An experimental study on ballistic impact response of jute reinforced polyethylene glycol and nano silica based shear thickening fluid composite

Vishws Mhesh ,Dineshkumr Hrursmpth ,Vinys Mhesh

a NMCAD Lab,Department of Aerospace Engineering,Indian Institute of Science(IISc),Bangalore,560 012,Karnataka,India

b Department of Industrial Engineering and Management,Siddaganga Institute of Technology Karnataka,Tumakuru,572102,India

c Department of Mechanical Engineering,National Institute of Technology Silchar,Assam,788010,India

Keywords:Ballistic impact Shear thickening fluid Nano silica Jute

ABSTRACT The present study aims at assessing the ballistic impact behaviour of jute reinforced polyethylene glycol(PEG)and nano silica based shear thickening fluid(STF).Preparation of STF is achieved by dispersing the nano silica particles at different weight percentage loadings of 10%,20%,30%and 40%in PEG and the effect of various weight percentages loading of nano silica particles on ballistic performance of the proposed composites is studied experimentally.Rheological studies of the prepared STF’s showed that at all nanosilica loading shear thickening occurred and also the shear thickening was highest at higher loading of nano silica at lower rate of shear.The study reveals that the ballistic performance of the jute fabric is enhanced with impregnation of STF.The ballistic results indicate that energy absorption of the proposed composites is enhanced with increased loading of nano silica particles and at the same time,the effect of STF was reduced.Speci fic energy absorption(SEA)of the neat fabric and the proposed composites was made use of for the purpose of comparing the energy absorption capabilities.It is found that the SEA of proposed composites with 10%nano silica loading is lesser than the neat fabric both in case of 3 layers and 6 layers.It was also found that proposed composite with 40%nano silica loading exhibits highest SEA compared to neat fabric and its counterparts with its SEA being 3.21 and 3.76 times highest compared to three and six layers of neat fabrics respectively.

1.Introduction

Body armours are mainly classi fied into soft body armour and hard body armour[1].If it is essential to deal with projectiles with very high speed,hard armours are most useful.This can be achieved by making use of ceramics or metal plates in between the fabrics.The main disadvantage of the hard armour lies in its weight.When the ballistic product is intended to be wearable armour,usage of hard armours results in restriction in movement of the personnel[1,2].Whereas,the soft armours are also find their usage in ballistic protection without affecting the restriction in movement.Various synthetic fibers including glass,carbon,kevlar,Twaron,spectra and their composites are extensively used as soft armours[3,4].Last few decades have witnessed the research on various high strength fabrics[5-8].

The recent trend witnesses the usage of nano particles dispersed in the polymers to enhance the performance of the polymers and such composites are termed as polymer nano composites[9].Various nano fillers such as carbon nano tubes,graphene,titania,lignin are used as fillers[10-15]inside the polymer based epoxies[16,17]and other polymers.Compared to pure polymers,the polymer based nano composites exhibit unique properties owing to their structure.This has led to extensive use of polymer based nano composites in wide variety of engineering fields[18-25].

The impact resistance of the fabrics are enhanced by impregnating them with nano particle disperses shear thickening fluids(STF).The nano silica particles are dispersed in a stable way inside the STF which is a polymer[26,27].Due to addition of the STF to the fabrics,the thickness,weight and stiffness of the fabric is increased.This also enhances the impact resistance of the fabrics[28].The ballistic and stab resistance of the STF impregnated fabrics are investigated by various researchers[29-34].

The ballistic impact applications such as body armours make extensive usage of synthetic fibers in both soft body armours and as a backing material/fabric in hard armours.Among the various available synthetic fibers,Kevlar finds a prominent place[35-38].Considering the economic and environmental aspects,it is found that there is a need to reduce the usage of synthetic fibers and look for an alternative.Thus,the researchers have started to explore the usage of natural fibers as a substitute for synthetic fibers[39-46].Though the natural fibers exhibit inferior properties as compared to synthetic fibers,their properties are found to be acceptable for few engineering applications[47,48]such as supporting materials for the primary components.The study carried out by Assis et al.[49]made use of jute in development of multi layered armour system.The results showed a promising outcome with jute non woven mat as a potential replacement for kevlar for polyester matrix composites by providing weight reduction of about 5.4%and cost reduction of 474%.Epoxy-fique fabric composites were successfully developed for use in multi layered armour system by Oliveira et al.[50].The outcome revealed that fique composite with 40 vol%proved to be better alternative to replace kevlar.Apart from this,the low cost of fique composites proved to be an additional advantage.Further,a new natural fiber namely guaruman fiber commonly found in Amazonian region was used for development of natural fiber based polymer matrix composites by Reis et al.[51].The study revealed that guaruman fiber presents one of the lower densities for natural fibers ever reported in literature.This can a major breakthrough in natural fiber based polymer composites for structural applications requiring low weight.Also,these composites exhibited superior tensile strength.Cyperus malaccensis,a type of sedge fiber was ef ficiently made us of in developing a natural fiber based composites by Neuba et al.[52].The results revealed that,as the fiber volume percentage increased,the impact strength and elastic modulus of the fiber increased up to 30 vol%of fiber.A comparative study was carried out by Luz et al.[53]on the composites making use of natural fiber(pineapple leaf fiber)and conventional materials(Dyneema)in hard armour.The outcome reveals that the hard armor with a ceramic front followed by the PALF/epoxy composite meets the National Institute of Justice(NIJ)international standard for level III protection and performs comparably to that of the Dyneema plate,commonly used in armor vests.This shows that several natural fiber composites have been shown to successfully replace synthetic fibers as ballistic protection materials.

Woven fabrics are the one of the constituents of body armours where the usage of natural fibers can be explored since they have proved that they are potential replacements for synthetic fibers in applications such as sacri ficial structures[54,55].Among the various natural fibers available,jute emerges as the most promising natural fiber due to its better thermo-mechanical properties,economy and availability.Hence,there is a wide scope for using the jute reinforced composites in various engineering applications[56],out of which high velocity impact applications are one.

