The irradiation variation of amorphous alloy FeSiB using for fusion devices induced by 2 MeV He ions

Xiaonan ZHANG(張小楠),Xianxiu MEI(梅顯秀) and Shanshan LI(李山山)

1 School of Science, Dalian Jiaotong University, Dalian 116028, People’s Republic of China

2 Key Laboratory of Materials Modification by Laser, Ion and Electron Beams, Dalian University of Technology, Ministry of Education, Dalian 116024, People’s Republic of China

3 Saybolt(Tianjin)Metrology&Inspection Co.Ltd.DaLian Branch,Dalian 116100,People’s Republic of China

Abstract Because of its unique long range disordered structure and numerous free volume, amorphous alloy is considered to be able to accommodate the damage caused by ion bombardment and has good irradiation resistance.2 MeV He+ ions were selected to irradiate amorphous alloy Fe80Si7B13, and it was found that the arrangement of atoms in the amorphous alloy became uneven.In the bubble layer located near the He ion range which was about 3.5 μm from the surface, the local atoms had a tendency of ordered arrangement.Under the irradiation, no obvious damage could be observed on the surface of the amorphous alloy, while the surface roughness increased,which reduced the surface relative reflectivity of the amorphous alloy.After the irradiation, the Fe-based amorphous alloy maintained the soft magnetic performance.The variation of atomic arrangement in the amorphous alloy enhanced its saturation magnetic induction intensity.

Keywords: He ions, Fe-based amorphous alloy, irradiation damage

1.Introduction

In fusion devices, the plasma optical diagnosis system is a key component to realize the controlled fusion process[1, 2].The first mirror in this system is exposed to the plasma environment and is irradiated by x-rays,gamma rays,neutrons and fusion plasma streams [3, 4].As a result,surface sputtering or deposition occurs in the first mirror[5].Meanwhile, the injection of energy will change the internal structure of the first mirror.This variation will affect the surface morphology and optical performance of the mirror,and ultimately affect the optical diagnosis result of the fusion device.Therefore, the irradiation resistance of the candidate materials for first mirror is required by the harsh irradiation environment.

Traditional irradiation resistant materials which have been widely studied include W [6, 7], Mo [8], low activated steel[9,10]and ceramics[11]etc.The previous studies show that these materials can withstand the irradiation of certain doses, however, surface cracking [12], fuzz [13], decrease of reflectivity [3], swelling [14] and other performance deterioration will occur under the irradiation of high dose.This limits their service life in the optical diagnostic system of fusion devices.

Amorphous alloy has long range disordered, isotropic structure,and lacking of dislocation,grain boundary and other common defects in crystal materials, so that the oriented sputtering can be avoided.Thus it may maintain a high surface reflectivity and can be used as the first mirror.Moreover,amorphous alloy contains a large number of free volumes,which can provide placement sites for the incident ions and thus increase the surface damage threshold.It is considered to have good irradiation resistance [15] and can be applied in optical diagnostic systems.Thereinto, Fe-based amorphous alloy owns high initial crystallization temperature, wide supercooled liquid region, relative higher thermal conductivity, high strength and good soft magnetic performance[16].Under stable plasma conditions, if Fe-based amorphous alloy with low activation and high crystallization temperature is selected as the candidate material of the first mirror, it is possible to maintain high optical reflectivity and low sputtering to meet the requirement for first mirror.

He ion is the main irradiated particle stream in the fusion reactor.As an inert gas atom, He will not react with target atom during the injection.Additionally, He ion source equipment is relatively popular.So choosing He ion to study the irradiation resistance of materials is a preferred choice.

The injection of MeV ions with high electronic energy deposition and low angle scattering can break the isotropic symmetry of the amorphous alloy system.Consequently,the density of amorphous alloy is fluctuated, and the evolution of irradiation damage is influenced.In this study,2 MeV He ion was used to irradiate amorphous alloy Fe80Si7B13to study its structural evolution, surface damage and property changes with electronic energy loss as the main energy transfer mode.

2.Experiments

The amorphous alloy Fe80Si7B13ribbons with a thickness about 35 μm for irradiation were manufactured by the meltquench method, and they were all cut to 10 mm wide.The irradiation experiment was carried out at 4.5 MV electrostatic accelerator located in the Institute of Heavy Ion Physics of Peking University.The doses of 2 MeV He+ions were 1×1017ions cm?2and 5×1017ions cm?2, the beam intensity was about 5 μA, and the temperature was RT.The incident angle of the ion beam is 90° relative to the sample surface.

