Effects of Mg/PTFE pyrotechnic compositions on reignition characteristics of base bleed propellants and heating mechanism

Xio-chun Xue ,Long-ze M ,Yong-gng Yu ,*

a School of Energy and Power Engineering,Nanjing University of Science and Technology,Nanjing,Jiangsu,210094,China

b BYD Company Limited,Shenzhen,Guangdong,518118,China

Keywords:Thermal effect High-temperature combustion gas Mg/PTFE pyrotechnic Compositions Reignition

ABSTRACT The effects of magnesium/polytetrafluoroethylene (Mg/PTFE) pyrotechnic compositions on the coupled flow field and reignition mechanism are important aspects governing the performance and range of base bleed projectiles (BBPs).Owing to a decrease in pressure and temperature when the BBP leaves the muzzle,rapid depressurization occurs,which extinguishes the base bleed propellant.The Mg/PTFE pyrotechnic composition pressed in the igniter of the base bleed unit (BBU) provides additional energy to the BBU via a chemical reaction.Thus,the extinguished base bleed propellant is reignited under the effect of high-temperature combustion gas jets from the igniter.In this study,a numerical analysis is conducted to evaluate the effects of PTFE and Mg granularity as well as Mg/PTFE pyrotechnic compositions.Owing to the rapid depressurization,the temperature and pressure was found to decrease for different Mg/PTFE pyrotechnic compositions.However,the depressurization time increased as the PTFE granularity increased,the Mg granularity decreased,and the Mg content increased.When the pressure in the combustion chamber of the BBU decreased to the atmospheric pressure,the combustion gas jets from the igniter expand upstream(rather than downstream).However,these combustion gas jets exhibit different axial and radial expansion characteristics depending on the pyrotechnic compositions used.The results show that the reignition delay time,td,of the base bleed propellant was 377.608,94.27,387.243,523.966,and 221.094 ms for cases A-E,respectively.Therefore,it was concluded that the Mg/PTFE pyrotechnic composition of case B was the most beneficial for the reignition of the base bleed propellant,with the earliest addition of energy and mass to the BBP.

1.Introduction

Aerodynamic projectiles such as artillery shells experience significant drag owing to the formation of a low-pressure and lowvelocity recirculation region near their bases [1,2].This drag,also termed as base drag,can account for up to two-thirds of the total drag acting on the projectile when it is launched from the muzzle.As a solution,base bleed units(BBUs)are conventionally used to reduce base drag,which,in turn,helps increase the range of the projectile[3-5].Generally,projectiles equipped with a BBU are termed as base bleed projectiles (BBPs).The base bleed jets in such projectiles are mainly composed of the combustion gases of the ammonium perchlorate/hydroxyterminated polybutadiene(AP/HTPB)propellant in the BBU.However,in case of an unsteady flow field in the BBU,rapid depressurization occurs,and the AP/HTPB propellant is extinguished as soon as the BBP exits the muzzle [6].However,this extinguished AP/HTPB propellant can be reignited,depending on the coupled flow field of the high-temperature combustion gas from the igniter in the BBU and the propellant gas in the gun.In an actual BBU,magnesium/polytetrafluoroethylene(Mg/PTFE) pyrotechnic compositions[7]are pressed as the igniter.Once the AP/HTPB propellant is reignited by combustion gas jets from the igniter,the base drag continues to decrease with increasing base bleed.However,uncertainties in the reignition mechanism of the AP/HTPB propellant can reduce the accuracy of the BBP and cause significant variations in its range.Consequently,the effects of different Mg/PTFE pyrotechnic compositions on the complex flow field characteristics of a BBU and the thermal mechanisms of the AP/HTPB propellant during rapid depressurization are essential parameters that need to be considered for improving the accuracy of BBPs.

As mentioned above,the AP/HTPB propellant in the BBU also undergoes depressurization when the BBP exits the muzzle.Focusing on the combustion of the AP/HTPB propellant under unsteady conditions,Steinz [8] carried out depressurization extinguishment experiments;using a high-speed video camera,it was observed that the gaseous flame was extinguished immediately owing to adiabatic expansion.Suhas [9] presented the unsteady combustion analysis of composite propellants and proposed a mechanism for the unsteady combustion of composite propellants subjected to rapid depressurization.Surzhikov [10] analyzed combustion behaviors under periodic high-frequency variations in pressure and found that the distribution of the average mass burning rate was non-uniform throughout the surface of the solid propellant.Wang [11] presented a laser technique for measuring the transient burning rate of a solid propellant;the aim of that study was to develop a depressurization system,where the starting time of depressurization could be set in advance by simply altering the initial rate of depressurization.Furthermore,Jackon [12]established an experiment to measure the burning rate of a solid propellant under a decreasing pressurization rate.Ye[6]conducted unsteady combustion experiments on the AP/HTPB propellant subjected to depressurization by using a semi-hermetic explosive device;three types of unsteady combustion characteristics-continuous combustion,flame extinguishment,and flame reignition-were observed.

Despite such studies on the unsteady combustion mechanism and the thermal effect of solid propellants,research pertaining to the combustion of Mg/PTFE-based pyrotechnic compositions has been significantly limited.Kuo [13] summarized the ignition and combustion characteristics of pyrotechnic compositions for a solid rocket engine.Deyong [14,15] reported theoretical studies on simulations of the combustion of pyrotechnic compositions.The effects of changing the formulations on the distribution of reaction temperatures and the heat effect were determined by providing a new chemical kinetic mechanism of 18 reactions and 17 species for the combustion of pyrotechnic compositions.Based on this,the detailed equilibrium chemistry of Mg/PTFE-based pyrotechnic compositions was examined for over 47 species and various initial conditions[16].Our previous studies[17,18]also modeled the flame evolution characteristics of an igniter by adopting Mg/PTFE-based pyrotechnic compositions under atmospheric conditions by simplifying Deyong’s detailed kinetics mechanism,and the obtained simulation results were in agreement with the experimental results.However,the abovementioned studies only focused on the burning characteristics of Mg/PTFE-based pyrotechnic compositions under a steady environment.Details regarding the coupled flow field characteristics for various combustion gas interactions under rapid pressurization processes are still scarce.Lu[19]studied the transient flame characteristics and performances of different types of igniters under rapid depressurization through semi-closed bomb experiments and found that the flame structure of the Mg/PTFE-based pyrotechnic igniter was the most stable for the longest duration.However,it is difficult to determine the thermal effect and reignition mechanism of the propellant in the Mg/PTFEbased pyrotechnic igniter of high-temperature and high-pressure BBUs under rapid depressurization by using nonvisual experiments alone;numerical investigations are also necessary to better understand such a complex system.

The remainder of this paper is organized as follows.First,the governing equations are presented.Here,we assume that the unsteady compressible flow equations account for the combustion of Mg/PTFE pyrotechnic compositions.Subsequently,the flow simulations are discussed in detail.The results highlight the complex coupled flow field characteristics for various combustion gases in the BBU with different Mg/PTFE pyrotechnic compositions when rapid depressurization occurs.Finally,the mechanism of the thermal effects on the extinguished AP/HTPB propellant is investigated by determining the optimal Mg/PTFE composition that is beneficial for reigniting the AP/HTPB propellant and facilitating the base bleed in projectiles.

