC,NG and nitroguanidine(NQ),Fong et al.conducted an impacting testing by Hopkinson bar apparatus in a three point bend mode[3].The results indicated that the impact fracture toughness was noticed to be actually independent of strain rates ranging from 3 sto 90 s.Long et al.studied the initiation fracture toughness of HTPB propellant under strain rates spanning from 400 sto 1100 s,by using the split Hopkinson pressure bar(SHPB),indicated a linear correlation between the fracture toughness and the logarithm of the strain rate[13].Wang et al.reported the uniaxial compressive properties of HTPB propellant under intermediate strain rates(0.4 sto 63 s).Based on the experimental results,a new constitutive model with damage was developed to predict the mechanical response of HTPB propellant at intermediate strain rates and low temperatures[14].Sun et al.examined the stressstrain responses of CMDB propellant under strain rates from 10sto 10s,the obtained curves exhibited in sequence with a viscoelastic phase,a yielding behavior and a strain hardening/softening stage,which was greatly in fluenced by the strain rate and temperature[15].Yang et al.focused on the compressive yield behavior of CMDB propellant across a wide scope of strain rates from 1.7×10sto 4×10s,indicated that the yield stress increase bilinearly with the logarithm of strain rate,and the transition strain rate is at 50 s.In addition,the Ree-Eyring model involving two rate-activated processes was proposed,which can well predict the yield behavior of CMDB propellant[16].

As stated above,to study the mechanical response of solid propellant at different strain rates,much attention has been attached to the development of mechanical constitutive models,which can be used to predict the mechanical behaviors under various loading condition.However,in terms of structural integrity analysis,understanding the deformation and the failure mechanisms of solid propellant is also very important,because that the damage of solid propellant can lead to an increase in sensitivity of SRMs and,in the worse situation,result in an increase in the burning surface area,which ultimately induces a de flagration-todetonation transition(DDT)[17,18].Furthermore,a thorough understanding of the relevance between mechanical properties and failure mechanisms of CMDB propellant is signi ficant for developing the numerical model,which is essential for reliable predictions of structural integrity and security of CMDB propellant grain.Unfortunately,researches related to this field is relatively insuf ficient[19].

In this study,the complete stress-strain properties of CMDB propellant under strain rates spanning from 0.001 sto 4210 swere investigated,by employing an universal testing machine and a SHPB apparatus.Based on the mechanical data,the rate dependence of yield stress,ultimate stress and strain energy of CMDB propellant were quantitatively analyzed.Meanwhile,SEM was introduced to explore the microscopic failure mechanisms of CMDB propellant under quasi-static and dynamic compressive loading.Furthermore,the real-time evolution of deformation and failure was recorded by a high-speed digital camera synchronizing with SHPB test,which revealed the correlation between mechanical properties and failure mechanisms of CMDB propellant.

2.Experimental procedure

2.1.Materials and sample preparation

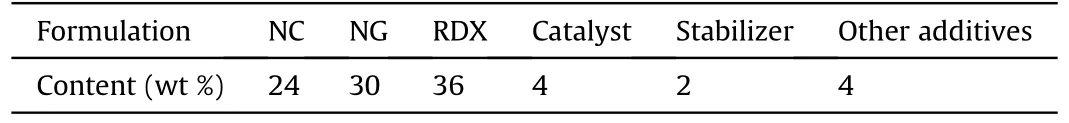

The experimental CMDB propellant was prepared by a typical kneading and extrusion technique,which consists of NC and NG as a double base binder,RDX as an oxidizer particle and some other additives(including lead/copper based compound salt as combustion catalyst,dimethyl diphenylurea as stabilizer and so on).The components of CMDB propellant is listed in Table 1.

Table 1 Formulation of CMDB propellant.

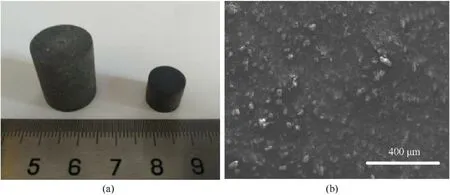

Herein,the used NC is the polymer matrix which bonds the rest of the component together and its degree of esteri fication is 13.0%.The used RDX are nearly spherical crystals with geometric sizes ranging from 70 to 180μm,and the mean size is 100μm.All ingredients of CMDB propellant were blended in a sigma blade kneading mixer for more than 2 h and the material becomes to a dough,then the dough were extruded into a prepared mold and cured in an oven at 65C for 5 days.After demolding,the obtained CMDB propellant was machined into cylinders with two geometric sizes,as depicted in Fig.1a.The specimen(left)for quasi-static testing has a size of 16 mm in diameter and 20 mm in length.The specimen(right)for dynamic testing has a size of 9 mm in diameter and 6 mm in length,because that a lower length-todiameter ratio can help to reduce the stress wave attenuation[20].Fig.1b shows the microscopic structure of the CMDB propellant,indicated that the RDX fillers is uniformly distributed in the binder matrix.Before testing,all specimens were stored in a vacuum oven at 40C over 24 h to eliminate the residual stress and humidity.

2.2.Quasi-static compressive testing

Quasi-static uniaxial compressive tests were conducted at room temperature(20C),by using a computer-controlled,universal testing machine(model:4104 MTS),as shown in Fig.2(a).The compression rate were set as 1.2 mm/min and 12 min/min corresponding to the strain rates of 0.001 sand 0.01 s,respectively.Three repeated tests were carried out at each strain rate,to ensure the repeatability of the quasi-static test.Afterwards,a post-test SEM was used to explore the microscopic failure morphologies induced by quasi-static tests.

