Brass tacks on iron: Ferrous metallurgy in Science and Civilisation in China

Donald B Wagner

University of Copenhagen, Denmark; Sichuan University, China

Abstract This article is a memoire of the author’s work in producing the volume of Science and Civilisation in China focusing on ferrous metallurgy.

Keywords Joseph Needham, ferrous metallurgy, Science and Civilisation in China

This article is a very personal account of my adventures in preparing the volume on ferrous metallurgy ofScience and Civilisation in China(SCC) (Wagner,2008). My first encounter with Joseph Needham’s monumental work was in 1968. I was 25 and a firstyear student of Chinese. A visiting professor, hearing that I had a background in science, led me to its place on the library shelf and insisted that I read it. (I send Schuyler Cammann many belated thanks.) At that time, the first two of the three parts of volume 4 had been published.

I was captured immediately by Joseph Needham’s erudition, his clear and precise language, and perhaps most of all his use of his scientific background in a constant concern for what he called ‘brass tacks’.Americans call it ‘the nitty gritty’, and a Swedish writer, Arne Dahl, recently coined the term ‘nonvirtual reality’.

Joseph asked me to write his volume on ferrous metallurgy in about 1980. I submitted the finished manuscript 25 years later, and it was finally published in 2008. In those years of work, I confronted numerous questions large and small. In this article I review some of them, starting with the big picture and then going on to a few brass tacks.

1. Theoretical framework

A writer of history needs a theoretical framework -or rather, a historianhasa theoretical framework whether she or he knows it or not. In studies of the history of technology, four approaches stand out.

1.1. Whig history

History is about progress, towards a goal that somehow is a given from the beginning. The term can be applied to Joseph Needham’s (1962) work, as the following passage testifies:

Some time ago a not wholly unfriendly critic of our previous volumes wrote, in effect: this book is fundamentally unsound for the following reasons. The authors believe (1) that human social evolution has brought about a gradual increase in man’s knowledge of Nature and control of the external world, (2) that this science is an ultimate value and with its applications forms today a unity . . ., (3) that along with this progressive process human society is moving towards forms of ever greater unity, complexity and organisation.We recognised these invalidating theses as indeed our own, and if we had a door like that of Wittenberg long ago we would not hesitate to nail them to it. (p. xxxi)1

My own subjective experience leads me to agree that ‘science is an ultimate value’, but for all my respect for Joseph Needham, I can find no subjective or objective basis for the idea that the evolution of society has any definite direction at all, positive or negative, or that progress is a useful concept in the study of history.

1.2. The social construction of technology

Technology is influenced in important ways by social forces, which are to be studied using the methods of the social sciences. This approach no doubt owes much of its popularity to a reaction against the Marxist emphasis on the ways in which technology influences society. For example, in a famous dictum in Marx’s (1936)The Poverty of Philosophy, ‘the handmill gives you society with the feudal lord; the steam-mill, society with the industrial capitalist’ (p.92). In my own work, I find it useful to see technologies in both ways. I have earlier used the term ‘technological choices’ and believed I had coined it myself. It turned out that this was a term already in wide use, with quite a different meaning from that I had intended. Basically, I see technologies - the ways people choose to satisfy their material needs and wants - as factors among myriad historical factors that interact with each other simultaneously as causes and effects. The historian’s challenge is to understand and articulate them in a meaningful way.

1.3. The evolution of technology

Technologies change and develop in ways that are closely analogous to the evolution of biological species. George Basalla (1988) in his bookThe Evolution of Technologymade an old idea explicit,adduced a large number of historical examples and made a convincing argument for it as a valid approach in the history of technology. Consulting a citation index, it seems that his work has had a certain impact. H. T. Huang used it inSCC, volume 6,part 5,Fermentations and Food Science(Needham and Huang, 2000: 597-605).

I have been very much attracted to this approach.In particular, the great geographical variation in iron-production technologies throughout China,apparent in recent centuries, is reminiscent of the ways in which new species develop in ecological isolation. Local ironmasters working in a traditional master-apprentice line can be expected to make small innovations in each generation, not necessarily aware of any change. The result has been that each isolated region had its own iron-production technology, precisely adapted to its geographical situation.

