Study of double-chamber air arc plasma torch and the application in solid-waste disposal

Yawen CAO(曹亞文),Bin LI(李斌),Xianwei HAN(韓先偉),Chang TAN(譚暢),Zhihao ZHANG(張志豪),Xizhe ZHANG(張晰哲) and Jianguo WEI(魏建國)

1 Shanxi Key Laboratory of Plasma Physics and Applied Technology,Xi’an 710100,People’s Republic of China

2 State Key Laboratory of Liquid Rocket Science and Technology,Xi’an 710100,People’s Republic of China

3 Academy of Aerospace Propulsion Technology,Xi’an 710100,People’s Republic of China

Abstract Arc plasma can be applied in hazardous solid waste disposal for higher temperature than common heating methods,but some practical issues exist in practical engineering application.In this study,an air arc plasma torch with double chambers and magnetic controlling is designed to realize wide variable power and long electrode life.The detailed characteristics and laws of the air arc are studied.The condition parameters of arc current(I),air flow rate(G)and the structure parameters of inlet area ratios and electrode diameters influence both the arc voltage and arc root positions.The arc rotating driven by magnetic field effectively lengthens the electrode life.The gasification process and product of organic wastes by air plasma are influenced largely by the waste compositions and the air flow rate.A furnace structure with more even atmosphere and longer residence time should be considered for better gasification.Oxygen-deficient environment is important to suppress NOx formation during the application of air plasma.Inorganic solid wastes can be melt by the air plasma and cooled down to form compact vitreous structures in which heavy metals can be locked and the leaching rates significantly decrease down.

Keywords:air arc plasma,electrical characteristic,electrode life,gasification,melting

1.Introduction

With rapid development of industrial level and living standard,more and more solid wastes are produced and required to be harmlessly dealt with.Among the solid wastes,some are hazardous and hard to be thoroughly disposed of by common combustion methods,for instance,solid wastes collected from some hospitals or chemical industry plants,of which the residual slag and ash after burnt are still hazardous.According to statistical data,up to 69 368.9 thousand tons of hazardous wastes were produced during 2017 in China[1],including the organic wastes and the inorganic wastes.Organic wastes like plastics and fabrics can be gasified and converted into combustible syngas and the resource reclamation can be realized due to the high heat value,while the inorganic wastes like furnace slag and fly ash have to be harmlessly treated further.

For the high efficiency of waste reduction,waste incineration has become the mainstream method for hazardous solid waste disposal.However,some drawbacks come out since the incineration temperature usually stays at 700°C–900°C,which is sometimes not high enough to avoid the dioxin forming under oxidation conditions and harmlessly treat the inorganic constituents.Also,medium temperature for pyrolysis and gasification brings problems of tar and coke,and the residues are still required to be further processed.As a result,the heat treatment of higher temperature is apparently a better choice for hazardous waste disposal.

Arc plasma has the advantages of focused power and active chemical particles,which can produce temperature much higher than conventional high-temperature incinerators and promote chemical reactions.The organics can be thoroughly decomposed in the thermal plasma and later form small molecules like CO,CH4in reducing atmosphere,and the inorganic matters can be molten at high temperature above 1200 °C.This technology has been investigated since 1990s and applied in industry since 2000s abroad,however,it develops much slower in China and was put into practical industry just a few years ago[2].The main drawbacks of the application of thermal plasma are the relatively high cost,short electrode lifetime,and low equipment dependability.

Many experiments and simulations have been conducted about thermal plasma application in solid waste treatment,and some of the studies are representative.Mountouris et al[3]set up an equilibrium model for the process of solid waste plasma gasification to predict the products and make energy analysis,and this model was further developed by other researchers[4–6].Tang et al[7–9]carried out many experiments and made comparisons about thermal plasma pyrolysis of different kinds of organic solid wastes.Zhang et al[10–12]carried out experiments and numerical simulations about the plasma gasification and melting process of municipal solid wastes with various parameters based on an engineering project.Chen et al[13,14]studied the melting of waste incineration fly ash with a DC arc plasma furnace and evaluated the effects of dioxin reduction and heavy metals solidification.Many relative studies focused on the energy conversion process and environmental effects[15],while the studies of plasma apparatus were relatively less.Zhukov et al[16]made abundant researches about the arc plasma torches and pointed out that reliability and lifetime were main restrictive factors for the industrial application of high-power arc plasma torches.DC non-transfer arc plasma torches with single chamber,multi-anode structure and relatively inert working gas like Ar or N2are the mainstream types in China for solid waste treatment according to past researches[17–19].Double-chamber arc plasma torch is a relatively uncommonly-used structure in China but foreign researches since 1960s[16,20,21]showed that it had potential in solid waste treatment industry for lower ablating rate and longer electrode lifetime,wider power range and flexible working gases and electrode materials.For practical industrial use,Researchers in Russia designed double-chamber arc plasma torches EDP-119 and EDP-212 for coal powder combustion[16].Lukiaschenko et al[20]designed a double-chamber linear circuit plasmatron VORTEX-200 with a conical nozzle for plasma ignition of a pulverized coal-fired power plant,the power of the plasmatron varied from 80 to 230 kW,the service life of the cathode could be up to 200 h and the service life of the anode exceeded 500 h.