2.3.Dynamic compressive loading

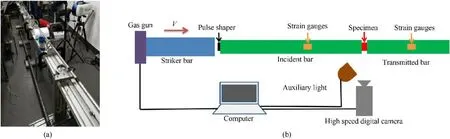

Dynamic compressive tests were performed using a SHPB apparatus,which is a widely available technique for high strain rate tests[21-28].The photograph and schematic of the SHPB setup equipped with a high-speed digital camera were shown in Fig.3.The main component of the SHPB setup includes a striker bar,an incident bar and a transmitter bar,all 3 bars are made of aluminum alloy,which has a Yong’s modulus of 72 GPa and density of 2.7 g/cm.The length of striker bar,incident bar and transmitter bar are 600 mm,2400 mm and 1500 mm,respectively.The diameters of all 3 bars are the same of 12 mm.When the size of specimen is determined,different strain rates can be obtained by changing the speed of striker bar,V,in a SHPB test.Furthermore,a high speed digital camera(frame number of 5 million/s)accompanied with SHPB test was employed to capture the deformation and failure images of specimen,and a synchronous light source can compensate the insuf ficient exposure,which helps to improve the clarity of photos.

The working principle of the SHPB test has been well documented.In our previous work,the SHPB setup was proved to be a reliable dynamic testing method for HTPB propellant[29].Based on the strain signals recorded by strain gauges,the relationship with the strain rate,strain,and stress of sample,can be de fined as Eq.(1)[21].

Fig.1.(a)Two sizes of specimens for quasi-static test(left)and dynamic test(right),(b)Microscopic structure of the prepared CMDB propellant.

In each SHPB test of this study,a constant strain rate can be achieved,and the specimen deforms uniformly under equilibrium of dynamic stress,which means a proper dynamic experimental procedure.For the dynamic tests,the peed of striker bar can be estimated as 2.0 m/s,3.5 m/s,6.0 m/s,10.0 m/s,14.5 m/s and 18.5 m/s corresponding to the strain rates of 260 s,440 s,980 s,1520 s,3160 sand 4210 s,respectively.It is noteworthy that the speed of striker bar was controlled by the pressure of gas gun,so the speed values only can be estimated roughly.During the SHPB test,at least three repeated tests were carried out at each strain rate,to ensure the repeatability of the dynamic test.For the SHPB test,each strain rate cannot be repeated exactly because of the experimental error.However,the validity of experimental results can be veri fied and the variance of stress-strain curves can be negligible.Afterwards,a post-test SEM was used to explore the microscopic failure morphologies after dynamic tests.

Fig.2.Photographs of 4104 MTS universal testing machine.