Sadly, I have had to abandon the effort to follow up on Basalla’s insight. I lack the kind of sources -documentary or archaeological - that would be needed to develop a fine-grained understanding of the evolution of any of the regional iron-production technologies.

1.4. Technology in economic history

One specific concern of mine has been to bring the insights of economic theory into the history of the iron industry in China. Especially important here is the Law of Comparative Advantage of David Ricardo(1772-1823). Boiled down to its essential minimum,it states thatthe economically rational course is not to do what one does best, but to do what gives the highest profit in the given market. This insight helps to explain why the iron industry in the region around Nanjing, until the Yuan period a major iron-producing region, died out by the early Ming: commercial development there gave the comparative advantage to other activities.

Another example of the effects of comparative advantage is given by the structure of the iron industry in the province of Guangdong from the Ming period onward. Here numerous large-scale ironworks had until about 1700 produced massive quantities of iron for a market that extended northward along the Chinese coast and southward throughout South-east Asia. This may well have been the largest and most technically sophisticated iron industry in the world at that time. The large-scale ironworks operated in parallel with myriad small-scale village ironworks throughout Guangdong that produced for local consumption.These were much less efficient than the large-scale works, but their comparative advantage lay in iron production because of low labour costs and the high cost of land transportation. It was economically rational to produce iron inefficiently rather than to produce something else for sale and buy iron produced by the efficient large-scale ironworks (Wagner,2008: 47ff, 2011).

Comparative advantage helps also to explain the effect of foreign trade on the iron industry of Guangdong. The large-scale sector went into a steep decline beginning in the early 18th century, and by the mid-19th century it was dead. The small-scale village ironworks continued production uninterrupted. An important part of the explanation for the decline of the large-scale iron industry was competition with imported foreign iron. Improvements in iron-production technology in the Industrial Revolution, as well as falling shipping costs, meant that British and American iron was competitive in China from the early 19th century. This is only part of the explanation, however, because the decline began long before foreign competition became a major factor. The explanation of the 18th-century decline is more likely to be that foreign trade brought new opportunities for Chinese investors, especially in tea and ceramics production but also in many other fields. Investors’ comparative advantage changed: the large-scale iron industry gave a smaller return on investment and could not compete for the capital necessary for continued operation.

2. Style and structure

In a book that emphasizes the historical implications of technological brass tacks, one must deal at length with technical details and make them comprehensible to non-specialist readers. This is a difficult task,and I doubt that it is even possible to explain these matters in a manner accessible to all of the intended readers ofSCC. I have, inSCCand elsewhere,attempted to write for ‘readers who know some chemistry and are accustomed to technical thinking’.Not all readers have been satisfied with this limitation, but further popularization of technical matters would, I believe, dull the sharp contours of the technical discussion and leave no one satisfied. I have at least attempted to make the broader implications clear to all readers, including those who skip over the technical explanations.

The natural organization for the book clearly had to be chronological, delineating for each period the historical events and developments that have influenced and been influenced by technological developments. However, technical matters are easiest to explain when dealing with a period that is wellknown through rich historical sources. I therefore moved the last period, the 18th-20th centuries, to the beginning of the book. This allowed me to describe the basic iron-production technologies in a concrete context, with clear contemporary written descriptions and illustrations. I could at the same time discuss the ways in which specific aspects of the technology could interact with the economics of the time and place. An example is the two-tiered iron industry in Guangdong and elsewhere, mentioned above - a phenomenon conditioned by, first, the extreme economies of scale that are possible in blastfurnace iron production, and second, the law of comparative advantage. This two-tiered industrial structure appears in the sources in the 3rd century BCE (Wagner, 2008: 187-188), but it would have been awkward and unconvincing to explain it in that context, with only a few uncertain sources.

Some readers were not happy with this arrangement, and I must admit that Chapter 2 of the book can be off-putting for some, a tough chunk to digest right at the start. Perhaps I should have found a compromise, with fewer details in this opening chapter,but by the time that the Publications Board of the Needham Research Institute began criticizing it, the book was nearly complete and there was no reasonable possibility of changing the arrangement.

3. Brass tacks

Of all the matters that it was necessary to take up in the preparation of mySCCvolume, I shall restrict myself here to some widely held wrong ideas about iron in China that I have had to correct.