2.Physical model for computation

2.1.Problem description

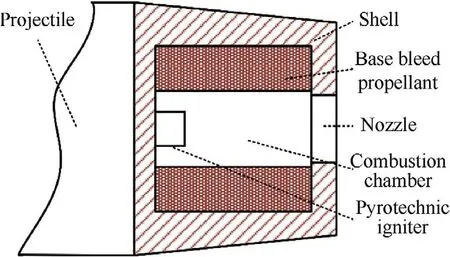

Details of the BBU in the BBP are presented in Fig.1;the BBU comprises a shell,base bleed propellant,combustion chamber,nozzle,and pyrotechnic igniter.There are two types of combustibles in the BBU:the AP/HTPB propellant,which is used as the base bleed propellant,and the ignition powder in the igniter.Generally,Mg/PTFE is adopted as the ignition powder and pressed in the igniter.Initially,when the BBP is in the muzzle,the hightemperature and high-pressure gas generated by the combustion of the gun propellant from the gun breech can enter the BBU through the nozzle.Here,it is assumed that the gun propellant is completely combusted in the gun breech;hence,only the combustion of Mg/PTFE in the igniter is considered,and the chemical reaction rate is calculated using the Arrhenius law.In the present study,we focus on the effects of the granularity and mass fraction of Mg/PTFE components on the coupled flow field of hightemperature combustion gases from the gun propellant and the Mg/PTFE pyrotechnic composition in the combustion chamber.With regard to an actual BBU,when the BBP exits the muzzle,rapid depressurization occurs in the combustion chamber,accompanied by a decrease in pressure and temperature,owing to the pressure difference with respect to the atmosphere.According to the experimental results in Ref.[6],when the BBP leaves the muzzle,AP/HTPB is extinguished within a significantly short period of time due to the flame separation effect.Thus,the combustion of the base bleed propellant is neglected in this study.However,the base bleed propellant is reignited under the effect of the high-temperature combustion gas from the igniter at the later stages of depressurization.Accordingly,the thermal effects of different igniter combustion gases on the base bleed propellant are considered in this study.

2.2.Governing equations

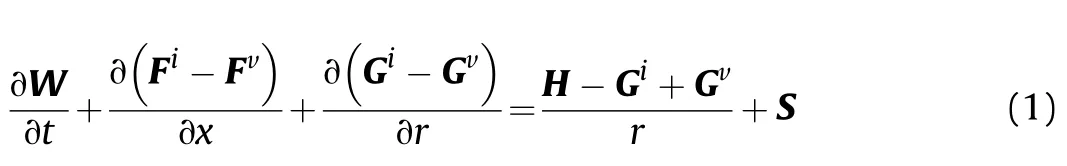

An ideal compressible and viscous gas in two dimensions is described by the continuity and transient Naiver-Stokes equations,as follows:

Fig.1. Schematic of a base bleed unit.

where W,F,and Gdenote the vectors of the conservative variables and vectors of the fluxes,respectively.

where E is the total energy;τ,τ,τ,and τare the shear stress tensors;and qand qare the vectors of heat flux.

where the subscripts x and r represent the axial and radial directions of combustion,respectively;u and v are the axial and radial velocities,respectively;ρ is the density of the combustion gas mixture;ρ,h,and ωrepresent the density,static enthalpy,and net production rate of species i produced via chemical reactions,respectively;and p is the pressure,which can be expressed by the ideal gas state equation according to the abovementioned assumptions:

where R and T are the universal gas constant and temperature,respectively;Yis the mass fraction,and it can be expressed as Y=ρ/ρ.Mis the molar mass of species i.

In a mixture of gases,the mass diffusion coefficient,D,of species i can be expressed as follows:

where μand Scare the turbulent dynamic viscosity and the turbulent Schmidt number,respectively.For species i,Drepresents the mean mass diffusion coefficient as

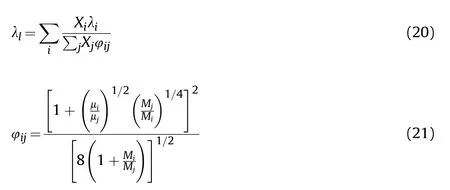

Here,Xis the mole fraction of species i,and Xis the mole fraction of species j.Drepresents the binary mass diffusion coefficient of species i in species j.The thermal conductivity coefficient λ is calculated as follows:

Pris the turbulence Prandtl number,and λis the mean mixture thermal conductivity,which is expressed as

The specific heat capacity of the mixture is expressed as

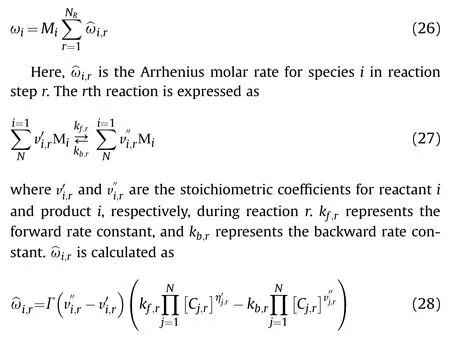

cdenotes the specific heat capacity of species i,and it can be calculated as

where μ is the dynamic viscosity.

The mean mixture dynamic viscosity μ,is expressed as

Here,μis the viscosity coefficient of species i.

2.3.Turbulence model

In this study,the compressible flow in the BBU was numerically investigated.Computations were conducted using axisymmetric mass averaged Navier-Stokes equations with the realizable k-ε turbulence model [20].The results for this turbulent model were validated using the experiments described in the following section.

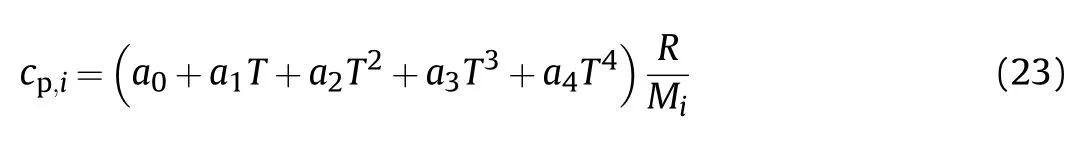

2.4.Chemical kinetic model

A careful review of existing experimental results[21]suggested that the combustion gases are strongly pressed on the surface of the igniter by the high-pressure combustion gas formed by the hightemperature and high-pressure gun propellant during the depressurization process.Consequently,fluctuations in the turbulence are weak.For a premixed reactant,combustion mainly occurs near the exit of the igniter,and the chemical reactions are key factors influencing this combustion process.Accordingly,the chemical reaction source term,ω,is calculated using a finite-rate kinetic model,and it can be expressed as

where γrepresents the third-body efficiency of the jth species in the rth reaction.

The forward rate constant is calculated using the Arrhenius law for reaction r:

Here,A,βand Erepresent the pre-exponential factor,temperature exponent,and activation energy,respectively.

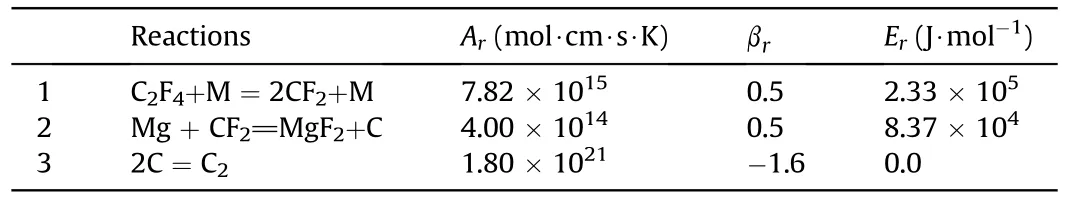

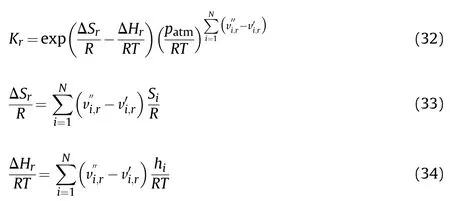

In the present study,we assume that the products of the solid evaporation and decomposition of Mg/PTFE pyrotechnic compounds are only Mg vapor and CFgas injected into the combustion chamber of the BBU and as the initial gaseous reactants in the combustion chamber.According to Ref.[17],the chemical reactions are reversible;they are presented in Table 1.For reaction r,the backward rate constant is calculated using the forward rate constant:

Table 1 Chemical reaction mechanisms.

where the equilibrium constant,K,is expressed as

Here,pis 101325 Pa Sis the entropy of species i,and hrepresents the enthalpy of the ith species.

