Lightweight structure of a phase-change thermal controller based on lattice cells manufactured by SLM

Ho ZHOU ,Xioyu ZHANG ,*,Huizhong ZENG ,Huning YANG ,Hongshui LEI ,Xio LI ,Yoing WANG

a Beijing Key Laboratory of Intelligent Space Robotic Systems Technology and Applications,Beijing Institute of Spacecraft System Engineering,CAST,Beijing 100094,China

b Institute of Advanced Structure Technology,Beijing Institute of Technology,Beijing 100081,China

KEYWORDS Lattice structure;Lightweight;Selective laser melting(SLM);Spacecraft;Thermal controller

Abstract Thermal controllers equipped with phase-change materials are widely used for maintaining the moderate temperatures of various electric devices used in spacecraft.Yet,the structures of amounts of thermal controllers add up to such a large value that restricts the employment of scientific devices due to the limit of rocket capacity.A lightweight structure of phase-change thermal controllers has been one of the main focuses of spacecraft design engineering.In this work,we design a lightweight phase-change thermal controller structure based on lattice cells.The structure is manufactured entirely with AlSi10Mg by direct metal laser melting.The dimensions of the structure are 230 mm×170 mm×15 mm,and the mass is 190 g,which is 60%lighter than most traditional structures(500-600 g)with the same dimensions.The 3D-printed structure can reduce the risk of leakage at soldering manufacture by a welding process.Whether the strength of the designed structure is sufficient is determined through mechanical analysis and experiments.Thermal test results show that the thermal capacity of the lattice-based thermal controller is increased by 50%compared to that of traditional controllers with the same volume.

1.Introduction

Thermal control systems with phase-change materials(PCMs)are widely used for ensuring the normal functions of spacecraft and aircraft equipment.1-5This passive type of energy storage or release is suitable for situations in which heat dissipation is periodic or transient.6,7Forty years ago,Schelden and Golden introduced a practical thermal controller design for spacecraft,including PCM selection,container design,test setup,and data analysis.1However,given that circuit densities continue to increase at a rate of 30%per year,problems associated with thermal control of electronic devices increase as well.2PCMs have attracted considerable attention owing to insistent demands for high-performance thermal controllers and to their higher removal capabilities compared with those of liquid and air options.For example,Darkwa et al.developed a technique that reduces the porosities of composite materials exhibiting high thermal conductivities and energy storage densities.5In another study,the transient thermal control performance of an avionics module using PCM was investigated by measuring temperatures at various locations as functions of time until the module temperature reached an acceptable maximum limit.6Different types of phase-change materials were employed for fabrication of thermal management systems.4To improve the performance of a thermal controller,including its thermal conductivity,latent heat,and mechanical property,Nofal et al.proposed an additive manufacturing technique of PCM,in which paraffin wax is mixed with a thermally conductive expanded graphite layer by layer.7Meanwhile,the performance of a PCM package can be characterized systematically by varying the power input,the orientation of the package,and melting or freezing times under cyclic steady conditions.3Nevertheless,although PCMs and the thermal performances of thermal controllers have been extensively researched,studies on lightweight hermetic structure design remain scarce.

The considerably heavy weights of structures in a spacecraft are due to thermal controllers.These heavy structures restrict the transport of scientific devices in the spacecraft owing to the limited capacities of rockets. Lightweight structures have become a major concern in space exploration operations,such as the Lunar and Mars exploration,apart from the risk of PCM leaks at the welding lines of hermetic structures fabricated by traditional manufacturing processes.In the past decade,the development of additive manufacturing techniques,such as selective laser melting(SLM)and electron beam melting,has enabled fabrication of high-precision lattice sandwich structures.8-11Lattice sandwich structures have been considered the most promising next-generation lightweight structures for spacecraft,and thus have started to gain interest from researchers.12-16For instance,Louvis et al.investigated the SLM processability of AlSi10Mg at the material scale,17and Tang et al.examined the weak anisotropy of the mechanical properties of AlSi10Mg specimens produced by SLM.8Zheng et al.presented that the hardness of SLM-processed FVS0812 samples far exceeded that of the as-cast FVS0812 alloy.18It has been found that the SLM processing of aluminum is challenging because of its poor laser beam absorption,high thermal conductivity,low viscosity,susceptibility to oxidation,high co-efficient of thermal expansion,and wide solidification temperature ranges19;nevertheless,aerospace engineers highly prefer aluminum because of its low density and high stiffness.Meanwhile,Yan et al.examined the mechanical properties of aluminum alloy cellular lattice structures at the lattice structure scale.11Tsopanos et al.investigated the dependence of mechanical properties of steel microlattice structures on processing parameters.9Additively-manufactured lattice sandwich structures are lightweight and welding-free,and thus enable designing novel phase-change thermal controller structures.