In this paper,an DC double-chamber arc plasma torch was designed with air as the working gas and magnetic controlled.The plasma torch power is adjustable in a wide range of 30–150 kW.The voltage?ampere characteristics and arc motions are studied to understand the rules and links of the fluid and electromagnetic parameters,all to provide guidance to better structure design and parameter matching of the plasma torch,so as to help alleviate the electrode erosion and prolong the electrode lifetime of the high-power arc plasma torch.An electrode lifetime experiment was conducted to verify the feasibility of longtime operation of the plasma torch and its potential for industrial application.

Besides,an integrative solid waste gasification and melting system was set up with the DC arc plasma torch.Several kinds of plastics and the blends were gasified in the plasma furnace,and the compositions of the syngas are analyzed to briefly look into the gasification mechanism in air plasma.Several kinds of inorganic solid wastes were treated by the arc plasma and the effects were evaluated.The objective of these experiments was to verify and evaluate the feasibility of the disposal routine and system.

2.Experimental arrangement

2.1.Plasma torch and experimental system

The air plasma torch is designed as non-transferable arc type with double arc chambers and magnetic controlled.Figure 1 shows the schematic diagram of the air plasma torch system.The whole length of the chambers is 30 cm,and the electrodes are made from Cu in experiments except for the electrode lifetime experiment.The arc is generated by a high voltage of 10 kV,and then automatically turns to direct current to maintain the arc.The current can be set and the feedback value can be directly read,and the voltage is measured by a probe.The air flow rate is controlled by an accurate flow controller with a range of 0–15 g s?1,and the distribution ratio of the two inlets can be adjusted by changing the inlet areas.The whole system is cooled down by deionized water,of which the flow rate changes with the torch power and keeps a temperature below 50 °C.A camera is placed on the side to measure the length of the plasma jet from images as figure 1 shows,and a high-speed camera is placed at the jet axis to observe the arc motion.

Figure 1.Schematic diagram of the air plasma torch system.

2.2.Air plasma gasification and melting system

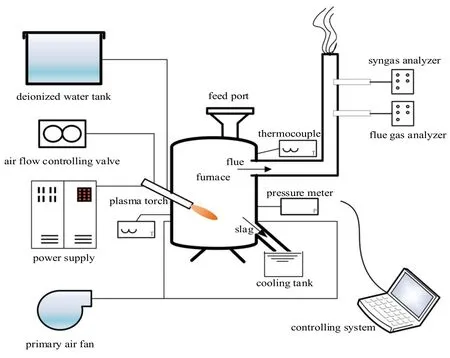

The plasma gasification and melting system is set up as figure 2 shows.The system is made up by the plasma system,the furnace system and auxiliary equipment.The plasma torch is inserted into the furnace with a degree of 30°.The materials are poured into the furnace through a feed port.The inner chamber size is 30 cm in diameter and 50 cm in height,and the whole furnace size is about 1.5 m in diameter and 1.8 m in height.Refractory and insulation materials are used to make the furnace and the furnace system operates without extra cooling water.Two platinum-rhodium thermocouples are inserted into the furnace to measure the temperature of the bottom and the top separately.Supplementary air can be supplied by a frequency conversion blower motor(0–50 Hz)so that the air volume can be freely adjusted.The analyses of the composition of syngas are completed by a syngas analyzer NOVA 970 P with 5 testing channels,which can synchronously show the volume fractions of O2,CO,CO2,CH4and H2.The syngas is sufficiently cooled down when flowing through a long sampling rod before entering the analyzer with the testing temperature below 100 °C.The pollutant emissions are tested by a flue gas analyzer Testo 310.The heavy metal contents of materials are tested according to HJ832-2017 and the leaching rates of heavy metals are tested according to the standard GB5058.3-2007.

Figure 2.Schematic diagram of the air plasma gasification and melting system.

2.3.Experimental parameters and materials

In the study of air plasma torch,the electricity characteristics of the torch were investigated,including the voltage?current characteristic(V?I),the voltage?flow characteristic(V?G)and the voltage characteristic influenced by the air distribution ratio(K)of anode flow rate(G1)and cathode flow rate(G2).The current varied from 80 to 250 A,the flow rate varied from 2 to 10 g s?1,and four air flow distribution ratios of anode and cathode(G1:G2)were studied,respectively 1:8,1:5.12,1:3.56 and 1:2.56.The voltage fluctuated within 5%.To measure the average length of plasma jet,each case was conducted and measured three times.To determine the arc root locations of different air distribution ratios,new pairs of electrodes were used for each case,ablation traces were left on the internal surfaces of the electrodes after operating for 30 min and the distance between the arc root position and the electrode gap could be measured by a caliper.The arc motion was monitored by the high-speed camera with power of 50–60 kW,for each case,6–10 rotations were averaged to obtain the frequency.For all experiments except for the electrode lifetime experiment,the electrodes were made from copper alloy(Cu).In the electrode lifetime experiment,two anode materials were selected to make a comparison,respectively the copper alloy(Cu)and the silver alloy(Ag),and the operation power was set at 120 kW.