3.Computational solution

3.1.Computational methodology

The finite volume scheme [22],which involves integrating the governing equations for each control volume and obtaining discrete equations that conserve each quantity on a control volume basis,is applied to simulate the coupled flow field characteristics of the high-temperature combustion gases generated by the gun propellant and the igniter pyrotechnics when subjected to rapid depressurization.The governing equations are discretized using the following methods with the AUSM+scheme to achieve the best accuracy [23].

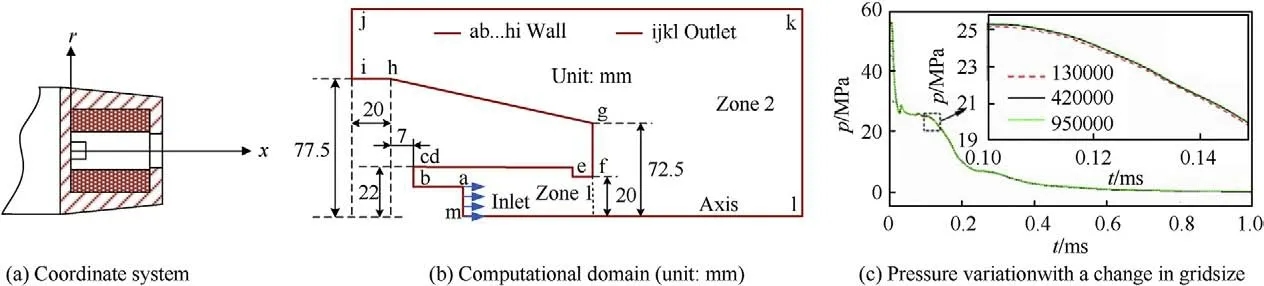

3.2.Computational domain and grid arrangement

Fig.2 depicts the computational domain with a twodimensional axisymmetric model and the results of grid independence.Combined with the actual BBU,the height and length of the igniter surface are ma=15 mm and ab=20 mm,respectively.The length of the base bleed propellant was cd=60 mm and ef=9 mm.The length of the axis is lm=1500 mm,and the radial distance of the computational domain is kl=800 mm.The remaining sizes are shown in Fig.2.For convenience,we divided the entire domain into two zones:Zone 1 represents the high-pressure inner flow zone and Zone 2 represents the outer flow zone.Computations were conducted on the grids in the range of 130000,420000,and 950000 nodes by using a block-structured grid.After grid independence verification,as shown in Fig.2(c),grid sizes with 420000 nodes or more afford less changes in the profiles of pressure distribution in the flow field of the BBU.Consequently,it is considered that 420000 nodes are sufficient to obtain grid-independent solutions for the present study.

3.3.Initial condition

Fig.2. Computational model.

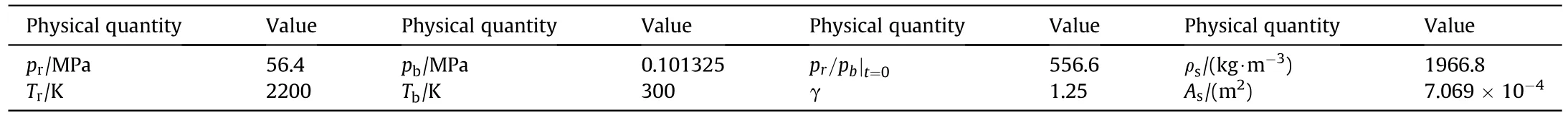

At the time when the BBU has just left the muzzle,the hightemperature and high-pressure gun propellant combustion gases occupy Zone 1 completely,with the total pressure p,temperature T,and specific heat ratio γ.Zone 2 comprises the atmospheric environment,where the absolute pressure and temperature are pand T,respectively.These initial parameters are listed in Table 2.Moreover,ρis the density of the pyrotechnics,and Ais the end face area of the igniter for an actual BBU.

3.4.Boundary conditions

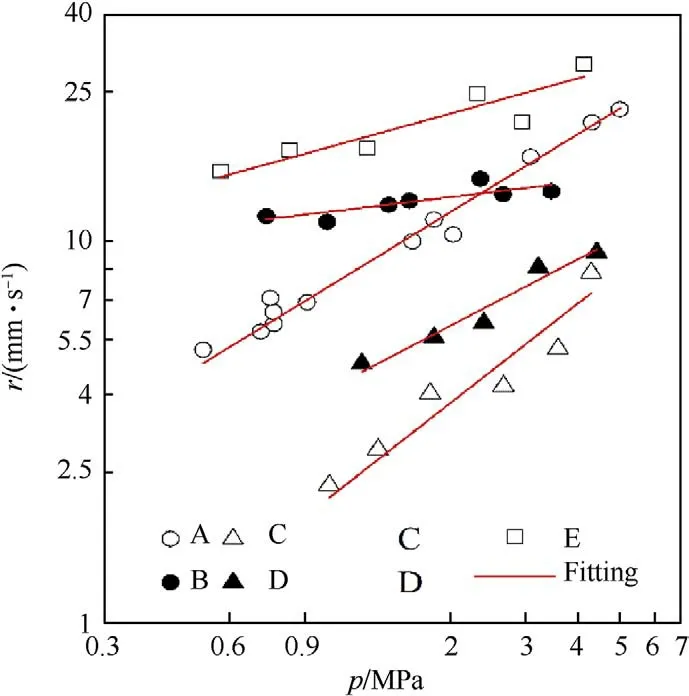

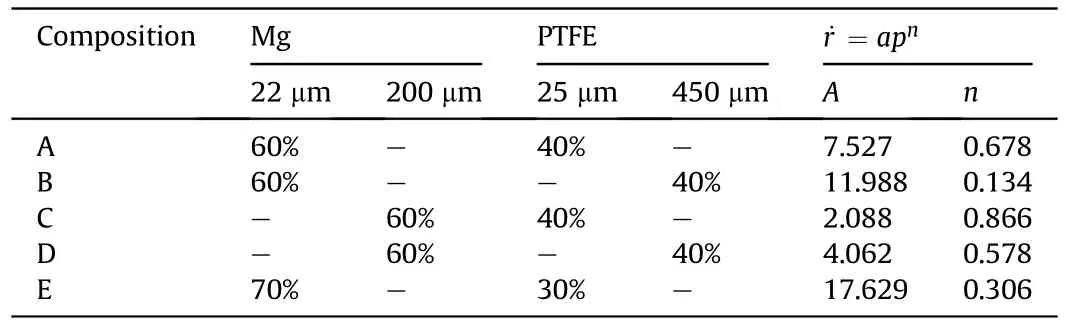

As shown in Fig.2,the central axis (ml) is the axisymmetric boundary,and the shell wall and surface of the base bleed propellant are adiabatic,without sliding walls.The boundary of the flow field for the computational domain is the pressure outlet,and the end face of the igniter is the inlet of the mass flow rate defined by ˙m=ρ˙rA.Here,the burning rate of the Mg/PTFE pyrotechnic composition,defined according to the experiments conducted by Kubota [24],is given by ˙r=ap,where a is the burning rate coefficient,p is the absolute pressure in Zone 1,and n is the pressure exponent.