The rheological properties of the STF are affected by various factors such as method of preparation,size and type of the particle,volume fraction of the particle,temperature and liquid medium[57,58].Out of all these factors,particle loading in STF plays a prominent role.Since the concentration of STF is the important factor affecting the shear thickening phenomenon and impact behaviour of the composites,the present study is aimed at exploring the usage of jute natural fiber for ballistic applications along with studying the effect of nano silica loading on the impact behaviour of the proposed STF/Jute composites with three and six layers.

2.Materials and methods

2.1.Materials

The materials used in the present study to prepare the composites are jute fabric and STF prepared using PEG and nano silica particles.

2.1.1.Jute fabric

The naturally available jute fibre in the form of woven fabric was procured from local market of Haryana(Vardhaman Jute Suppliers)and used as obtained in the present study sine the obtained raw material had undergone all the prerequisite cleaning before being supplied.

2.1.2.STF

The present study makes use of STF prepared by dispersing nano silica particles supplied from ultrananotech Pvt.Ltd.,Bangalore,India with average particle size of 500 nm at different weight percentage of 10%,20%,30%and 40%in PEG supplied by Red Exports,Dombivli,Mumbai.Rheological characterization of this STF con firmed discontinuous shear thickening at shear rate of approximately 1-10s.The nano silica particles with 10%,20%,30%and 40%by weight is dispersed in PEG for the preparation of STF with the aid of shear mixing homogenizer at 8000 RPM and ultra sonication.

2.2.Preparation of proposed composites

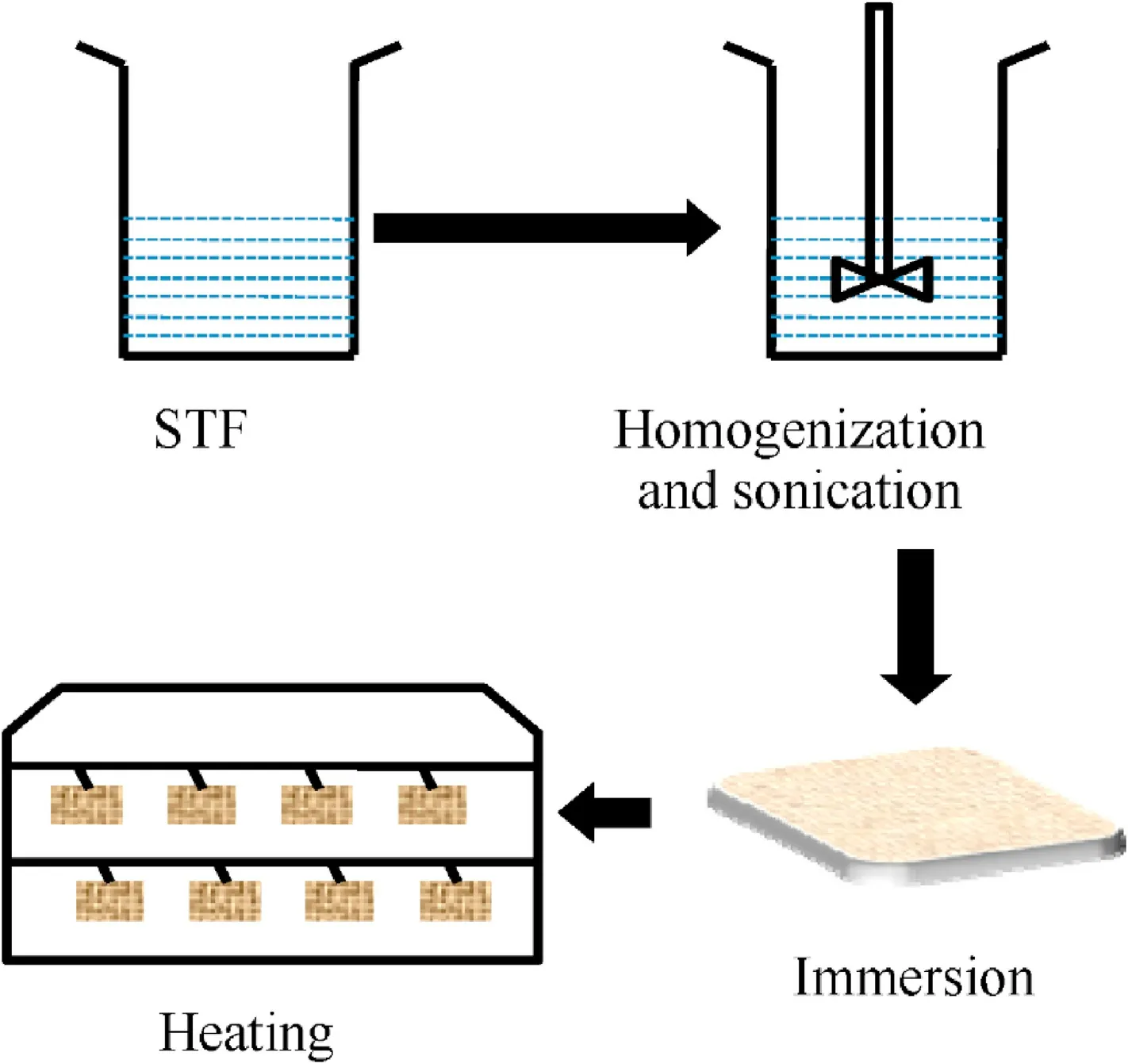

The prepared STF is further diluted with ethanol(1:2 vol)and the jute fabrics are impregnated for about 1 min in the diluted STF.Further,the fabrics are placed in oven and heated at 70C for 20 min in order to facilitate the removal of ethanol.The steps involved in preparation of proposed composites are shown schematically in Fig.1.