In this paper,we design a lightweight phase-change thermal controller structure based on lattice cells.The structure is manufactured entirely with AlSi10Mg by direct metal laser melting.The dimensions of the structure are 230 mm×170 mm×15 mm,and the mass is 190 g,which is 60%lighter than most traditional structures (about 500-600 g) with the same dimensions.Whether the structure has sufficient strength is determined through inner pressure analysis and experiment.A thermal test shows that the thermal capacity of the latticebased thermal controller increases by 50%compared with those of traditional controllers.

2.Structural design and mechanical analysis

In this work,our aim is to fabricate a lightweight thermal controller structure.The emphasis is on the design flow and experimental verification of the engineering structure.The design flow is shown in Fig.1.In the‘‘Design objective”process,the main objective of design is set,i.e.,the light-weight property of the thermal controller structure.In the‘‘Structural configuration”process,the structural configuration is designed as lattices with an external closed shell because of the lightweight and open properties of lattice cells and their leak-proof shells.In the‘‘SLM limits”process,the minimum diameter of the lattice struts and the minimum thickness of the shell are determined by experiments.In the‘‘Lattices and shell parameters”process,the type of lattice cells,the diameter of the lattice struts,and the thickness of the shell are designed.In the‘‘Mechanical analysis”process,the finite element model of the thermal controller structure is built.The stress is calculated and compared with the yield strength of a material under an internal pressure load.In the‘‘Thermal controller model”process,the geometric model of the thermal controller is built with 3D modeling software.In the‘‘Structural fabrication”process,the thermal controller structure composed of lattices and shells is fabricated with the direct metal laser melting technique.In the‘‘Experimental verification”process,an internal pressure experiment, leak detection, and a thermal experiment are conducted.

Fig. 1 Design flow of the lightweight thermal controller structure.

Fig.2 Pyramid-type lattice cells and their dimensions.

Fig.3 Structure of the phase-change thermal controller.

Fig. 4 Schematic of connections between large and small lattices.

Fig.5 Stress contours calculated under an internal pressure.

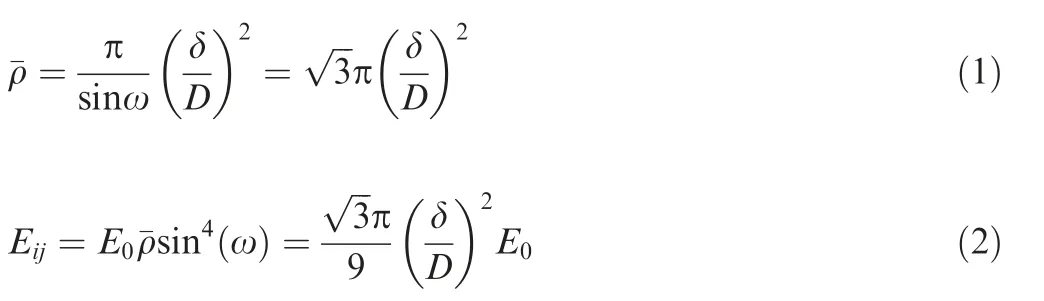

The structure of the phase-change thermal controller is composed of internal lattices and an external shell.The lattices are of the same type(pyramid),but have different dimensions,as shown in Fig.2.Pyramid-type cells have low relative densities and high stiffness-to-weight ratios.20,21The dimensions of large cells are represented by D1=D2=D3,whereas those of the small cells are represented by d1=d2=d3.The angle among adjacent lattice struts is 70.5°.The relative density ρa(bǔ)nd the effective elastic modulus Eijin the principal direction of a cell are determined as follows:

where ω is the angle between the lattice struts and the horizontal plane,δ is the diameter of the struts,D is the dimensions of the lattices,such as D1or d1,and E0is the elastic modulus of the parent material.This type of cell is lightweight and highly stiff.The lattices array all over the space inside the shell.The lattices not only support the external shell,but also facilitate the run-through internal space, thereby maintaining good mechanical stiffness and fluidity of the PCM.The small lattices are employed to avoid a collapse during the SLM process.