To define the effect of the particle sizes of Mg and PTFE and the content of Mg on the burning rate of the Mg/PTFE pyrotechnic grain,Kubota [24] studied the burning rate characteristics of various Mg/PTFE pyrotechnic compositions.The test results of five such compositions are shown in Fig.3.Thus,the burning rate formulas for these Mg/PTFE compositions can be obtained by fitting the experimental results in this figure,as presented in Table 3.In this study,we focus on the effect of these compositions of Mg/PTFE on the flow field characteristics of the BBU as well as the thermal feedback mechanism affecting the base bleed propellant under depressurization.

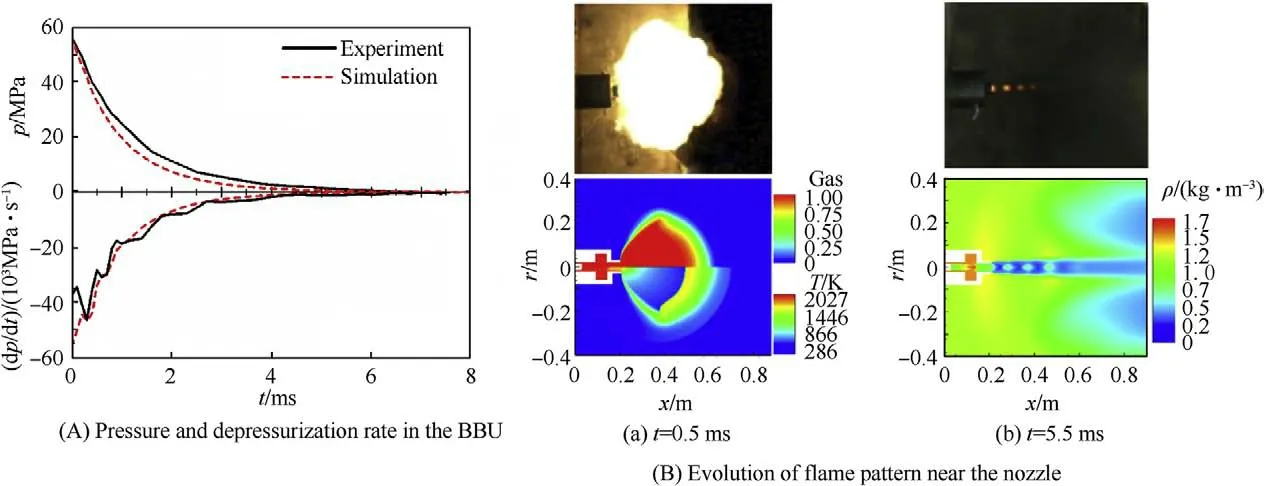

3.5.Validation of the models

A simulation considering the experimental conditions was performed in advance in order to validate the present models and computational solutions for the prediction of the thermal effect of high-temperature Mg/PTFE compositions with different granularities and mass ratios in the BBU when subjected to rapid depressurization.The experiment conducted by Ma [21],where the BBU was evaluated under such extreme conditions,was chosen as a reference;further details and information regarding the experimental device and conditions can be found in Ref.[21].Fig.4(a)shows the pressures and depressurization rates in the combustion chamber of the BBU,obtained using the present models and the experiment,with respect to time.Evolutions of the flame pattern near the nozzle are also obtained,as depicted in Fig.4(b),using the abovementioned experimental results and the corresponding numerical results below.From the figures,overall,it can be considered that the present numerical models were validated successfully based on the previous experimental study.In particular,the evolution of the flame pattern was in good agreement with the experimental observations.

Fig.3. Burning rate of Mg/PTFE.

Table 3 Parameters of Mg/PTFE compositions and the burning rate.

Table 2 Initial parameters.

Fig.4. Comparison of computational and experimental data.

4.Results and discussion

In actual BBUs,the flow field structure,particularly the thermal effect of the high-temperature combustion gas from the igniter of the AP/HTPB base bleed propellant,plays a significant role in the performance and accuracy of BBPs.The choice of pyrotechnic composition pressed in the igniter is an important factor determining this flow field structure and the thermal feedback affecting the base bleed propellant.Consequently,through numerical simulations,we study the detailed effects of the granularity and mass fraction of the pyrotechnic composition in the BBU when the BBP exits the muzzle.The results are presented in the following sections.

