Variation of toxic pollutants emission during a feeding cycle from an updraft fixed bed gasifier for disposing rural solid waste☆

Ming Lei,Jing Hai*,Jiang Cheng ,*,Jiawei Lu Jieru Zhang Tao You

1 School of Chemistry and Chemical Engineering,South China University of Technology,Guangzhou 510640,China

2 South China Institute of Environmental Sciences,Ministry of Environmental Protection(MEP),Guangzhou 510655,China

1.Introduction

With the continuous improvement of living standards in rural areas of China the produced amount of rural domestic solid waste is increasing year by year.The annual output of rural domestic solid waste reached about 50–240 million tons in 2014[1].In China,69%of the land area is mountainous or hilly,bringing difficulty in treatment of solid waste in these regions due to the scattered population,inconvenient traffic and lack of fund especially for applying the traditional centralized processing method such as incineration orl and fill[2,3].Because of the advantages of low investment cost and flexible site-selection,many small-scale gasifiers have been built for disposing these solid waste in rural China in recent years[4,5],with most of them being the updraft fixed bed gasifier.Generally,in practical engineering application,the small-scale updraft fixed bed gasifier runs in batch mode with 2–4 times feeding a day and no feeding at night in order to save the running cost,thus resulting in a long feeding cycle with about 4–8 h.Therefore,the operation conditions such as temperature and intake of air in gasifier chamber may vary gradually with the reduction in amount of the raw solid waste during such a long feeding cycle.

In gasification of solid waste,the temperature and oxygen concentration in gasifier chamber play a very importantrole in formation of dioxins.Previous studies[6–8]showed that the dioxins would be synthesized in temperature range of 200–700 °C during thermal treatment process of solid waste,with the most suitable temperature zone of 300–500 °C.Zhang et al.[9]found that the formation of dioxins increased with oxygen concentration,and suggested the excess oxygen levels should be kept lower than 10%(V/V)during solid waste incineration.Simultaneously,the oxygen content may also affect the generation of other pollutants such as SO2,NO2and CO,and the removal efficiency of flue gas cleaning system.However,the variation of toxic pollutants emission arising from the unsteady-state batch operation within a feeding cycle in a batch feeding gasifier has not yet been reported in literatures with respect to the practical engineering application.

Accordingly,in this study,toxic emission from a typical batch feeding updraft fixed bed gasifier for disposing rural solid waste was examined by field monitoring.Four target pollutants including NOx,SO2,HCl and dioxins in flue gas were analyzed in different time after feeding,and the oxygen content in flue gas was also monitored in the whole feeding cycle to examine the effect of oxygen on the variation of toxic emission.More importantly,the synthesis of PCDD/Fs in flue gas was discussed before and after the flue gas passed through the electric heating device,which is used as the flue gas cleaning system for removing the produced combustible gas and CO during gasifying.The knowledge gained would assist in developing the effective toxic pollutant control strategies for running the batch feeding updraft fixed bed gasifier in disposing rural solid waste and providing scientific experience in rural waste management.