3.Results and discussion

3.1.Quasi-static mechanical response and failure mechanism

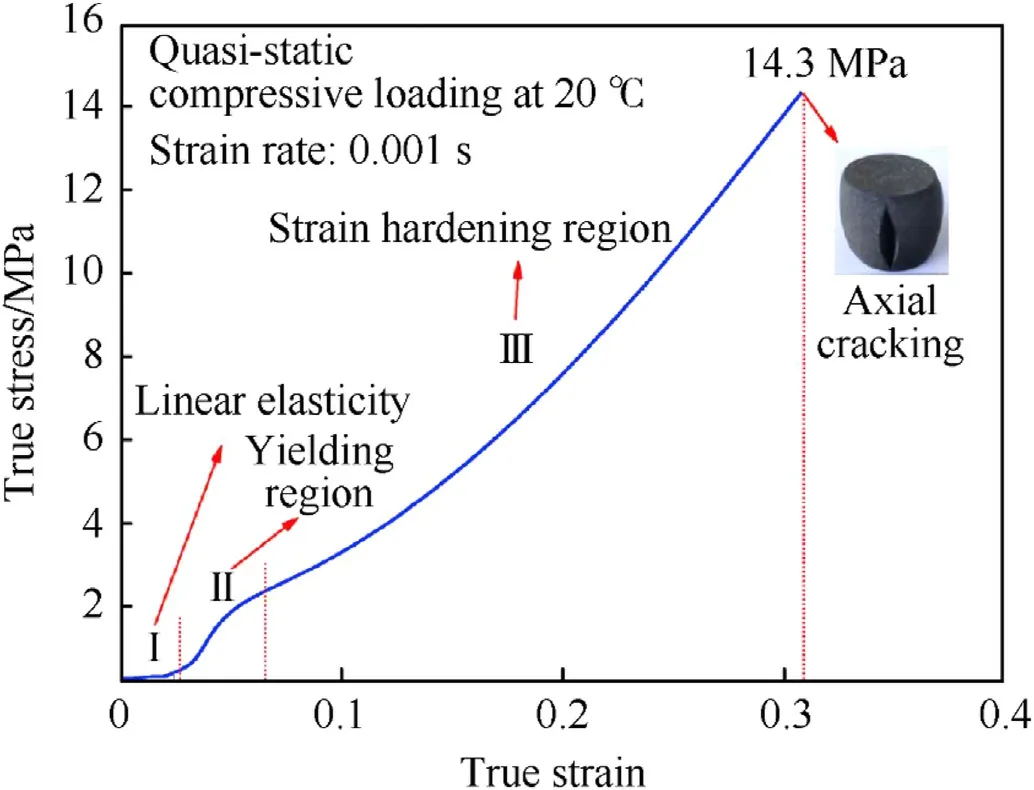

The true stress-strain curve of the CMDB propellant under strain rate of 0.001 sis shown in Fig.4.The pro file of the stress-strain plot displays the characteristics of a elastomeric manner,which can be divided into three characteristic regions,an initial linear elasticity region corresponding to uniform deformation(Region I),followed by a nonlinear transition to yielding with a yield stress of 2.2 MPa(Region II);and an approximate linear strain hardening region with a fast increase of stress(from2.2 MPa to 14.3 MPa)until fracture(Region III).As shown in Fig.4,an obvious strain hardening effect of CMDB propellant can be observed in region III,where the true stress keeps rising to 14.3 MPa at a strain of 0.31.For the quasistatic loading,the initiation of macro-crack can be determined as the point of ultimate stress.After that,an axial cracking occurs and spreads throughout the whole specimen,indicating that the CMDB propellant underwent a typical ductile failure under quasi-static test[30].

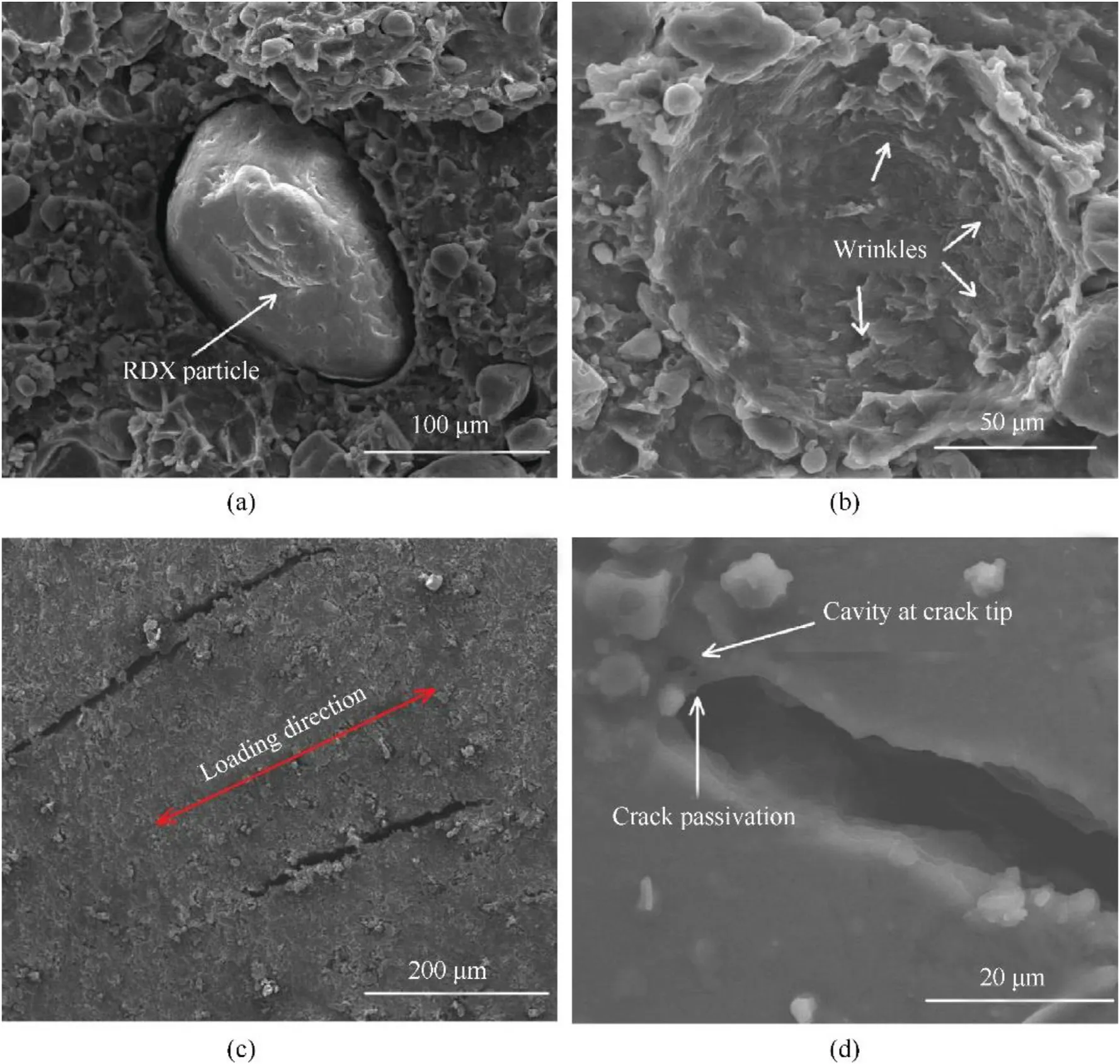

As depicted in Fig.5,a further SEM analysis on the post-test specimen can be helpful to understand the damage characteristic of CMDB propellant.From Fig.5a,a complete RDX particle without fragmentation can be found debonding from the binder matrix.Some RDX particles were even pulled out from binder matrix,remaining the rough concave surface of matrix with wrinkles,as revealed in Fig.5b.Under quasi-static loading,besides the macroscopic main crack,more micro-cracks can be found in the post-test CMDB propellant,and the orientation of the multiple micro-cracks were almost consistent with the axial loading direction,as shown in Fig.5c.In fact,the initiation of macroscopic main crack can be attributed to the convergence of the multiple micro-cracks.A zoom in image of the micro-crack tip is depicted in Fig.5d,there is a small cavity at the blunted crack tip,which refers to a considerable plastic zone at the crack tip.The plastic zone at the crack tip can be attributed to the relative slow propagation of microcraks under quasi-static test,because that the molecular chain of binder matrix has enough time to rearrangement to adapt the applied stress,which is helpful to release the localized stresses.The plastic zone at the crack tip may result in a shielding mechanism for micro-crack propagation,which implies the reduction of the stress concentration and induce the crack passivation process[31].In conclusion,The crack morphology of CMDB propellant under quasi-static testing behaves in a typical ductile manner.