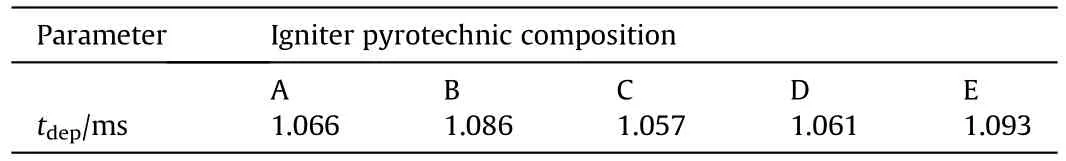

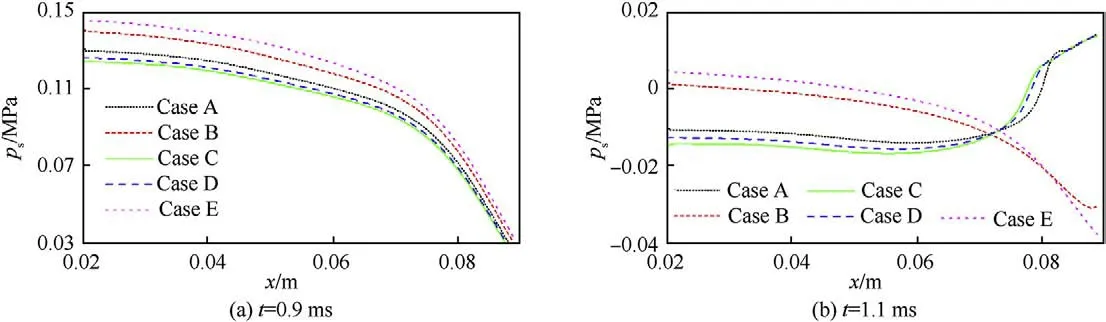

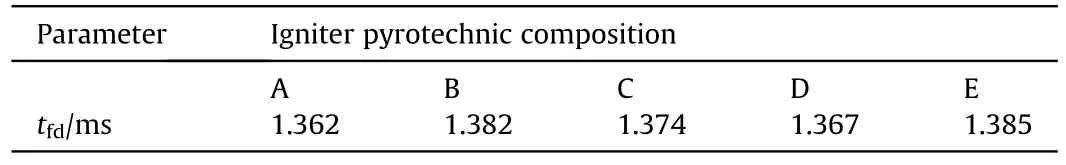

4.1.Depressurization characteristics in BBU

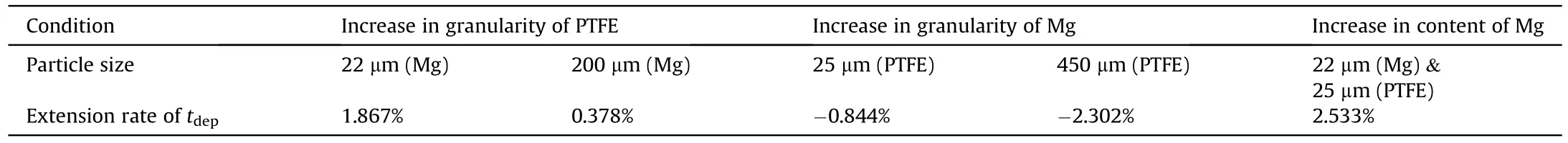

Fig.5 depicts the pressure distributions along the central axis of the combustion chamber at 0.9 ms and 1.1 ms for different Mg/PTFE compositions.Once the BBP leaves the muzzle,the pressure in the combustion chamber decreases significantly.The pressure variations under all these cases demonstrate identical trends;the pressure in the combustion chamber continues to decrease,falling below the atmospheric pressure,due to the continuous expansion of the combustion gas during the later stages of depressurization.Consequently,the igniter combustion gas jets move upstream due to the negative pressure difference,thereby improving radial expansion;this is beneficial for the heating of the base bleed propellant(located on both sides of the BBU)by the high-temperature igniter combustion.However,the depressurization times for these five cases are different.Table 4 presents the time required for the combustion chamber pressure to decrease to the atmospheric pressure when using different granularities and mass fractions of the pyrotechnic compositions;these results were obtained by analyzing the pressure distributions at different times on the basis of the simulation results.The depressurization times are in the range of 1.0-1.1 ms.The depressurization time was noted to increase with an increase in the PTFE granularity,Mg granularity,and mass fraction,as presented in Table 5.According to Kubota[24],the burning rate of the Mg/PTFE igniter increases with a decrease in the Mg particle size and an increase in the PTFE particle size and Mg content.The rate of combustion gas production increases with an increase in the burning rate of Mg/PTFE.Consequently,the depressurization time as well as the increasing rates of the depressurization time increase with combustion gas production,due to an increase in the Mg/PTFE reaction rate.In other words,the depressurization time is determined by the burning rate of Mg/PTFE.This conclusion in combination with Fig.3 indicates that the burning rate for case E is the highest;accordingly,the depressurization time and the increasing rate of the depressurization time in this case are the highest,as presented in Tables 4 and 5.

Table 4 Depressurization time.

Fig.5. Pressure distributions along the central axis of the BBU.

Table 5 Increasing rates of depressurization time.

4.2.Flow field characteristics of BBU under depressurization

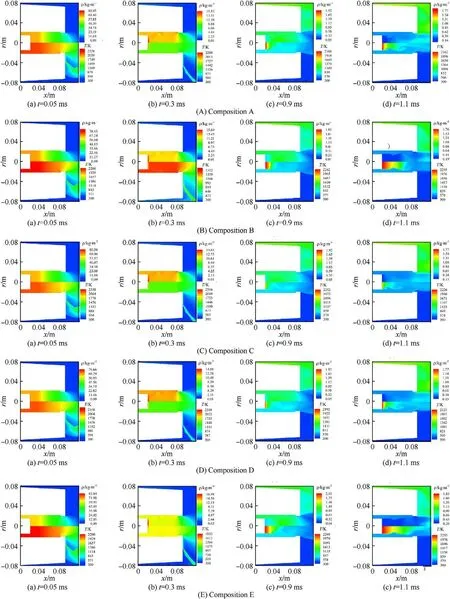

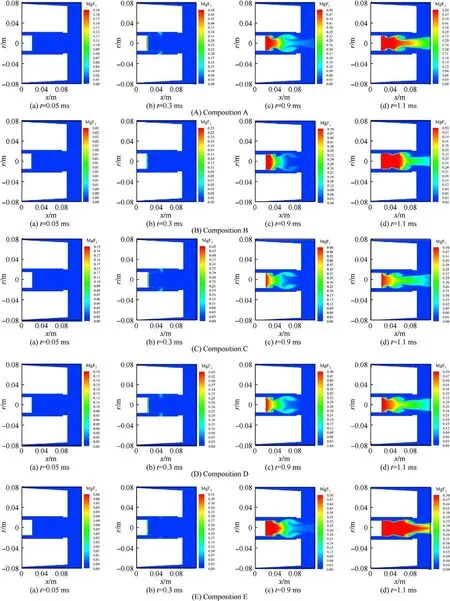

The observed thermal feedback affecting the base bleed propellant in the combustion chamber of the BBU is attributed to the production of the igniter combustion gas and the coupled interaction effect between the gun propellant combustion gas and the igniter combustion gas.When the BBP has just exited the muzzle,the combustion chamber is filled with high-temperature gun propellant combustion gases.With the production of the hightemperature combustion gas from the igniter,the temperature of the combustion chamber continues to increase.However,rapid depressurization occurs due to the difference in the combustion chamber pressure and the atmospheric pressure.Thus,the pressure and temperature of the gun propellant combustion gas in the combustion chamber rapidly decrease with the expansion of the combustion gas (and its subsequent release into the atmosphere).In addition,the axial expansion of the igniter combustion gas is greater than its radial expansion due to the axial power provided by the pressure difference.Consequently,the complex coupled flow field in the BBU determines whether the continuous heat from the combustion in the igniter is received by the base bleed propellant.With regard to the effects of different Mg/PTFE pyrotechnic compositions on the flow field characteristics of the BBU,Fig.6 depicts the density and temperature distributions in the BBU under depressurization,while Fig.7 depicts the mass fraction distribution of MgF,the product of the high-temperature igniter combustion,for different cases.

When depressurization occurs,the temperature in the combustion chamber decreases with the expansion of the gun propellant gas.However,the high-temperature combustion gases from the igniter are pressed on the end face of the igniter initially,and gradually expand with the expansion of the gun propellant combustion gas at a later time.The axial expansion of the igniter combustion gas is considerably faster than its radial expansions;therefore,the gun propellant is gradually surrounded by lowtemperature gun propellant gases.For cases A,C,and D,the characteristics of the combustion gas jets from the igniter remain the same even under depressurization,and small-and large-sized vortices exist when the pressure in the combustion chamber decreases to the atmospheric pressure.This induces stronger Kelvin-Helmholtz instability due to the velocity difference between the gun propellant combustion gas and the igniter combustion gas.However,for cases B and E,the small-sized vortices disappear and only large-sized vortices remain,resulting in weaker Kelvin-Helmholtz instability.The radial expansion of the combustion gas is significantly faster in cases B and E,as compared to that that for the other cases,which implies that the igniter heats the base bleed propellant earlier.This is because,as shown in Fig.3 and Table 4,the burning rates of the igniter for cases B and E occupy the absolute advantage gradually under the depressurization process.Subsequently,the quantities of combustion gases produced by the igniter also increase with the depressurization time.In summary,with an increase in PTFE granularity,a decrease in Mg granularity,and an increase in the Mg content of the Mg/PTFE pyrotechnic composition,the Kelvin-Helmholtz instability is weakened,accompanied by significantly quicker expansions along the axial and radial directions of the combustion chamber.