In the study of plastic gasification by air plasma,four kinds of plastic particles and their blends were investigated.The feed rate was 1 kg/5 min.The four kinds of plastic particles are common in daily life,industry and medical treatment,respectively polypropylene((C3H6)n),polyethylene((C2H4)n),polyformaldehyde((CH2O)n)and ABS plastic(polymers of C3H3N,C4H6,C8H8).The polypropylene and polyethylene have similar elementary composition.Comparing with polypropylene and polyethylene,the polyformaldehyde has a certain content of O and the ABS plastic has higher ratio of C/H.The temperature significantly lowered down during the gasification,and rose up again as the gasification finished.Each gasification experiment took about 5 min to completely decompose the materials.The materials were inserted into the furnace when the bottom temperature rose up to(1500±15)°C and the top temperature rose up to(1200±40)°C.To keep the same air flow rate and heat coming from the plasma for each experiment,the plasma power was kept at a fixed value of 55 kW and the air flow rate was kept at 250 l min?1.The experiment results were averages of four readings for each material.The pollutant emissions were averages of three readings.In the melting study of the inorganics,slags and fly ash were collected from an incineration furnace after medical solid wastes burnt.Materials were treated under temperature of 1550 °C and cooled down to form vitreous body.Additives such as glasses and CaO were added to help form the vitreous body.Two samples were used to test the leaching rates of the heavy metal for each material.

3.Results and discussions

3.1.Characteristics of the plasma torch

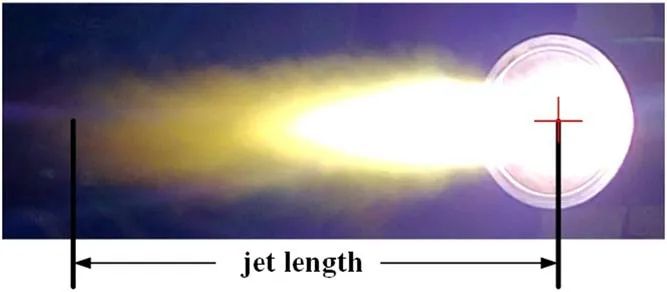

Figure 3 shows the plasma jet of this type of plasma torch.The length of the jet was measured under different typical powers and is shown in table 1.

Figure 3.Plasma jet of the arc plasma torch.

Table 1.Average length of arc plasma jet.

In general,the average length of arc plasma jet elongates with the increasing power and the growth rate is not so high,which shows the typical feature of turbulent flow plasma[22].

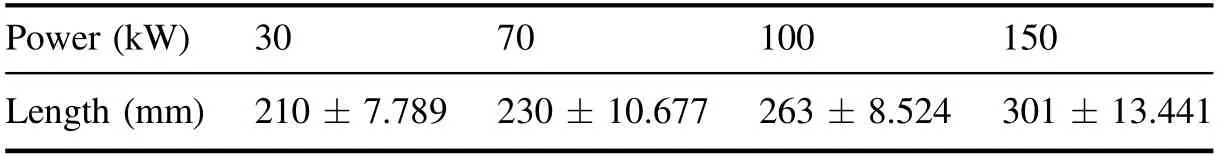

Figures 4 and 5 show the curves of voltage?flow and voltage?current.It can be seen from the curves in figure 4 that with a fixed current,the voltage increases with the air flow.According to the previous study[23,24],this trend can be explained by the cooling wall effect.The cold gas will compress the arc column in the radial direction and stretch it axially,leading to the increase on voltage.However,as the arc length reaches the limitation,the voltage tends to gain a slower growth.Similar effect of the gas flow rate has been presented in other former studies[23,24].

Figure 4.Curves of voltage-air flow(voltage fluctuation within 5%).

Figure 5 shows the curves of voltage changing with current.In this double-chamber design,the arc roots are movable both on the anode and the cathode.Result shows that the arc voltage decreases with the increase of arc current.It can be concluded that negative slope of voltage characteristics should be expected in this design.However,the descend range tends to narrow with the flow rate increasing.This phenomenon could be explained by the balance of fluid force and electromagnetic force[16].The cold gas would radially compress and axially stretch the arc column,while the increasing electromagnetic force would shrink and contract the arc.Therefore,increasing air flow helps restrain the arc length shortening caused by current increase.Besides,the air conductivity increases with the temperature due to higher degree of ionization,which also contributes to the voltage decrease.As a contrast,Lukiaschenko V G et al[20]found a voltage?ampere trend of down first and then up in the double-chamber design,of which the difference might result from the conical nozzle structure of the anode(external electrode).

Figure 5.Curves of voltage?current(voltage fluctuation within 5%).

Apart from the process parameters such as current and air flow rate,structure parameters also show influences on the electrical characteristics.

