The effect of atmospheric pressure glow discharge plasma treatment on the dyeing properties of silk fabric

Cheng FENG (馮誠), Yibo HU (胡一波), Chenggang JIN (金成剛),Lanjian ZHUGE (諸葛蘭劍), Xuemei WU (吳雪梅),6 and Wenli WANG (王文利)

1 School of Physics Science and Technology & Collaborative Innovation Center of Suzhou Nano Science and Technology, Soochow University, Suzhou 215006, People's Republic of China

2 Key Lab of Advanced Optical Manufacturing Technologies of Jiangsu Province & Key Lab of Modern Optical Technologies of Education Ministry of China, Soochow University, Suzhou 215006, People's Republic of China

3 Analysis and Testing Center, Soochow University, Suzhou 215123, People's Republic of China

4 College of Textile and Clothing Engineering,Soochow University,Suzhou 215021,People's Republic of China

5 National Engineering Laboratory for Modern Silk, Suzhou 215123, People's Republic of China

Abstract In this study, the effects of plasma treatment parameters on surface morphology, chemical constituent, dyeability and color fastness of silk fabric were investigated. Atmospheric pressure glow discharge plasma generated with different applied voltages (0 kV to 45 kV) was used to treat the surface of silk fabrics. C I Natural Yellow 3 was used to dye untreated and plasmatreated silk fabrics. The physical analysis based on scanning electron microscopy showed that the surface of silk fabrics was affected by plasma treatment. The chemical analysis was investigated with x-ray photoelectron spectroscopy and attenuated total reflection Fourier transform infrared spectroscopy.The results showed that the content of C 1s decreased with the increasing applied voltage, the content of N 1s and O 1s increased with the increasing applied voltage. The increasing K/S values represented that the dyeability of silk fabrics was improved after plasma treatment. The color fastness to dry and wet rubbing was decreased after plasma treatment.

Keywords: APGD plasma, silk fabric, surface treatment, natural dye, dyeability(Some figures may appear in colour only in the online journal)

1. Introduction

In all ages, textile processing industry is one of the major environmental polluters in the society. The effluent from the factories contains a large amount of chemicals such as remnant dyes and other chemical reagents used in the course of processing [1]. Among all kinds of textile productions, silk fabric is called the queen of fibers. Due to its excellent physical properties such as low weight, great lustre, soft handle and special durability, silk fabric has become more and more popular[2,3].On the other hand,the disadvantage of silk is its poor wettability and dyeability, especially when the dye used to process the silk is natural dye [4-7]. In order to reduce the pollution and improve the dyeability of silk fabric, it is necessary to seek physical and chemical modification technologies to treat silk fabric.

Nowadays, plasma treatment has been considered as an important technique and applied for the surface treatment in various fields. Plasma treatment is an environmentally friendly method to treat the surface of textile and protect the performance advantages without using supererogatory gas or reagent [8-10]. Glow discharge plasma is one kind of common plasma. Compared to other plasma such as plasma jet,glow discharge plasma has better uniformity that is very important to treat the surface of textile [11, 12]. Glow discharge plasma can be generated at low pressure.Bengi Kutlu et al studied the effect of low pressure glow discharge plasma treatment on the surface of wool [13]. Another kind of glow discharge plasma is atmospheric pressure glow discharge(APGD)plasma.Prasanta Kumar Panda et al investigated the effect of atmospheric pressure helium plasma on felting [14].As it is known, extra energy and time needed to create the condition that is necessary to produce low pressure glow discharge plasma. In other words, low pressure glow discharge plasma is difficult to be commercialized in textile industry as a batch process [15]. On the other hand, some specific gases such as helium or nitrogen used to produce APGD plasma will increase cost, and this is not up to the purpose of factory.

In fact, APGD plasma can be generated in ambient air that is considered to be a better approach for industrial application.The environmental pressure is 0.1 MPa,and there is no need to supply specific gas to produce plasma. These conditions are similar with production environment in textile industry. However, the effect of APGD plasma treatment on the dyeing properties of silk fabric has rarely been reported.

Hence,in this study,a self-designed equipment is used to generate APGD plasma.The APGD plasma is uniform and in large scale with 1000 × 60 mm2[16]. This is one of the innovation points. The method used in this study is given in figure 1.The effect of APGD plasma treatment with the use of air on silk fabric is evaluated. A detailed analysis of the morphology of untreated and APGD plasma treated silk fabric is carried out by scanning electron microscope (SEM). The chemical analysis of samples is carried out by x-ray photoelectron spectroscopy (XPS) and attenuated total reflection Fourier transform infrared (ATR-FTIR). The dyeability and color fastness of untreated and APGD plasma-treated silk fabric are tested by automatic color measuring instrument and friction tester.