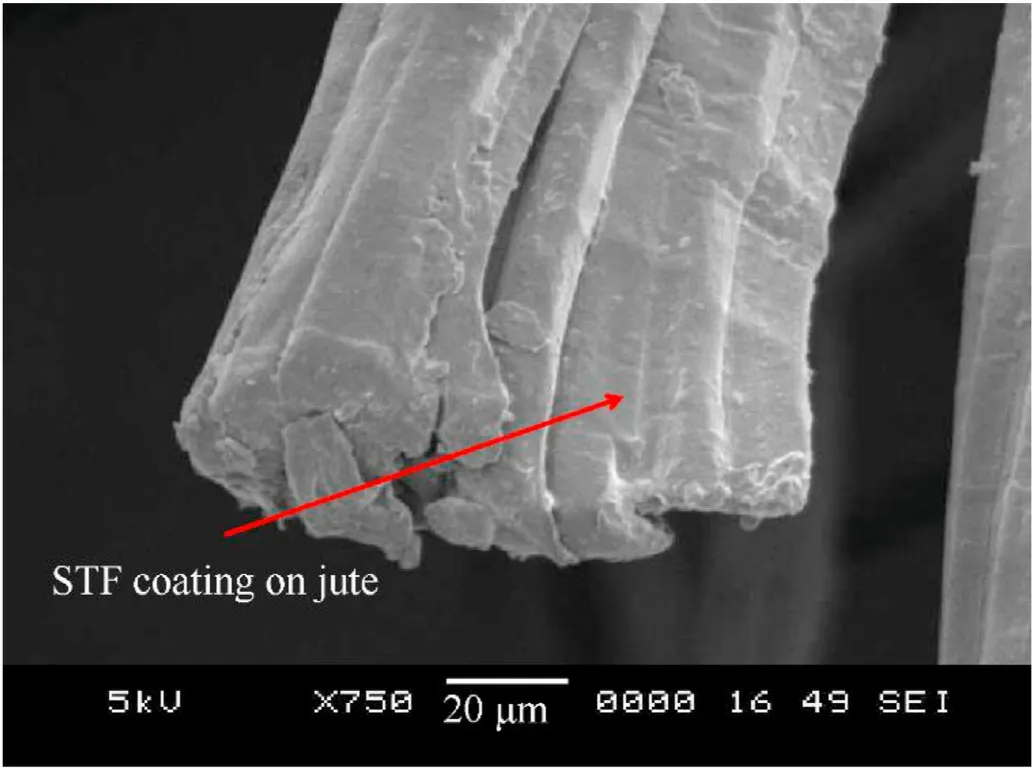

The impregnation of Jute fiber with STF can be con firmed with the help of scanning electron microscope(SEM)image presented in Fig.2.

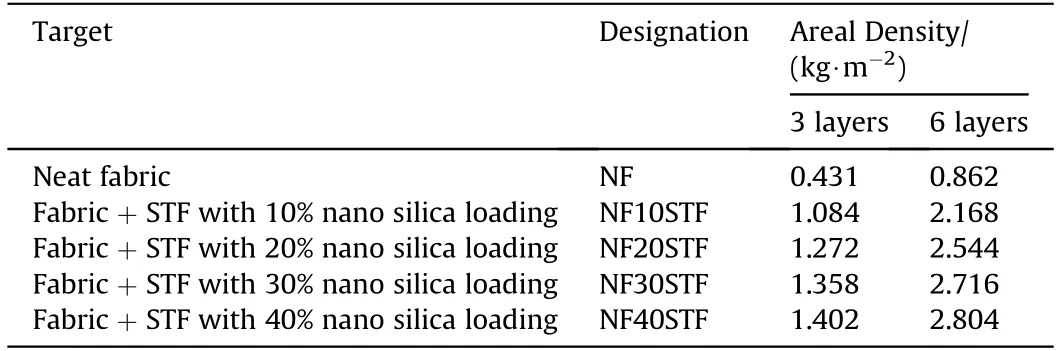

The areal densities of the prepared composites are determined and tabulated in Table 1.

Table 1Designation and areal densities of neat fabric and proposed composites.

2.3.Rheological study

The rheometer having a torque ranging from 0.01μN(yùn)·m to 300 mN·m,shear rate ranging from 0.01 to 2000 sand torque resolution of 0.1 nN·m is made use of to study the rheological behaviour of the prepared STF’s.The rheometer used in the present study is Anton Paar MCR501 stress controlled rheometer with cone-plate geometry of 75 mm diameter and 1angle.

2.4.Ballistic impact test

The ballistic impact testing was carried out according to National Institute of Justice(NIJ)standard 0108.01.The neat fabrics and the proposed composites with 3 layers and 6 layers of fabrics are subjected to ballistic loading using a gas gun apparatus in the velocity range of 15 m/s to 90 m/s at room temperature.Three tests were carried out on each sample and their average is taken as the result.The impact and residual velocity of the projectile was measured by means of a chronograph placed immediately before and after the target.The size of the target was kept at 150 mm×150 mm.The projectile used in the present study is conical in shape having a mass of 10 g,diameter of 10 mm,and overall length of 28 mm.The schematic representation of the apparatus is presented in Fig.3.

The energy absorbed(E)by the target during ballistic impact event is calculated using Eq.(1)and the Further,the energy absorption percentage(E)is calculated using Eq.(2)

Fig.1.Steps involved in preparation of jute-STF composites.

Fig.2.STF coating on jute fiber.

where,Eis the energy absorbed by the target in J,mis the mass of the projectile in kg,vand vare the impact and residual velocities in m/s

Fig.3.Schematic arrangement of gas gun.