The shape of the thermal controller is brick,which is usually identified with the mounting dimensions surface of the equipment to be thermally controlled.It is composed of a shell and lattices,as shown in Fig.3.The dimensions of the thermal controller(W×H×T)are 230 mm×170 mm×15 mm.The thickness of the shell(t)is 0.5 mm.The connections between large and small lattices are illustrated in Fig.4.The diameters of the lattice struts(δ)are 0.5 mm.The dimensions of a large unit cell are D1=D2=D3=(T-δ)/2=7.25 mm. The region filled by a large unit cell is W1×H1×T1, where W1=W-δ=229.5 mm, H1=H-δ=169.5 mm, and T1=T-δ=14.5 mm.The region filled by a large unit cell is smaller than the dimensions of the thermal controller,so the edges of the lattices do not exceed the outer surface of the shell.The dimensions of a small unit cell are half of those of a large unit cell,that is,d1=d2=d3=D1/2=3.625 mm.The region filled by a small unit cell is W2×H2×T2,where W2=W-δ=229.5 mm, H2=(1+0.25)×D1=9.0625 mm,and T2=T-δ=14.5 mm.The region filled by the small cells connects the struts and prevents the cantilevers.Two auxiliary tubes are designed for the output of internal powder and the input of PCM.The inner and outer diameters of the tubes are 4 mm and 6 mm,respectively.The lengths of the tubes are 4.5 mm.A chamfering with a radius of 0.5 mm is designed for reduction of the stress concentration at the edges inside and outside of the thermal controller structure.

An inner pressure of 0.2 MPa must be tolerated by the cavity structure.A mechanical analysis is conducted with Patran/Nastran software.In finite element modeling,the lattice struts and the external shell are simulated with beam and shell elements.The dimensions of the elements range from 1 mm to 8 mm.The elastic modulus and yield strength of AlSi10Mg are 70 GPa and 220 GPa,respectively,which are obtained by subjecting the SLM specimens to tension tests.The shell elements are subjected to a 0.2 MPa pressure.The inertia relief approach is used for the static analysis,and the central node is used as the Wt.Gener.The stress contours calculated under an internal pressure are shown in Fig.5.The maximum stress(bar stress)of the lattices is 40.3 MPa,as shown in Fig.5(a),and the maximum stress(von Mises stress)of the shell is 3.2 MPa,as shown in Fig.5(b).The stress is much lower than the yield stress of AlSi10Mg,that is,220 MPa.Therefore,the safety margin(s)is 4.4(220 MPa/40.3 MPa-1),which is adequate for aerospace applications.

Fig.6 Photographs of the AlSi10Mg powder,the lightweight phase-change thermal controller,and the internal pressure experimental setup.

Fig.7 Schematic,photograph,and temperature-time curves of the thermal test.

3.Fabrication and characterization

The structure is fabricated with AlSi10Mg powder through a selective laser melting technique.A Concept X-line 1000R machine(Concept Laser Company)is employed.The laser power is 370 W,and the scanning speed is 1500 mm/s.The hatch spacing is 0.19 mm,and the layer thickness is 30 μm.The particles size is 0-62 μm in diameter.The equivalent diameters of the maximum particles with cumulative distributions of 10%, 50%, and 90% in the distribution curve are D10≥15 μm,30 μm ≤D50≤40 μm,and D90≤62 μm,respectively.The morphology of AlSi10Mg powder is shown in Fig.6(a)and(b).The diameters of several particles are labeled with[1]d,[2]d,[3]d,etc.The SLM parameters are determined by comparing the yield strengths of specimens fabricated with ten sets of processing parameters.The set of parameters used in this work achieves a superior mechanical strength.After the production,the internal powder is cleaned with argon and mechanical vibration.Thermal treatment at 250°C is conducted for 4 h for reduction of the residual stress inside the structure.The structure is finally polished with a grinding machine and abrasive paper.The weight of the final structure is 190 g, whereas the weight of a traditional structure fabricated using the brazing technique with the same capacity is 500-600 g.The mass reduction is more than 60%.It should be stated that the traditional structures refer to the thermal controller structures used by China Academy of Space Technology.The weight property of thermal controllers is scarcely reported in public literature.