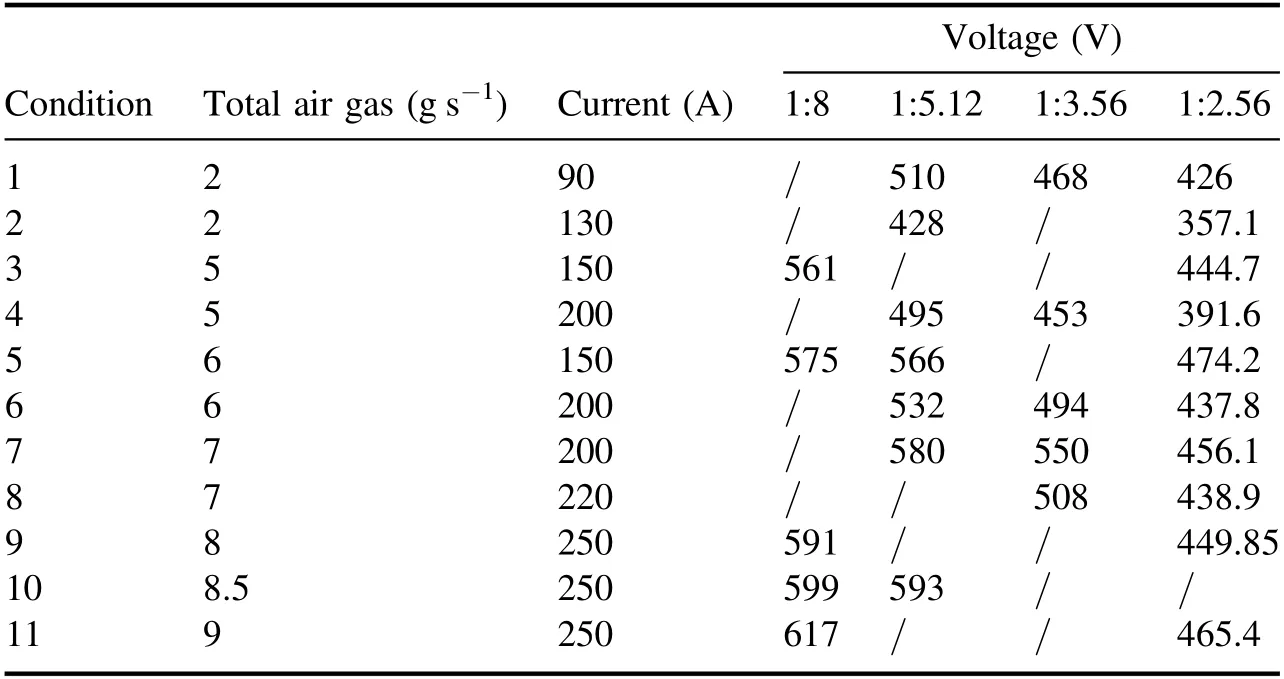

For a double-chamber arc plasma torch,since the arc root positions are results of fluid force and electromagnetic force balance,the anode arc root and cathode arc root could be expected to be respectively restrained by adjusting the air flow rate ratio of anode and cathode[16,20].Table 2 presents the effect of air flow rate ratio of anode and cathode(G1:G2)on voltage.Four air flow distribution ratios of anode and cathode were studied,respectively 1:8,1:5.12,1:3.56 and 1:2.56,and the experiments covered most working conditions.It could be pointed out from the results that increasing air inlet ratio of the anode causes voltage to decrease.

Table 2.Effect of air flow ratio of anode and cathode on voltage(voltage fluctuation within 5%).

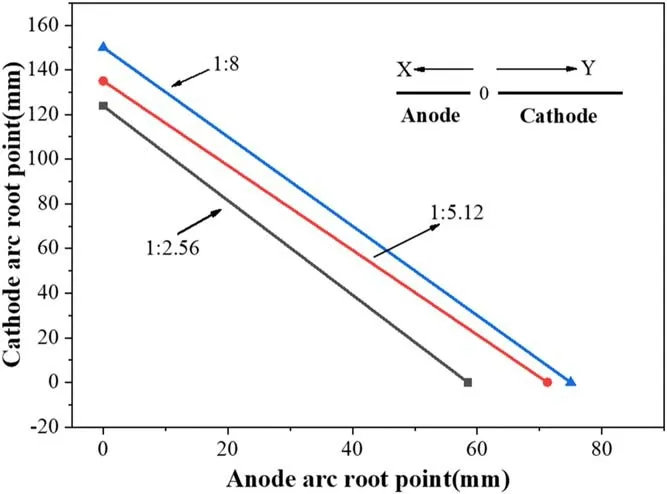

The arc root moving with the air flow rate ratio changing could be studied through the ablation marks on the internal surface of the electrodes.Figure 6 shows the roughly arc root positions of three different air flow rate ratios with a working condition of 6 g s?1and 150 A.Figure 7 shows the photos of the worn electrodes.

Figure 6.Arc root positions with different air flow rate ratios.