Fig.3.(a)Photograph of the split Hopkinson pressure bar device,(b)Schematic of the split Hopkinson pressure bar device.

Fig.4.True stress-strain curve of CMDB propellant at strain rate of 0.001 s-1 with inducing an axial cracking,which can be divided into three regions:linear elasticity region(I),yielding region(II)and strain hardening region(III).

3.2.Dynamic mechanical response and failure mechanism

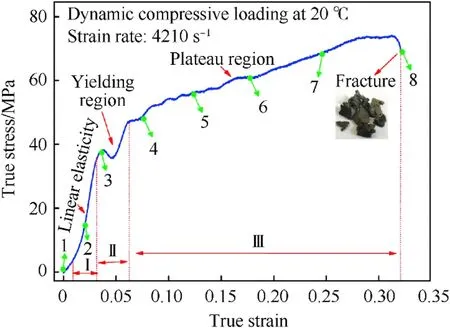

Fig.6 presented the true stress-strain curve under strain rate of 4210 sat room temperature,causing a final fracture.Similar to the quasi-static loading,the stress-strain curve of CMDB propellant at strain rate of 4210 salso can be divided into three regions,an initial linear elasticity region,followed by a yielding behavior,and a plateau region until fracture.The yield stress and ultimate stress of CMDB propellant at strain rate of 4210 sare 38 MPa and 74 MPa,respectively,which are signi ficant higher than that under quasistatic testing.From Fig.6,after the yielding domain,a plateau domain accompanied with a considerable straining(from 0.06 to 0.31)and a moderate increasing of stress(from 47 MPa to 73 MPa)can be found,indicated that the deformation of CMDB propellant after yielding exhibits a signi ficant elastic-plastic manner.In addition,there exists a distinct difference in the pro file of stress-strain curves between the quasi-static and dynamic testing:a softening behavior with a slight decrease of stress following the yielding point can be found in Fig.6,whereas the similar phenomenon cannot be seen in the case of quasi-static test.Furthermore,the strain energy density,signi fied by the area below the stress-strain plot can be calculated as 17.8 MJ/m,which implies the total energy input upon CMDB propellant during the SHPB testing at strain rate of 4210 s.Finally,because that the real stress is greater than the ultimate stress,the fragmentation of specimen was induced.

