基于疊層定向結(jié)構(gòu)調(diào)控的高導(dǎo)熱柔性聚偏氟乙烯/膨脹石墨復(fù)合材料*

For high-performance photoelectric devices and electronic systems such as LED,CMOS circuit,CPU and precise power supply,reducing working temperature by effectively exporting heat of device itself is one of major approaches to improve the operation efficiency of devices and systems. To realize the export of electronic device’ss heat,it is important to build the heat transfer path between device and radiator. With endless emergence of polymer thermal conductivity materials,employing polymer thermal conductivity material as the thermal interface material between devices and radiator have been widely researched and developed[1-2]. At present,the method of adding high thermal conductivity filling material into polymer has become the major preparation method to form the thermal conductivity macromolecule composite for its low cost and simple preparation process[3]. Since EG has larger specific surface area than that of natural graphite,thermal conductivity network chain can be more easily formed in the polymer[4-9]. Therefore,EG as a filler material is widely used and studied[10-15]. For example,Mochane1 prepared PP/EG composite material and PP/paraffin/EG composite material. When the mass fraction of EG is 10%,the thermal conductivities of PP/EG composite material and PP/paraffin/EG composite material are 0.55 W/(m·K)and 0.69 W/(m·K),respectively[16]. Huang et al. prepared a LiNO3/KCl-EG composite phase-change composite material,which can be used for solar regenerative system. The thermal conductivity of such LiNO3/KC-EG leutectic salt,which is prepared by mass fraction of 1∶1,is 1.749 W/(m·K)[17].

Wu et al. prepared polypropylene PP/EG thermal conductivity composite by using different particle sizes of EG as filling material,and found that when the mass fraction of EG was over 30wt%,the thermal conductivity of the composite was greatly increased. When the filling amount of EG reached 50wt%,the thermal conductivity can reach 1.791 W/(m·K)[18]. XuRuijie et al. prepared PP/EG/CF ternary thermal conductive composite,and found that when the mass fracture of EG and carbon fiber within is 20wt% and 5wt%,respectively,the thermal conductivity of the composite was increased to 0.91 W/(m·K),which 5 times that of pure PP,meanwhile the system was still of sound mechanical property[19]. Zhao Fu et al. prepared EG/epoxy resin composite material based on solution blended process,and analyzed the thermal characteristics of such material,finding that when mass fraction of EG is 4.5%,the conductivity of such composite material can reach 1 W/(m·K)[20]. From above analyses we can see that although large mass fraction of EG as filling material is used,it can only exert limited effect in increasing conductivity of the composite material,which can hardly meet the requirements of high conductivity of interface material. Therefore the key problem and challenge for increasing the conductivity of EG filling composite material is how to obtain high conductivity of composite material with lower filling content.

In addition,the matrix of higher crystallinity has lower proportion of amorphous phase,it is more likely to form dense pathway and network of thermal conductive particles under the same content of thermal conductive particle as filling material[21]. PVDF is a kind of polycrystalline polymer,as of now,they have been discovered 5 types of crystalline forms includingα,β,γ,δandεcrystalline form according to the difference of preparation conditions[22]. Crystalline state of PVDF is greatly affect by factors including crystallization temperature and time,solvent polarity,external pressure and other specific environmental factors. Of 5 types of crystalline forms,αcrystalline form of PVDF has higher degree of crystallinity,βcrystalline of PVDF has been widely applied for its unique piezoelectricity and thermoelectricity[23-25]. This paper analyzed thermal conduction characteristics and thermodynamic property of PVDF(α phase)/EG orderly composite thin-film material,explored the preparation technology and thermal conductivity mechanism of PVDF/EG orderly high thermal conductivity composite resulted by two-step forming process,and presented characterization analysis of its thermal conductivity based on the feature that the thermal conductivity in parallel direction is more superior than that in perpendicular direction.

1 Experiment

1.1 Materials and chemicals

PVDF powders used as matrix powers were supplied by Juhua Group Corporation.,China. EG were supplied by Shanghai 3F New Material Co.,Ltd.,China. Titanate coupling agent were supplied by Nanjing Upchemical Co.,Ltd.,China. Absolute ethyl alcohol were supplied by Chemical Reagent Company of Sinopharm.,China.;N,N-dimethyl formy(DMF)were supplied by Chemical Reagent Company of Sinopharm.,China.