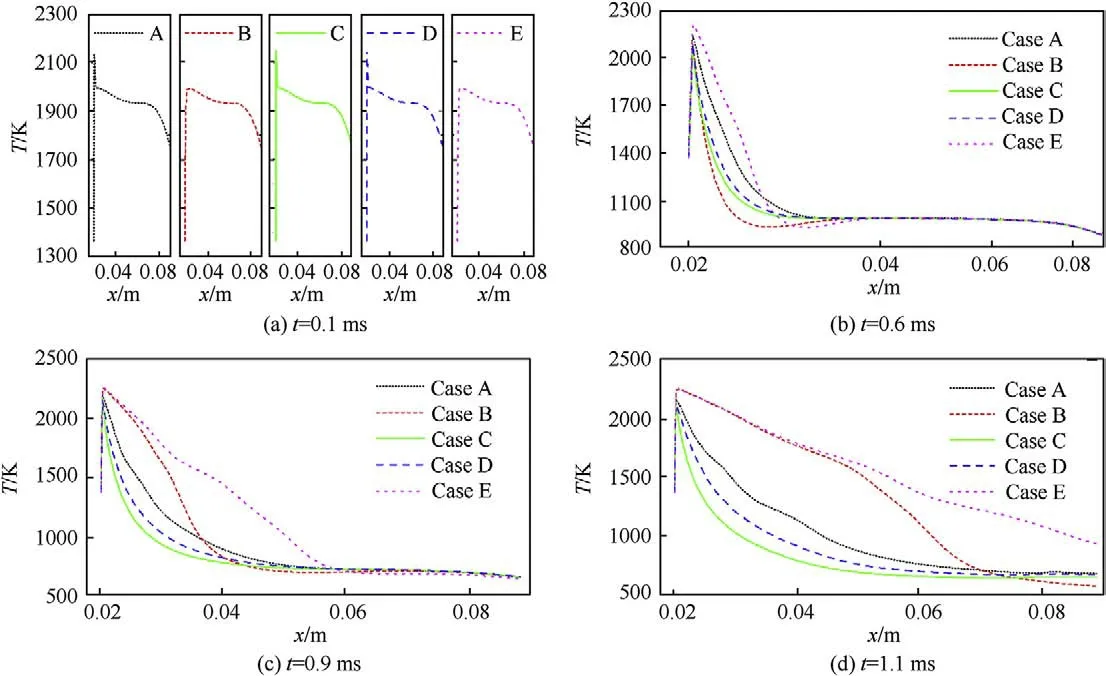

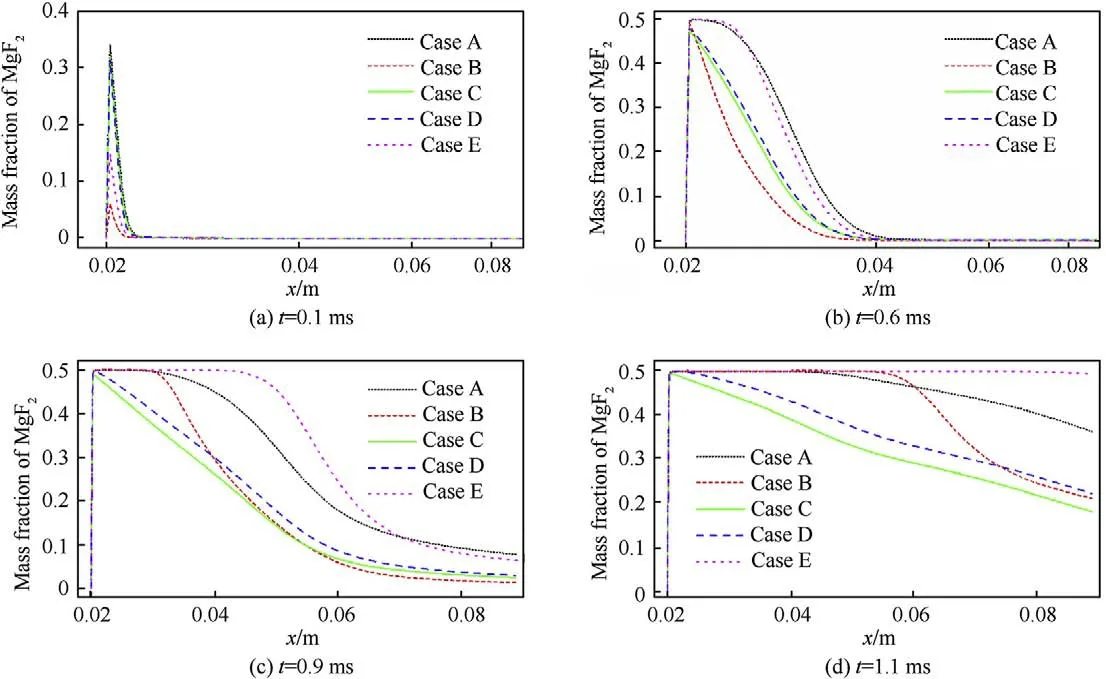

Fig.8 and Fig.9 depict the distributions of the combustion chamber temperature and the mass fraction of the main product from the igniter combustion,i.e.,MgF,at high temperatures along the central axis of the combustion chamber at different times,respectively.As depicted in Figs.6 and 7,because the hightemperature combustion gases from the igniter are pressed onto the end surface of the igniter and cannot completely expand along the combustion chamber at 0.1 ms,the mass fractions of MgF,which is the main product of the igniter combustion gas,are the highest near the end surface of the igniter for all five cases.The temperatures increase sharply to 2180 K near the igniter and then decrease significantly along the central axis of the combustion chamber for cases A,C,and D at 0.1 ms.In contrast,the temperatures for cases B and E increase sharply to 2050 K and then decrease gradually at 0.1 ms.This is because the burning rates for cases B and E increase with an increase in the production rate of the combustion gas,and the combustion gas acquires greater pressure,allowing it to expand downstream.This results in the hightemperature zones expanding downstream along the axial direction,instead of these zones accumulating near the igniter at the initial stages.At 0.6 ms,the mass fraction peaks of MgFfor case E do not indicate any change and maintain 0.5,indicating that the igniter combustion gases are in a state of chemical equilibrium.The corresponding temperature peak of the igniter combustion gas for case E is also the highest under the highest burning rate and the chemical equilibrium state.From 0.9 ms onwards,except for case C,which exhibits the lowest burning rate,the igniter combustion gases are in a state of chemical equilibrium,and the corresponding mass fraction peaks of MgFdo not exhibit any changes with respect to time.At 1.1 ms,case C reaches chemical equilibrium,with a constant mass fraction peak of MgF.In summary,the depressurization time increases with an increase in the PTFE particle size and a decrease in the Mg particle size(as presented in Table 4),and the pressure of the flow field decreases to the atmospheric pressure the earliest,accompanied by a decrease in the PTFE particle size and an increase in the Mg particle size.Thus,the temperature of the igniter combustion gas decreases with a decrease in the pressure and the depressurization time in the flow field;however,the slowest decrease in temperature was observed for the slowest decrease in pressure.Consequently,the temperature of the igniter combustion gas increases with an increase in the PTFE particle size and a decrease in the Mg particle size under depressurization.

Fig.6. Density and temperature distributions in the BBU.

Fig.7. Mass fraction distributions of MgF2 in the BBU.

Fig.8. Temperature distributions along the central axis of the BBU.

Fig.9. Mass fraction distributions of MgF2 along the central axis of the BBU.