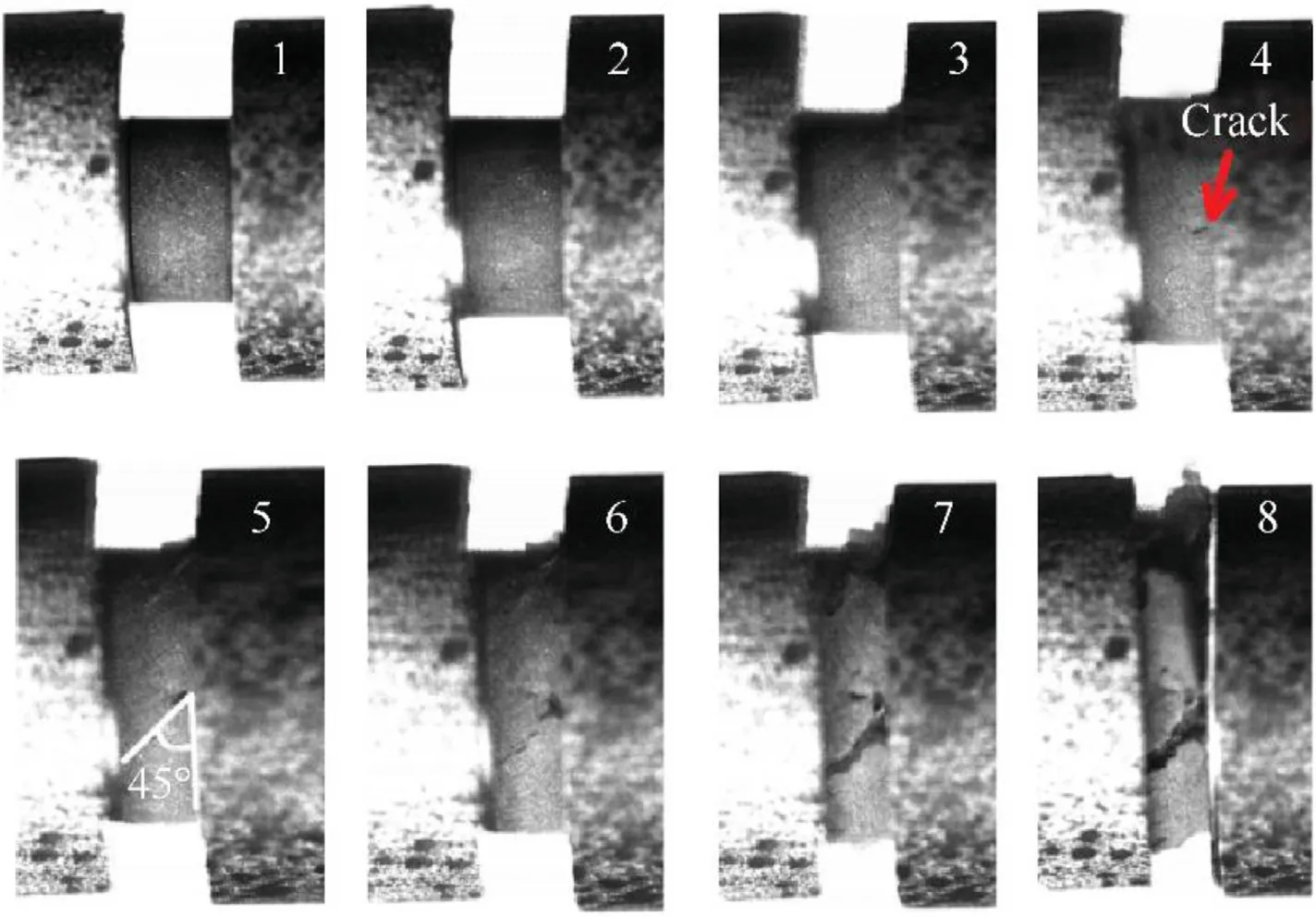

In order to reveal the correlation between mechanical behavior and failure evolution of CMDB propellant under high strain rate loading,a high-speed digital camera was applied to synchronously capture the deformation procedure of specimen during the SHPB test.Fig.7 shows the high speed images marked by green numbers corresponding to the stress-strain curve with green dots as presented in Fig.6.

At the beginning,the specimen was sandwiched between 2 bars and an uniform deformation was sustained from image of No.1 to No.3,which implies the stress equilibrium in the specimen.According to Fig.6,No.3 image corresponds to the yielding point at stress of 38.2 MPa,then,the homogeneous deformation related to strain softening behavior was continued.Until No.4 image,no macroscopic damage can be detected in the specimen.From No.4 image,a small crack initiated near the boundary between the specimen and right bar,where the stress level is 47 MPa.Because that the micro cracks were de finitely produced before the macroscopic crack,it can be deduced that the microscopic cracking is supposed to occur from the yielding point(image No.3),where initiate at the particle-binder interfaces.Afterwards,a typical maximum shear failure with an angle of about 45to the loading direction can be observed from image No.5,where crack propagate along the shear band of specimen[32].In the later stage from image No.5 to No.7,although macroscopic damage has already appeared,the CMDB propellant still keeps a capacity of load-bearing,which leads a continuous increasing of stress up to 74 MPa.Finally,a totally fragmentation of specimen was induced and the broken debris was squeezed out,which resulted in the rapid drop of stress.

Fig.5.Post-test SEM images of CMDB propellant at strain rate of 0.001 s-1 at room temperature:(a)debonding of the RDX particle from binder matrix;(b)the rough concave surface of matrix with wrinkles left by pulling out of RDX particle;(c)the multiple micro-cracks propagate along the axial loading direction;(d)the plastic zone represented by a small cavity at crack tip and the crack passivation.

Fig.6.True dynamic stress-strain curve of CMDB propellant at strain rate of 4210 s-1 with inducing a final fracture,which can be divided into three regions:linear elasticity region,yielding region and plateau region.The green numbers distributed in the plot correspond to the numbers in the recorded images in Fig.7.

The post-SEManalysis on the CMDB propellant under strain rate of 4210 swas shown in Fig.8.The microscopic failure morphology of specimen under dynamic loading is quite different from that under quasi-static loading.As shown in Fig.8a,an obviously localized shearing cracking can be detected,where two converging microcracks are 45to the loading direction respectively.These microcracks related to maximum shear band correspond well to the macroscopic crack stated above.During the SHPB test,the micro-cracks initiate along the maximum shear surface,where the localized stress concentrates.From Fig.8b,debonding of RDX-binder interface as well as broken pieces of RDX particle can be observed.Because that higher localized stresses can be transferred from NC matrix to the RDX particles under high rate loading,it can be deduced that the crack initiates from the RDX-binder interface,which is the weakest point of specimen,and propagates into the RDX particle,leads to crushing of RDX particle.Compared with the rough concave surface of matrix under quasi-static testing,a relative smooth concave surface left by pulling out of RDX particle can be found in Fig.8c,indicated that the dewetting of RDX particle from NC matrix is more faster under high rate loading than in a quasi-static case[33].Fig.8d revealed the tiny crazes with scale of only several microns spreading in the RDX-binder interface,which implies the origin of micro-crazes formation and debonding behavior induced by high rate loading.

Fig.7.Deformation and failure procedure of CMDB propellant captured by a high speed digital camera at strain rate of 4210 s-1,the green numbers in the photos correspond to the numbers in Fig.6.

