Enzyme-Induced Carbonate Precipitation for the Protection of Earthen Dikes and Embankments Under Surface Runoff: Laboratory Investigations

HE Jia, FANG Changhang, MAO Xunyu, QI Yongshuai, ZHOU Yundong, KOU Hailei, and XIAO Liang

Enzyme-Induced Carbonate Precipitation for the Protection of Earthen Dikes and Embankments Under Surface Runoff: Laboratory Investigations

HE Jia1), FANG Changhang1), MAO Xunyu1), QI Yongshuai1), ZHOU Yundong1), KOU Hailei2), *, and XIAO Liang3)

1) Key Laboratory of Ministry of Education for Geomechanics and Embankment Engineering, Hohai University, Nanjing 210098, China 2) College of Engineering, Ocean University of China, Qingdao 266100, China 3) Department of Finance and Audit, Army Logistics University, Chongqing 401331, China

Earthen structures such as shore protection dikes and river embankments easily suffer from erosion under surface water runoff. This study made experimental efforts to explore the enzyme-induced carbonate precipitation (EICP) method for slope erosion control under surface runoff for earthen structures. The sandy soils were treated by the EICP method for various rounds. Surface characteristics were evaluated by the surface penetration resistance, calcium carbonate content, and surface hard crust thickness of EICP-treated soils. Slope runoff erosion experiments were carried out to evaluate the erosion control performances of the EICP treatment. The surface penetration resistance, calcium carbonate content, and surface hard crust thickness were found to significantly increase with the treatment rounds. In the erosion experiments, it was observed that the level of damages decreased and the water flow volume required to trigger the damage increased with more treatments. The increase in the soil slope angle led to more serious surface damages. The amount and rate that the soil particles were eroded from the slope surfaces declined with more EICP treatments, which was consistent with those of visual observations. The preliminary investigations presented in this study have shown the potential of the EICP method for slope erosion control under surface runoff for earthen structures.

enzyme-induced carbonate precipitation; urease; erosion; soil slope

1 Introduction

Earthen structures such as shore protection dikes and river embankments are easily affected by various forms of erosions. At seashore regions, the erosions of sea dikes and beach sand can be induced by rainfall, storms, water flow, tide fluctuation, etc. These forms of erosion can lead to the damages of shore protection systems, loss of soil resources, and other safety and ecological issues (Salifu, 2016; Ghasemi, 2019; Imran, 2019; Dary-ono, 2020; Shahin, 2020). Due to global warming and the rise of sea level, erosion and deterioration at seashore areas are becoming more severe (Daryono, 2020). Countermeasures against water erosion in earthen structures include engineering protections and plant protections (Wang, 2003). Engineering protections generally include cement mortar plastering, shotcrete, and stone and concrete surface protection. There are some limitations in engineering protection measures. A large amount of rain-water directly runs off the slope without vegetation coverage, leading to serious erosion of soils outside the protected area. The engineering materials are not aesthetic. There are also other problems such as material weathering and corrosion in the long term. Plant protections include planting grasses, bushes, and trees. The plants on the earthen slopes can strengthen the soil mechanically and improve the stability of soil slopes. In addition, vegetation can adjust the near-surface climates and surface hydrological conditions to reduce soil erosion. Vegetations can also regulate the local environment and have aesthetic benefits. The combination of engineering and vegetation protection measures can reduce soil erosion. However, the cost of plant protection is relatively high. The slope angle is sometimes too high for plant growth.

In recent years, soil modification technologies based on biological processes have gained increasing interests for strengthening and erosion control in soils and earthen structures (Salifu, 2016; Amin, 2017; Wang, 2018; Jiang, 2019; Shahin, 2020; Wang, 2020). Using these biological methods can potentially bring more technical and environmental benefits to engineering projects. Several microbial processes have been tested for related applications. Bio-mineralization in the soil can produce cementitious mineral crystals in soil pores, which consequently enhance the shear strength greatly and reducethe permeability of soils (DeJong, 2010; Van Paassen, 2010; Chu, 2012; Al Qabany and Soga, 2013). Extracellular polymeric substances (EPSs), which are slime-type materials excreted by some soil microbial species, can reduce the soil permeability by around two orders of magnitude (Ivanov and Chu, 2008; Thullner, 2010; Proto, 2016). It has been reported that the leakage in earth dikes can be effectively controlled by facilitating thegrowth of bacteria for EPS production (Blauw, 2009).Among these microbial methods, bio-mineralization based on the enzyme- or microbially-induced carbonate precipitation (EICP or MICP) by the ureolytic process has received most of the research focus. The reaction involves the hydrolyzation of urea into ammonia and carbonate. With the aqueous calcium in the system, calcium carbonate can be precipitated in the soil as,

Calcium carbonate can form crystals and bring strong and persistent cementation effects between soil particles. The mechanical properties of soils can thus be greatly improved.