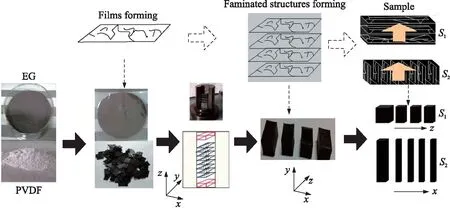

1.2 Preparation of orderly polymer composites

In the preparation of orderly polymer composites,two-step forming processing is used,which include seven process:Firstly,EG and PVDF are dried in vacuum drying oven at 80 ℃ for 24 h;Secondly,dissolve titanate coupling agent in absolute ethyl alcohol to modify EG,which is then applied with magnetic stirring and ultraphonic treatment before being dried in vacuum drying oven at 80 ℃ to constant weight for stand-by use;Thirdly,dissolve PVDF using DMF by water bath heating for 2 hours in constant temperature(60 ℃)with magnetic stirring,so as to obtain PVDF solution;Fourthly,put modified EG into PVDF solution,and then keep water bath heating for 2 hours in constant temperature(60 ℃)with magnetic stirring before ultrasonic degassing for 15 min,so as to obtain the PVDF/EG mixed solution;Fifthly,prepare PVDF/EG thin film using K4340M102 film coating machine at 120 ℃;Sixthly,sectioning of PVDF/EG thin film into samples in size of 10 mm*10 mm,and then put the sectioned samples into hot embossing mould lay by layer,and finally result in orderly composite with height of 12 mm at 160 ℃ and 2 MPa;Seventhly,post-treatment of material,the PVDF/EG orderly composite materials were oriented to the thin films and the vertical thin films,and theS1andS2of the two series orderly composite materials were prepared. The preparation processing diagram is shown as Fig.1.

Fig.1 Preparation diagram of PVDF/EG orderly thermal conductivity composite

1.3 Characterization

X-ray diffraction(XRD)patterns of PVDF/EG composite materials were obtained by X-ray diffractometer(XRD-6000)from Shimadzu with scanning range of 10°~40°. Scanning electron microscopic(SEM)photos of PVDF/EG composite material where in the mass fraction of EG is 15wt%. The thermal conductivities of the PVDF/EG composite were measured using TPS 2500S type multifunctional thermal conductivity tester from Swedish Hot Disk,wherein the mass fraction of EG is 5wt%,10wt%,15wt%,20wt% and 25wt%,respectively. The compression stress(Mechanical property)of the PVDF/EG composite was measured using GS-X 1KN from SHIMADZU of Japan,which the EG mass fraction is 0wt%,5wt%,and 10wt%,respectively.

2 Results and Discussion

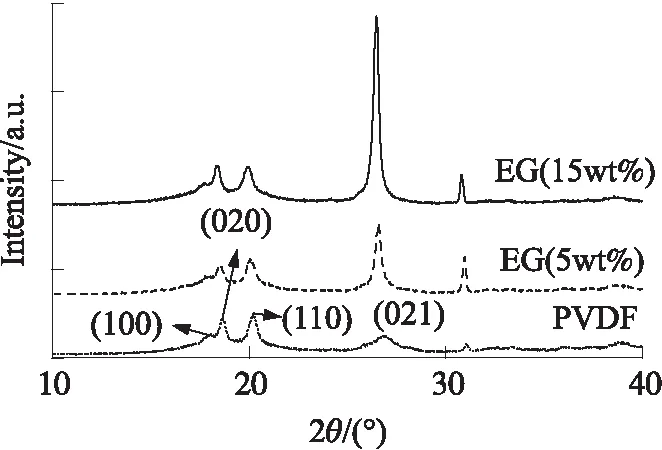

Fig.2 shows the X-ray diffraction pattern of PVDF/EG composite materials,of which the mass fraction of EG is 0wt%,5wt%,15wt%,respectively. According to Fig.2,it can be seen that for the PVDF and PVDF/EG composite materials which are prepared at 160 ℃and cooled to room temperature by a fast cooling rate,diffraction angles of 17.9°,18.6°,20.1° and 26.5°are corresponded to diffraction peaks at crytal faces of(100),(020),(110)and(021),indicating that the PVDF film prepared at 150 ℃is of typicalαcrystal phase. In addition,according to the integral areas of crystallization peak and amorphous peak of PVDF film,it can be known that the degree of crystallinity of PVDF film is 59.7%. When EG was added into PVDF matrix,PVDF/EG composite materials,there can be seen a strong EG diffraction peak,meanwhile the diffraction peaks at 18.6°and 20.1° move to 18.4° and 20°,respectively with small deviation.