2. Experiment

2.1. Material

Silk fabric used in the experiment was raw silk. The silk fabric was weaved to 40 threads in warp and 38 threads in weft per 1 cm.The density of silk fabric was 30 g · cm?2and the size of sample was 300 × 50 mm2. The air permeability of silk fabric was excellent and the density of the samples was applicable.The samples were pretreated before APGD plasma treatment. To remove the impurity and sericin on the surface of silk fabric, the samples were washed with absolute ethyl alcohol and acetone for 15 min. After that, deionized water was used to wash away the residual chemical agents,and then the silk fabrics were dried in a drying oven.

2.2. Plasma treatment

As shown in figure 2, a self-designed APGD plasma treatment apparatus was used to treat silk fabric[16].The power electrode of plasma generator was connected to a CTP-2000K power supply (maximum power 500 W, frequency 20 kHz). The applied voltage can be adjusted from 0 kV to 60 kV. Figure 3 showed the photo of APGD air plasma topography. Pretreated silk fabrics were placed on the surface of plasma generator.The APGD plasma was generated with the use of air and the pressure of the treatment system is 0.1 MPa. During the process of APGD plasma treatment, the plasma treatment time was set to 100 s and the environment temperature was 25°C ± 2°C. Different treatment parameter was the applied voltage (0, 25, 30, 35,40 and 45 kV).

2.3. Dyeing process

After APGD air plasma treatment, the untreated and treated silk fabrics were dyed with C.I.(color index)Natural Yellow 3. The structural formula of the natural dye is shown in figure 4. The dye used was 2% of the weight of the sample.The dye liquor was made of deionized water and dye. The ratio of dye to deionized water is 1: 100. During the process of dyeing,the dye liquor needs to be set at 65°C firstly.Silk fabrics were added to a solution at 65°C and kept for 30 min NaCl (20 g l?1) was put in the solution at the end of first period. Then the temperature of the solution was raised to 90°C and kept for 45 min. After dyeing, the samples were washed with a lot of water and dried in an oven.

2.4. Analysis of silk fabric

A Hitachi SU8010 SEM was used to characterize the morphology of untreated and plasma-treated silk fabric with the accelerating voltage kept at 20 kV. Magnification of the picture was 800 and 3000. The element analysis obtained by XPS(Thermo ESCALAB 250 XI).An Al Kα monochromatic excitation x-ray source with energy of 1486.6 eV was employed at 150 W. The functional group analysis was carried out by ATR-FTIR (Vertex 70P+ Hyperion 2000). The color strength was measured by an automatic color measuring instrument (UltraScan PRO). The exact K/S value was achieved at the maximum absorption in 485 nm. The color fastness to rubbing was measured with a friction tester and assessed by ISO 105 X12(textiles-tests for color fastness-part X12: color fastness to rubbing) [17].

3. Results and discussion

3.1. SEM analysis

Figure 5 showed the SEM micrographs of untreated and plasma treated silk fabrics. The magnification of SEM micrographs was 800 and 3000.The surface of untreated silk was smooth and glossy,as shown in figure 5(a).As shown in figures 5(b)-(d), with the applied voltage raised from 25 kV to 35 kV,more and more pit areas appeared on the surface of samples and the edges were dropped off. When the applied voltage was 40 kV,some tiny tears appeared on the surface of silk fabric that was shown in figure 5(e). The maximum applied voltage was 45 kV, the tear strength increased, as shown in figure 5(f),the surface of this specimen has changed greatly. It may have the following explanations: since the APGD plasma generator worked in ambient air, the plasma contains active particles. When the silk fabrics were treated by APGD plasma, theses active particles touched the surface of silk fabric. The surface of silk fabrics was sculptured and etched, this led to those small pits and fine cracks appeared.As the applied voltage increased, more and more active particles were produced within the same amount of time. It meant that more active particles etched the surface of silk fabric and the change of silk fabric became more obvious.After APGD plasma treatment, the roughness was increased[2, 3, 9, 15]. As a result, the dyeability of silk fabric was increased which would be discussed next.

