Controllable combustion behaviors of the laser-controlled solid propellant

Bu-ren Duan ,Hao-nan Zhang ,Li-zhi Wu ,c,*,Zuo-hao Hua ,Zi-jing Bao ,Ning Guo ,Ying-hua Ye ,c,Rui-qi Shen,c,**

a School of Chemical Engineering,Nanjing University of Science and Technology,Nanjing,210094,China

b Institute of Space Propulsion,Nanjing University of Science and Technology,Nanjing,210094,China

c Micro-Nano Energetic Devices Key Laboratory,Ministry of Industry and Information Technology,Nanjing,210094,China

d Shanghai Space Propulsion Technology Research Institute,Shanghai,201109,China

Keywords:Laser-controlled solid propellant Laser ablation Multiple ignition Controllable combustion Combustion behaviors

ABSTRACT Microsatellites have been widely applied in the fields of communication,remote sensing,navigation and science exploration due to its characteristics of low cost,flexible launch mode and short development period.However,conventional solid-propellant have difficulties in starting and interrupting combustion because combustion is autonomously sustained after ignition.Herein,we proposed a new type of solidpropellant named laser-controlled solid propellant,which is sensitive to laser irradiation and can be started or interrupted by switching on/off the continuous wave laser.To demonstrate the feasibility and investigate the controllable combustion behaviors under different laser on/off conditions,the combustion parameters including burning rate,ignition delay time and platform pressure were tested using pressure sensor,high-speed camera and thermographic camera.The results showed that the increase of laser-on or laser-off duration both will lead to the decrease of propellant combustion performance during re-ignition and re-combustion process.This is mainly attributed to the laser attenuation caused by the accumulation of combustion residue and the change of chamber ambient temperature.Simultaneously,the multiple ignition tests revealed that the increased chamber ambient temperature after combustion can make up for the energy loss of laser attenuation and expansion of chamber cavity.However,the laser-controlled combustion performance of solid propellant displayed a decrease trend with the addition of ignition times.Nevertheless,the results still exhibited good laser-controlled agility of lasercontrolled solid propellant and manifested its inspiring potential in many aspects of space missions.

1.Introduction

Microsatellite is increasingly playing an important role in the fields of communication,remote sensing,military and engineering technology because it features low cost,low orbit and fast networking,which can make up the deficiencies of large satellite.In recent years,many scientific institutions and commercial companies have developed and launched microsatellites to implement related tasks [1-5].Meanwhile,microsatellite have shown strong demands on flexibility and cooperativity due to the high complexity of space tasks.Thus,it is critical for microsatellites to carry on an effective and throttleable micro-propulsion system.The traditional solid-propellant thrusters have difficulties in starting and interrupting combustion because combustion is autonomously sustained until the entire propellant is consumed,so it is hard to be applied in microsatellites.Therefore,new types of micropropulsion system such as electric propulsion,MEMS-based micro-propulsion,laser-ablation propulsion,and colloid propulsion have attracted more and more attention.With the rapid development of laser technology,higher power and energy conversion efficiency with compact size for the laser can be realized,which makes laser become an ideal energy source for micro-propulsion system.In laser-ablation propulsion,an intense laser beam[pulsed or continuous wave(CW)]strikes onto a condensed-matter(solid or liquid)surface and produces a jet of vapor or plasma.Just as how it works in a chemical rocket,thrust is produced by the resulting reaction force on the surface [6].Phipps et al.began to study the interaction between pulsed laser and matter,and designed various laser-ablation micro-thrusters for space exploration since the mid-1990s[7-9].Horisawa et al.designed the laserelectric hybrid thrusters,which used an electromagnetic field to accelerate the laser-induced plasma and to improve the specific impulse of thrusters [10-12].Unlike the principle of interaction between pulsed laser and matter mentioned above,Kakami et al.developed a throttleable solid-propellant micro-thruster using continuous wave laser [13-16].A CW laser was connected to a linear traverser which can make the laser move as propellant combustion surface is shifted.At the same time,the propellant can be initiated or interrupted by switching the laser input (on/off).In comparison,Shen et al.designed a laser-ablation thruster based on reflective mode.The CW laser directly irradiates to the surface of propellant,so that the combustion can be controlled by laser heating without a linear traverser.This new type of propulsion system is termed laser augmented chemical propulsion(LACP)[17].

The propellant used in LACP is named laser-controlled solid propellant (LCSP),which is sensitive to laser and can be started or interrupted by switching on/off the laser heating.This technology,which is helpful to achieve controllable combustion and repeated ignition,will hopefully expand the application scope for solid propellant.Owing to properties stated above,it is particularly important to have fast response characteristics and great combustion performance after laser irradiation.Studies on combustion behavior under different laser on/off conditions make sense to improve the accuracy of thruster control system and optimize the structural design of propulsion system.In addition,it can help to enhance the reliability of propulsion system.Therefore,the research on the combustion behavior of laser-controlled solid propellant has both theoretical and practical significance for the application of micro-propulsion system.

The investigations on combustion behaviors of solid propellant under laser irradiation were mostly concentrated on composite propellant.Isakari et al.[14,16] enhanced the laser absorption of propellant by adding carbon black,and found that the addition of carbon black was helpful to sustain stable combustion of propellant,but the specific impulse of propellant decreased significantly with the increase of carbon black content.Based on traditional AP/HTPB composite propellant,Qin et al.[18] realized the lasercontrolled combustion by adding a small amount of carbon black.Meanwhile,they found the laser irradiation did have a positive effect on enhancing burning rate of propellant.Belal et al.[19]initiated the effort toward metal additives and studied the ignition and combustion behavior with different metal particles under COlaser irradiation.The results showed the size of metal particles had a great influence on burning rate,ignition temperature and delay time.Out of all the metal materials investigated,they found the mechanically-activated Al-Mg particles provided the best combination of burning rate and product sizes.Kakami et al.[20,21]evaluated the heat balance on burning surface of fuel-rich (AP/HTPB/CB/Al) composite propellant under laser irradiation and found that approximately 70% of the energy was provided by combustion itself and the laser supplied supplementary heat flux to compensate for the heat insufficiency to sustain combustion.Furthermore,they investigated the effect of laser power attenuation on the heat flux rate from flame to burning surface.Ulas et al.[22]conducted the ignitibility of a family of potential gasgenerator solid propellants under different laser heat fluxes and chamber operating conditions.These potential gas-generator included ammonium perchlorate (AP),triamino guanidine nitrate(TAGN),guanidine nitrate (GN),cyclotrimethylene trinitramine(RDX) and carbon black.