Many previous studies demonstrated that the MICP method could successfully enhance the strength and reduce the permeability of soils (Ivanov and Chu, 2008; DeJong, 2010, 2013; Van Paassen, 2010; Dhami, 2013; Xiao, 2018; Gao, 2019a; Wu, 2019a; Wu, 2019b; Xiao, 2019). The EICP method using the urease enzyme was also effective in enhancing the strength and mechanical properties of sand (Neupane, 2013, 2015; Zhao, 2014; Hamdan and Ka- vazanjian, 2016; Jiang, 2016). Urease is the enzyme that catalyzes the hydrolyzation of urea. It plays a key role in the MICP and EICP methods. In the MICP method, urease is present in or on the live bacterial cells. In the EICP method, urease is obtained from ureolytic bacteria or some types of plant seeds, such as soybeans, jack beans, and watermelon seeds. In some research studies, laboratory-grade urease was used to induce a cementation effect (Neupane, 2013, 2015; Zhao, 2014;Hamdan and Ka- vazanjian, 2016; Jiang, 2016). Laboratory-grade urease is usually used for research and medical purposes, and it is expensive to be used in large-scale applications. Alternatively, crude urease can be extracted from the lysis of bacterial or plant cells (Park, 2014; Dilrukshi, 2018; Gao, 2019b; He, 2020; Cui, 2021). The cell lysis or the destruction of cells can be achieved by applying some external force or conditions, such as chemical reactions, osmotic pressure, electrolysis, ultrasonic waves,or mechanical forces (Brown and Audet, 2008). Such techniques are often used for the extraction and purification of cell ingredients, including enzymes, DNA, and organelles. In recent studies, crude urease has been successfully obtained from soybean using the mechanical grinding method (Gao, 2019b) and from ureolytic bacteria using the ultrasonic method (He, 2020). The advantages and limitations of the EICP and the MICP methods are of research and practical interest. In the MICP method, the urea- hydrolyzing activity of live cells is more stable during the reaction (Gao, 2019b; He, 2020). However, for the treatment of soils with fine particles, the EICP method has advantages because of the larger treatment range and more treatment uniformity (Gao, 2019b; He, 2020). The EICP method based on plant-derived urease avoids the efforts of bacterial cultivation, which reduces the workload and the level of complexity (Gao, 2019b).

For the soil erosion control with biological methods, several forms of erosion have been investigated in research studies, including surface runoff erosion on soil slopes (Amin, 2017; Wang, 2018; Cuccurullo, 2019; Ghasemi, 2019; Ossai, 2020), raindrop erosion on soils (Jiang, 2019; Shih, 2019; Bian, 2020; Wang, 2020), coastal and sea dike erosion by waves and tidal changes (Salifu, 2016; Sha- nahan and Montaya, 2016; Shahin, 2020), soil internal erosion under water seepage (Jiang and Soga, 2017; Jiang, 2017), wind erosion (Hamdan and Kavazanjian, 2016), and chemical erosion and erosion due to changes in temperatures and moisture conditions (Liu, 2019). In a surface runoff erosion test using an erosion function apparatus (EFA), it was found that the sand treated by the MICP method led to a 95% reduction in erodibility and a five-fold increase in the critical shear stress relative to the untreated sand (Amin, 2017). Wang(2018) used a polymer-modified MICP method for surficial soil stabilization and found that the critical shear stress of the treated sand is over 500 times higher than that of the untreated sand. Although most of these studies adopted the MICP method based on live bacteria, there were a few studies related to soil erosion control where the EICP method was adopted (Amin, 2017; Ossai, 2020).

This paper performed experimental studies to explore the EICP method for soil slope erosion control under surface runoff. The sandy soils were treated by the EICP method for various rounds. Surface characteristics experiments and slope runoff erosion experiments were carried out to evaluate the treatment effects and erosion control performances. To the authors’ knowledge, the EICP method for surface runoff erosion control has not been studied in the past.

2 Materials and Methods

2.1 Materials

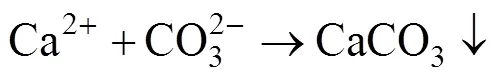

The testing soil used in the study was Fujian Sand, which was the sea sand collected from Pingtan, Fujian, China. It is a type of Chinese standard sand with an angular particle shape and more than 96% quartz content. Fig.1 shows the particle size distribution.

Fig.1 Particle size distribution of the testing soil.

The soil treatment with the EICP method required calcium salt, urea, and urease enzyme. Calcium chloride and urea used in the experiments were laboratory-grade reagents. The soybean purchased from the market was used for the extraction of crude urease. The soybeans were dried in a 40℃ oven for six hours and were then ground into powder using a kitchen grinder. The soybean powders were stored in a 4℃ refrigerator before use. The soybean powders were added into deionized water at 25gL?1concentration and mixed in water using a magnetic stirrer to obtain a homogeneous suspension. The suspension was placed for 3h to release the urease enzyme into a liquid phase. The suspension was then filtered with double-layer cotton gauze. The filtered liquid was further centrifuged at 3000rmin?1and at 4℃ for 15min. After centrifugation, the clean supernatant liquid containing the crude urease was used for the soil treatment. The urease liquid prepared in this way had a urea-hydrolyzing activity of around 4.4mmolL?1min?1.