2.Materials and Methods

2.1.Information of the updraft fixed bed gasifier

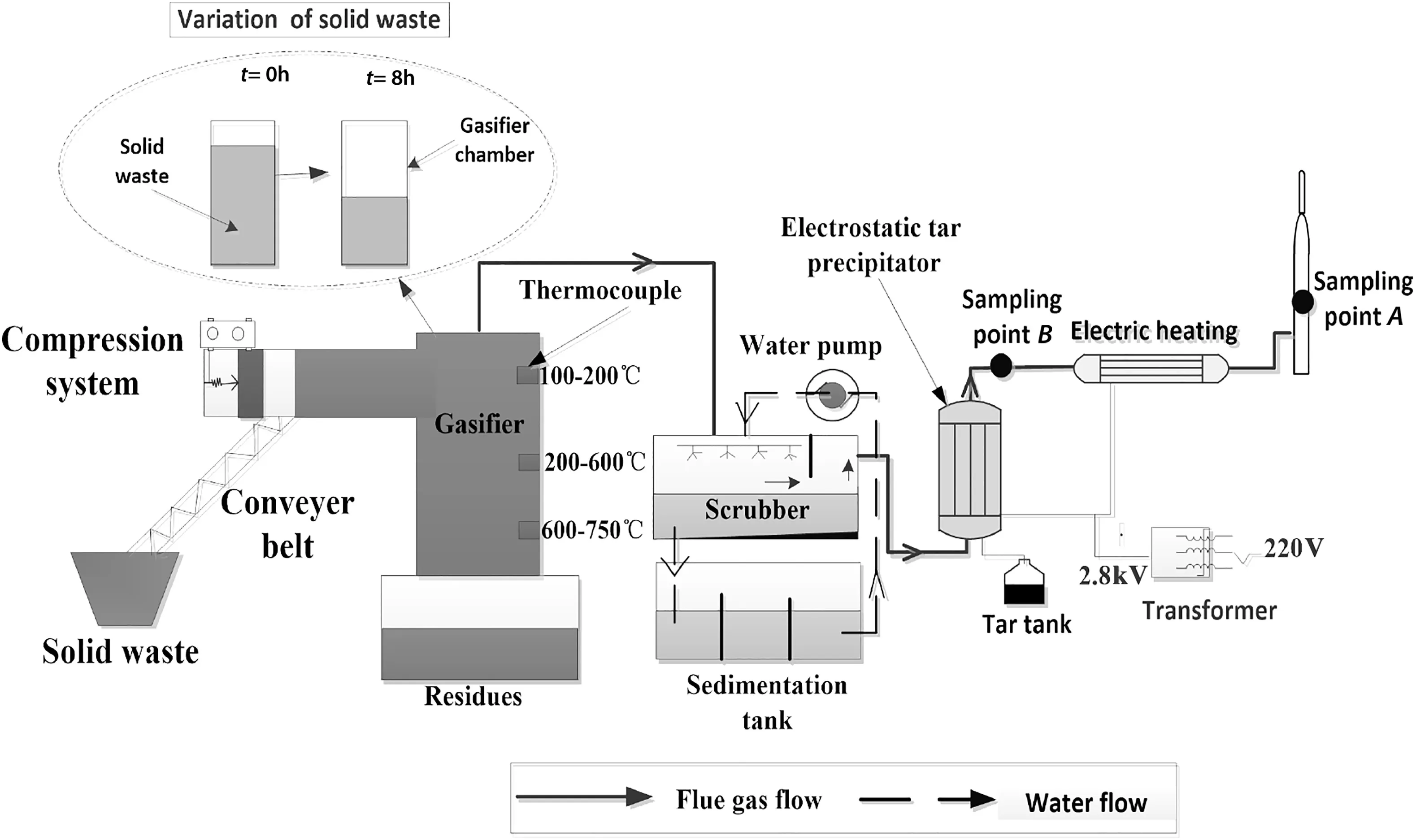

The investigation was carried out on a batch feeding updraft fixed bed gasifier with the capacity of 2 t·d?1located in a mountainous rural area in southwest China.Generally,the raw waste feeding was 2–3 times in the day and no feeding at night,and the feeding time is 8:00,13:00 and 18:00,respectively.In the present study,we examined the variation of toxic pollutants emission in a long feeding cycle of8 h by an average of both daytime and night.The main components and technical process of the gasifier are demonstrated in the Fig.1.Prior to entering the gasifier,the raw solid waste was simply sorted by hand in order to remove big stone,glass and other non-combustible materials,the solid waste was then sent into the compression system through the conveyer belt for compressing,and finally fed into the gasifier chamber.In this study,around 0.65 t of the raw solid waste was fed into the gasifier chamber,with the initial height of solid waste layer within the gasifier chamber of 1.8 m.After 8.0 h gasification,the height of raw waste decreased to about0.8 m(Fig.1).During gasifying the low-temperature flue gas with almost no fly ash in the outlet of gasifier was generated due to the adsorption and filtration of the raw solid waste on the top of gasifier.The produced flue gas flowed sequentially through the wet scrubber,electrostatic tar precipitator(ETP)and electric heating device.The consumption of scrubbing water was very low with about 1.0–1.5 m3per month because the high moisture of 35 wt%–50 wt%contained in the raw solid waste was transferred into the scrubber during the process of flue gas cleaning.The role of ETP was to remove the tar in flue gas instead of fly ash.The electric heating device(EHD)with high temperature(850°C)is to effectively remove the high content of CO in flue gas(power consumption:50 kW·h·d?1).It should be noted that the gasified gas was not further used as combustible gas due to the very low yield of 46.5 m3·h?1,but were directly removed by the electric heating device at the current study.