The above studies provide a reference for the component selection of laser-controlled solid propellant.However,the aim of these studies is to realize laser-controlled combustion and optimize combustion performance by changing the composition of propellant,rather than focusing the change of response characteristics and combustion behaviors of propellant after multiple ignitions.This current research thus aimed at the issue by actual experiments.The semiconductor CW laser,pressure sensor,high-speed camera and thermographic camera were employed for analyzing the combustion behavior and the variation of ignition delay time,burning rate and chamber pressure under multiple ignition conditions.The acquisitions provided a theoretical basis for understanding the non-self-combustion mechanism of laser-controlled solid propellant.

2.Experimental

2.1.Laser-controlled solid propellant (LCSP)

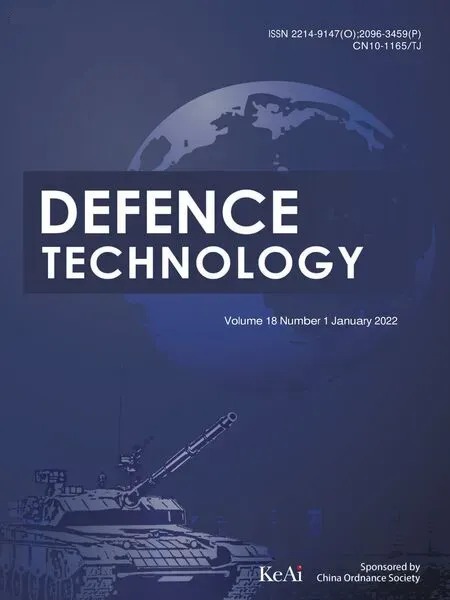

Since the LCSP must satisfy the requirements of controllable combustion and throttleable thrust,the components that can produce high specific impulse and more gas production should be selected.To prevent the blockage of gas channel by combustion products,the combustion residue should be as little as possible.Also,in order to improve the absorptivity of propellant to laser,the light-absorbing agent should be added.Based on the analysis above,the components of LCSP should include oxidizer,gasgenerating agent,light-absorbing agent and adhesion agent.The selected components according the above description were ammonium perchlorate (AP:106 μm),5-aminotetrazole (5-ATZ:106 μm),carbon black powder (CB:30 nm) and phenol formaldehyde resin(PF:62 μm).Different from the traditional AP/HPTB based propellant [23-26] preparation method,the ingredients of LCSP were homogeneously blended through mechanical method in an agate mortar with the optimized formulation(mass fraction:AP/5-ATZ/CB/PF=88/7/5/3).As shown in Fig.1,photographs of LCSP were taken using X-ray micro-computed tomography (μCT,SANYING nanoVoxel-2000).As can be seen,the particles of components were closely combined,which indicated pores and fractures inside the strand were properly inhibited.The prepared propellant sample was usually shaped as a solid column with dimensions of φ 6.0 mm × 15.0 mm,so that the surface of propellant could be heated by the laser spot with approximately φ6.0 mm.