A picture of the phase-change thermal controller is shown in Fig.6(c).Owing to its light-weight property,the structure can stand on a plant.To test the mechanical performance of the lightweight structure,we conduct an internal pressure experiment.In this experiment,nitrogen is subjected to a pressure of 0.2 MPa at maximum in the cavity.The pressure is maintained for 10 min.Then,the pressure is removed.After the experiment,leak is detected with an INFICON UL1000 Fab helium mass spectrometer,as shown in Fig.6(d).The test result shows that the leak rate is less than 5×10-9Pa m3/s,and thus satisfies the desired leak rate of 5×10-7Pa m3/s.The flatness values of the top and bottom surfaces of the structure are 0.07 mm/100 mm×100 mm and 0.06 mm/100 mm×100 mm before and after the pressure experiment.The values are lower than the desired value(0.1 mm/100 mm×100 mm).A steady flatness can ensure a good area contact between electronic equipment and the phase-change thermal controller,and thus heat conduction is not blocked by the air gaps between the contact surfaces.

After the pressure test, a phase-change material,n-Tetradecane(a type of organic phase-change material with a phase-change temperature of 279 K),is filled into the thermal controller via the auxiliary tube.The auxiliary tube is blocked by soldering after filling of the phase-change material.The thermal capacity of the phase-change thermal controller is tested in a vacuum chamber.The experimental setup is shown in Fig.7(a)and(b).Two heater bands glued on the top face of the thermal controller are used as heat sources.The heat power density of the heater bands is 0.5 W/cm2.The temperatures at the top and bottom surfaces of the phase-change thermal controller are measured with thermocouples.The temperature-time curves(B-P)at eight positions are plotted in Fig.7(c).The temperature at the top face of the controller is shown as the upper curves(B-H)in Fig.7(c).The temperature at the bottom face of the controller is shown as the lower curves(J-P)in Fig.7(c).After heat is applied,thermal energy transports from the upper face to the bottom face of the thermal controller,thereby heating the solid-state n-Tetradecane.The temperature at the top face of the thermal controller increases from 273 K to 287 K within 120 s,and then increases rapidly from 120 s to 190 s.The rapid rise of temperature indicates that most of the phase-change material has become liquid.The phase-change process stores large amount of energy.The heat energy G absorbed by the thermal controller in a unit area before the temperature increases rapidly can be calculated as

where P is the power density of the heater bands,t1is the initial moment when the heater bands work,and t2is the moment when the temperature increases rapidly. The heat energy absorbed by the thermal controller in a unit area is 60 J/cm2,which is obtained by the formula.However,the energy capacities of thermal controllers with the same dimensions manufactured by a traditional technique are about 40 J/cm2.Therefore,the lattice-based thermal controller enables a 50%increase in thermal capacity compared with those fabricated by a traditional technique because of the increase in cubage.

4.Conclusions

This paper presents a design of a lightweight phase-change thermal controller structure based on lattice cells.The design is verified by mechanical and thermal tests.The following conclusions are drawn:

(1)A lightweight structure of a phase-change thermal controller based on lattice cells is successfully designed and fabricated.The mass reduction is more than 60%of that observed in traditional products.

(2)Mechanical analysis and experiments verify the strength of the structure under pressure and the satisfactory leakproof property of the thermal controller.

(3)The lattice-based thermal controller enables a 50%increase in thermal capacity because of an increased cubage.

Acknowledgements

The authors acknowledge the supports from Beijing Institute of Spacecraft System Engineering and the Young Elite Scientists Sponsorship Program by China Association for Science and Technology(Nos.2017QNRC001,2016QNRC001).The authors are grateful to Ms.He ZHAO from Capital Normal University for carefully proofreading the manuscript.

CHINESE JOURNAL OF AERONAUTICS2019年7期

CHINESE JOURNAL OF AERONAUTICS2019年7期

- CHINESE JOURNAL OF AERONAUTICS的其它文章

- Guide for Authors

- Prediction of cutting forces in flank milling of parts with non-developable ruled surfaces

- Configuration synthesis of planar folded and common overconstrained spatial rectangular pyramid deployable truss units

- A new error-controllable method for smoothing the G01 commands

- Electrochemical trepanning with uniform electrolyte flow around the entire blade profile

- Thermal-structure coupling analysis and multiobjective optimization of motor rotor in MSPMSM