2.2 Soil Sample Preparation and EICP Treatments

The soil samples for the surface characteristics experiments were prepared in plastic trays with a size dimension of 24cm×16cm×4.5cm (length×width×depth). The soil samples for the slope erosion experiments were prepared in a specially designed apparatus, as shown in Fig.2. The size of the samples was 36cm×20cm×4.0cm (length×width×depth). In both types of experiments, the sandy soil was compacted into the tray to a dry density of 1.8gcm?3.

The EICP treatment required the use of calcium chloride, urea, and urease enzyme liquid. The soil treatment liquid contained a half-volume of urease enzyme liquid and a half-volume equimolar calcium chloride-urea solution. The two liquids were mixed together right before applying to soil surfaces. After mixing, the concentration of calcium chloride and urea was 0.5molL?1, and the pH was 7–8. The treatment liquid was uniformly applied to the soil surface by a hand sprayer. In each treatment round, the volume of the treatment liquid used was 4Lm?2. The treatment liquid is retained at the soil surface for 24h before the next round of treatment. For surface characteristics experiments and slope erosion experiments, the soil samples received 1 to 4 treatment rounds. The selection of these soil treatment parameters was based on previous studies and some preliminary trial tests (Gao, 2019a, b). The objective of the treatment is to obtain relatively high soil strengths, high reaction conversion rates, and reduced treatment time duration. After the EICP treatment, a hard crust layer could be formed on the surface, which had relatively high strength and strong resistance to erosion.

Fig.2 Slope erosion test apparatus. (a), photograph of the test; (b), schematic illustration of the model box.

2.3 Surface Characteristics Experiment

The surface characteristics experiments focused on the physical and mechanical properties of the sand surfaces after the EICP treatment. Four samples were prepared and received 1 to 4 treatment rounds. After the treatments, the surface strength was measured using a flat-bottom penetrometer with a diameter of 5mm. The penetrometer was pushed into the soil at a rate of 2.5mms?1. The maximum value during the penetration was recorded as the penetration resistance. Penetration resistances were first measured after the surfaces were dried in a natural environment. The soil samples were then immersed in water for 12h before the next measurement of penetration resistance. Comparisons were made between the penetration resistances in the two conditions. In addition, the calcium carbonate content and thickness of the biocemented hard crust were measured.

For the measurement of calcium carbonate content, small pieces of soil were taken from the soil samples. The soil pieces were rinsed in deionized water and dried to remove the soluble salts. Each piece of soil was then placed in hydrochloric acid to dissolve all the CaCO3. The concentration of aqueous calcium in the hydrochloric acid was measured using the EDTA titrimetric method (ISO, 1984), which was found to be consistent with the calcium carbonate content in the soil.

2.4 Slope Erosion Experiment

A specially designed apparatus was adopted for the slope erosion experiments (Fig.2) The soil samples were prepared in a flat tray of 36cm×20cm×4cm (length×width×depth) in size. The angle of the soil could be adjusted for different tests. The surface flow for the erosion experiments was applied from the top of the slope through some small holes with a flow rate of 2Lmin?1(Figs.2(a) and (b)). The eroded soil particles were collected at the toe of the slope during the experiments. These soil particles were dried and weighed to evaluate surface erosion. The water flow continued until the complete destruction of the soil samples or for two hours if there was no significant destruction. Photographs were taken to investigate the surface erosion modes. The flow velocities on the sand surfaces were measured using a color dye method. A high-speed camera was used to track the color dye flow in the water runoff on the soil surface. For the measurement of the flow velocity at different heights, the slope was divided into three equal parts from the top down, and the measurements were carried out at all three parts. Calcium carbonate contents were also measured after the erosion tests. Eight tests were conducted with varying treatment round sand slope angles. Table 1 shows the testing program.

Table 1 Testing program

3 Results and Discussion

3.1 Surface Characteristics

After the EICP treatments, the properties of soil surfaces were characterized by measuring the surface penetration resistance, the calcium carbonate content, and the thickness of the hard crust. Fig.3 presents the surface penetration resistance values under dry and wet conditions. Results show that the penetration resistances improved greatly with the treatment rounds. The penetration resistances increased to 92.1N and 71.5N at dry and wet conditions after four rounds of treatments, respectively. These values were 7.7- and 11.3-time improvements compared with those with one treatment round. The penetration resistance values under wet conditions were lower than those under dry conditions. However, the level of reduction due to immersion alleviated with more treatment rounds. The penetration resistance values reduced by 47.6%, 33.6%, 30.0%, and 22.4% after immersion in water in the soil samples with 1, 2, 3, and 4 treatment rounds, respectively. The reduced penetration resistance values after wetting could be due to the presence of soluble salts in the soil samples. It was reported that the soluble salts in dry soil could greatly enhance the unconfined compression strength of soil compared with that of the counterpart under a wet condition (He and Chu, 2017). These results indicated that soil samples with a higher level of EICP treatments were more stable to water immersion.

Fig.3 Penetration resistance values in the surface characteristics test.