2.2.Experimental setups

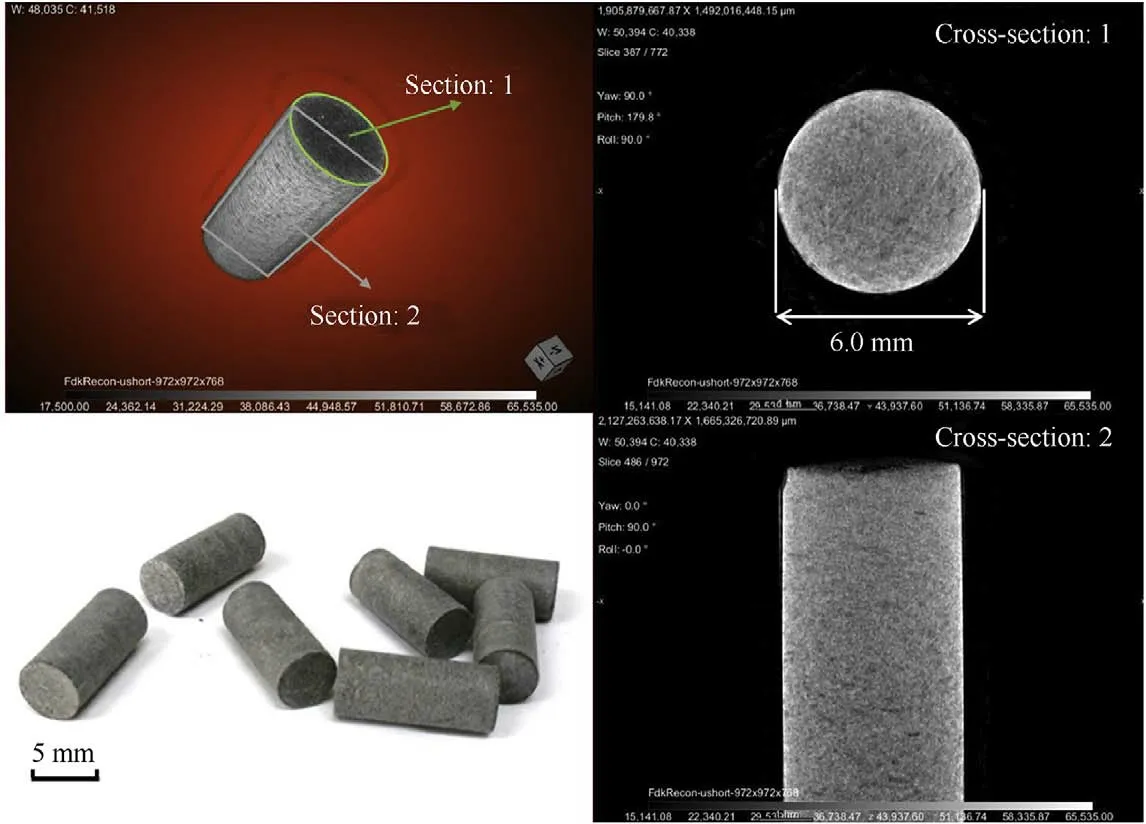

Fig.2a displayed the schematic view of prototype microthruster applied for the experiment.After being collimated by lens,the laser was irradiated to the propellant surface through an optical window.Subsequently,the high-temperature gas and flame flew along the direction perpendicular to laser beam and were finally ejected out through the nozzle above.The propellant column covered by an adiabatic quartz tube was inserted into the microthruster and the optical window was set to prevent collimating lens damage from the combustion flame.As shown in Fig.2b,the prototype micro-thruster was made of transparent quartz with dimensions of 34 mm × 34 mm × 72 mm for better observation.Meanwhile,the free chamber volume of micro-thruster used in the experiment was 1.26 cm.

Fig.1. Practical and X-ray micro-computed tomography (μCT) images of LCSP.

Fig.2. (a) Schematic diagram of micro-thruster based on reflective mode and (b) the practical micro-thruster prototype made of transparent quartz.

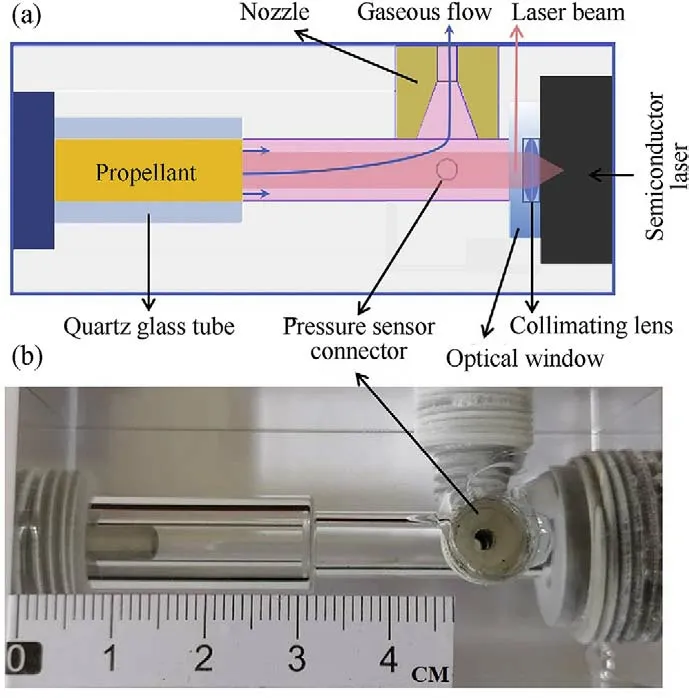

Fig.3 shows the schematic diagram of experimental setups.A fiber-coupled semiconductor laser (WPL2-80810-100 W) with wavelength of 808 nm and rated power of 100 W was used as the heat source.The collimating lens (WPL-GCX-L007-SMA) was used to focus the laser.The diameter of laser spot was adjustable from 5.8 mm to 6.4 mm.In the experiment,the laser spot was fixed to 6.0 mm after being collimated.The ratio of laser operating power to output power was 39.7% and the minimum ignition power of the propellant was 3.5 W.An external control circuit was constructed to realize the programmable on-off control of laser.A laser power meter(VEGA LP100)with measuring range of 100 W was applied to laser power measurement.The combustion process was recorded by a high-speed camera(Redlake HG-100)at 1000 fps.Meanwhile,the thermal distribution of propellant during combustion and extinction was characterized by a thermographic camera (FOTRIC 220RD) at 120 fps.The chamber pressure of micro-thruster was measured using a high-precision pressure sensor (HR-MPS Range:0.1 MPa) at resolution of 0.1 kPa through the interface nearby the nozzle.Both signals of laser and chamber pressure were simultaneously collected by an oscilloscope (TEKTRONIX MDO3000).

By means of the above techniques,such as the burning rate,ignition delay time and chamber pressure under different ignition conditions can be obtained,so that the controllable combustion behaviors of LCSP can be analyzed.

Fig.3. Schematic diagram of experimental setups.

3.Results and discussions

3.1.Ignition and combustion performance of LCSP

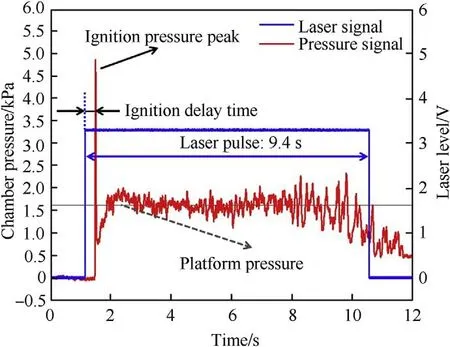

Fig.4. A typical time history of chamber pressure under laser power density of 0.531 W/mm2.