Figure 7.Arc root ablation traces on the internal surface of the electrodes.

Results shows that as the anode air inlet ratio increases,the arc contracts and both of the anode arc root and the cathode arc root move towards the electrode gap.If the arc is too long or too short,erosion would take place in vulnerable structures,such as sealing parts and areas near air inlet passages,which would obviously reduce the structure reliability and shorten the torch working life.Individually adjusting the total gas flow might cause some issues,for examples,arc roots will move in the same direction,or the gas flow is not abundant to hold the arc steady.Similarly,individually adjusting the current might cause the current mismatching with air flow.These characteristics would limit the power regulation ability of the plasma torch to some extent.According to the above experiment results,controlling the arc root positions by changing the inlet air ratios of the electrodes proves to be a more effective and flexible method for power regulation.Another enlightenment from this experiment is that the width of the electrode ablation surface area can be significantly increased by axial scanning of the near-electrode portion of the arc through changing the gas dynamic parameters of K.Thereout,the utilization of the electrodes could be largely increased and the working life could be largely prolonged[20].

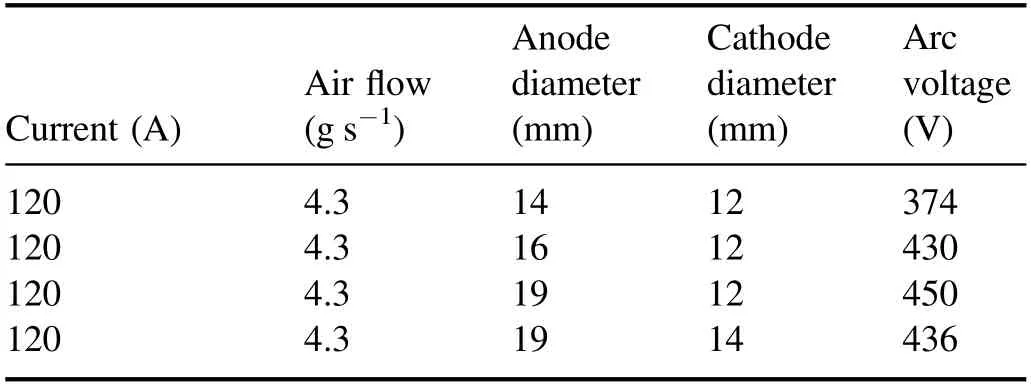

The inner diameter ratio of the anode and the cathode(Da:Dc)is another important structure parameter that influences the electrical characteristic of the arc.Table 3 shows the experimental results of four different matches of electrode inner diameters.

Table 3.Effect of electrode inner diameters on arc voltage(voltage fluctuation within 5%).

It can be seen from table 3 that increasing the anode inner diameter leads to the increase of arc voltage.This phenomenon could be explained by the influence of the air pressure.For the anode arc root,increasing the anode inner diameter reduces the air pressure in the anode passage,which leads to the reduction of the aerodynamic force and the stretching of the anode arc.Similarly,increasing cathode inner diameter leads to the reduction of arc voltage,since the reduction of cathode air pressure leads to the reduction of cathode aerodynamic force which helps the arc stretch.

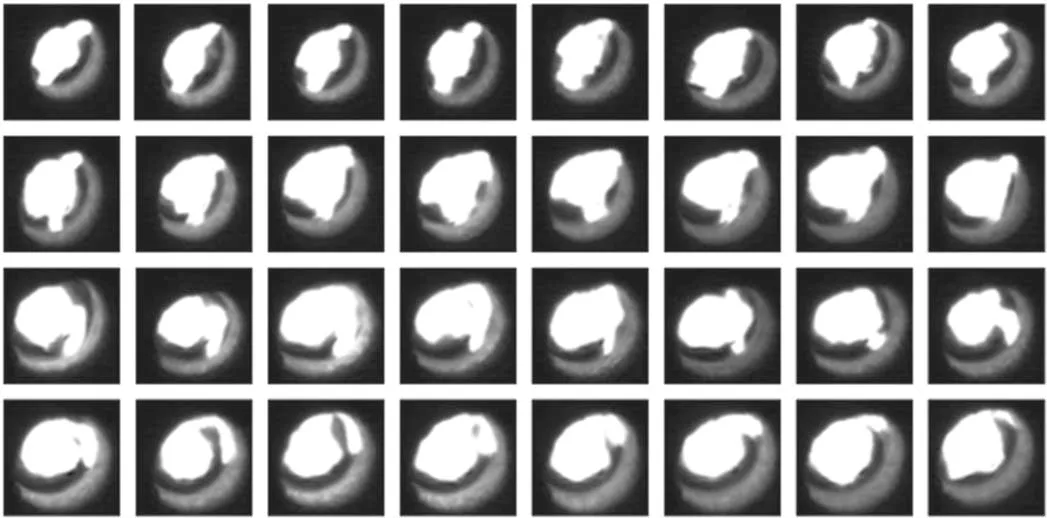

To alleviate the electrode ablation and prolong the electrode working life,magnetic field is designed to surround the electrodes and drive the arc to rotate.Figure 8 shows the movement of the arc within 1.28 ms.All the images were taken by the high-speed camera at the jet axis[25].Current(A)Air flow(g s?1)Rotational frequency(Hz)

Figure 8.Arc circumferential movement(Δt=0.04 ms,G=4 g s?1,I=100 A).