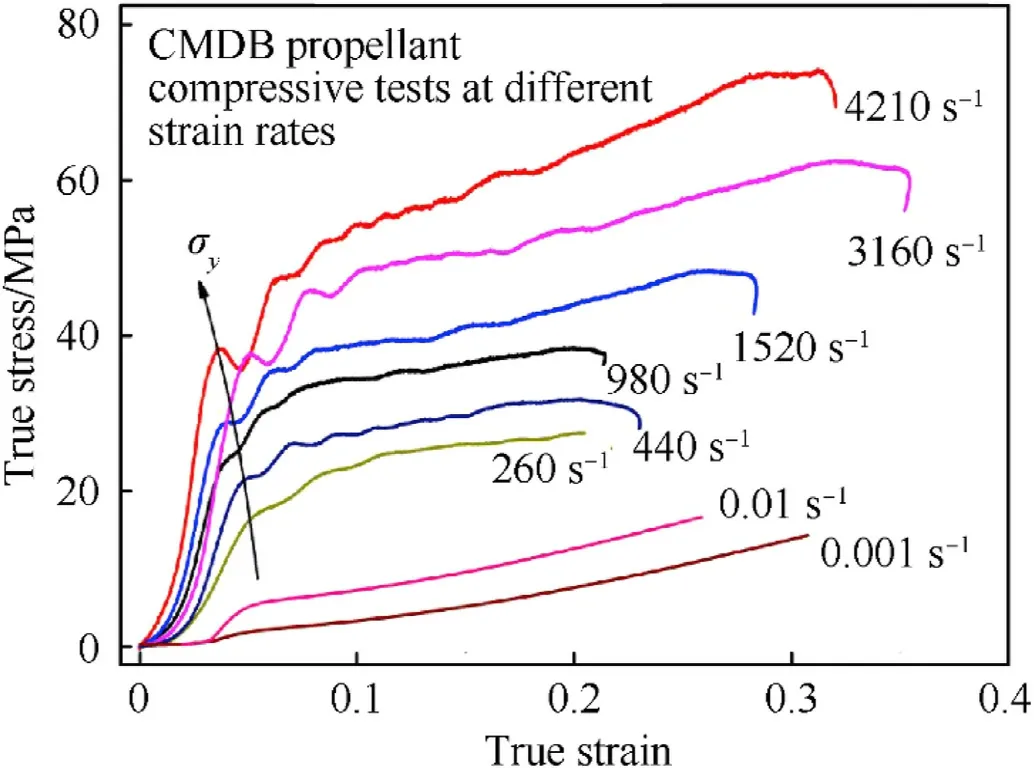

3.3.Quantitative analysis on strain rate dependence of mechanical response

4210 s.Herein,the curves under quasi-static loadings(0.001 sand 0.01 s)are included as a reference.As shown in Fig.9,the CMDB propellant behaves in a plastic type under dynamic loadings(from 260 sto 4210 s),while under quasi-static circumstance,the mechanical characteristic of CMDB propellant displays an elastomeric feature,which undergoes a ductile deformation with large straining and low increase of stress.Furthermore,the pro file of the dynamic stress-strain curves at different strain rate is similar,and all of which can be divided into three parts,an initial linear elasticity domain,followed by a yielding domain and then a plateau domain with moderate increase of stress.Consequently,the similar pro file of dynamic stress-strain plots can be attributed to the similar deformation procedure.According to the experimental results from Fig.9,the mechanical properties of CMDB propellant show a prominent rate-dependence,indicated that the yield stress,ultimate stress and strain energy all increase with increasing strain rate.In particular,as the strain rate increasing from 0.001 sto 4210 s,σ,the yield stress of CMDB propellant rises from 2.2 MPa to 38.2 MPa,whereas the yield strain appears to be declined,which means that CMDB propellant yielding at lower strain under higher rate loading.Besides,it is noteworthy that a softening behavior after yielding becomes more pronounced as increasing the loading rate.A possible explanation for the softening induced by yielding lies in the debonding and crushing of the RDX particles[34].

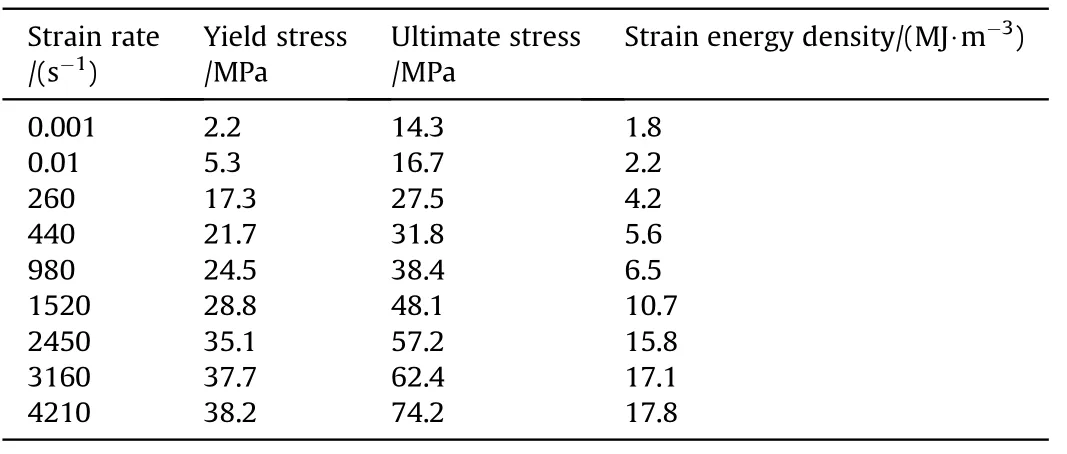

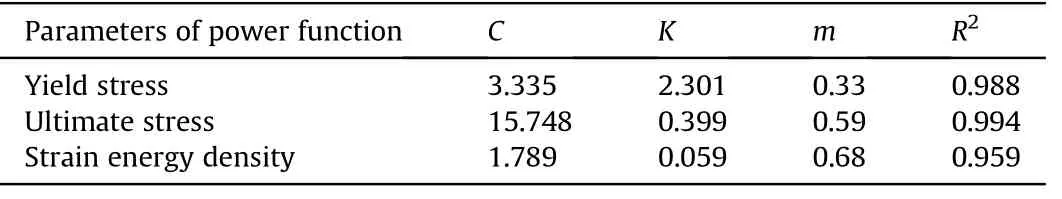

The mechanical parameters of CMDB propellant,in terms of yield stress,ultimate stress and strain energy density which derived from Fig.9 are summarized in Table 2.