3.1. Cast-iron versus steel ploughshares

Joseph Needham wrote in 1956,

It has often been said that the Chinese farmer was ploughing with a cast-iron ploughshare long before the farmers of the West knew anything else but wood; but that they continued to plough with a cast-iron ploughshare long after the farmers of the Far West had ploughshares of steel.

This was in a short epitome of his famous lecture to the Newcomen Society for the History of Engineering and Technology, ‘Iron and steel production in ancient and medieval China’, on 9 May 1956.He did not include that sentence when the full lecture was published in 1964 (Needham, 1964), perhaps because he had learned the brass tacks of cast-iron ploughshares. White cast iron (the principal kind in premodern China) is highly abrasion-resistant and therefore an excellent material for ploughshares (see,for example, Massari, 1938). Cast-iron ploughshares were in use in the West from the 18th century well into the 20th, and are presumably still used today: in 1976, ‘[m]ost shares used in Britain are made of chilled cast iron, but cast alloy steel and forged steel are also used’ (Culpin, 1976: 51).

It is true that this supposed example of Chinese technological stagnation has often been expressed; I have not found its source, but here is a version of the story, as stated by a Danish author in 1975:

One of the oldest and most important uses of iron is for ploughshares. In China it was possible to use brittle cast iron for this purpose. This was because China’s agricultural land has been cultivated for centuries, and therefore does not contain stones. In Europe a ploughshare of cast iron would be shattered by the stones. (Thomsen, 1975: 12)2

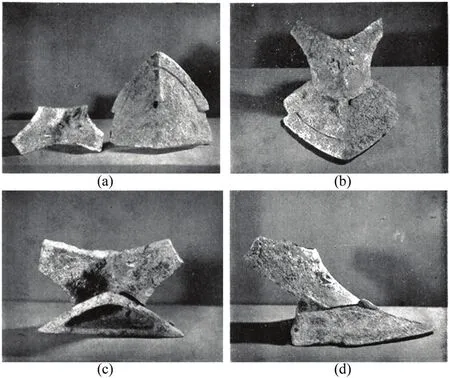

Of course, China’s agricultural land contains stones, and various means have been used to deal with them. Figure 1 shows a Han-period cast-iron ploughshare.3The edge, the part most subject to damage, is protected by a small V-shaped cap, also of cast iron. This can be replaced quickly and cheaply when damaged and thereafter recycled. From the Yuan period we have a text describing the use of a wrought-iron cap in the same way on a cast-iron ploughshare (Wang, 1956: 11; Wagner, 2008: 286).

The history of the cast-iron ploughshare in the West seems not to have been dealt with by serious historians of technology. The sources I have found in a cursory search are mostly laudatory stories of heroic inventors, often with details that look suspiciously like tall tales. Here are some bare brass tacks,gleaned from those suspect sources: A cast-iron ploughshare was on the market in New York in 1794,and was declared to be much superior to wrought iron (Smith, 1974). A cast-iron plough was patented in Britain by Robert Ransome in 1795 (Ransome,1843: 17-19; Mirzoeff, 1980), and in the USA by Jethro Wood in 1814 (Allen, 1848; Gilbert, 1882).John Deere produced some of the first steel ploughshares in about 1837, and within a few decades his company (which still exists today) became a major supplier of agricultural equipment of all kinds(Clark, 1937: 32-38). His fawning biographer explains that the heavy clay soils of the American Midwest stuck to the cast iron and hindered the plough’s progress through the earth, but did not stick to the smooth steel. The question of damage to cast iron by stones is not even mentioned.

3.2. Robert Hartwell’s iron-production figures for the Song period

Working chronologically through Chinese history,writing the history of Chinese iron and steel one period at a time, I several times, starting on a new chapter, felt like a beginning graduate student again,having to familiarize myself with the sources for the period, the outstanding events and trends, and the important issues confronting its historians.

When I began working on the Song period, my most important guide was the works of the late Professor Robert Hartwell: his 1963 Chicago dissertation and several articles on the iron industry in the‘commercial revolution’ of the Northern Song period(Hartwell, 1962, 1963, 1966, 1967). He not only confronted the broad issues in Song economic history,with lasting influence on the field,4but also did some hard work on the detailed brass tacks of the primary sources. In the course of his dissertation work he went through the most important primary sources for Song history page by page - thousands of pages -seeking out references to iron, steel, coal, and other key subjects. I needed only to go through the footnotes in his dissertation to find a wealth of sources for my own work.