Fig.2 XRD diffraction pattern of PVDF/EG composite

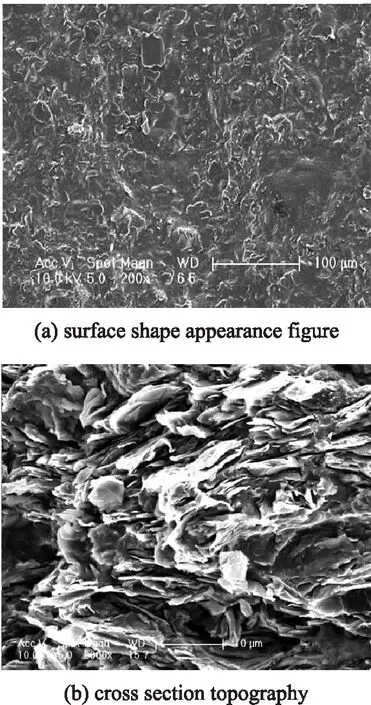

Fig.3 is the SEM image of PVDF/EG composite materials,of which the mass fractions of EG are 15wt%,it can be seen that there is significant layered structure distributed inside of PVDF/EG thin film. Due to the large contact thermal resistance between layers,the thermal conductivity property of PVDF/EG thin film is anisotropic,therefore the conductivity in parallel direction is superior than that in perpendicular direction.

Fig.3 SEM image of surface and cross section of PVDF/EG composite thin film for mass fraction of EG 15wt%

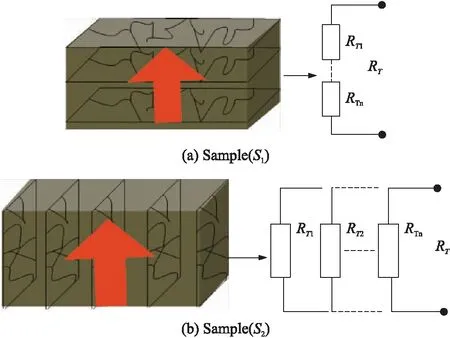

The thermal diffusion coefficients of the two samples of mass fraction of EG reaches 25wt% are tested using LFA427 typed thermal diffusion tester from NETZSCH of Germany,and testing diagram is shown as Fig.4. The thermal diffraction coefficients of both orderly materials are shown in Table 1.

Fig.4 Diagram of thermal diffusion coefficients of two samples

From the test results,in terms of thermal conductivity of PVDF/EG orderly composite,it can be seen that sample 2(S2)has thermal diffusion coefficient which is 4.1 times larger than that of sample 1(S1). AsS1andS2are the same in composition and size but different in internal structure only.

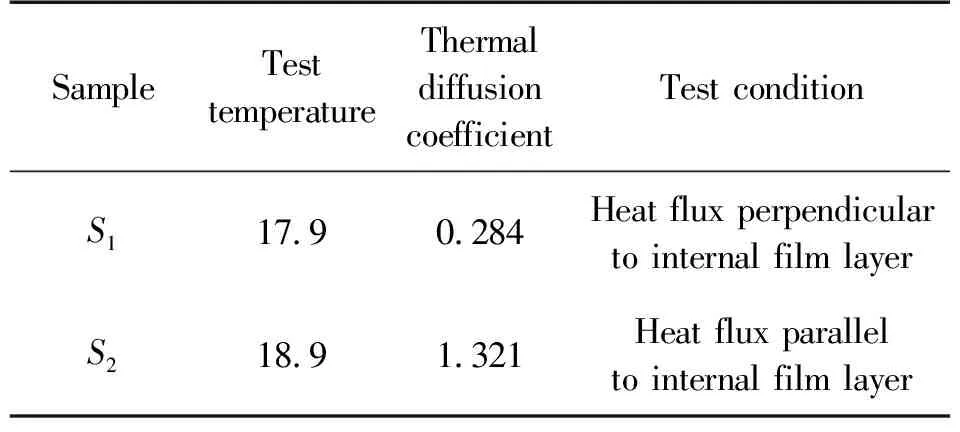

Table 1 Thermal diffusion coefficients of two samples

According to the relation among thermal diffusion coefficient,thermal conductivity and thermal resistance,shown as equation(1)and(2):

k=a·Cp·V

(1)

(2)

Where,αis thermal diffusion coefficient,CPis specific heat capacity of sample,Vis the volume of sample,his the height of sample,Sis the basal area of sample.