Fig.9 presented the true stress-strain plots of the CMDB propellant across a wide scope of strain rates ranging from 0.001 s-1 to

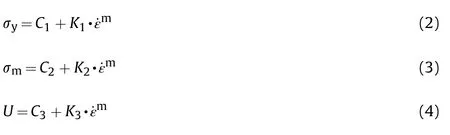

The strain-rate sensitivity(SRS)index,m,is usually introduced to evaluate the effect of strain rate on the stress of various materials.In order to quantify the rate dependence of mechanical parameters,the Backofen formula,a famous empirical power law function,can be deduced to represent the strain rate dependence of mechanical index[35,36].Herein,the rate-dependence on yield stress,ultimate stress and strain energy density of CMDB propellant can be given by Eq.(2),Eq.(3)and Eq.(4),respectively.

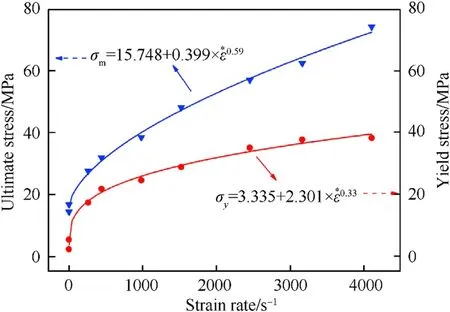

whereσ,σand U are yield stress,ultimate stress and strain energy density,respectively.˙εand m are strain rate and SRS index,respectively.In addition,both C and K are the intrinsic parameters of materials,which is relevant to the experimental conditions and microstructure of materials.In order to quantify the strain-rate dependency of CMDB propellant,the values of yield stress and ultimate stress based on the mechanical parameters in Table 2 can be plotted as a function of strain rate,by fitting the power law formula of Eqs.(2)and(3),as shown in Fig.10.For details,the material parameters,C,K,and SRS index,m,have been listed in Table 3.

Table 2 Mechanical parameters of CMDB propellant under different strain rates which derived from Fig.9.

Table 3 Mechanical parameters of CMDB propellant under various strain rates which derived from Fig.9.