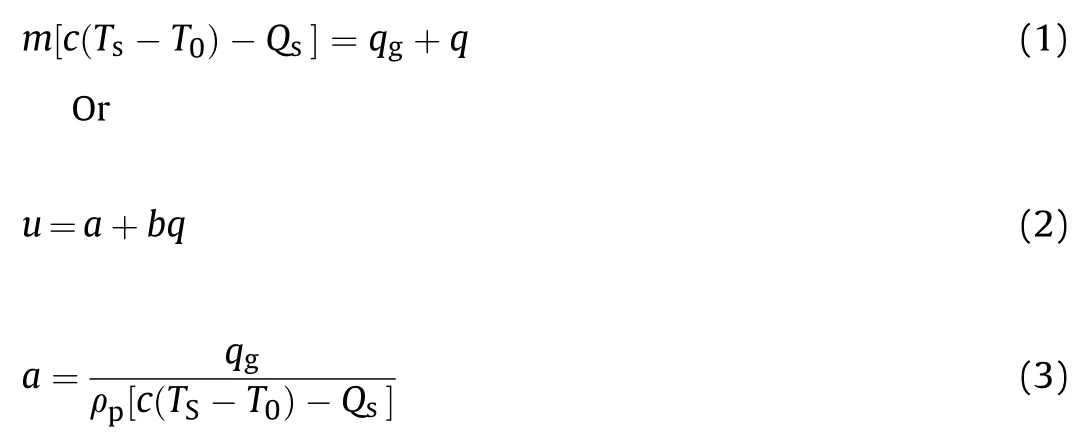

Typically,the ignition delay time of solid propellant refers to the lag between the laser irradiation and the start of burning.However,the moment that the first light emission occurs at the propellant surface is not easy to observe,so that the starting moment of ignition pressure peak is deemed as the sign of start burning in the experiment.Fig.4 presents the collected data by oscilloscope during combustion.The blue rectangle curve is the laser trigger output signal and the red curve is the chamber pressure of micro-thruster.It is possible to see there is an obvious hysteresis of ignition pressure peak after the laser action.During this period,gases produced by the thermal decomposition of propellant led to the chamber pressure rise up until the ignition pressure peak appears.After that the combustion begins.The lag-interval between the laser and pressure peak is approximately defined as the igniton delay time.In addition,we defined the average chamber pressure after propellant reaching a stable combustion state as the platform pressure.It should be noticed that the propellant shows pronounced pressure oscillation after half the propellant is burnt.This is mainly due to the increase of chamber cavity caused by propellant consumption and the attenuation of laser power caused by combustion residue.Fig.5 shows the high-speed photographs at different moments during combustion.The length-scale of scale bar stuck on the microthruster is 1.0 mm.The propellant surface regression rate can be obtained by comparing captured pictures at different moments,which approximately representes the buring rate.The burning rate in the experiments is the average burning rate,that is,the average regression rate from the beginning to the end of combustion.

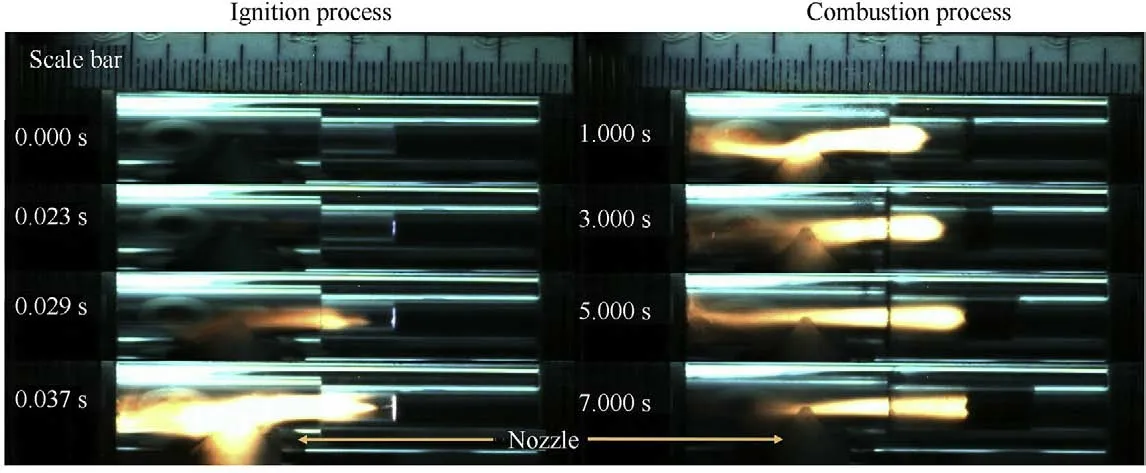

Fig.6 represents the dependence of burning rate u (mm/s),ignition delay time t(s) and chamber pressure P(KPa) on laser power density I(W/mm) and the error bar represents the standard deviations of three parallel tests.The dependence is easy treated by a simple expression[27,28]with a simplified solution of the Fourier equation.

Fig.5. High-speed photographs of combustion chamber for calculating the burning rate under laser power density of 0.531 W/mm2.

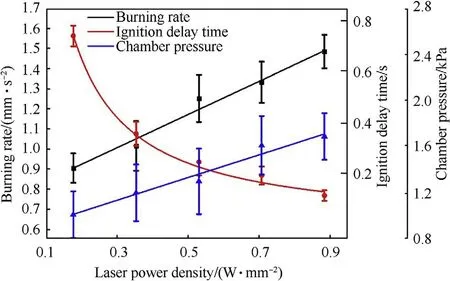

Fig.6. Dependence of the burning rate,ignition delay time,and chamber pressure on laser power density for LCSP.

where m is the mass burning rate;ρis the propellant specific mass,m=ρu;c is the mean specific heat capacity in the temperature region from Tto T;q is the external laser radiant flux,qis the flux of heat in the condensed phase at the expense of gas phase reactions,Tis the surface temperature,Tis the initial temperature,Qis the reaction heat of the condensed phase.

Eq.(6) fitted by the least square method shows the highly consistency with Eq.(2).

The varying pattern of chamber pressure and burning rate with laser power density is similar.With the increase of burning rate,the gas production generated from combustion per unit time increased,so that the chamber pressure rose up accordingly.The corresponding relationship as follows.