3.Results and discussions

3.1.Rheological properties

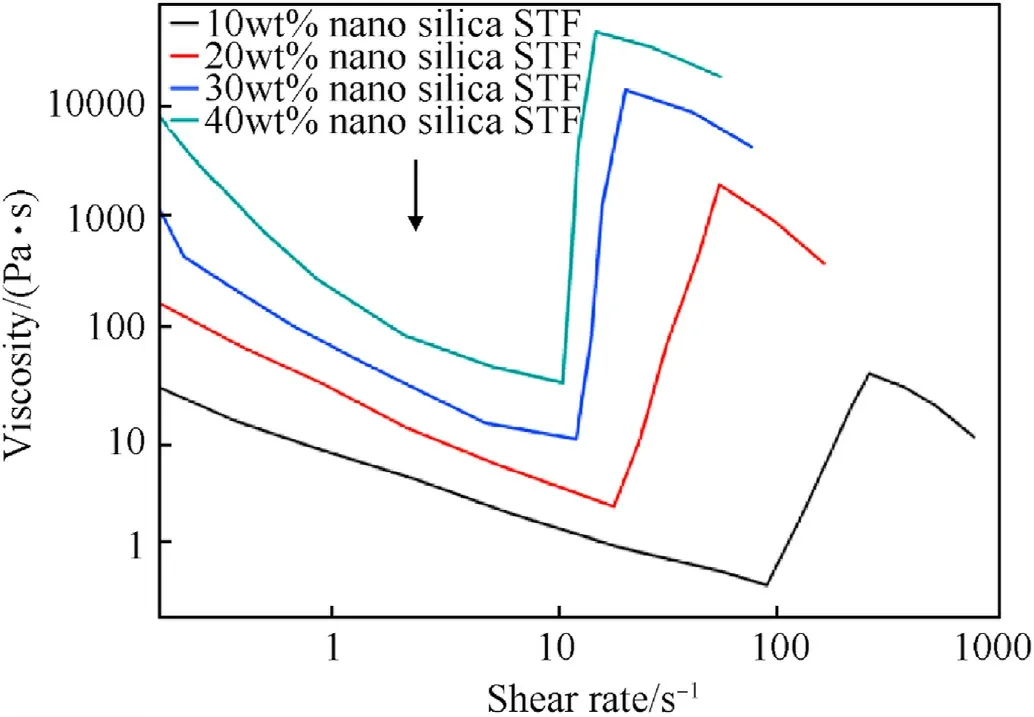

Rheological behaviour of the prepared STF’s are presented in Fig.4.

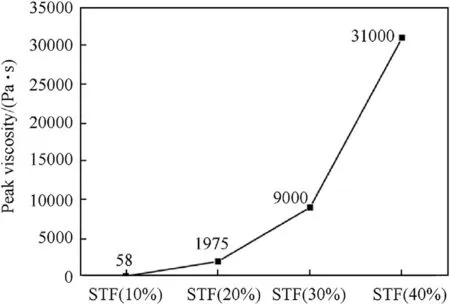

It can be seen that for all the prepared STF’s the response of viscosity to shear rate in non Newtonian,exhibits non linear behaviour and they also exhibit both shear thickening and shear thinning behaviour.Lower and higher shear rates witness the shear thinning and thickening respectively.The transition of the dispersed nano particles from equilibrium to agglomerated state represents the phenomenon of STF and it appreciably depends on the suspension’s volume fraction.A sudden increase in viscosity can be seen when the shear rate increases to critical value.The critical shear rate and nano silica loading are inversely proportional to each other as the amount of nano filler increases in the suspension,it restricts the movement of the fluid layers which results in enhanced viscosity.The critical shear rate for STF having 10%of nano silica loading is around 100 sand this critical shear rate value reduces as the percentage of nano silica loading is enhanced in the suspension and for the STF with 40%nano silica loading,the critical shear rate is found to be around 10 s.It can also be seen from Fig.2 that initial viscosity of the STF will be more with increased nano silica loading.The peak values of the STF’s with varied nano silica loading can be seen in Fig.5.

It can be seen from Fig.4 that as the weight percentage of nano silica loading increases,the peak viscosity of the corresponding STF is increased.The STF with 40 wt%of nano silica loading exhibits a peak viscosity of 31,000 Pa s which is approximately 534.5 times higher than the peak viscosity of STF with 10 wt%of nano silica loading.

Fig.4.Rheological behaviour of STF prepared using various weight percentage of nano silica.