The Stopping Range of Ions in Matter (SRIM) procedure was used to calculate the displacement damage in the amorphous alloy.The phase structure of samples was detected by x-ray diffractometer (XRD) with Cu Kαradiation in grazing incidence model, the incident angle was 1°.The sectional damage morphologies induced by the irradiation of maximum dose were observed by transmission electron microscope(TEM), the operating voltage was 200 kV.Focused ion beam was used to fabricate the TEM sample.The surface morphology of samples was observed by scanning electron microscope(SEM).The atom force microscope(AFM)with tapping mode and the ultraviolet spectrophotometer within the wavelength of 200–3000 nm were chosen to measure the root-meansquare (RMS) roughness and the relative reflectivity of the amorphous alloy.The magnetic property of Fe-based amorphous alloy was analyzed by vibration sample magnetometer,the external magnetic field was 238 800 A m?1.

Figure 1.XRD patterns of Fe80Si7B13 amorphous alloy irradiated by 2 MeV He+ of different doses.

Table 1.The damage parameters of Fe80Si7B13 amorphous alloy irradiated by 2 MeV He+ calculated by SRIM procedure.

3.Results and discussion

Based on Monte-Carlo simulation, the irradiation damage caused by 2 MeV He+in amorphous alloy Fe80Si7B13was calculated via SRIM procedure [17].The average displacement threshold used in the calculation was 35 eV, table 1 gives the detailed damage parameters.The projection range of He ion in the alloy was relatively large because of its high energy, and its sputtering yield was smaller than that of the 500 keV He ion irradiated Fe-based amorphous alloy in our previous study[18].In the irradiation process of 2 MeV He+,the electronic energy loss played a leading role as it was three orders of magnitude higher than the nuclear energy loss.He+ions mainly transmitted energy through electron–phonon coupling when they collided with the target atoms, and this process would bring the temperature rise of lattice and electron excitation.He+ions mainly lost energy in this way and generated displacement damage in the Fe-based amorphous alloy.The damage was up to 23 dpa as the dose reached 5×1017ions cm?2.

The XRD patterns of amorphous alloy Fe80Si7B13are given in figure 1 with and without He+ions irradiation by different doses.Merely one broad peak appeared in the pattern of original samples, demonstrating amorphous structure of the unirradiated alloy.Under the irradiation, no additional diffraction peak could be observed indicating that no major structural changes occurred in Fe-based amorphous alloy under the high energy He+irradiation.

Figure 2.(a)The cross-sectional TEM image,the corresponding SAED pattern of(b)none-He bubbles layer A and(c)He bubbles layer B in(a) of amorphous alloy Fe80Si7B13 irradiated by He+ at a dose of 5×1017 ions cm?2.

Figure 2(a)gives the cross-sectional TEM topography of Fe-based amorphous alloy under He+irradiation at a dose of 5×1017ions cm?2.A bright belt with 300 nm width appeared at about 3.5 μm away from the surface,namely a He bubble layer.The depth was close to the He ions range calculated by SRIM procedure.He ions collided with the target atoms,lost their energy through the electronic energy loss and slowed down,eventually stayed in the amorphous alloy.Then the He atoms gathered and merged with the vacancies and other He atoms through migration and diffusion to nucleate,absorbed more free He atoms and collected into bubbles[19].Thus a bubble layer could be observed by TEM.Figures 2(b)and (c) present the selected area electron diffraction (SAED)patterns of ions-passing area A and bubble layer B in figure 2(a), respectively.Merely one diffused halo appeared in figure 2(b).It means that amorphous state was the main structure of the ions-passing area under the irradiation.While in figure 2(c),a hazy halo corresponding to the plane(211)of β-Mn type phase was observed,there was a tendency of atom ordered arrangement formed in the severely damaged He bubble layer.