3.2. XPS analysis

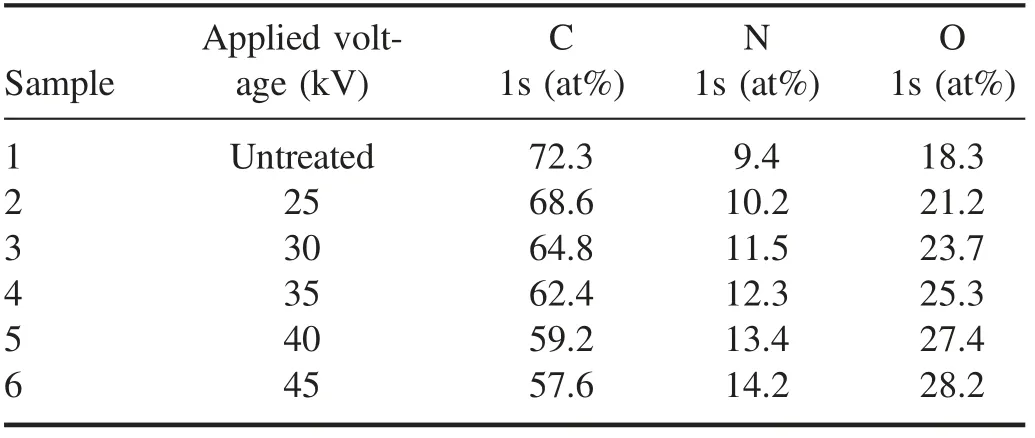

To investigate the chemical state and element content of untreated and plasma-treated silk fabric,XPS was used during the analysis. The XPS spectra of C 1s, N 1s and O 1s were shown in figure 6.The content of C 1s,N 1s and O 1s is listed in table 1.

In figure 6(a), the spectra were fitted into three peaks.Three peaks indicate three carbon-containing groups. The peaks at 284.7 eV, 286.1 eV and 287.8 eV were C-C/C-H,C-O and C=O, respectively. After APGD plasma treatment,as the applied voltage increased, the intensity of C-C/C-H was increased, the intensity of C-O and C=O was decreased[2, 3, 18-23].

As shown in figure 6(b), the spectra of N 1s contained two peaks. The peak located at 399.7 eV was attributed to-NH. The peak at 401.2 eV was C-N [2, 21, 23]. It was obvious that the intensity of C-N was increased after APGD plasma treatment.

Figure 6(c)showed that the spectra of O 1s were divided into two peaks.The peak at 531.6 eV represented-COOH or-CONH. The peak at 533.4 eV was attributed C-O or -OH[2, 18-23]. The intensity of C-O or -OH was increased with the increasing applied voltage.

The content of C 1s, N 1s and O 1s is shown in table 1.As the applied voltage increased, the content of carbon decreased while the content of nitrogen and oxygen increased after APGD plasma treatment. The phenomenon could be explained by active particles, such as,OH, O3, being formed after the plasma generator worked in ambient air[24-26]. The chemical bonds in the protein molecules were broken when these active particles touched the surface of silk fabric.This led to some new carbon radicals being formed on the surface of samples. The carbon radicals combined with oxygen or OH when the oxygen was ionized. This led to the formation of -COOH and C-OH. When the applied voltage was increased,more active particles were generated to change the chemical state of the surface of silk fabric within the same amount of time. This meant that more -COOH and C-OH were introduced into the surface of silk fabric within the same amount of time.That is one of the reasons for the increase of the intensity of the peak at 533.4 eV.Although N2molecules were difficult to be ionized, the generator had enough energy to turn N2molecules into excited state when it worked.When the applied voltage was increased, more N2molecules were turned into the excited state to react with the chemical construction on the surface of silk fabric.As a result,the intensity of the peak at 401.2 eV was increased. More -NH were introduced into the surface of silk fabric with the increasing applied voltage. With more oxygen-containing and nitrogencontaining functional groups were formed on the surface of silk fabric, the content of oxygen and nitrogen was increased while the content of carbon was decreased as listed in table 1.

3.3. AFR-FTIR analysis

ATR-FTIR spectroscopy of samples was showed in figure 7.Apart from the intensity of some peaks, the spectra of untreated and plasma-treated silk fabric were found to be similar. This conformed that APGD plasma treatment could change physical and chemical structure of silk fabric without changing most of the original properties. The intensity of the peak at 1523 cm?1which was distorted N-H of amide II was increased after APGD plasma treatment. The peaks at 1614 cm?1and 1653 cm?1were assigned to stretching C=O of amide I and stretching C-O of amide I, respectively. The intensity of two peaks was increased.The peak at 1718 cm?1was C=O. The bands in range of 800-1200 cm?1were known as specific polypeptide with respect to amino acid linkage [8, 15, 18, 27]. As discussed earlier, the active particles in APGD plasma changed the chemical structure of silk fabric slightly, the intensity of these specific peaks changed after APGD plasma treatment.More nitrogen and oxygen was introduced into the surface of silk fabric with the increasing applied voltage. More -OH, -NH and -COOH were formed and grafted into the protein which was the main chemical component of silk [15, 18]. These hydrophilic functional groups could increase the wettability and dyeability of silk fabric.