As seen from Fig.6,the ignition delay time decreased with increasing laser power density.The relationship between ignition delay time and laser power density can be curve-fitted by the following equation.

According to the theory in literature [29-32],the ignition of solid propellant under laser irradiation can be divided into three regions.In the first region,the laser irradiation starts the inertheating of propellant until the gas evolution occurs from the propellant surface.As the time increased,the gas production rise up due to continous heating of propellant.The exothermic reaction of pyrolyzed gas eventually led to the first visible light formation,this second region is characterized by the first light emission time[31].In the third region,with the continous heating of laser,the propellant reaches the Go/No-Go ignition boundary and finally achieved the steady combustion state.The third region can be described as the active preignition reaction region [31].With the increase of laser power density,the rate of inert-heating and gas evolution rises,which makes the time spent in the first and second region decreases significantly.Meanwhile,the “cold ambient gas effect” caused by the heat loss from propellant surface to cold surrounding gas is another important factor affecting the ignition of propellant [29,33].As the laser power density increased,the high generation rate of pyrolyzed gas can effectively suppressed the heat loss caused by“cold ambient gas effect”,thus the time required for the formation of first visible light is reduced.From these perspectives,the ignition delay time of propellant presents obvious decline trend under higher laser power density.

3.2.Effects of laser-on duration on re-combustion process

The ignition temporal response characteristics under different laser on-off conditions is one of the most important properties of LCSP and the duration of laser on/off affects the controllable combustion performance to a great extent.In this study,the duration of the laser irradiation was defined as the laser-on duration.Meanwhile,the duration after laser shut-down was defined as the laseroff duration.We therefore explored the effects of laser-on duration and laser-off duration on re-combustion process.

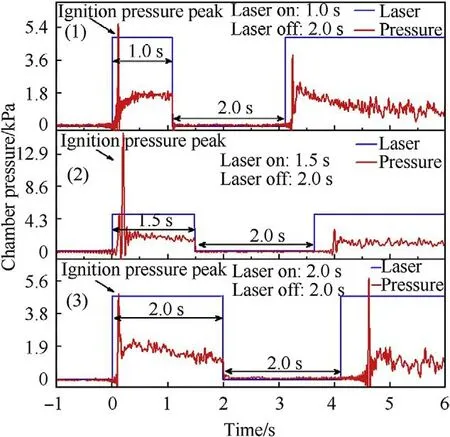

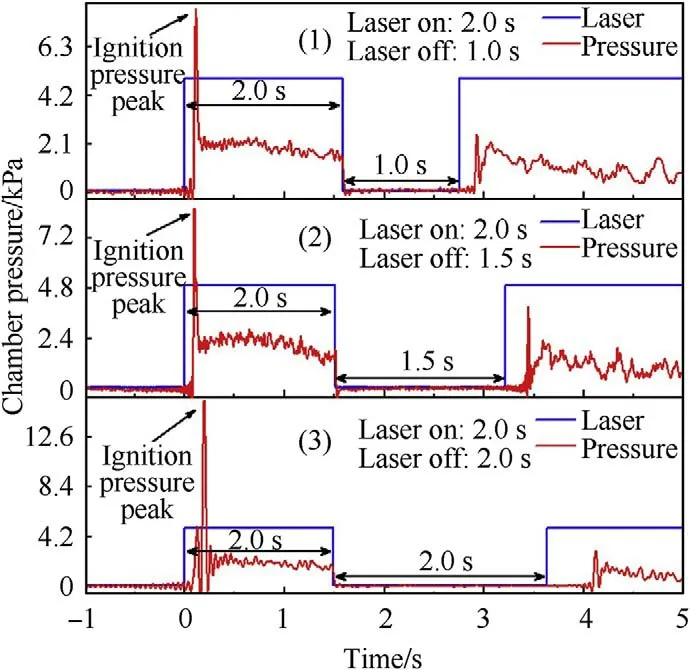

Fig.7 represents the chamber pressure curve with different laser-on duration under laser power density of 1.061 W/mm.The laser-off duration was set to 2.0 s and the laser-on duration to 1.0 s,1.5 s and 2.0 s through an external control circuit.Seen from Fig.7,the ignition delay time for re-ignition tends to increase with increasing laser-on duration.The first ignition delay time under all conditions were lower than 0.13 s,and the re-ignition delay time increased from 0.129 s to 0.509 s with the increase of laser-on duration.Although the ignition delay time for re-ignition increases substantially with the laser-on duration,the LCSP still exhibits good performance in controlling combustion with the on-off control of laser.

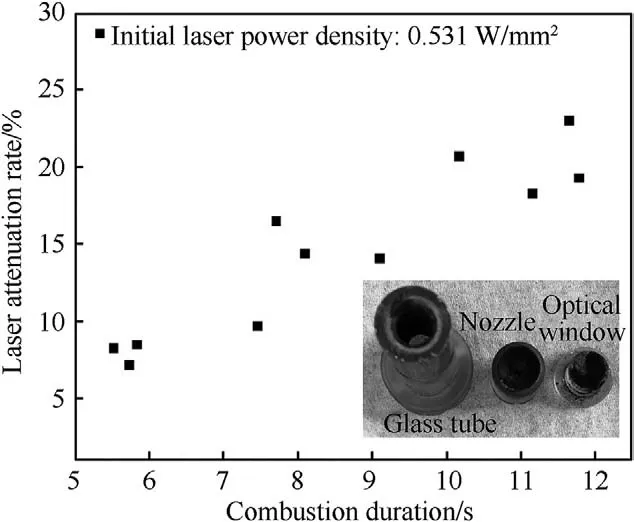

The effects of laser-on duration can be attributed to two aspects.On one hand,an increasing combustion duration cause an elevation of combustion chamber temperature,thereby providing higher chamber temperature for re-combustion process.On the other hand,as shown in Fig.8,we tested the attenuation rate of laser power density after different combustion duration through the laser power meter and the definition of laser attenuation rate(η)is shown in Eq.(9).

where Iis the laser power density before combustion;Iis the laser power density after combustion.