3.2.Yarn pullout test

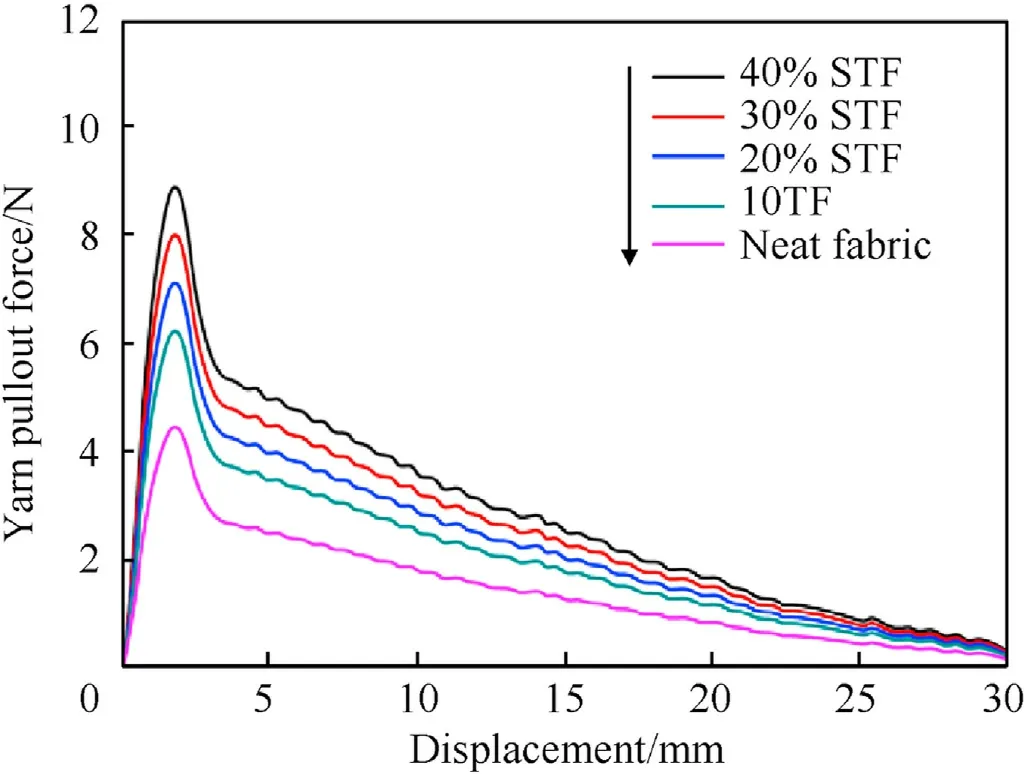

It is established form the previous literature[59]that fabric impregnated STF demonstrated increase in inter-yarn friction and this is the main cause of performance improvement of STF.

The concentration of additive nano particles in STF is effective in increasing the pull-out force.This means the inter-yarn friction increases by increasing particle loading.The in fluence of the impregnation on inter-yarn friction is investigated by yarn pull-out tests.

Fig.6 shows the single yarn pullout force against displacement for neat and impregnated fabrics.The tests were carried out at 100 mm/min.It can be seen that initially the pullout force increases as the yarn is progressively straightened until the peak point is reached.

Fig.5.Peak viscosities of STF’s with varied nano silica loading.

When the pull-out force surpasses the static friction limit,it drops gradually from the peak point and oscillates while the free end of the yarn passes each crossing yarn.The figure shows considerable higher attaining frictional load for the STF impregnated yarn.Thus,as the nano particle loading increases,the pull out force required to overcome the inter yarn friction also increases.

3.3.Ballistic impact test

3.3.1.Ballistic limit

Three and six layers of neat jute fabric and Jute/STF composites are subjected to ballistic loading.The samples are subjected to different impact velocities by means of varying the pressure in the gas gun in order to determine the ballistic limit of the neat fabrics and the composites.

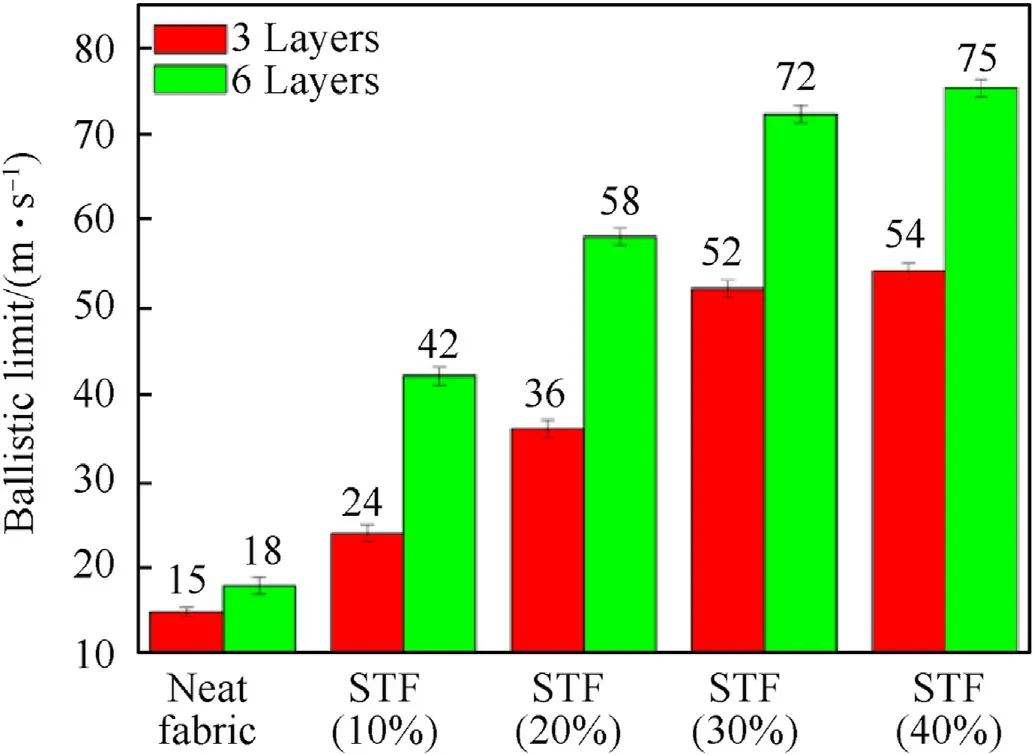

In order to determine the ballistic limit velocities,minimum of three highest partial penetration velocities and three minimum complete penetration velocities are used and their average provides the ballistic limit velocity of the particular target and projectile combination[60].This approach followed to determine the ballistic limit velocities experimentally are in line with the approach followed by Khodadadi et al.[61].Thus obtained ballistic limits for the neat fabrics and the proposed composites are presented in Fig.7.

It can be seen from Fig.7 that the ballistic limits of 6 layers of either neat fabric or proposed composites are better than the three layers.Also,it is found that impregnation of jute fabric in STF signi ficantly enhances the ballistic limits compared to neat fabrics.The ballistic limit of STF with 10 wt%nano silica loading is enhanced by 60%and 133.33%compared to neat fabric of 3 layers and 6 layers respectively.It is also found that the ballistic limit of the proposed composites increases signi ficantly with increase in nano silica loading up to 30 wt%.Further addition of nano silica loading results in very negligible increase in ballistic limits.This can be witnessed by comparing the ballistic limits of STF with 30 wt%nanosilica loading with ballistic limits of STF with 40 wt%nanosilica loading.The ballistic limit of STF with 40 wt%nanosilica loading with 3 layers and 6 layers is enhanced by merely 3.8%and 4.1%respectively when compared with ballistic limit of STF with 30 wt%nanosilica of 3 layers and 6 layers.