Fig.4 presents the results of calcium carbonate content and crust thickness. After four rounds of EICP treatments, the calcium carbonate content was 1.4%, which was a 7-time improvement compared to the sample with one treatment. As for the hard crust formed by calcium carbonate cementation, the thickness increased from 7mm to 17mm from one treatment round to four treatment rounds, which shows a 2.4-times improvement. The results implied that with more treatment rounds, the hard crusts did not only become thicker, but they also gained a higher calcium carbonate content. Both the increase in hard crust thickness and calcium carbonate content resulted in higher surface strength and penetration resistance, which might consequently enhance the resistance to runoff erosion.

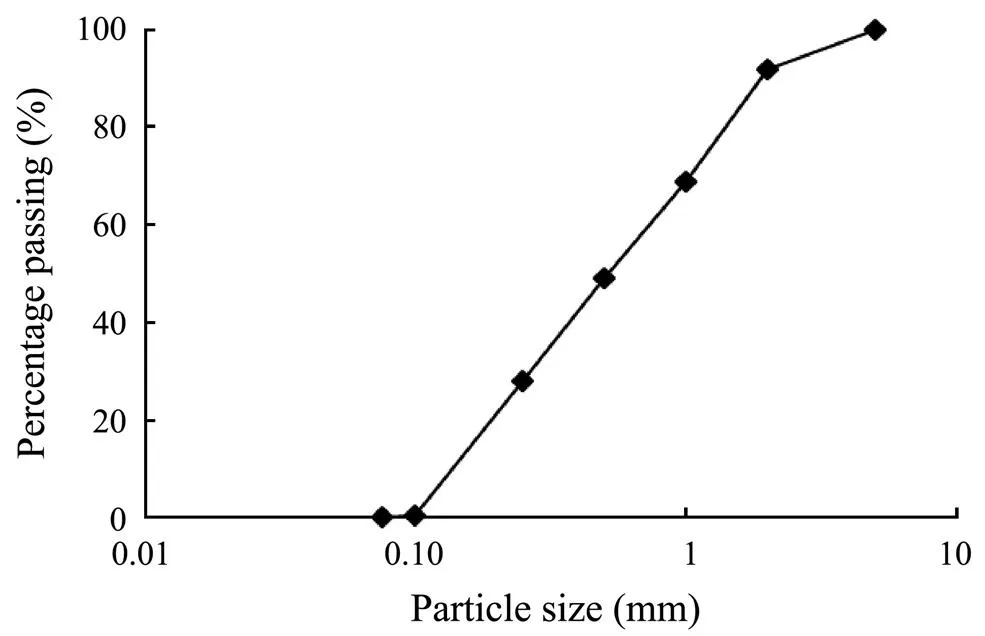

3.2 Slope Erosion Modes

Figs.5 and 6 present the soil conditions during surface runoff erosion. Figs.5(a)–(e) correspond to soil samples with no treatment, and 1–4 treatment rounds (TC-0-30, TE-1-30, TE-2-30, TE-3-30, and TE-4-30), respectively. In the untreated soil sample, the water flow quickly eroded the soil particles and formed a concentrated flow channel. The soil sample destructed completely several minutes after the start of the test. With 1 and 2 treatment rounds, the soil surfaces started to show sizable damages at the corners around half an hour or one hour after the start of the tests for TE-1-30 and TE-2-30, respectively. Meanwhile, only small damages until the end tests were observed for soil samples with 3 and 4 treatment rounds.