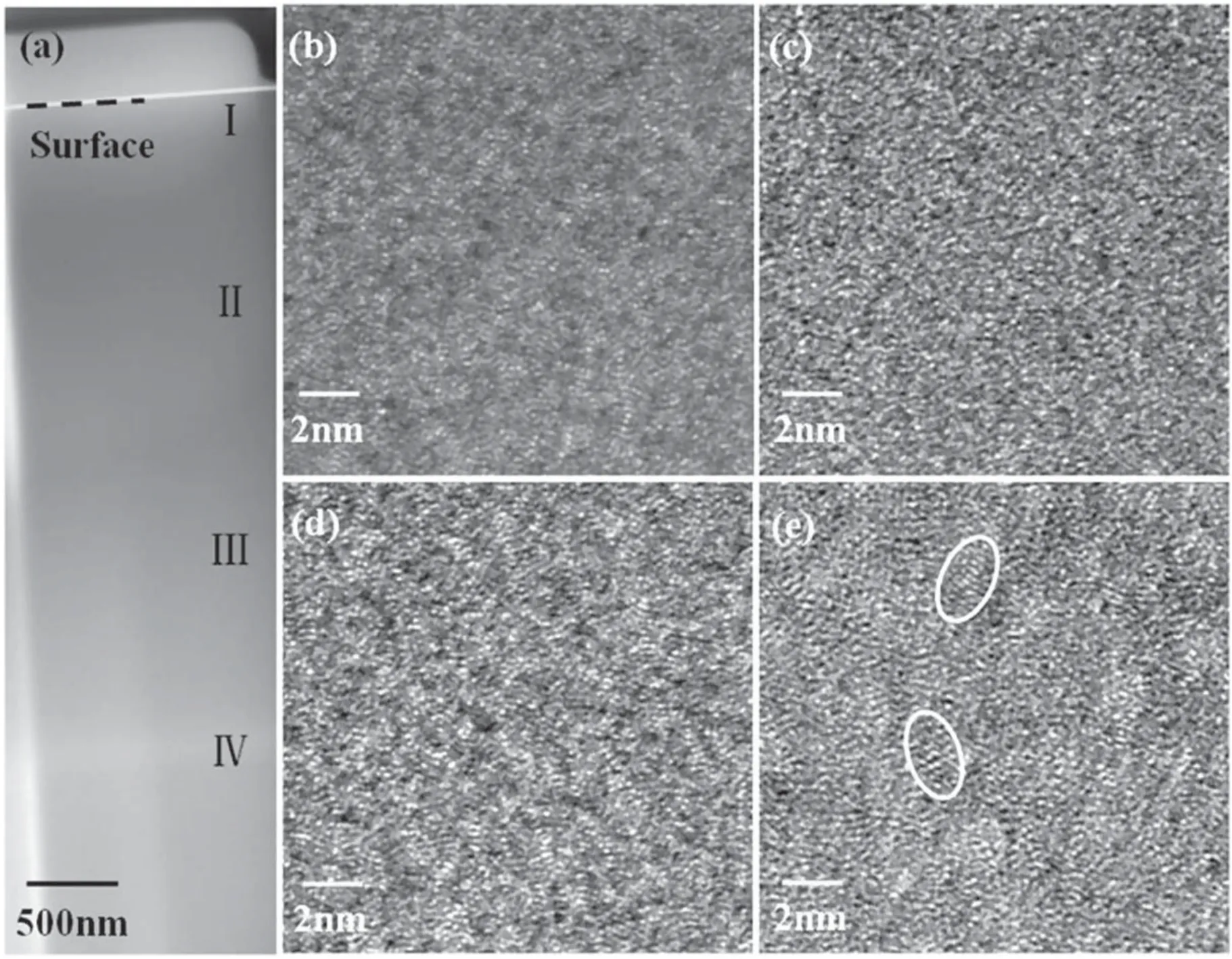

Figures 3(b)–(e)present the high resolution transmission electron microscopy(HRTEM)topographies of areas I–IV in figure 3(a), respectively.Area I was the near surface area.Areas II and III were He ions-passing area and they were respectively about 1.1 μm and 2.6 μm away from the surface.Area IV was located on bubble layer, namely He ions occupied area.Atoms in area I arranged disorderly and evenly.With the increase of the ion injected depth, it could be seen from figures 3(c) and (d) that the atomic distribution became uneven from area II to area III.In the He ions occupied area IV, the tendency of local ordered arrangement of atoms appeared, as shown in the oval area of figure 3(e).As these ordered arrangement areas were small and dispersed, their clear fast Fourier transform patterns could not be obtained.The SAED pattern of the bubble layer in figure 2(c) shows that the ordered arrangement of atoms tended to form the β-Mn type phase.The DPA distribution calculated by SRIM procedure confirmed the changes of atomic arrangement from the surface to the bubble layer in the alloy observed by TEM:within the ions range, the DPA value increased with the depth, and the atomic arrangement became uneven, the local ordered arrangement appeared even, and DPA reached its maximum value at the projected range.With the increase of the atomic displacement damage,numerous atomic migration occurred during the irradiation, leading to more free volume and atomic aggregation.The uneven atomic arrangement led to the crystallization [20].The introduction of excess free volume into the He bubble layer would promote the diffusion rate of atoms.Meanwhile, area with atomic dense heap formed around the bubbles to balance the high pressure in the bubble, this also led to the uneven arrangement of atoms and the occurrence of crystallization.In our previous study [21],nanocrystals mainly formed among He bubbles within the bubble layer,indicating that the high pressure induced by He atoms injection and aggregation was the most important factor driving the movement and orderly arrangement of target atoms.