The addition of nanosilica loading to STF up to 30%results in enhanced friction between fibers leading to better arrangement,uniformity,consistency and leading to lesser gap,sliding,extracting and windowing when subjected to impact.Further addition of nano silica particles beyond 30 wt%results in diminishing of the STF effect due to high stress concentration between the fibers.

Fig.6.Single yarn pullout force against displacement for neat and impregnated fabrics.

Fig.7.Ballistic limits of the neat fabric and proposed composites(Error bars represent standard errors).

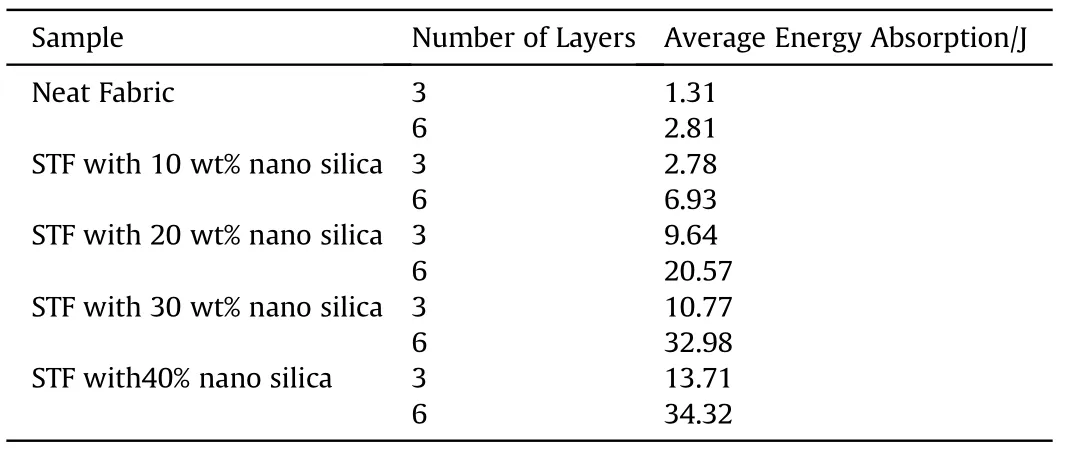

Once the ballistic limits are identi fied,the impact velocities for the respective targets are set above their ballistic limits to analyse the energy absorption behaviour of the respective targets.Table 2 presents the overview of the results obtained through ballistic impact testing.Each target is impacted thrice and their average is considered for the computation of results.It is evident from Table 2 that the average energy absorption of STF with 30 wt%nano silica and STF with 40 wt%nano silica are pretty much same,further investigation might be necessary to assess the behaviour of these composites.

Table 2 Energy absorption behaviour of the neat fabric and proposed composites.

Table 3 Comparison of ballistic limit of the proposed composites with the literature[62].

3.3.2.Speci fic energy absorption

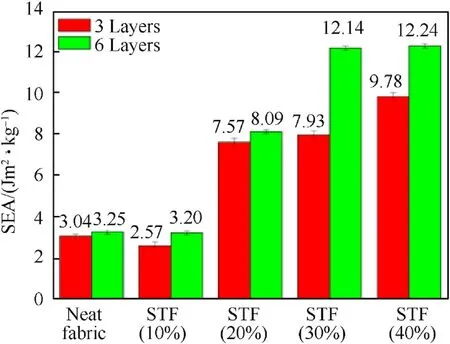

The SEA of the neat fabrics along with the proposed composites are presented in Fig.8.

It can be seen from Fig.8 that the SEA of the targets with 6 layers are more compared to targets with 3 layers.Also,the addition of STF results in enhanced SEA of the proposed composites.However it is noted that the composite with STF having 10 wt%nano silica loading exhibits SEA which is lesser than the neat fabrics though the energy absorption of the same composite is more than the neat fabric.This is due to the fact that addition of STF results in added weight compared to the neat fabric.Among all the targets considered,the composite comprising of STF with 40 wt%nano silica loading exhibits better SEA compared to its counterparts.The SEA of the composite comprising of STF with 40%nano silica loading is greater than 23.32%,29.2%and 280.5%compared to composites having STF with 30 wt%,20 wt%and 10 wt%nano silica loading respectively for 3 layers.The same in case of 6 layers are 0.01%,51.3%and 282.5%more compared to composites having STF with 30 wt%,20 wt%and 10 wt%nano silica loading.From this,it is clear that for 6 layers,the variation of SEA of composite with STF 30 wt%nano silica loading and STF 40 wt%nano silica loading are negligible.This indicates the usage of composite with STF 30 wt%nano silica loading seems to be reasonable.

Fig.8.SEA of the neat fabrics and proposed flexible composites(Error bars represent standard errors).