Table 4.Effect of magnetic field intensity on rotational frequency.

It can be seen from figure 8 that the arc rotates with nonuniform velocity and sometimes distributaries to form double arcs.Still,the average rotational frequency could be calculated by the formula:

According to the images,arc rotational frequency with conditions of 4 g s?1air flow and 100 A current is 391 Hz.To study the influence of magnetic field intensity on rotational frequency,the current was changed and the air flow kept unchanged,and the average rotational frequency was calculated as table 4 shows.

Apparently the arc rotating frequency accelerates with the increasing current,which protects the electrodes from being burned through fast by converting single-point ablation to multiple-point ablation.The arc rotating frequency is up to several hundred rounds per second(Hz)and helps prolong the electrode working life.

According to the electrode lifetime experiments,with the power of 120 kW,the maximum working life is up to 400 h for the cathode(Cu).For the anode,the electrode lifetime exceeds 500 h with Cu material and exceeds 700 h with Ag material,which could satisfy the longtime running requirement of practical engineering.

3.2.Plastic gasification by air plasma

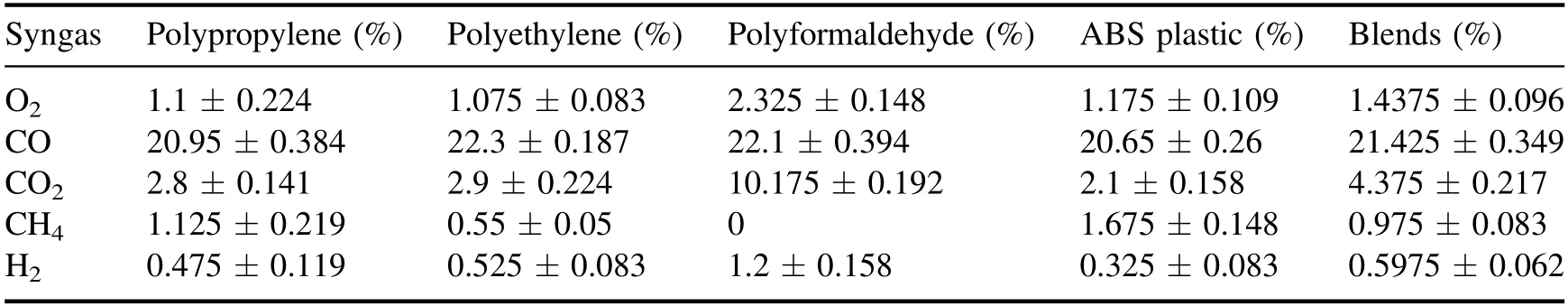

Table 5 presents the syngas compositions of the four kinds of plastics and their blends of equal proportions at a high temperature condition with the bottom(1500±15)°C and the top(1200±40)°C.

According to the results,plastic particles decompose rapidly in the air plasma and form more than 20% combustible syngas,including CO,CH4and H2.The primary air fan is closed to keep an oxygen deficit condition,so the O2content is far below 21%in air.As the air is the working gas,N2absolutely takes a high proportion in the syngas.

Table 5.Syngas composition of plastic gasification by air plasma.

The gasification results are not so ideal as CH4and H2present relatively low contents.The furnace atmosphere is heterogeneous as the plasma torch locates at the bottom with a degree of 30°,which presents high air/oxygen content at the furnace bottom and low air/oxygen content at the furnace top.As the materials fall into the furnace from the feeding port at the furnace top,the particles begin pyrolysis process without air/oxygen since the temperature is high enough.A considerable amount of materials decompose in this phase,forming some detected constituents like CH4,CO and H2.In the meantime,undetected constituents such as HCN,other hydrocarbons like C2H2,C2H5,etc,or even dissociated H and C atoms form during the process.The updraft furnace is directly connected with a short chimney,and the hot gas velocity is high,which leads to short residence time and rapid emission of these constituents.Compared to the carbon black which may stick to the wall and remain for later gasification,the H element may lose a lot during this process.For the part of materials falling down to the bottom of the furnace,the air/oxygen is relatively abundant,some CO2and H2O form in this phase.The results are in fact the mixture of the syngas from different positions of the furnace.The loss of H element in undetected pyrolysis products at the furnace top and the undetected H2O from the furnace bottom may lead to the nonideal results.For better gasification,a furnace with a plasma torch and feeding port in the middle to realize a more even atmosphere and longer residence time should be considered.