Figure 3.(a)The cross-sectional TEM image and the HRTEM image of(b)area I within(a),(c)area II within(a),(d)area III within(a),(e)area IV within (a) of amorphous alloy Fe80Si7B13 irradiated by He+ with a dose of 5×1017 ions cm?2.

Figures 4(a)and(b)respectively give the under and over focus TEM images of He bubble layer in amorphous alloy Fe80Si7B13with the dose of 5×1017ions cm?2.The bubbles in figure 4(a)showed bright Fresnel stripes while dark Fresnel stripes in figure 4(b), which proved that the bright belt about 3.5 μm away from the surface in figures 2(a) and 3(a) was indeed He bubble layer [22].Figure 4(c) gives the HRTEM morphology image of He bubble layer in Fe-based amorphous alloy.A large number of bubbles with a diameter about 2 nm are distributed evenly throughout the field of view.During the irradiation, the ion implantation accompanied by energy deposition enhanced the atomic diffusion rate in the alloy,and promoted the combination of intrinsic or introduced‘vacancy-like’ defects with the He atoms to form bubbles.Small He bubbles attracted and connected with each other and grow into larger bubbles to decrease the surface energy via the reduction of surface curvature, in order to attain a stable state.A large number of He bubbles led to changes in the distribution of elements in the alloy, as shown in figure 4(d).From the surface to the He ions range, the content of Fe and Si elements decreased continually, and the minimum value was located near the ion range due to the existence of He bubbles.The formation of composition gradient in amorphous alloy caused by the accumulation of massive He atoms also promoted atomic migration, resulting in uneven arrangement of atoms and inducing the crystallization[23].In our previous research, 300 keV He ion irradiated the Fe-based amorphous alloy,numerous He bubbles with similar diameters were also observed at the dose of 4×1017ions cm?2[21].The size of the bubbles was mainly dependent on the irradiated dose during the irradiation rather than on ion energy.

High-energy He ions injected into the amorphous alloy,after the primary collision, the primary knock-on atoms and ions with the residual energy collided with target atoms,secondly the energy was transferred by collision to form the collision cascade.Due to this, the atoms tended to arrange orderly via displacement and migration.The Frank–Kasper coordination polyhedron existing in the amorphous alloy as a local structure could transform to metastable β-Mn type crystalline phase merely through a radiation energy actuated short-range diffusion [24].Therefore, in this study, the hazy halo of β-Mn type crystalline phase was observed when the dose was 5×1017ions cm?2.In our previous research [22],β-Mn type phase was also observed in the Fe-based amorphous alloy under 300 keV He ion irradiation with a dose of 4×1017ions cm?2.Figure 5 shows the distribution of DPA with depth under the two aforesaid irradiation conditions.The injected range of 300 keV He ions was smaller than that of 2 MeV ions.Atomic displacement under 300 keV He ions irradiation occurred in the ions-passing area near the surface,while it rarely appeared in the latter case.MeV He ion irradiation with high energy deposition brought more serious cascade effect,in the figure,the full width at half maximum of DPA distribution of 2 MeV He ion irradiation was greater than that of 300 keV ions:larger damage area and more serious atomic diffusion formed due to the high energy.The maximal DPA values of the two irradiation condition near the respective ion range were relatively close,and the same crystallization phase(or any of the trend) was observed in the TEM analysis.It indicated that in the ion irradiation process with non-equilibrium energy injection, the metastable β-Mn type crystallization phase would form firstly in Fe-based amorphous alloy within the He ions energy range from hundreds of keV to several MeV.

Figure 4.(a)The under-focus and(b)the over-focus TEM image,(c)the HRTEM image of He bubbles layer,and(d)the content distribution of Fe and Si element with depth in amorphous alloy Fe80Si7B13 irradiated by He+ with a dose of 5×1017 ions cm?2.