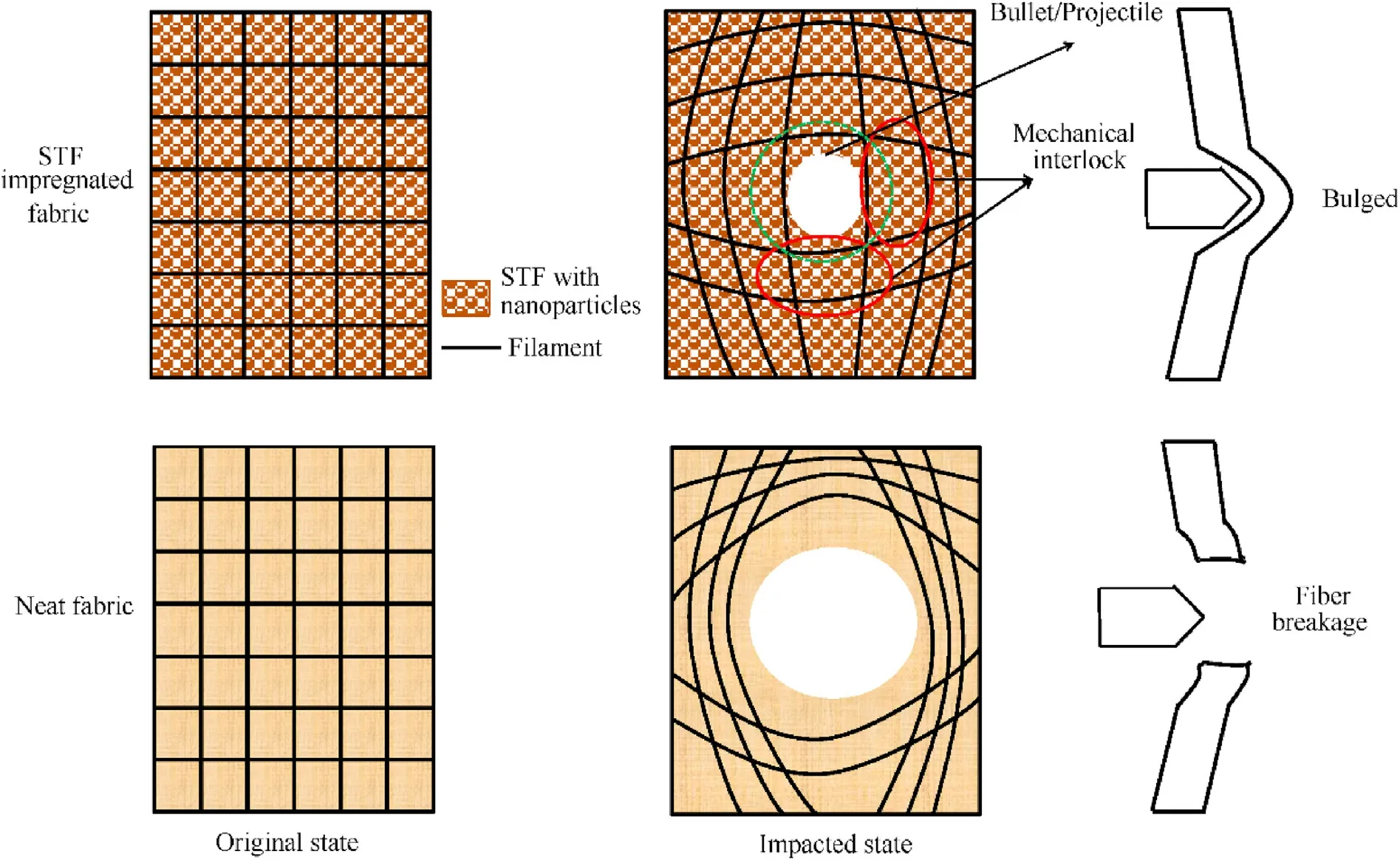

Fig.9.Proposed damage mechanisms of neat fabric and STF impregnated fabrics.

3.3.3.Fabric deformation behaviour

There are various mechanisms that contribute to energy absorption in case of neat fabrics and the proposed composites.The proposed damage mechanism in the neat fabric and the STF impregnated fabrics are shown in Fig.9.It can be seen that in case of neat fabrics,after the impact event,the distortion of the fibers are more since the mechanical interlocking as in case of STF impregnated fabrics are absent in case neat fabrics.This leads to fiber pullout and breakage at the early stage since the resistance offered by neat fabrics will be less compared to STF impregnated fabrics.In case of STF impregnated fabrics,the dispersion of STF is uniform leading to triggering of shear thickening behaviour when the fibers try to move during an impact event.This leads to enhanced resistance for the damage.At the point of impact,the compression leading to mechanical interlocking as shown in green circle.This leads to enhanced ballistic resistance of the STF impregnated fabrics.

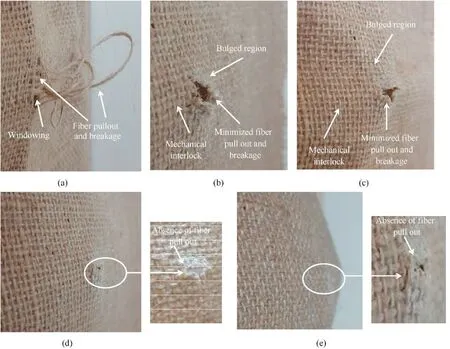

The most important factors such as yarn pullout,slippage and yarn breakage affects the energy absorption mechanism.Fig.10 shows the various targets including neat fabrics and proposed composites subjected to impact.It can be seen that the both the neat fabrics and the proposed composites exhibit the same global transverse de flection shapes.However when local structure of the fabrics at the impacted region is considered,it can be seen that they are distorted in case of neat fabrics and are well maintained in case of proposed composites.In case of neat fabrics windowing effects can be clearly seen bringing out the inability of jute fabric to engage secondary fabrics in energy absorbing during an impact event.As a result,the energy absorbing and damage resistance ability of the neat fabric remains low and hence signi ficant amount of yarn pullout is visible in case of neat fabrics.

However,in case of composites,where the fabrics are impregnated with STF,the fiber pullout is hardly visible.As the nano silica loading increases,the damage resistance of the composite is enhanced and also the region of damage becomes minimal.The increased frictional properties induced by STF impregnation restrict the movement of the yarns,thus encouraging neighbouring yarns to arrest the projectile.The STF impregnated fabrics are able to maintain their weave integrity during the impact process.It can be seen that in case of fabrics impregnated with STF having 30 wt%and 40 wt%nano silica loading there is no sign of yarn pull out.

Fig.10.Damage morphologies of(a)neat fabric and proposed composites with(b)STF+10 wt%nanosilica;(c)STF+20 wt%nanosilica;(d)STF+30 wt%nanosilica;(e)STF+40 wt%nanosilica.