As can be seen from Fig.8,the laser attenuation rate increased significantly with the increase of combustion duration.Increased combustion duration leads more residue to remain on optical widow and combustion chamber,so that the laser power density irradiated to propellant surface will be attenuated compared with the first combustion process.

Fig.7. Micro-thruster chamber pressure with different laser-on duration:1.0 s,1.5 s and 2.0 s with 2.0 s laser-off duration.

Fig.8. Laser attenuation rate with different combustion duration under initial laser power density of 0.531 W/mm2.

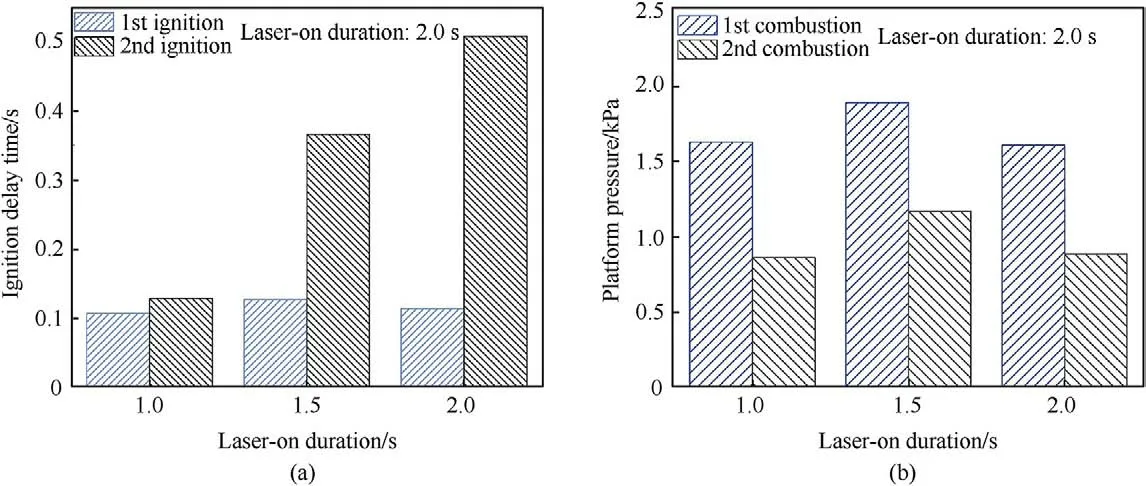

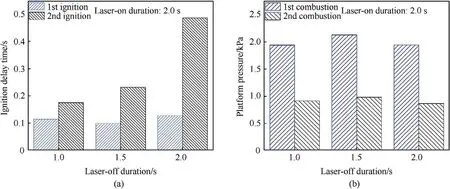

Fig.9 shows the comparison of (a) ignition delay time and (b)platform pressure between the first and re-combustion process under different laser-on duration.Compared with the first combustion process,the ignition delay time during re-combustion process increased by 0.022 s,0.240 s,0.395 s with the increase of laser-on duration,which shows an obvious upward trend.Indeed,the propellant will be consumed with the increase of laser-on duration,leading to the increase of distance between laser source and propellant surface.In addition,the increased laser-on duration inevitably brought more residue.Therefore,the laser power density received by propellant surface decreases,which led to the increase of ignition delay time for re-ignition under the joint action of the two factors.It should be noted that the divergence angle of collimating lens used in our experiment was 0.5 mrad,so that the laser has higher parallelism.The impact of the increased distance on laser attenuation is less clear.Hence,it can be considered that the residue on optical window and combustion chamber is the main reason for the increase of ignition delay time.

Fig.9. Comparison of (a) ignition delay time and (b) platform pressure between the first and re-combustion process under different laser-on duration (1.0 s,1.5 s and 2.0 s).

The platform pressure during re-combustion process shows a trend of first increasing and then decreasing when the laser-on duration increased.Compared with the first combustion process,the platform pressure of re-combustion process reduced by 46.9%,38.2%and 44.9%,respectively.As can be seen,the platform pressure has the highest value and the lowest reduction percentage when the laser-on duration is 1.5 s.Generally,within a certain range,the increase of combustion duration releases more heat so that the chamber temperature of re-combustion process increased,which acted as a role in promoting combustion.However,when the laseron duration exceeds to a certain range,the attenuation of laser power density caused by the chamber pollution became the dominant factor,which makes the platform pressure decrease during re-combustion process.Therefore,the best combustion status is attained at the laser-on duration of 1.5 s.

3.3.Effects of laser-off duration on re-combustion process

To study the effect of laser-off duration on re-combustion process of LCSP,the laser-on duration was set to 2.0 s while the laseroff duration was set to 1.0 s,1.5 s and 2.0 s,respectively.Fig.10 shows the change of chamber pressure with different laser-off duration under laser power density of 1.061 W/mm.As seen,the ignition delay time required for re-ignition increased with increasing laser-off duration.However,there is no significant change in platform pressure during the re-combustion process.

From Fig.10,the ignition delay time for re-ignition increases from 0.175 s to 0.487 s and the platform pressure in the recombustion process decreases from 0.918 KPa to 0.865 KPa with the increase of laser-off duration from 1.0 s to 2.0 s.The effect of laser-off duration on re-combustion process is mainly reflected by the initial temperature of combustion chamber.Increasing laser-off duration increases the cooling time experienced by combustion chamber,which led to the decrease of ambient temperature for reignition.In addition,the concentration and temperature of combustible hot gas generated from propellant decomposition also has some effect on ignition process of composite solid propellant occurring in gas phase [34,35].The increase of laser-off duration reduces the concentration and temperature of hot gas near the propellant surface,which has negative effect on ignition process.