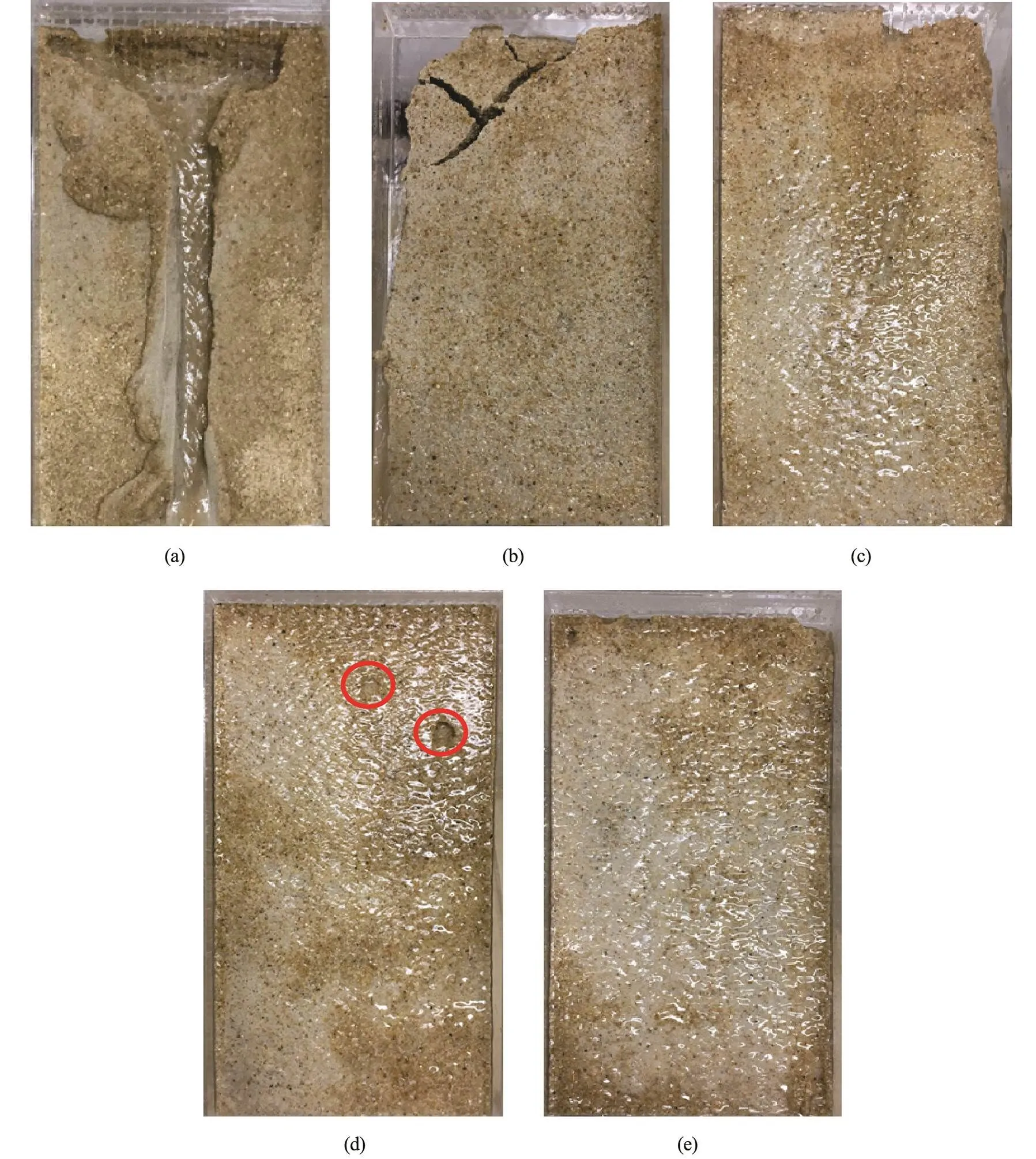

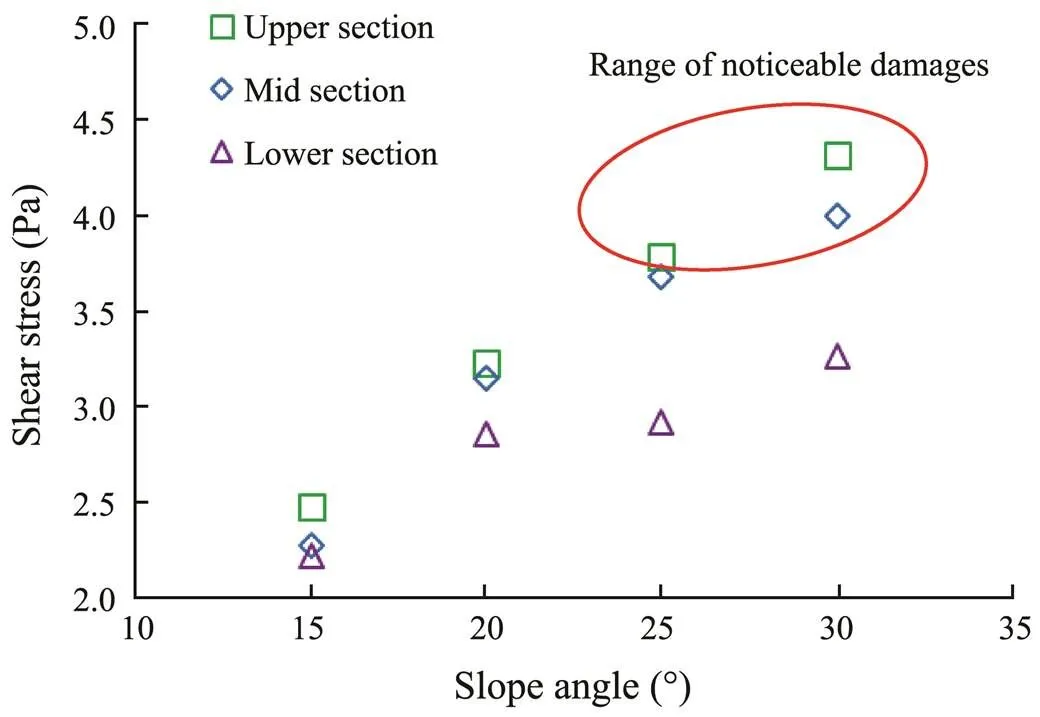

Fig.6 displays the images of the four soil samples tested under different slope angles. The soil samples tested under 15? and 20? angles (TE-3-15 and TE-3-20) were almost intact without noticeable damage. The soil samples tested under 25? and 30? angles (TE-3-25 and TE-3-30) have some slight damages, but the overall shapes of the samples remained the same. This was related to the flow velocities on different soil samples. A higher slope angle leads to a faster flow velocity, which in turn causes larger hydraulic shear stress acting on the soil surface (Amin, 2017; Wang, 2018).