Figure 1. Mouldboard, ploughshare and V-shaped cap found at Wangxiangcun in Liquan County,a Shaanxi: (a) The three artefacts. The cap is rusted fast to the ploughshare. Ploughshare 23.3 × 28 × 8.6 cm, mouldboard 22 × 23 cm.On the underside of the mouldboard are two lugs for tying with cord and a peg that fits precisely into the hole in the ploughshare. (b-d). Three views of the artefacts when fitted together.

Having now acknowledged my immense debt to Hartwell in matters both broad and detailed, I must now go on to criticize him severely. A famous part of his work is the estimate that iron production in 11thcentury China was 125,000 English tons (115,000 metric tonnes) per year. In a couple of my early publications I quoted this estimate as a fact, established as it was by a respected scholar. However, when, in research forSCC, I looked more closely at the background for this figure, I became angry; I felt that I had been duped by a conman. There is, put bluntly,no basis at all for Hartwell’s estimate.

I gave a detailed argument for this conclusion in a separate article, which I referred to only briefly in theSCCvolume (Wagner, 2001, 2008: 279-280). In that article I was concerned to avoid explicitly calling a recently deceased and highly respected scholar a liar.I concealed my anger so well, unfortunately, that some readers have taken the article to be praising rather than criticizing Robert Hartwell. Part of my effort to soften the criticism was writing that the estimate of 115,000 tonnes was ‘plausible’, and this has led several historians to accept the figure as the best estimate possible. In fact, I believe that a figure three times higher or three times lower would be equally‘plausible’. We simply have no basis for any quantitative estimate of iron production for the period.

In Hartwell’s publications he refers to his unpublished dissertation for details of the calculation, but this has not been easily accessible, and very few have read it.

Two official surveys of metal mining and smelting, dated 1064-7 and 1078, give the ‘receipts’ or‘quotas’ of iron from localities throughout the Empire. The total receipts are about 3,400 tonnes in 1064-7 and 3,300 tonnes in 1078. Hartwell makes two assumptions about these surveys.First, that they refer to different sectors of the iron industry, so that they should be summed to obtain the annual total receipts of iron by the government in the 11th century.Second, that these ‘receipts’ represent a ten-percent in-kind tax on iron production. This gives 67,000 tonnes of taxed iron production, to which he adds estimates for untaxed government ironworks, receipts accidentally omitted from the surveys, and illegal production. The result is a total annual production of 115,000 tonnes (Hartwell, 1962: 154-155, 1963:178-195, 1966, 1967: 104-105).

Hartwell’s only argument for the first assumption is that the two surveys show very different figures for most localities and greater changes than would normally be expected in the course of only 14 years.This ignores the fact that the period between the two surveys was the period of the reforms of Wang Anshi (Wang Anshi bianfa),5which influenced most aspects of the economic life of the time. He cites no sources indicating a recognized distinction between two well-defined sectors of the iron industry in the Song period.

The second assumption is based ultimately on one 10th-century source, which states that in one place (modern Shangrao,6Jiangxi) there is an ‘iron mountain’ where, at some unspecified time in the past, common people were allowed to mine, with the government receiving one-tenth. This is the only Song source that mentions a 10% tax on iron production. It concerns a single place, in the past, and says nothing about the general situation in the Empire in the 11th century.

There is thus no evidence at all for Hartwell’s production estimate. None.

3.3. Economies of scale in iron blast furnaces

In many places inSCC, I invoke as an explanatory factor the economies of scale that the blast furnace makes possible. A general rule in modern iron production is that, for maximum efficiency, a blast furnace should be as large as the supply of its raw materials and labour, and the market for its product,will reliably allow (Jones, 1933; Pratten and Dean,1965; Sidney, 1920). No larger than that, for efficiency also requires that the furnace should operate continuously for years at a time.