Comparison of ignition delay time and platform pressure between the first and re-combustion process under different laser-off duration are shown in Fig.11.With the increase of laser-off duration,the ignition delay time for re-ignition increased by 0.061 s,0.133 s and 0.360 s.At the same time,the platform pressure of recombustion process decreased by 52.7%,53.7%and 55.5%compared with the first combustion process.

Fig.10. Micro-thruster chamber pressure with different laser-off duration:1.0 s,1.5 s and 2.0 s.The laser-on duration was set to 2.0 s.

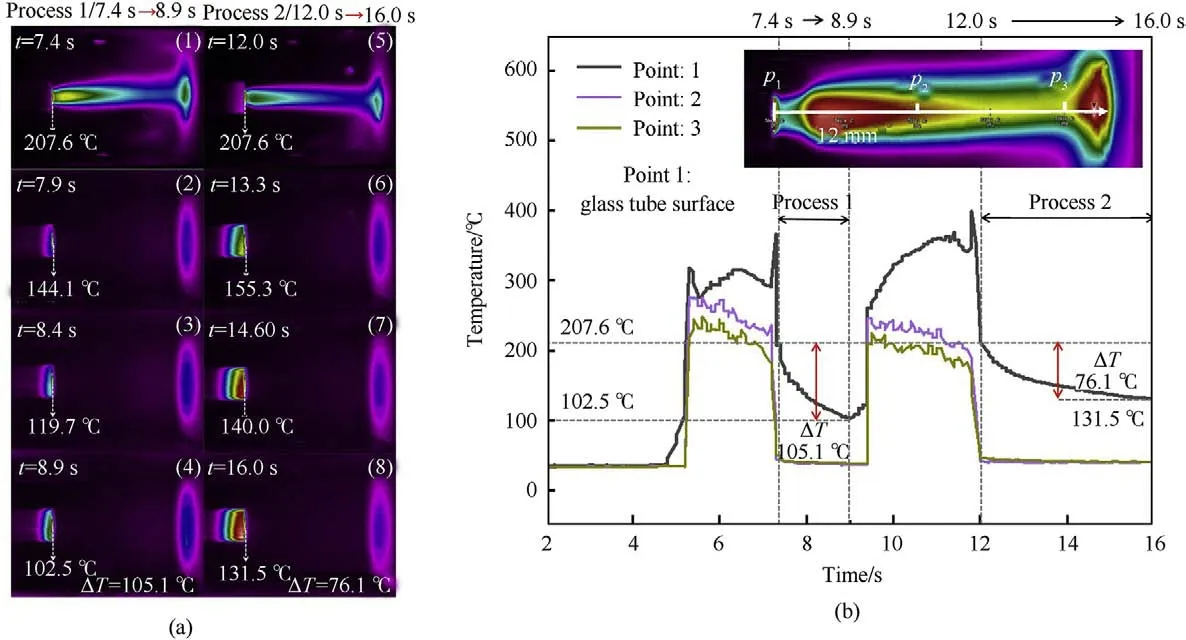

The extinction (laser-off) process and temperature distribution recorded by thermographic camera are shown in Fig.12.Point 1 on Fig.12b represents the center of glass tube surface,which can be approximately expressed as the temperature of combustion chamber.Point 2 and point 3 represents the flame temperature at 12.0 mm and 24.0 mm away from point 1,respectively.However,the thermographic camera cannot accurately reflect the flame temperature due to the limitation of the test wavelength,so that the flame temperature in the figure is only for quantitative analysis.

As shown,the temperature at point 1 decreased rapidly from 207.6C to 102.5C and 131.5C respectively during the laser-off duration of 1.5 s and 4.0 s.Therefore,it hints that the increase of laser-off duration makes the initial ambient temperature substantially decrease before re-ignition process.

Fig.11. Comparison of (a) ignition delay time and (b) platform pressure between the first and re-combustion process under different laser-off duration (1.0 s,1.5 s and 2.0 s).

Fig.12. (a)Two times of extinction processes(1.5 s and 4.0 s)under ambient pressure recorded by thermographic camera.(b)Temperature distribution at different positions during combustion.

Based on the ignition theory of composite propellant in literatures[36,37],the initial ambient temperature Tmainly effects the inert-heating time τduring ignition process.

where a,b and c are related to the propellant performance and environmental parameters respectively.

According to Eq.(10),the inert-heating time τexperienced by the propellant increases with the decrease of initial ambient temperature T.This ultimately results in an increase of ignition delay time.Therefore,the ignition delay time for re-ignition process is prolonged.This is consistent with the conclusion in the literature[38] that the ignition delay time increased with the initial temperature.Meanwhile,as reported in literatures [39,40],both the burning rate and the temperature of hot gas increased with the initial ambient temperature.The propellant needs to absorb heat in the process of heating from the initial temperature to the burning surface temperature.The net heat release of condensed phase decreased when the initial ambient temperature is low.At the same time,the radiation and heat conduction from gas phase to burning surface decreased with decreasing concentration of hot gas.This will eventually lead to a substantial decline of the burning rate.According to Eqs.(6) and (7),the platform pressure drops linearly with the decreasing burning rate.Hence,the lower initial temperature for re-ignition will led to the increase of percentage reduction of platform pressure.

3.4.Multi-time ignition and combustion performance of LCSP

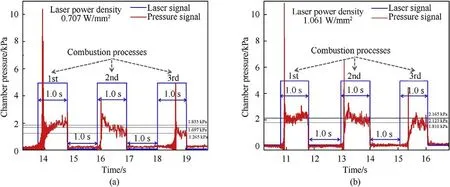

Fig.13. Multiple combustion processes at laser power density of (a) 0.707 W/mm2 and (b) 1.061 W/mm2.