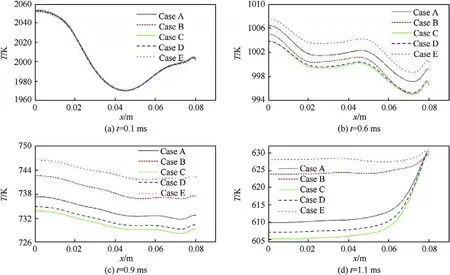

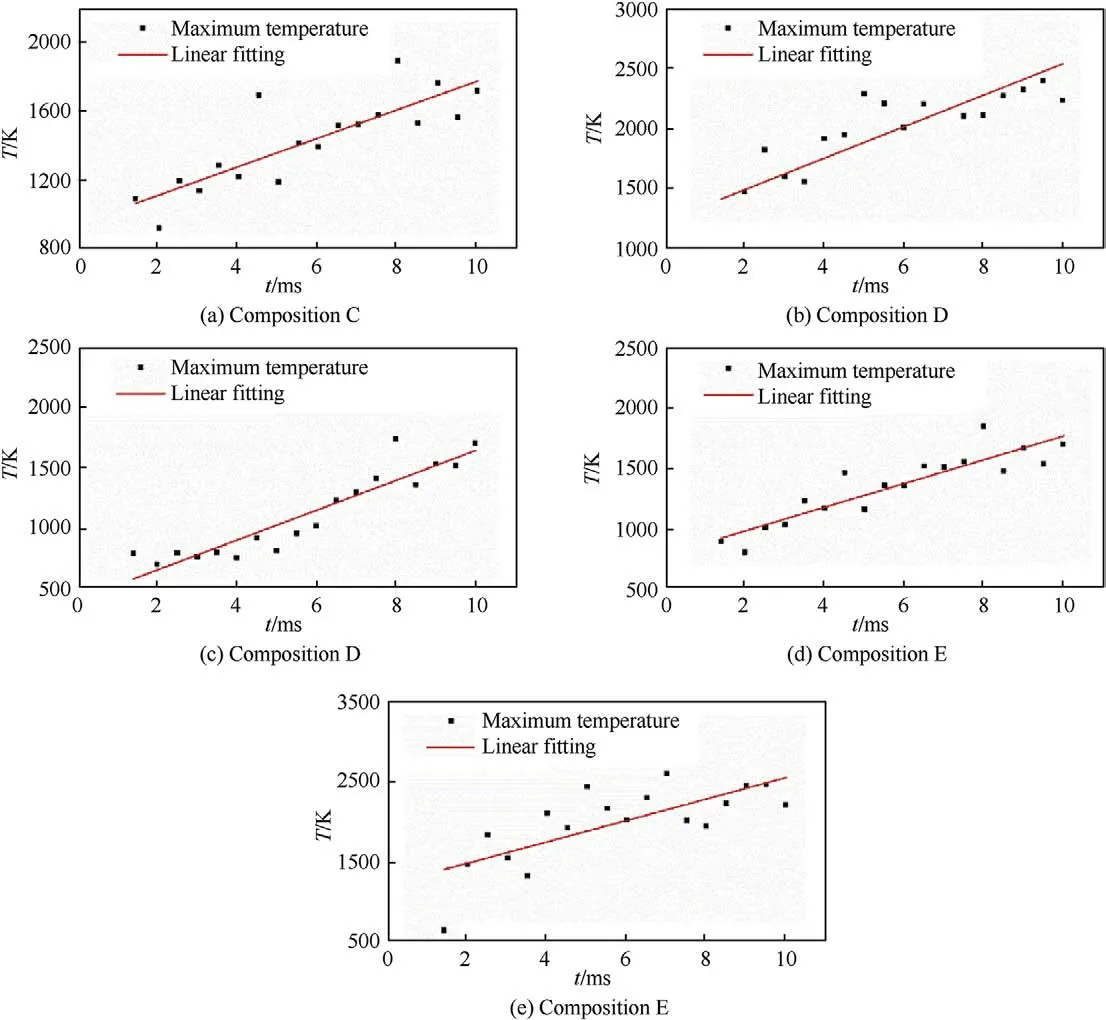

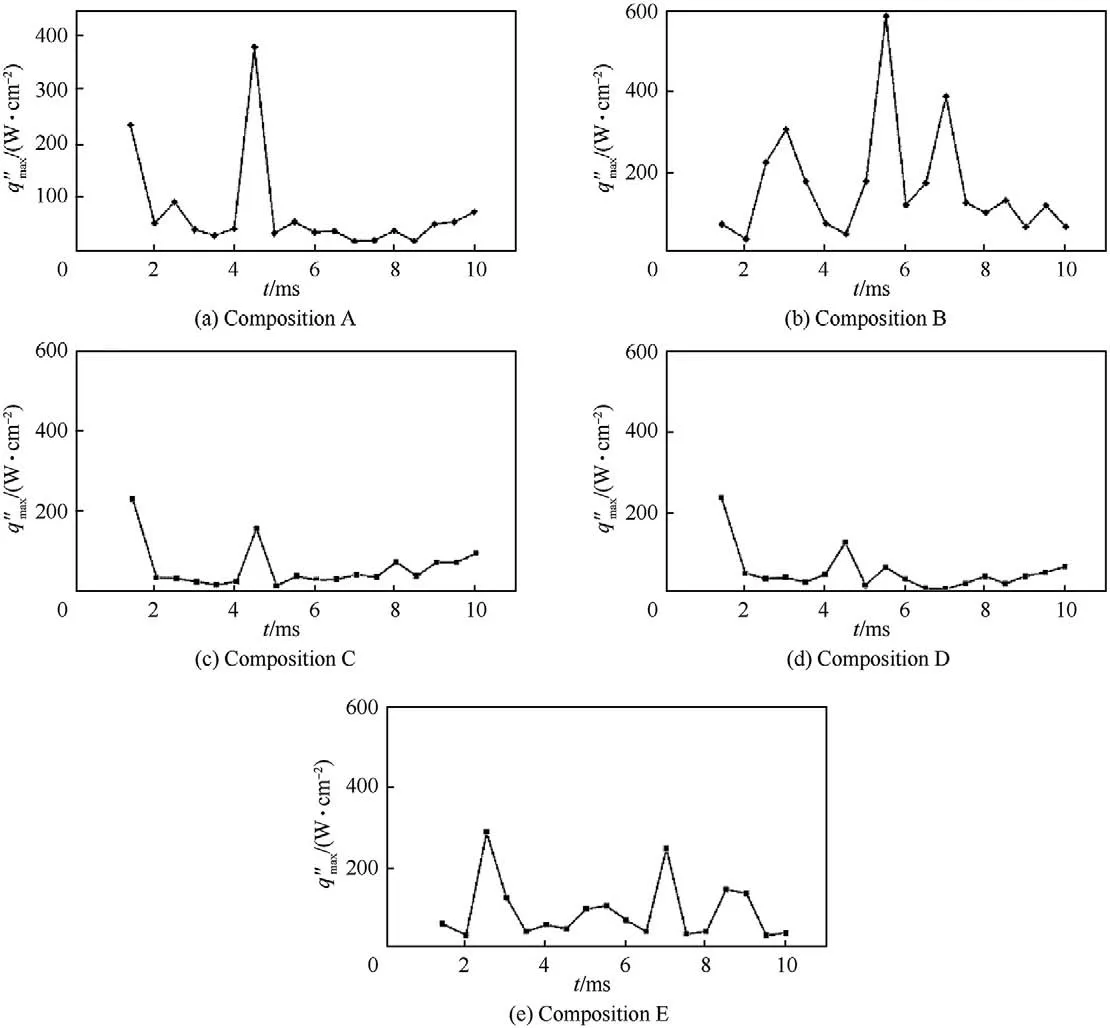

With regard to the secondary ignition phenomenon,the temperatures of the combustion gas acting on the base bleed propellant surface along the r=0.022 m axial direction are calculated at different times under depressurization for the five cases;the results are depicted in Fig.10.At 0.1 ms,the pyrotechnic compositions on this temperature have a negligible effect.At 0.6 ms,the temperature of the combustion gas acting on the base bleed propellant surface is the highest for case E and the lowest for case C.The difference between the temperatures acting on the base bleed surface in cases E and C is approximately 4 K.At 0.9 ms,the temperature for case E is the highest,while the temperature difference between cases E and C increases to approximately 12 K.At 1.1 ms,the combustion gas temperature acting on the base bleed propellant surface for cases B and E are significantly higher than those for the other cases.Furthermore,the temperature difference between cases E and C increases to approximately 23 K.In other words,as the PTFE granularity decreases and the Mg granularity and content increase,the temperature of the combustion gas acting on the base bleed propellant surface decreases.As a result,the heating of the base bleed propellant afforded by the combustion gas is decreased,and the temperature of the base bleed propellant surface decreases with the temperature of the combustion gas.As reported in Ref.[25,26],the critical ignition temperature of the base bleed propellant is 650 K;thus,the base bleed propellant is reignited when the local temperature increases to 650 K;thereafter,this temperature remains above 650 K under continuous heating.

Fig.10. Temperature distributions on the surface of the base bleed propellant.

4.3.Reignition delay under the heating effect of igniter combustion gas

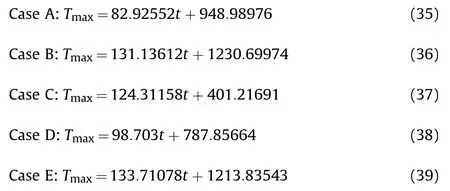

According to the abovementioned analysis,the hightemperature combustion gas jets from the igniter continuously heat and even ignite the base bleed propellant as the depressurization process progresses.To reveal the reignition characteristics of the base bleed propellant under this continuous heating afforded by the high-temperature igniter combustion gas under depressurization for different cases,Fig.11 depicts the distributions of the mass fraction of MgF,the product of the high-temperature combustion in the igniter,and the temperature in the combustion chamber after its pressure decreases to the atmospheric pressure.The combustion gas jets from the igniter move upstream (rather than downstream) under the negative pressure difference due to the inertia effect of the combustion gas.The axial and radial expansions of the igniter combustion gas jets for different pyrotechnic compositions exhibit two significantly different trends.One trend refers to cases A,C,and D,where small,high-temperature vortices are formed on the end face of the igniter and then expand to the base bleed surface under the heating effect along the radial direction.It is clear that the combustion gas jets move back into the BBU along the axial direction with the upstream expansion of the igniter combustion gas jets,which is caused by the negative pressure difference.Thus,radial expansion is relatively enhanced.The second trend refers to cases B and E.The igniter combustion gas jets directly expand toward the base bleed propellant along the radial direction of the BBU and undergo heating with the downstream expansion of the igniter combustion gas jets.Thereafter,the igniter combustion gas jets along the axial direction of the BBU shrink,making them extremely weak.However,the igniter combustion gas jets can still be released into the atmosphere from the BBU.Even under different characteristics of the igniter combustion jet,the igniter combustion gas jets all reach the base bleed surface and heat it from 1.35 ms to 1.40 ms for all the five cases studied.

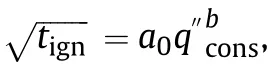