Figure 5.The comparison of DPA in amorphous alloy Fe80Si7B13 induced by the irradiation of 300 keV He2+ ions with a dose of 4×1017 ions cm?2 and 2 MeV He+with a dose of 5×1017 ions cm?2.

The SEM morphologies of amorphous alloy Fe80Si7B13before and after 2 MeV He+ions irradiation are given in figure 6.Under the irradiation,no obvious irradiation damage appeared on the surfaces of the amorphous alloy.As amorphous alloy exhibits long term disordered structure and it is short of grain boundaries,dislocations[25]and stacking fault etc which are common in crystals, so that the occurrence of directional selection sputtering was restrained during the irradiation.Meanwhile, amorphous alloys have vast free volume, and the atoms have a disorganized arrangement,which make the amorphous alloys have a high capacity of He+ions.So under the irradiation of this study, no obvious damage could be observed on the surfaces.

Figure 6.The SEM images of Fe80Si7B13 amorphous alloys before and after He+ irradiation with different doses: (a) original,(b) 1×1017 ions cm?2, (c) 5×1017 ions cm?2.

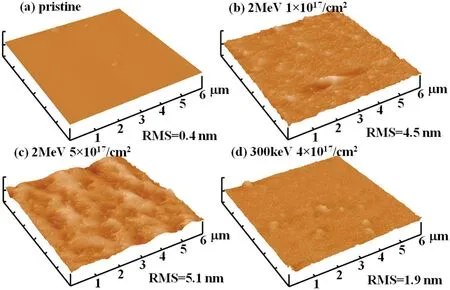

Figure 7.The AFM images of Fe80Si7B13 amorphous alloys before and after He+ irradiation with different conditions: (a) original,(b) 2 MeV, 1×1017 ions cm?2, (c) 2 MeV, 5×1017 ions cm?2, (d) 300 keV, 5×1017 ions cm?2 (Z-scale: 80 nm/division).

Figure 8.The relative reflectivity of Fe80Si7B13 amorphous alloys before and after He+ irradiation with different doses.

Figure 7 gives the AFM image of original amorphous alloy Fe80Si7B13and its morphologies after He+ions irradiation of different conditions.It can be observed from the figure that the original flat surface became rough after irradiation,and the RMS roughness of the surface largened from 0.4 nm of the original sample to 5.1 nm as the dose increased to 5×1017ions cm?2under the bombardment of 2 MeV ions.While during the irradiation of 300 keV He ions, the RMS roughness of the surface was 1.9 nm with a dose of 5×1017ions cm?2.Compared with 300 keV He ions,during the deceleration process of high-energy ions of 2 MeV when they injected into the solid, the ions would transfer part of their kinetic energy to the target atoms in the solid.Recoil atoms in turn transferred some of their energy to other atoms.The transfer of energy resulted in the formation of a strongly damaged, extraordinary hot region in the solid.There would be huge pressure in this region, as the particles collided,within a few ps the peak pressure would even reach 5–8 GPa which would cause a micro-explosion in local region.The ejective pressure waves reached the surface and roughen it up[25, 26].In addition, the inherent impurities in the original sample surface would capture the diffuse atoms, and the accumulation of adsorptive atoms also caused the surface roughening [15].

The relative reflectivities of the amorphous alloy before and after He+ions irradiation are presented in figure 8.After the irradiation,the relative reflectivity decreased significantly.In the range of visible light with a wavelength of 400–700 nm, the relative reflectivities were about 23% and 38%lower than that of the original samples respectively when the doses were 1×1017ions cm?2and 5×1017ions cm?2.Bennett’s formula[27]shows that the relative reflectivity and surface roughness of materials have a negative exponential relationship, that is, the reflectivity decreases with the rise of roughness,and this result verified the roughness change of the alloy given in figure 7.The decrease of surface relative reflectivity observed in the study is also related to the macroscopic plastic deformation of thin banded samples under ion irradiation.

Figure 9(a) gives the hysteresis loops of the Fe-based amorphous alloy before and after He+ions irradiation.The alloy maintained soft magnetic properties when the dose reached 5×1017ions cm?2.Figure 9(b) shows the changes of saturated magnetic induction intensity (Bs) and coercive force(Hc)with He+ions doses.As the doses increased,theBsof the alloy increased significantly, when the dose was 5×1017ions cm?2, theBsincreased by 53%, whileHcdecreased slightly.This is consistent with the variation of magnetic property in Fe-based amorphous alloy under electron irradiation observed by Kaneet al[28].Kaneet alfound that the change was related to the atomic arrangement in amorphous alloy.After irradiation, the width of the first coordination shell in amorphous alloy reduced,indicating that the amorphous structure transformed to ordered phases.In this study, the tendency of local atomic ordered arrangement was observed by TEM,and a significant increase inBscaused by the change of local atomic arrangement in the bubble layer of Fe-based amorphous alloy appeared under 2 MeV He+ions irradiation.