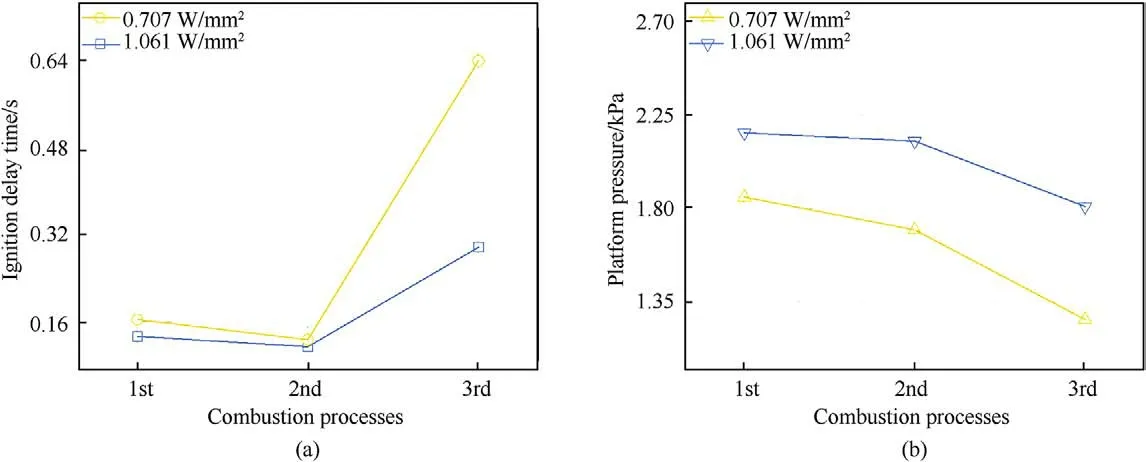

Fig.14. (a) Ignition delay time and (b) platform pressure during three combustion processes at laser power density of 0.707 W/mm2 and 1.061 W/mm2.

Multiple ignition tests were carried out to further clarify the controllable combustion performance of LCSP.As shown in Fig.13,three times of successful combustion processes were actualized sequentially under laser power density of 0.707 W/mmand 1.061 W/mm.Both the laser-on duration and laser-off duration of three times combustion process were set to 1.0 s.As shown,the ignition delay time and platform pressure increased and decreased respectively with increasing ignition times.In particular,there is a remarkable degradation of combustion performance and lasercontrollability during the third combustion process under laser power density of 0.707 W/mm.

As shown in Fig.14,the ignition delay time of LCSP increases from 0.165 s to 0.641 s,while the platform pressure decreases from 1.855 kPa to 1.265 kPa at laser power density of 0.707 W/mm.Simultaneously,the same trend was observed under laser power density of 1.061W/mm.Indeed,with the addition of ignition times,the cavity of combustion chamber enlarged due to the consumption of propellant.It hints that more combustion gas needs to be filled in chamber cavity per unit time to achieve the required ignition pressure.Therefore,the expansion of chamber cavity is not conducive to the establishment of ignition pressure.This is in accordance with the conclusions by Zhu et al.[41] that the maximum pressure and burning rate constantly decreased with the chamber cavity volume becoming bigger.In the meantime,the laser power density irradiated to burning surface will be attenuated caused by the accumulation of combustion residue.In this case,the increased ignition times has a negative impact on the combustion state of propellant.Moreover,as we can see,the platform pressure shows a relatively small drop and a slight decline can be observed in the ignition delay time during second combustion process.It should be noted that the laser-on duration and laser-off duration are relatively low (both were 1.0 s),so that the increased ambient temperature compensates for the energy loss of laser attenuation and expansion of chamber cavity to a certain extent.Hence,the combustion state has not changed much during second combustion process.Thereafter,the expanded chamber cavity makes it more difficult to establish pressure.Thus,the combustion performance decreased substantially.Nevertheless,the results of multiple ignition and combustion processes still manifests good laser-controlled agility and fairish combustion performance of LCSP compared with the related laser propulsion cases to date[15,16].

4.Conclusions

To solve the difficulties of conventional solid propellant,which is hard to achieve repeated initiation and interruption.The lasercontrolled solid propellant applied to laser ablation was designed and prepared.Meanwhile,the combustion behaviors of LCSP were tested under different laser on-off conditions.As the laser-on duration increased,the ignition delay time required for reignition increased,while the platform pressure showed a tendency of first increasing then decreasing during the re-combustion process.Furthermore,incremental laser-off duration increased both the ignition delay time for re-ignition and the percentage reduction of platform pressure.With the addition of ignition times,the combustion status of laser-controlled solid propellant weakened due to the laser attenuation and the expanded cavity.The results showed that the LCSP was able to switch the ignition and combustion state sensitively and had fast response characteristics after laser irradiation.These results are of considerable significance to improve the accuracy of thruster control system and optimize the structural design of propulsion system,which provided theoretical and practical reference for the application of micropropulsion system.

The authors declare that they have no conflicts of interest to this work.All authors have read and approved this version of the article.Neither the entire paper nor any part of its contents has been published or has been accepted elsewhere.

This work was supported by the Shanghai Aerospace Science&Technology Innovation Fund [grant number SAST201363],and the Fundamental Research Funds for the Central Universities [grant number 30919012102 in part].We gratefully acknowledge the technical support provided by Hao-yu Wang,Wei-kang Chen and Zhi-jing Xu (Shanghai Space Propulsion Technology Research Institute,China).

- Defence Technology的其它文章

- Defence Technology

- A study on the surface overpressure distribution and formation of a double curvature liner under a two-point initiation

- Performances and direct writing of CL-20 based ultraviolet curing explosive ink

- One-step synthesis of FeO(OH) nanoparticles by electric explosion of iron wire underwater

- Driving force coordinated control of an 8×8 in-wheel motor drive vehicle with tire-road friction coefficient identification

- Monitoring and Prediction of the Vibration Intensity of Seismic Waves Induced in Underwater Rock by Underwater Drilling and Blasting