By equation(1)and(2),it can be known that thermal resistance along the in parallel direction is 0.25 times larger than that which is vertical to in parallel direction. Therefore it can conclude that the thermal conductivity along the in parallel direction of internal thin film is more superior over that which is vertical to in parallel direction of internal thin film.

In order to prove the validity of orderly polymer composites based on PVDF,using two-step forming process.

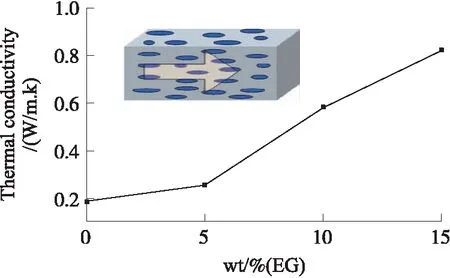

Firstly,PVDF/EG composite materials were prepared based on the mixed hot-press method at 180 ℃ using mixed power of PVDF and modified EG,wherein the mass fractions of EG were 5%、10% and 15%,respectively. The thermal characteristics of composite material was test using DiskTPS 2500S(Sweden)as multi-function thermal conductance meter,the test result of thermal conductivities with different mass fractions of EG are shown in Fig.5. It can be seen from Fig.5 that when the mass fractions of EG are 10wt% and 15wt%,respectively,the thermal conductivities of the composite material are 0.583 W/(m·K)and 0.81 W/(m·K),respectively.

Fig.5 Characteristic of thermal conductivity of PVDF/EG mixed pressure composite material with mass fraction of EG

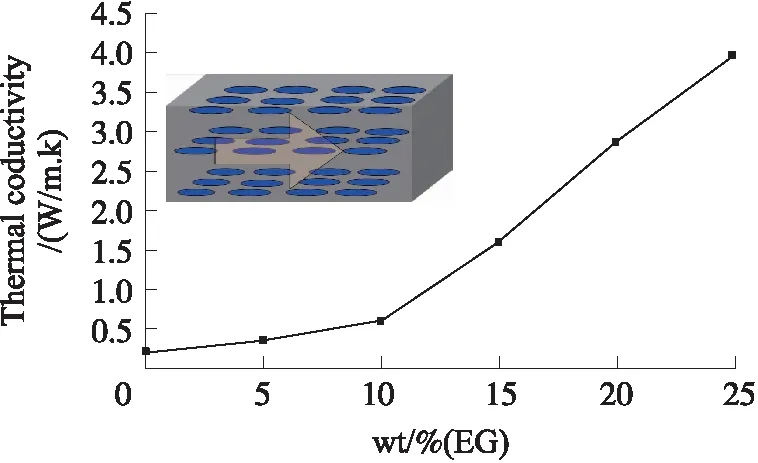

Secondly,using two-step forming process,it prepared the PVDF/EG orderly composites,of which the mass fractions of EG are 5wt%,10wt%,15wt%,20wt%,and 25wt%,respectively. SampleS2is obtained by cutting the composite along vertical direction of laminating surface,and then the thermal conductivity property ofS2is analyzed using TPS 2500S typed multifunctional thermal conductivity tester from Swedish Hot Disk,and the results are shown in Fig.6.