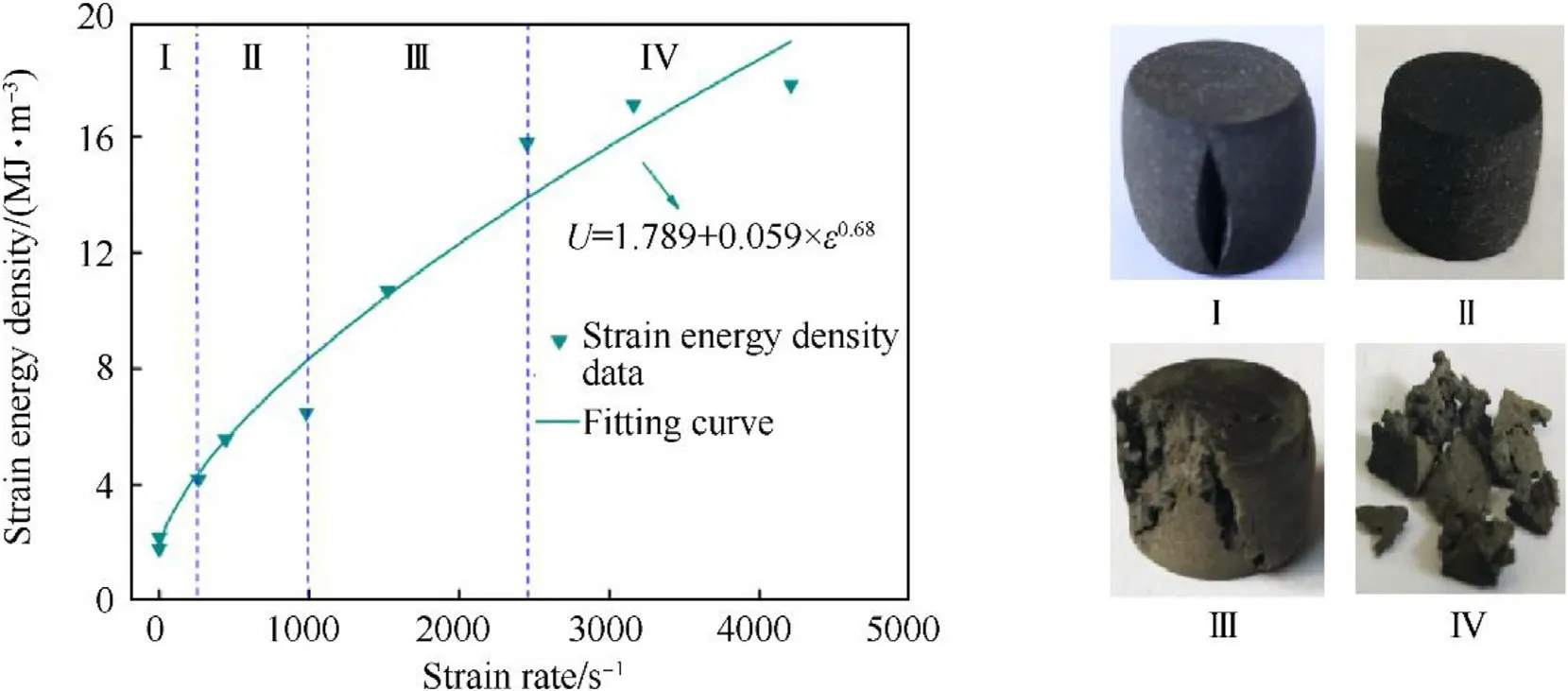

The fitted formula of yield stress and ultimate stress can be expressed as,σ=3.335+2.301˙εandσ=15.748+0.399˙ε,respectively.Both of the two fitted curves all exhibit an upward tendency with increasing strain rate,whereas the strain rate sensitivities of yield stress and ultimate stress are different,which can be explained by the structural mechanism of CMDB propellant.As a typical particle-filled composite,the yield stress of CMDB propellant corresponds to the debonding behavior of RDX/binder,while the ultimate stress is relates to the complete failure of the material,which includes the tearing of NC binder and the crushing of RDX particles.By analyzing the m value of yield stress(0.33)and ultimate stress(0.59),it can be concluded that the complete failure of CMDB propellant accompanying with tearing of NC binder and cracking of RDX is more dependent on strain rate,in compared with the debonding process.Furthermore,as Fig.10 depicted,both yield stress and ultimate stress display a faster increasing tendency under low strain rate than that of high strain rate,which is owing to the more signi ficant adiabatic temperature-rise softening effect on CMDB propellant during dynamic loading than that of quasi-static loading[37].in Region II under strain rates from 200 sto 1000 swithout inducing fracture,which means that the energy input is insuf ficient to damage the specimen.III,maximum shear failure in RegionШ under strain rates from 1000 sto 2500 s,with cracks propagating at an angle of about 45to the loading direction.Ⅳ,complete fragmentation in RegionⅣ,with the interaction of numerous cracks.It is noteworthy that the boundaries between these regions are referring to a certain range of strain rate,rather than a speci fic strain rate.

Fig.8.Post-test SEM images of CMDB propellant at strain rate of 4210 s-1 at room temperature:(a)the micro-cracks propagate along the maximum shear band with 45°to the loading direction;(b)debonding of RDX-binder interface and broken pieces of RDX particle;(c)the relative smooth concave surface of matrix left by pulling out of RDX particle;(d)the tiny crazes with scale of several microns spreading in the RDX-binder interface induced by high rate loading.

Fig.9.True stress-strain curves of CMDB propellant under different strain rates ranging from 0.001 s-1 to 4210 s-1.

Fig.10.The strain rate dependence on yield stress and ultimate stress of CMDB propellant.

Fig.11.(left)The strain rate dependence on strain energy density of CMDB propellant,which can be divided into four characteristic regions:I,axial cracking;II,homogeneous deformation;III,maximum shear failure cracking;andⅣ,complete fragmentation,(right)The post-test specimens with four characteristic failure modes related to different strain rate.

4.Conclusions

In this study,the strain rate dependence on mechanical properties and failure mechanism of CMDB propellant was analyzed across a wide scope of strain rates spanning from 10sto 4210 s.The resultant remarks can be concluded as below.

With increasing of strain rate,the deformation and damage characteristic of CMDB propellant has changed from an elastomeric manner to a plastic manner.According to SEM findings,microcracks propagating along the axial direction and the debonding of RDX particle without particle crushing can be observed under quasi-static loading,while under dynamic loading,a maximum shear cracking occurs accompanying with fragmentation of RDX particles.

The mechanical parameters of CMDB propellant,in terms of yield stress,ultimate stress and strain energy density,were largely affected by strain rate.Based on the stress-strain data,some empirical functions to describe the strain-rate sensitivity(SRS)of yield stress,ultimate stress and strain energy density were developed.The results indicated that ultimate stress has a greater SRS index(m)than the yield stress,because that the complete failure of CMDB propellant corresponding to ultimate stress is more dependent on strain rate,in compared with the debonding process corresponding to yield stress.In addition,both yield stress and ultimate stress display a faster increasing tendency in the lower strain rate than that of high strain rate,which is owing to the more signi ficant adiabatic temperature-rise softening effect on CMDB propellant during dynamic loading than that of quasi-static loading.Finally,the correlation between strain energy density and failure mechanisms of CMDB propellant was revealed by developing four characteristic failure modes.In conclusion,the findings of this research is bene ficial for assessing the structural integrity and improving the mechanical performance of CMDB propellant.

The authors declared that there is no Con flict of Interest related to this paper.

- Defence Technology的其它文章

- High explosive unexploded ordnance neutralization-Tallboy air bomb case study

- Dynamics and rebound behavior analysis of flexible tethered satellite system in deployment and station-keeping phases

- Finite element analysis of functionally graded sandwich plates with porosity via a new hyperbolic shear deformation theory

- Investigation on the penetration of jacketed rods with striking velocities of 0.9-3.3 km/s into semi-in finite targets

- Adaptive target and jamming recognition for the pulse doppler radar fuze based on a time-frequency joint feature and an online-updated naive bayesian classi fier with minimal risk

- In fluence of metal/composite interface on the damage behavior and energy absorption mechanisms of FMLs against projectile impact