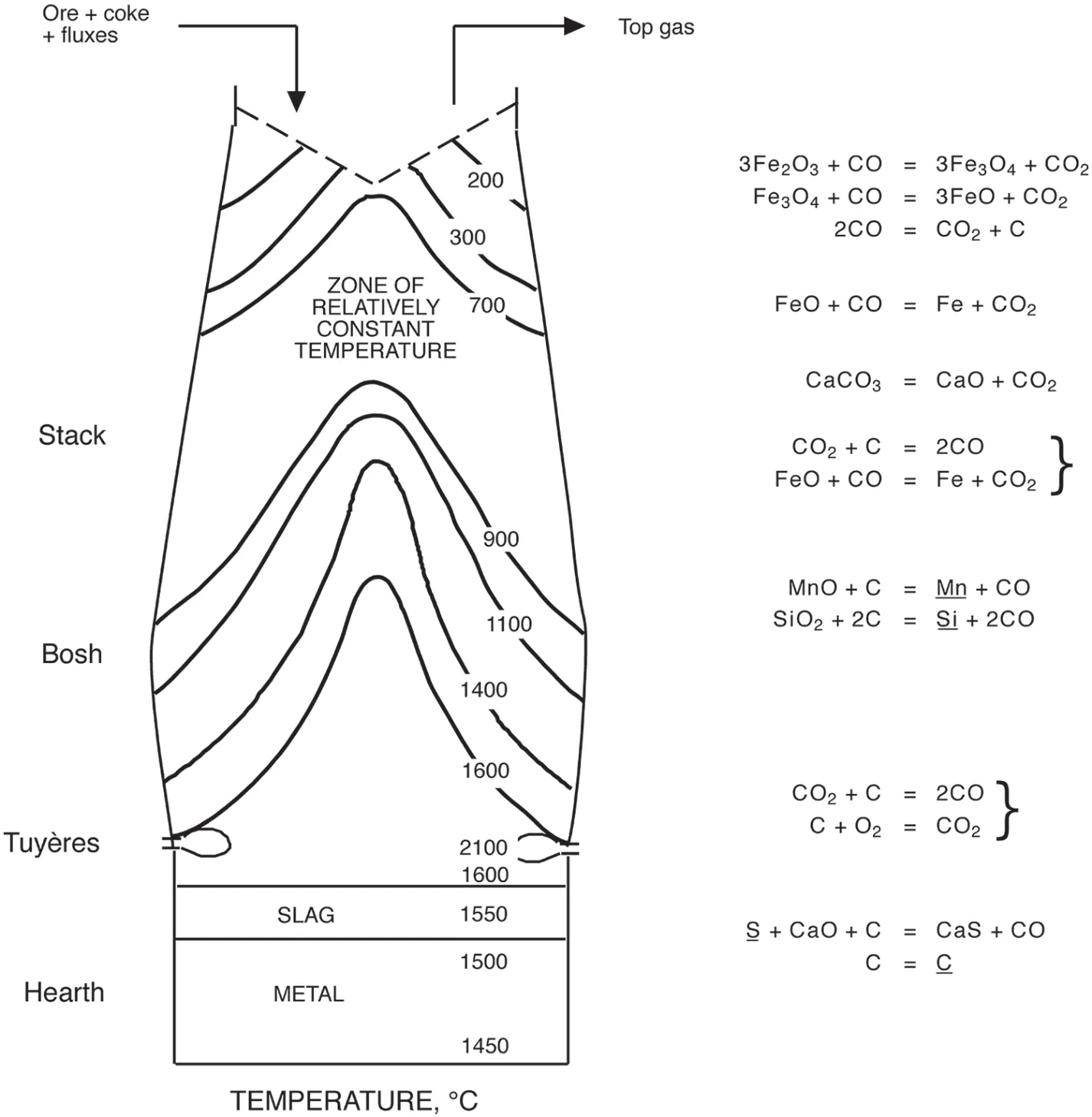

Figure 2 shows technical details of the operation of a modern blast furnace. It can be seen that there is a ‘zone of relatively constant temperature’ near the top of the shaft; this zone acts as a buffer, shielding regions further down in the shaft from outside perturbation. This means that the furnace is extremely stable in normal operation, and remains so even when it is scaled up to an enormous size. The principal reasons why efficiency increases with size are,first, that a larger volume means less heat lost to the surroundings, and second, that a reduction zone with higher temperature and larger volume means faster reduction. Both factors lead to more efficient use of fuel.