Under 2 MeV He+ions irradiation,the surface roughness of amorphous alloy Fe80Si7B13increased, while no obvious damage appeared on the surface,it was due to the unique long range disordered atomic arrangement and the existence of numerous free volume in the alloy.The roughened surface induced by ion bombardment resulted in the reduction of surface relative reflectivity of the amorphous alloy.Numerous He bubbles were formed by the mass migration and accumulation of He atoms after they recombined with electrons in the material during the incident process.Compared with the size of He bubbles formed by the irradiation of 300 keV He ions with similar doses conditions, it could be obtained that the irradiated dose has more significant influence on the size of He bubbles than ion energy.The energy introduced by irradiation would induce extensive atom migration,destroyed the isotropy of amorphous alloy and promoted the uneven arrangement of atoms.The tendency of local ordered arrangement of atoms observed in the bubble area indicated that the high pressure of He bubbles is the most important factor driving the movement and ordering trend of target atoms.This tendency of local ordered atomic arrangement caused a significant increase of theBsin the alloy.Meanwhile, the free volume introducted by irradiation could stabilize the magnetic properties of the amorphous alloy.After the irradiation, Fe-based amorphous alloy remained soft magnetic performance.The irradiation-induced ordered arrangement trend of atoms observed in this study tended to form the β-Mn type crystallization phase, and the formation of β-Mn type nanocrystals was also observed at similar dose in He ion irradiation with a lower energy(300 keV).In He ion irradiation with the energy range of hundreds of keV to several MeV, the metastable β-Mn type crystallization phase would form firstly in Fe-based amorphous alloy.

We studied the irradiation resistance of Fe-based amorphous alloy as the candidate material of the first mirror.However, the limit processing size of Fe-based amorphous alloy is in the order of centimeters,which currently limits the practical application of Fe-based amorphous alloy.We do some basic research on the irradiated resistance of Fe-based amorphous alloy, so as to provide some new ideas for the selection of the first mirror material.We will pay attention to the irradiation resistance of bulk Fe-based amorphous alloy in the following work.

Figure 9.(a) The hysteresis loop and (b) the variation of saturation magnetic induction intensity and coactivity of Fe80Si7B13 amorphous alloy before and after He+ irradiation with different doses.

4.Conclusions

Under 2 MeV He+ions irradiation, when the dose reached 5×1017ions cm?2,extensive He bubbles with a diameter of about 2 nm can be observed near the ion range in the amorphous alloy Fe80Si7B13.The size of bubbles depends on the dose of irradiation rather than the energy.Under the drive of the high pressure of bubbles and the effect of incident ion energy deposition,the atomic arrangement in the bubble layer became uneven, and the tendency of local atomic ordered arrangement corresponding to the β-Mn type phase was observed.Except for the slightly increase of surface roughness, which resulted in the decrease of the surface relative reflectivity of the alloy, no obvious damage was observed on the surface at this dose.The saturation magnetic induction intensity of the amorphous alloy was enhanced by the ordered arrangement trend of local atoms caused by He ions irradiation.

Acknowledgments

This work is financially supported by National Natural Science Foundation of China (Nos.11675035, 11975065 and 11375037).The experimental work was carried out at the 4.5 MV electrostatic accelerator at the Institute of Heavy Ion Physics of Peking University.

Plasma Science and Technology2021年2期

Plasma Science and Technology2021年2期

- Plasma Science and Technology的其它文章

- Erosion research of CX-2002U carbon composites under low-temperature high-flux hydrogen plasma

- NOx storage and reduction assisted by non-thermal plasma over Co/Pt/Ba/γ-Al2O3 catalyst using CH4 as reductant

- Research on corona discharge suppression of high-voltage direct-current transmission lines based on dielectric-film-covered conductor

- Enhanced electrocatalytic activity of carbon cloth by synergetic effect of plasma and acid treatment

- Spatio-temporal evaluation of Zr plasma parameters in a single-beam-splitting double-pulse laser-induced plasma

- Plasma activation towards oxidized nanocarbons for efficient electrochemical synthesis of hydrogen peroxide