Fig.4 Calcium carbonate content and crust thickness in the surface characteristics test.

Fig.5 Surface erosion conditions of soil samples with various treatment rounds. (a), TC-0-30 at 2min; (b), TE-1-30 at 34min; (c), TE-2-30 at 70min; (d), TE-3-30 at 103min; and (e), TE-4-30 at 2h.

Fig.6 Surface erosion conditions of soil samples tested under different slope angles. (a), TE-3-15 at 2h; (b), TE-3-20 at 2h; (c), TE-3-25 at 2h; and (d), TE-3-30 at 2h.

3.3 Erosion Process

Figs.7 and 8 present the amounts of eroded soil particles with time. There are four soil samples with different treatment rounds in Fig.7. The rate that the soil eroded from the surfaces decreased with the increased number of treatment rounds. The soil samples in TE-1-30 and TE-2-30 (the samples with 1 and 2 treatment rounds) showed gradual increases in the erosion rates and finally led to an uncontrollable form of collapse. The erosion rates in TE-3-30 and TE-4-30 (the samples with 3 and 4 treatment rounds) gradually slowed down and the erosion came to a halt when approaching the end of the tests. In this form of erosion, only weakly cemented soil particles on the surface were eroded and the overall shapes of the soils were intact. As for the soil sample with no treatment (TC-0-30), the soil particles’ erosion rate was too fast to measure, as could be seen in Fig.5(a). Thus, there was no data obtained for TC-0-30.

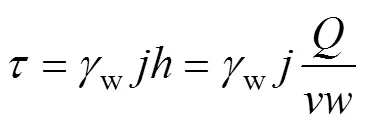

Fig.8 shows four soil samples tested under different slope angles, which all received the same level of EICP treatments. Thus, the levels of cementation on the soil surfaces were the same. It could be seen that the rate that soil eroded from the surfaces increased with the slope angles, although the levels of damages in the soil samples were not serious. Under surface water runoff, the soil condition (damaged or not) was related to the shear stress induced by hydraulic forces. In the tested condition, the shear stress could be calculated as (Zhang, 2004)

where γw is the unit weight of water, j is the hydraulic gradient (sine of slope angles here), h is the water depth, Q is the water flow quantity, v is the flow velocity, and w is the soil sample width. It should be noted that the flow velocity v measured here is that on the surface of the water. For the estimation of flow velocity at the soil-water interface, the measured velocity needed to be multiplied by a factor of 0.75 according to fluid mechanics (Zhang et al., 2004). Fig.9 presents the calculated shear stresses in the soil samples under different slope angles. The runoff-induced shear stress increased with slope angles. Thus, the soil sample tested under a higher slope angle had more eroded particles (Fig.8). For the same soil sample, the upper range of the soil received higher shear stress according to the calculation results. This was consistent with the experimental findings that the upper range of the soil was damaged easily, as shown in the circled region in Fig.9 and in photographs shown in Fig.6. It should be noted that the shear stress given in Eq. (3) was only applicable to soil samples with no or slight damages. If there were serious damages on the soil, the surface flow was not uniform and Eq. (3) was no longer applicable.

Fig.8 Time evolution of eroded soil mass for soil samples tested under different slope angles.

Fig.9 Hydraulic shear stress in relation to the slope angle.

3.4 Calcium Carbonate Content

After the surface erosion tests, the calcium carbonate contents in the soil samples were measured, as shown in Fig.10. The calcium carbonate content increased with the treatment rounds. It is also evident that after surface runoff erosion, the calcium carbonate content slightly decreased compared with that of the soil samples before the erosion tests (see Fig.4). This indicates that some calcium carbonate in the soil eroded together with the eroded soil particles.

Fig.10 Calcium carbonate content after runoff erosion.

4 Conclusions

In this paper, experimental studies were made to explore the EICP method for soil slope erosion control under surface runoff. The following conclusions can be drawn:

1) In the surface characteristics experiments, the surface penetration resistance, calcium carbonate content, and surface hard crust thickness significantly increased with the treatment rounds. The penetration resistance decreased after immersion in water. However, the percentage of decrease became less with more treatment rounds.

2) According to the visual observation in the slope surface erosion experiments, the level of damages decreased and the water flow volume required to trigger the damage increased with more treatments. The increase in the soil slope angle led to more serious surface damages. For the soil samples with three or more treatment rounds, the overall shapes of the soil remained the same with slight or no damages.

3) The amount and rate that the soil particles were eroded from the slope surfaces declined with more EICP treatments, which was consistent with that of visual observations. For samples with the same treatment levels, the increase in the slope angle led to higher shear stress and a more eroded soil mass.

4) After the erosion experiments, calcium carbonate in samples with EICP treatment still existed. Higher calcium carbonate content was retained as the number of treatment rounds increased.

Acknowledgements

This work was financially supported by the National Na- tural Science Foundation of China (Nos. 51978244, 51979088, 52078188 and 51879246).

Al Qabany, A., and Soga, K., 2013. Effect of chemical treatment used in MICP on engineering properties of cemented soils. G, 63 (4): 331-339.