Fig.6 Thermal conductivity of PVDF/EG orderly composite

According to Fig.6,it can be seen that in PVDF/EG thermal conductivity composite material with orderly structure,when mass frictions of EG are 5wt% and 10 wt%,the thermal conductivities of the composite material will be 0.35 W/(m·K)and 0.59 W/(m·K),respectively. When mass frictions of EG are 15wt%,20 wt% and 25%,the thermal conductivities of the composite material will be 1.595 W/(m·K),2.87 W/(m·K)and 3.984 3 W/(m·K),respectively. When mass friction of EG over 10wt%,the variable of thermal conductivity forPV DF/EG orderly polymer composites will be 4 times larger than that with mass friction of EG lower than 10wt%. This indicates that“l(fā)eakage”transition point will occur when mass fraction of EG reaches 10wt%,which is smaller than EG mass fraction of 30wt%“l(fā)eakage”threshold of PP/EG composite material[16]. In addition,when mass fraction of EG reaches 15wt%,the thermal conductivity of PVDF/EG composite material prepared by mixed compression method will be 0.81 W/(m·K)(Fig.5),which will be 1/2 of that of PVDF/EG thermal conductivity composite material with orderly oriented structure. This indicates that the application of orderly oriented structure can increase the thermal conductivity of composite material. Therefore,according to the feature that the in parallel conductivity of PVDF/EG composite thin film material is larger than in perpendicular direction thermal conductivity and through oriented structure control of PVDF/EG composite material,it can realize the purpose of high thermal conductivity while less filling mass friction of EG.

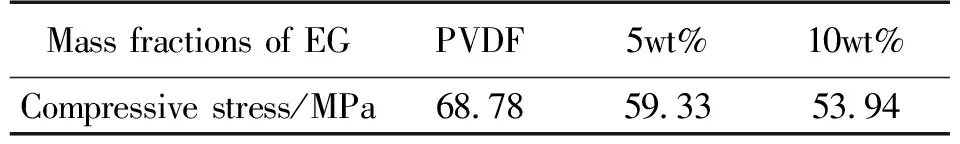

In addition,to measure the deformation behavior of PVDF/EG orderly composite under the condition of compression,AGS-X 1KN typed mechanical properties tester from SHIMADZU Japan is employed. The maximum compression stresses upon various mass fractions of EG are shown in Table 2.

Table 2 The maximal compressed stress at different mass fractions of EG

This indicates that the compression stress(mechanical strength)of PVDF/EG composition is relative lower than that of PVDF,making it easier to contact with the interface of electronic devices,thus reducing thermal contact resistance. Of course,the mechanical strength of PVDF/EG composite is affected by factors in preparation process such as temperature and pressure.

3 Conclusion

In the PVDF/EG orderly polymer composite material prepared using two-step forming process,PVDF is in sound α crystal structure with degree of crystallinity reaching 59.7%. PVDF/EG thermal conductivity composite material with laminated oriented structure is of significant anisotropic characteristics,and the thermal diffusion coefficient along in-plane direction of internal film is 4.1 times larger than that in vertical direction;Thermal conductivity of orderly polymer composite material prepared using two-step forming process increased with mass fraction of EG. When the mass fraction of EG is over 10wt%,the variable of thermal conductivity for composite material is 4 times larger than that when mass fraction of EG is less than 10wt%. Thus,the mass fraction of EG reaches 10wt%,the "leakage" threshold of composite material is realized. Moreover,thermal conductivity of PVDF matrix got improved from 0.18 W/(m·K)to 3.984 3 W/(m·K)upon 25% mass fraction of EG. In summary,it is interesting to note that the microstructure of parallel arrangement could introduce excellent thermal conductivity with obvious anisotropic thermal behaviors. In addition,as PVDF/EG thermal conductivity orderly composite material has a sound flexibility. The PVDF/EG composites with the microstructure of parallel arrangement is a promising interface thermal conductivity material.

4 Acknowledgments

The work was supported by National Natural Science Foundation of China(51566001),Education department Major Project Foundation of Yunnan province(ZD2014014).

- 傳感技術(shù)學(xué)報(bào)的其它文章

- 基于光纖傳感的輸電線(xiàn)路覆冰監(jiān)測(cè)系統(tǒng)研究*

- 面向海島環(huán)境的海霧能見(jiàn)度監(jiān)測(cè)系統(tǒng)應(yīng)用研究*

- WSNs中數(shù)據(jù)融合樹(shù)的時(shí)隙分配算法*

- 線(xiàn)型無(wú)線(xiàn)傳感器網(wǎng)絡(luò)中一種聯(lián)合優(yōu)化中繼節(jié)點(diǎn)選擇策略*

- 無(wú)線(xiàn)傳感器網(wǎng)絡(luò)延遲約束的MDC分布式軌道規(guī)劃算法*

- 一種RSS和CSI融合的二階段室內(nèi)定位方法*