To better understand the heating effects under different pyrotechnic compositions,the reignition process is divided into two stages depending on the moment when the combustion gas jets from the igniter contact the surface of the base bleed propellant.The two stages are as follows:the delay stage of the combustion gas jet from the igniter,t,and the heating time of the base bleed propellant,t.Here,tis the period between the time when the BBU exits the muzzle and the time when the high-temperature igniter combustion gases come in contact with the surface of the base bleed propellant.The heating time for the base bleed propellant,t,refers to the period between the time when the igniter combustion gases come in contact with the surface of the base bleed propellant and the time when the base bleed propellant is reignited under the continuous heating.Thus,the reignition delay time,t,can be expressed as t=t+t.Table 6 lists the delay stages of the combustion gas jet from the igniter,t,for all the five cases considered.Fig.12 depicts the corresponding highest temperature distributions of the combustion gas on the surface of the base bleed propellant for different times.As shown in Fig.12,the equations for the highest temperature on the surface of the base bleed propellant with respect to time can be fitted for different pyrotechnic compositions,as shown in Eqs.(35)-(39).

To determine the heating time of the base bleed propellant,t,we assume that the surface temperature of the base bleed propellant is T.The heat flux from the igniter combustion gas jets acting on the base bleed surface can then be expressed as

Fig.11. Distributions of the mass fractions of MgF2 and temperatures after rapid depressurization.

Table 6 Delay time of combustion gas jets from the igniter.

5.Conclusion

Fig.12. Highest temperature distributions for r=0.022 m after rapid depressurization.

Fig.13. Highest heat flux variations in igniter combustion gas jets with respect to time.

A clear understanding of the effect of different Mg/PTFE pyrotechnic compositions on the coupled flow field characteristics of the gun propellant combustion gas and the igniter combustion gas is essential.In particular,the heating of the base bleed propellant by the high-temperature igniter combustion gas is crucial for achieving suitable performance of the BBPs.In this work,numerical models were developed,and their accuracy was validated using a previously reported experiment.Based on the numerical results,depressurization occurs as soon as the BBP exits the muzzle.When this depressurization occurs,the temperature and pressure were found to decrease for the different Mg/PTFE pyrotechnic compositions studied;moreover,the depressurization time increased when the PTFE granularity increased,the Mg granularity decreased,and the Mg content increased.Meanwhile,the lower the PTFE granularity and the higher the Mg granularity and content,the lower the temperature of the combustion gas acting on the base bleed propellant surface.Thus,the heating of the base bleed propellant by the combustion gas is reduced;the temperature of the base bleed propellant surface decreases with that of the combustion gas.

In particular,after the pressure in the combustion chamber decreases to the atmospheric pressure,the combustion gas jets from the igniter tend to move upstream(rather than downstream)under the negative pressure difference resulting from the inertia effect of the combustion gas.The axial and radial expansions of the igniter combustion gas jets are significantly different for the various pyrotechnic compositions used.Finally,the reignition delay times tof the base bleed propellants were calculated to be 377.608,94.27,387.243,523.966,and 221.094 ms for cases A-E,respectively.These results indicate that the reignition delay time decreases as the PTFE granularity increases and the Mg granularity decreases.Consequently,case B was determined to be the most beneficial for the reignition of the base bleed propellant in the BBU,and for adding mass and energy to the BBP.

Future research should focus on identifying the coupled flow field characteristics and the effect of adding energy and mass after the ignition of the base bleed propellant AP/HTPB under the heating afforded by the high-temperature igniter combustion gas.Moreover,studies should also attempt to enhance the performance and range of BBPs using measures for drag reduction.

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

This work was supported by the Fundamental Research Funds for the Central Universities (No.30918011324).

- Defence Technology的其它文章

- Defence Technology

- A study on the surface overpressure distribution and formation of a double curvature liner under a two-point initiation

- Performances and direct writing of CL-20 based ultraviolet curing explosive ink

- One-step synthesis of FeO(OH) nanoparticles by electric explosion of iron wire underwater

- Driving force coordinated control of an 8×8 in-wheel motor drive vehicle with tire-road friction coefficient identification

- Monitoring and Prediction of the Vibration Intensity of Seismic Waves Induced in Underwater Rock by Underwater Drilling and Blasting