3.4. Dyeability of silk fabric

Figure 8(a)showed the photograph of silk fabric after dyeing.With the rise of the applied voltage, the color depth of the samples was increased obviously. Figure 8(b) showed the K/S value of untreated and plasma-treated silk fabric after dyeing. The K/S value represented the color strength of samples. The higher K/S value meant better color strength.The K/S value of samples was increased from 1.97 to 5.1 with the increasing applied voltage.It could be explained that the physical and chemical structure of silk fabric was changed after APGD plasma. When the silk fabric was treated by APGD plasma, the surface of silk fabric was etched. The SEM micrographs showed that new tiny pits appeared on the surface of silk fabric after APGD plasma treatment. The roughness and surface area of the surface was increased on account of these microcracks. Because of this, more dye was absorbed during the process of dyeing.Another reason for the increase of better color strength is the change of chemical structure. According to the result of XPS and ATR-FTIR analysis, more -COOH, -OH and -NH were introduced into the surface of silk fabric with the increasing applied voltage.As the content of these hydrophilic functional groups increased,it became easier for the C I Natural Yellow 3 to be absorbed due to the fact that these functional groups could be combined with the group (-OH) in the dye (C I Natural Yellow 3)easily.The combination modes included hydrogen bonds, van der Waals forces and covalent bonds [2, 3, 15,27-29]. During the process of dyeing, no mordant that was required for dyeing natural dye was used to promote the absorption of dye. Obviously, the effect of APGD plasma treatment on the dyeability of silk fabric was positive.

Table 1.Atomic concentration of samples.

3.5. Color fastness properties

The results of color fastness to dry and wet rubbing of untreated and plasma-treated silk fabric were given in figure 9.The color fastness was graded from level 1 to level 5.There was a level between two levels such as Levels 3-4. In fact,level 3 was high enough to up to industrial standard.The color fastness to dry rubbing of silk fabric was decreased after APGD plasma treatment. When the applied voltage was adjusted from 25 kV to 40 kV, the color fastness of samples was the same.When the applied voltage was 45 kV,the color fastness of sample was decreased to level 4 and the result met the requirement of industrial application. The variation trend of color fastness to wet rubbing of samples was similar with color fastness to dry rubbing, and the minimum is level 3 at 45 kV. The result of color fastness may have the following explanations: when the K/S value increased, more dye was absorbed on the surface.SEM micrographs showed that more microcracks appeared on the surface of silk fabric with the increasing applied voltage. The roughness of the surface increased, the force of friction was increased during the friction test.As a result,more dye was lost during friction test and the color fastness of silk fabric was decreased[2,15,27,30].Although the color fastness was decreased,the results of the test still met the requirement of textile industry.

4. Conclusions

In this study,APGD plasma was generated in ambient air and silk fabrics were treated by APGD plasma. The untreated and plasma-treated silk fabrics were dyed with C I Natural Yellow 3. Within the same amount of treatment time, the applied voltage had great effect on the physical structure, chemical state and dyeing properties of silk fabric. After APGD plasma treatment, microcracks appeared on the surface of silk fabric.The content of C 1s decreased while the content of N 1s and O 1s increased, as the applied voltage increased. The K/S value increased from 1.97 to 5.7 with the increasing applied voltage.It meant that APGD plasma treatment was useful to improve the dyeability of silk fabric. The color fastness to dry and wet rubbing of untreated and plasma-treated silk fabric was decreased with the increasing applied voltage. But the color fastness of silk fabric was still up to the standard. During the process of APGD plasma treatment, no harmful reagent or specific gas was used for the purpose of protecting environment and cost savings. No mordant was used during the process of dyeing. It could be found that APGD air plasma treatment was useful to improve the dyeing properties of silk fabric, and it was beneficial for the textile industry to protect environment without using harmful or unnecessary reagent.

Acknowledgments

This work is financially supported by National Natural Science Foundation of China (Nos. 11435009, 1137516,11505123), a Project Funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions(PAPD),the Program for Graduates Research&Innovation in University of Jiangsu Province (No. KYCX17_2025).

Plasma Science and Technology2020年1期

Plasma Science and Technology2020年1期

- Plasma Science and Technology的其它文章

- Experimental study of current loss of a single-hole post-hole convolute on the QG I generator

- Development of a data acquisition and control system for the International Thermonuclear Experimental Reactor neutron flux monitor

- Effect of the amount of trapped particulate matter on diesel particulate filter regeneration performance using nonthermal plasma assisted by exhaust waste heat

- Spectral characteristic of laser-induced plasma in soil

- Weighted-averaging-based classification of laser-induced breakdown spectroscopy measurements using most informative spectral lines

- Numerical simulation of atmospheric pulsemodulated radio-frequency glow discharge ignition characteristics assisted by a pulsed discharge