Still,it could be identified that elementary compositions in raw materials greatly influence the syngas products.The polypropylene and polyethylene have similar syngas products due to their similar mole ratio.Polyformaldehyde has the same mole ratio of C/H=1:2 with polypropylene and polyethylene,but the extra O element causes higher CO2content of 10.175% and completely blocks the formation of CH4.Also,the residual oxygen(O2content)in polyformaldehyde gasification products reaches 2.325%,which is obviously higher than the other three plastics.For the blends of equal proportion,the syngas composition approximates the average of the four mono-components.This means no complex synergistic reaction occurs during the cracking and recombination of the chemical bonds of the high polymer materials.

3.3.NOx emission characteristics

Table 6 presents NOxemissions before polypropylene gasification and during polypropylene gasification.The data was collected shortly after the polypropylene poured into the furnace.

Results show that large amount of NOxgenerates from air plasma when no plastic is fed into the furnace.It is apparent that all NOxcomes from the reaction of N2and O2due to the air discharge and high temperature.NOxgenerating by this methodis called thermal NOx,which only exists where the temperature is higher than 1500°C.However,the NOxdecreases rapidly at the time the gasification process begins.This phenomenon could be explained by the furnace atmosphere.It is certain that the air would be decomposed into N and O atoms or ions when flowing through the high temperature arc,and recombines to NOxin the furnace at lower temperature.When polypropylene mixes with the air plasma,the gasification is prior to consume O atoms and ions,besides,the gasification causes regional cooling around the plasma jet,which would also suppress the NOxgeneration.This experiment verifies that the reductive and high temperature atmosphere set up by air thermal plasma is suitable to be applied to organics gasification in terms of NOxemission reduction,and air thermal plasma application in combustion is not expected to be so environmentally friendly due to the high NOxemission rate.

Table 6.NOx emissions during the polypropylene gasification.

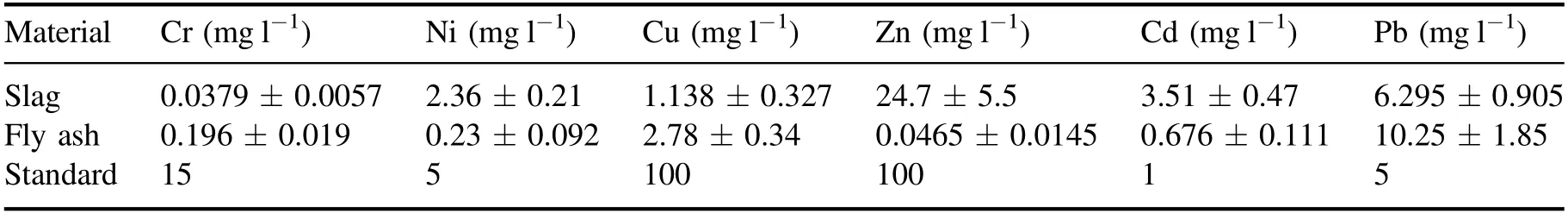

Table 7.Leaching rates of the rotary kiln slags and fly ash.

3.4.Melting characteristics of the inorganic solid wastes

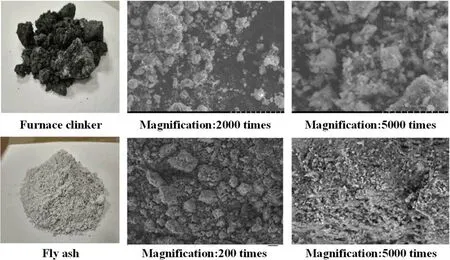

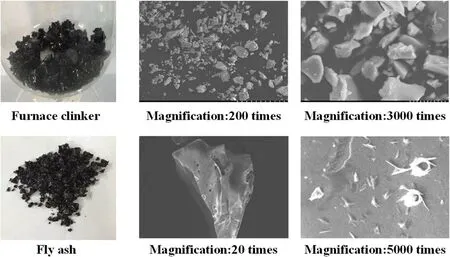

Table 7 shows the heavy metal leaching rates of the rotary kiln slag and fly ash collected from a hazardous solid waste incineration plant.Figure 9 shows the SEM pictures of the rotary kiln slag and fly ash.

Those on shore thought theyheard cries for help from those on board, and could plainlydistinguish the busy but useless efforts made by the stranded sailors

Figure 9.SEM pictures of the rotary kiln clinker and fly ash.

According to the tests above,leaching rates of some heavy metals in rotary kiln clinkers and fly ashes show significant excessive contents,such as Cd and Pb.The SEM pictures show that the rotary kiln clinkers have loose structure with a lot of pores and sinter slightly on the surface.The SEM pictures show that structure of the fly ashes is loose,disperse and unbonded.