3.3.4.Comparison of present work with literature

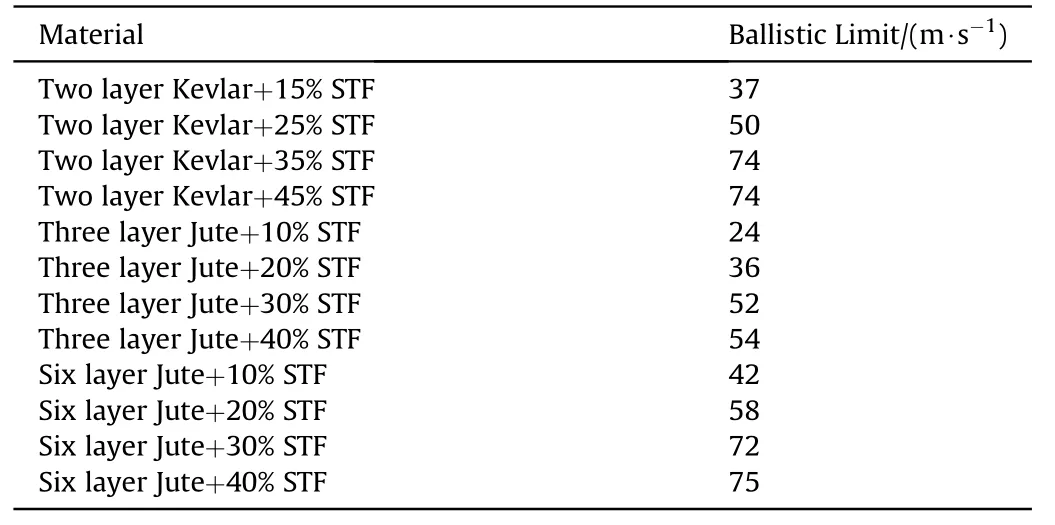

Table 3 presents the comparison of ballistic response of the proposed composites with the other materials available in literature.

The study carried out by Khodadadi et al.[62]showed that two layers of kevlar reinforced in 35%and 45%shear thickening fluid results in ballistic limit of 74 m/s.The composites proposed by the authors with six layers of jute along with 30%and 40%STF presents a ballistic limit of 72 m/s and 75 m/s respectively which are comparable to two layers of kevlar reinforced in 35%and 45%shear thickening fluid.Also,the six layers of jute with 10%STF exhibits a ballistic limit of 42 m/s which is better than two layers of kevlar with 15%STF.This shows that the proposed composites comprising of natural fiber can be better substitutes for similar composite with synthetic fiber provided the number of layers is increased.

4.Conclusions

Ballistic impact test is carried out on three and six layers of neat fabric and STF/Jute composite in order to assess their ballistic behaviour and the following conclusions are drawn upon:

·It is found that the energy absorption ability of the fabric is enhanced by impregnating the fabric with shear thickening fluid.The critical shear rate and nano silica loading are inversely proportional to each other.The peak viscosity of the STF is found to be dependent on the loading of nano silica particles in PEG.The STF with 40 wt%of nano silica loading exhibits a peak viscosity of 31,000 Pa S which is approximately 534.5 times higher than the peak viscosity of STF with 10 wt%of nano silica loading.

·It is found that increasing the nano silica loading from 10%to 30%,the ballistic behaviour of the fabrics are improved extraordinarily and there is an appreciable improvement in their performance with ballistic limit of 30 wt%nanosilica loading STF being enhanced by 116.6%and 71.42%for 3 and 6 layers respectively compared to 10 wt%of nano silica loading STF.However,this rate of improvement in ballistic performance is very little when the nano silica loading is increased from 30%to 40%with the enhancement being merely 3.8%and 4.1%for 3 and 6 layers respectively.

·Yarn pull-out tests were also carried out neat and impregnated jute fabrics.By increasing the nano particles loading a notable increase of pull-out force was shown,which indicates the effect of friction.On the other hand,by increasing nanosilica loading from 30 to 40 wt%,the energy absorption of composite doesn’t vary signi ficantly which means the yarn pull-out force doesn’t affect the energy absorption directly and shows the different effect of friction in static and impact forces.

·The deformation behaviour of the neat fabrics and proposed composites shows that in case of neat fabrics,after the impact event,the distortion of the fibers are more since the mechanical interlocking as in case of STF impregnated fabrics are absent in case neat fabrics.This leads to fiber pullout and breakage at the early stage since the resistance offered by neat fabrics will be less compared to STF impregnated fabrics.In case of STF impregnated fabrics,the dispersion of STF is uniform leading to triggering of shear thickening behaviour when the fibers try to move during an impact event.This leads to enhanced resistance for the damage

·In case of neat fabrics windowing effects can be clearly seen bringing out the inability of jute fabric to engage secondary fabrics in energy absorbing during an impact event.As a result,the energy absorbing and damage resistance ability of the neat fabric remains low and hence signi ficant amount of yarn pullout is visible in case of neat fabrics.However,in case of composites,where the fabrics are impregnated with STF,the fiber pullout is hardly visible.As the nano silica loading increases,the damage resistance of the composite is enhanced and also the region of damage becomes minimal.

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to in fluence the work reported in this paper.

- Defence Technology的其它文章

- High explosive unexploded ordnance neutralization-Tallboy air bomb case study

- Dynamics and rebound behavior analysis of flexible tethered satellite system in deployment and station-keeping phases

- Finite element analysis of functionally graded sandwich plates with porosity via a new hyperbolic shear deformation theory

- Investigation on the penetration of jacketed rods with striking velocities of 0.9-3.3 km/s into semi-in finite targets

- The effect of strain rate on compressive behavior and failure mechanism of CMDB propellant

- Adaptive target and jamming recognition for the pulse doppler radar fuze based on a time-frequency joint feature and an online-updated naive bayesian classi fier with minimal risk