Amin, M., Zomorodian, S. M. A., and O’Kelly, B. C., 2017. Reducing the hydraulic erosion of sand using microbial-induced carbonate precipitation., 170 (GI2): 112-122.

Bian, X., Cui, Y. J., Zeng, L. L., and Li, X. Z., 2020. State of compacted bentonite inside a fractured granite cylinder after infiltration., 186: 105438.

Blauw, M., Lambert, J. W. M., and Latil, M. N., 2009. Biosealing: A method forsealing of leakages.. Singapore, 125-130.

Brown, R. B., and Audet, J., 2008. Current techniques for single-cell lysis., 5: 131-138.

Chu, J., Stabnikov, V., and Ivanov, V., 2012. Microbially induced calcium carbonate precipitation on surface or in the bulk of soil., 29 (6): 544-549.

Cuccurullo, A., Gallipoli, D., Bruno, A. W., Augarde, C., and Borderie, C. L., 2019.Springer, Switzerland, 753-762.

Cui, M. J., Lai, H. J., Hoang, T., and Chu, J., 2021. One-phase-low-pH enzyme induced carbonate precipitation (EICP) methodfor soil improvement., 16: 481-489, https://doi.org/10.1007/s114 40-020-01043-2.

Daryono, L., Nakashama, K., Kawasaki, S., Suzuki., K., Suyanto, I., and Rahmadi, A., 2020. Investigation of natural beachrock and physical-mechanical comparison with artificial beachrock induced by MICP as a protective measure against beach erosion at Yogyakarta, Indonesia., 10 (4): 143.

DeJong, J. T., Mortensen, B. M., Martinez, B. C., and Nelson, D. C., 2010. Bio-mediated soil improvement., 36 (2): 197-210.

DeJong, J. T., Soga, K., Kavazanjian, E., Burns, S., Van Paassen, L. A., Al Qabany, A.,, 2013. Biogeochemical processes and geotechnical applications: Progress, opportunities and challenges., 63 (4): 287-301.

Dhami, N. K., Reddy, M. S., and Mukherjee, A., 2013. Biomineralization of calcium carbonates and their engineered applications: A review., 4: 314-314.

Dilrukshi, R. A. N., Nakashima, K., and Kawasaki, S., 2018. Soil improvement using plant-derived urease-induced calcium carbonate precipitation., 58 (4): 894-910.

Gao, Y. F., Hang, L., He, J., and Chu, J., 2019a. Mechanical behaviour of biocemented sands at various treatment levels and relative densities., 14 (3): 697-707.

Gao, Y. F., He, J., Tang, X. Y., and Chu, J., 2019b. Calcium carbonate precipitation catalyzed by soybean urease as an improvement method for fine-grained soil., 59 (5): 1631-1637.

Ghasemi, P., Zamani, A., and Montoya, B., 2019. The effect of chemical concentration on the strength and erodibility of MICP treated sands.. Reston, Geo-Congress GSP, 309: 241-249.

Hamdan, N., and Kavazanjian, E. J., 2016. Enzyme-induced carbonate mineral precipitation for fugitive dust control., 66 (7): 546-555.

He, J., and Chu, J., 2017. Cementation of sand due to salt precipitation in drying process., 35 (3): 441-445.

He, J., Gao, Y. F., Gu, Z. X., Chu, J., and Wang, L. Y., 2020. Characterization of crude bacterial urease for CaCO3precipitation and cementation of silty sand., 32 (5): 04020071.

Imran, M. A., Kimura, S., Nakashima, K., Evelpidou, N., and Kawasaki, S., 2019. Feasibility study of native ureolytic bacteria for biocementation towards coastal erosion protection by MICP method., 9 (20): 4462.

International Organization for Standardization (ISO), 1984. Water quality–Determination of calcium content–EDTA titrimetric method. ISO 6058:1984.

Ivanov, V., and Chu, J., 2008. Applications of microorganisms to geotechnical engineering for bioclogging and biocementation of soil., 7 (2): 139-153.

Jiang, N. J., and Soga, K., 2017. The applicability of microbially induced calcite precipitation (MICP) for internal erosion control in gravel-sand mixtures., 67(1): 42-55.

Jiang, N. J., Soga, K., and Kuo, M., 2017.Microbially induced carbonate precipitation for seepage-induced internal erosion control in sand-clay mixtures.,143(3):04016100.

Jiang, N. J., Tang, C., Yin, L., Xie, Y., and Shi, B., 2019. Applicability of microbial calcification method for sandy-slope surface erosion control., 31 (11): 04019250.

Jiang, N. J., Yoshioka, H., Yamamoto, K., and Soga, K., 2016. Ureolytic activities of a urease-producing bacterium and purified urease enzyme in the anoxic condition: Implication for subseafloor sand production control by microbially induced carbonate precipitation (MICP)., 90: 96-104.

Liu, S., Wen, K., Armwood, C., Bu, C., and Li, L., 2019. Enhancement of micp-treated sandy soils against environmental deterioration., 31 (12): 04019294.