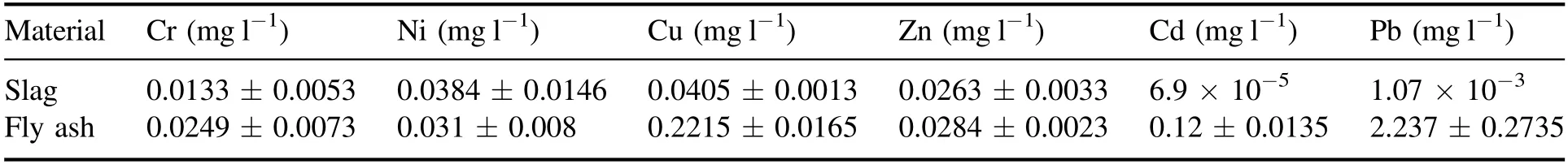

Table 8 shows the heavy metal leaching rates of the rotary kiln clinker and fly ash being melt at 1550°C by the air plasma with 10% glasses added in and cooled down by cold water.Figure 10 shows the melting process,and figure 11 shows SEM pictures of the rotary kiln slag and fly ash treated by air plasma.

Table 8.Leaching rates of the rotary kiln slags and fly ash treated by air plasma.

Figure 10.The air plasma melting process.

Figure 11.SEM pictures of the rotary kiln clinker and fly ash treated by air plasma.

According to the experiment results,the heavy metal leaching rates lower down vastly for both the furnace clinker and the fly ash.The effects for the furnace clinker are relatively more significant than that for the fly ash,which may result from the different element compositions and physical structures.It comes to a conclusion from SEM pictures in figure 11 that the loose structures of the materials have converted to compact and smooth vitreous structures.

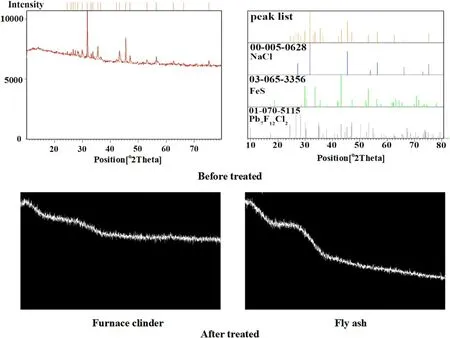

The XRD results of the rotary kiln clinker and fly ash treated by air plasma are presented in figure 12.The crystal structures of the materials are irregular with sharp diffraction peaks,and the sharp diffraction peaks disappear after treated and amorphous structures form instead.The XRD spectrum of the melting products shows dispersed envelope curves,which also indicates that the materials have converted to vitreous structures.

Figure 12.XRD result of the materials and products treated by air plasma.

Since the vitreous structures are compact,the heavy metals can be locked in the structures,thus lowering down the leaching rates and realize harmless disposal[13,14].

4.Conclusions

This work studied the detailed characteristics of an air arc plasma torch with double chambers and magnetic controlling,in order to realize wide variable power range and long electrode working life for practical engineering of solid waste treatment.A solid waste treatment system is set up with this air arc plasma torch to study the gasification of organic solid wastes and the melting of inorganic solid wastes.The effects of hazardous solid wastes treated by air arc plasma could be confirmed through series of experiments.The major conclusions are as follows:

(1)The air plasma shows the typical feature of turbulent flow plasma and the plasma jet lengthens with the increasing power.The arc of double-chamber plasma shows the characteristic of self-stabilization.The arc voltage increases with the increase of gas flow,and decreases with the increase of the current.

(2)Changing the structure parameters can realize widerange power adjustment by influencing the arc voltage.The area ratio of the two air inlets influences the arc root positions significantly due to the change of the aerodynamic force and flow field structure.When the area ratio of inlet1 and inlet2 increases,the anode arc root moves significantly towards the downstream.The inner diameters of the electrodes also influence the arc root position and arc voltage to a large extent due to the influence of air pressure.

(3)The arc is rotating at high speed of several hundred rounds per second driven by the magnetic field,and the rotating frequency increases along with the current,which helps protect the electrodes and prolong the electrode life.The maximum working life is up to 400 h for the cathode(Cu)at 120 kW.For the anode,the electrode lifetime exceeds 500 h with Cu material and exceeds 700 h with Ag material.

(4)The constituent of the organic solid waste and the air flow influence the composition of the syngas vastly.In air plasma gasification,no complex synergistic reaction occurs during the cracking and recombination of the chemical bonds of the high polymer materials.A furnace structure with more even atmosphere and longer residence time should be considered for better gasification.

(5)Oxygen-deficient environment is important to suppress the formation of NOxduring the application of an air plasma torch.

(6)In the high temperature produced by air plasma,inorganic solid wastes can be melt and cooled down to form compact vitreous structures in which heavy metals can be locked and the leaching rates significantly decrease down.

Acknowledgments

This work is supported by National Key R&D Program of China(No.2019YFC1907000)and National Natural Science Foundation of China(No.11475131).

Plasma Science and Technology2021年6期

Plasma Science and Technology2021年6期

- Plasma Science and Technology的其它文章

- Special issue on selected papers from HVDP 2020

- Microwave transmittance characteristics in different uniquely designed one-dimensional plasma photonic crystals

- Burst pulses for positive corona discharges in atmospheric air:the collective movement of charged species

- Effect of plasma step gradient modification on surface electrical properties of epoxy resin

- Reconstruction of energy spectrum of runaway electrons in nanosecond-pulse discharges in atmospheric air

- The enhanced aerosol deposition by bipolar corona discharge arrays