With the technical explanation clear enough, and the empirical observation that modern industry prefers large blast furnaces to small ones, it is surprising to find two well-known archaeometallurgists,William Rostoker and Bennet Bronson (1990),claiming that the economies of scale in blast-furnace iron production are illusory (pp. 186-189). They cite some data for Indian and South-east Asianbloomeryiron smelting, which are irrelevant. They make much of the fact that in Shanxi, in the 1920s, cast iron from the crucible smelting process sold for about the same price as imported blast-furnace cast iron. This is again not a comparison of blast furnaces, but more striking still is the economic naiveté of the argument.In Shanxi, ironmasters and workers lived in utter poverty and produced iron because they had no other means of living, and obviously they could not sell that iron at a higher price than that of imported iron produced by well-fed investors and workers in Britain and the United States. The same argument applies to blast-furnace iron production in many other parts of China.

Figure 2. Diagram of a modern large-scale coal-fuelled iron blast furnace.

Rostoker and Bronson state that ‘[m]anagers of American steel corporations in the twentieth century have consistently preferred larger furnaces, but there is little good evidence that these produce significant savings in costs’, citing as their only authority a survey of 20th-century American blast furnaces by Myles G Boylan. But what Boylan (1975) actually said is this: ‘In summary, the data indicate that while large blast furnaces were more efficient than smaller furnaces, their edge in efficiency was reduced when agglomerates of high quality were used (for example, pellets) in place of standard domestic ore’ (p.176). Ore agglomeration is an innovation of the 20th century and has no relevance for Rostoker and Bronson’s argument.

Thus, Rostoker and Bronson, in an otherwise very useful textbook of archaeometallurgy, have on this issue merely introduced confusion into an issue that has been clear for centuries: larger blast furnaces are overall much more cost-efficient than smaller ones.

4. Joseph Needham’s intellectual heritage

The work I have described here was possible because Joseph Needham showed the way. In his publications, he made clear the importance of Chinese science and technology to me and many of my generation, and also to universities hiring staff and foundations supporting research.

A large part of his impact lay in his insistence on taking on the whole of a subject:SCCwas and is intended to consider all fields of natural science through all of Chinese history, and each of the volumes attempts to treat the whole of one of those fields. This was his implicit challenge to me and his other collaborators and an important part of his intellectual heritage: do the whole job; do not accept limitations.

An important fixed point for me in the work was the Needham Research Institute. Its unconventional library, together with the truly great Cambridge University Library nearby, was of course essential,but of equal importance was the scholarly milieu of the place, with Joseph himself as long as he was in good health, his enthusiastic staff and a constant stream of visitors from all parts of the world. I visited once or twice a year from 1979 on and worked there for 4 years (1990-1991 and 1993-1996). The institute has always provided the physical framework for discussions and debates that have shaped many scholars’ work, including my own. This is the bricks-and-mortar aspect of Joseph Needham’s intellectual heritage.

Declaration of conflicting interests

The author(s) declared no potential conflicts of interest with respect to the research, authorship and/or publication of this article.

Funding

The author(s) received no financial support for the research, authorship and/or publication of this article.

Notes

1. Here Needham was reacting to a review of volume 2 by Arthur F Wright (1957). He is not entirely fair in his summary of Wright’s critique.

2. A similar statement is made by Mathieu Arnoux(2014).

3. Figure 1 is reproduced fromCultural Relics(1966:19-26 + plates 3-4, plate 3); also reproduced inScience and Civilisation, vol. 5, part 11, p. 160.Further examples can be seen in Wagner (1993:232-235); Chinese translation by Li Yuniu (李玉牛)(2018: 113-117).

4. For more on Hartwell’s work and its influences see especially Tim Wright (2007).

5. 王安石變法

6. 上饒

- 科學(xué)文化(英文)的其它文章

- Chinese organic materialism and modern science studies: Rethinking Joseph Needham’s legacy

- My farewell to Science and Civilisation in China

- Introduction: Needham’s intellectual heritage

- How can we redefine Joseph Needham’s sense of a world community for the 21st century?

- The East Asian History of Science Library/Needham Research Institute as an intellectual hub in the late 1970s and 1980s

- After Joseph Needham: The legacy reviewed, the agenda revised - some personal reflections