Neupane, D., Yasuhara, H., Kinoshita, N., and Ando, Y., 2015. Distribution of mineralized carbonate and its quantification method in enzyme mediated calcite precipitation technique., 55(2): 447-457.

Neupane, D., Yasuhara, H., Kinoshita, N., and Unno, T., 2013.Applicability of enzymatic calcium carbonate precipitation as a soil-strengthening technique., 139(12): 2201-2211.

Ossai, R., Rivera, L., and Bandini, P., 2020. Experimental study to determine an EICP application method feasible for field treatment for soil erosion control.. American Society of Civil Engineers, Reston, 205-213.

Park, S. S., Choi, S. G., and Nam, I. H., 2014. Effect of plant-induced calcite precipitation on the strength of sand., 26 (8): 06014017.

Proto, C. J., Dejong, J. T., and Nelson, D. C., 2016. Biomediated permeability reduction of saturated sands., 142(12): 04016073.

Salifu, E., Maclachlan, E., Iyer, K. R., Knapp, C. W., and Tarantino, A., 2016. Application of microbially induced calcite precipitation in erosion mitigation and stabilisation of sandy soil foreshore slopes: A preliminary investigation., 201 (4): 96-105.

Shahin, M. A., Jamieson, K., and Cheng, L., 2020. Microbial-induced carbonate precipitation for coastal erosion mitigation of sandy slopes., 10 (2): 1-5.

Shanahan, C., and Montoya, B. M., 2016. Erosion reduction of coastal sands using microbial induced calcite precipitation.. American Society of Civil Engineers, Reston, 42-51.

Shih, D. S., Lai, T. Y., and Hsu, Z. M., 2019. Applying biomineralization technology to study the effects of rainfall induced soil erosion., 11(12): 1-15.

Thullner, M., 2010. Comparison of bioclogging effects in saturated porous media within one- and two-dimensional flow systems., 36(2): 176-196.

Van Paassen, L. A., Ghose, R., Der Linden, T. J., Der Star, W. R., and Van Loosdrecht, M. C., 2010. Quantifying biomediated ground improvement by ureolysis: Large-scale biogrout experiment.,136(12): 1721-1728.

Wang, X., Tao, J., Bao, R., Tran, T. V., and TuckerKulesza, S., 2018. Surficial soil stabilization against water-induced erosion using polymer-modified microbially induced carbonate precipitation., 30 (10): 04018267.

Wang, Y. M., 2003. Study on erosion and soil stabilizer properties for highway subgrade slope. PhD thesis. South China University of Technology.

Wang, Z., Li, Q., Zhang, N., Jin, Y., and Ding, J., 2020. Slope failure of biotreated sand embankments under rainfall conditions: Experimental investigation and numerical simulation..Springer-Verlag GmbH Germany, part of Springer Nature 2020.

Wu, C., Chu, J., Wu, S., and Hong, Y., 2019a. 3D characterization of the microbially induced carbonate precipitation within rock fracture and the resulted permeability reduction., 249: 23-30.

Wu, M., Hu, X., Zhang, Q., Xue, D., and Zhao, Y., 2019b. Growth environment optimization for inducing bacterial mineralization and its application in concrete healing., 209: 631-643.

Xiao, P., Liu, H., Xiao, Y., Stuedlein, A. W., and Evans, T. M., 2018. Liquefaction resistance of bio-cemented calcareous sand., 107: 9-19.

Xiao, Y., Stuedlein, A. W., Ran, J. Y., Evans, T. M., Cheng, L., Liu, H. L.,, 2019.Effect of particle shape on strength and stiffness of biocemented glass beads., 145(11): 06019016.

Zhang, Q., Lei, T., Pan, Y., and Gao, P., 2004. Rational computational method of soil erodibility and critical shear stress from experimental data., 21 (4): 468-475.

Zhao, Q., Li, L., Li, C., Li, M., Amini, F., and Zhang, H., 2014.Factors affecting improvement of engineering properties of MICP-treated soil catalyzed by bacteria and urease.,26(12): 04014094.

October 29, 2020;

March 17, 2021;

May 27, 2021

? Ocean University of China, Science Press and Springer-Verlag GmbH Germany 2022

. E-mail: hlkou@ouc.edu.cn

(Edited by Xie Jun)

Journal of Ocean University of China2022年2期

Journal of Ocean University of China2022年2期

- Journal of Ocean University of China的其它文章

- Probabilistic Methods for Reliability Assessment of Floating Structures Based on Extreme Wave Simulation

- Structure of the Potential Vorticity of an Explosive Cyclone over the Eastern Asian Region in Late November 2013

- Isolation, Identification, and Quantitative Determination of Saponin in Apostichopus japonicus by HPLC-DAD

- Transcriptome Analysis of Pacific White Shrimp (Litopenaeus vannamei) Under Prolonged High-Salinity Stress

- Evaluation of the Bioavailability of Metals in Sediment from the Southern Coastal Wetland of the Qiantang Estuary by Using Diffusive Gradients in Thin Films Technique

- The Combined Effect of Plastic Particles Size and Concentration on Rotifers’ (Brachionus plicatilis) Performance