2.2.Sampling

The flue gas sampling was according to the Sampling Method of Total Particulate Matter and Gaseous Pollutant for Stationary Pollution Sources of Chain(GB/T16157-1996).SO2,NOx,HCl and CO in flue gas were all sampled at sampling point A(Fig.1)0.5,2.5 and 4.5 h after feeding.In order to know the effect of electric heating on removing dioxins in flue gas the sampling of dioxins both at sampling point A and B was conducted synchronously(Fig.1),and the sampling time of each dioxins sample was about 2.0 h.The content of oxygen in flue gas from the sample point A was measured every 1.0 h.The scrubbing water was collected in the sedimentation tank with continuous running for about 6 months.The tar sample came from all tar produced during the one feed cycle.

2.3.Analytical methods

The concentration of SO2,NOxand CO in flue gas was monitored by the flue gas measuring instrument(LAO YING,China,3012H).HCl was absorbed by the solution of 0.005 mol·L?1of NaOH and analyzed by the mercuric thiocyanide spectrophotometric method.The sampling of PCDD/Fs in the flue gas was according to the American standard method EPA 23A.Analysis of PCDD/Fs in the flue gas,scrubbing water and tar were performed using a high-resolution gas chromatography(HP,6890 gas chromatography)coupled with a high-resolution mass spectrometer(HRGC/HRMS)(Waters,Autospec Premier).13C12-labeled PCDD/Fs(purchased in Cambridge Isotope Laboratories,Austin,Texas,USA)was used in the processes of sampling and analyzing as the standard substance.Chromatographic separation was achieved with a DB-5MS fused-silica capillary column(60 cm × 0.25 mm i.d.,0.25 μm film thickness).The GC temperature program was performed as follows:initially the oven temperature began at 150°C(held for 3 min),then increased at 20 °C·min?1to 230 °C(held for 18 min),further increased at 5 °C·min?1to 235 °C(held for 10 min)and finally reached 320 °C(held for 3 min)with a heating-up rate of 4 °C·min?1.The sampling and analytical recoveries were 89.7%–129.8%and 71.5%–118.9%,respectively.Laboratory method blanks were run for each batch of samples for ensuring quality assurance.More details on the analytical procedure were reported in our previous work[10].The international toxic equivalency quantity(I-TEQ)was calculated according to the international toxicity equivalency factor(I-TEF)(NATO/CCMS,1988).

Fig.1.Schematic diagram of the updraft fixed bed gasifier.

2.4.Information of raw domestic solid waste

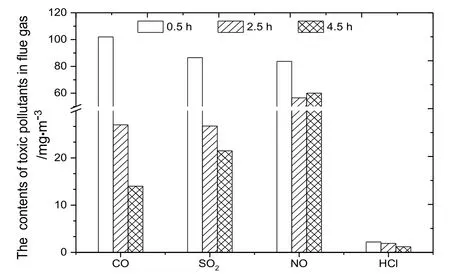

The sampling of raw solid waste was according to the Methods of Sampling and Analysis of Municipal Solid Waste of China(CJ 313-2009-T).The contents of C,H,O,N,S,and Cl in raw solid waste were measured by the elemental analyzer(Elementar Vario EL(III)).The calorific value was analyzed by using the microcomputer automatic calorimeter(HAO TIAN Co.Ltd.China.ZDHW-9L).As shown in Table 1,the calorific value of rural solid waste was lower than that of common municipal solid waste due to the higher content of kitchen waste containing great moisture,indicating not suitable for direct combustion of the domestic rural solid waste.

3.Results and Discussion

3.1.Emission variation of O2,NOx,SO2,CO and HCl in flue gas

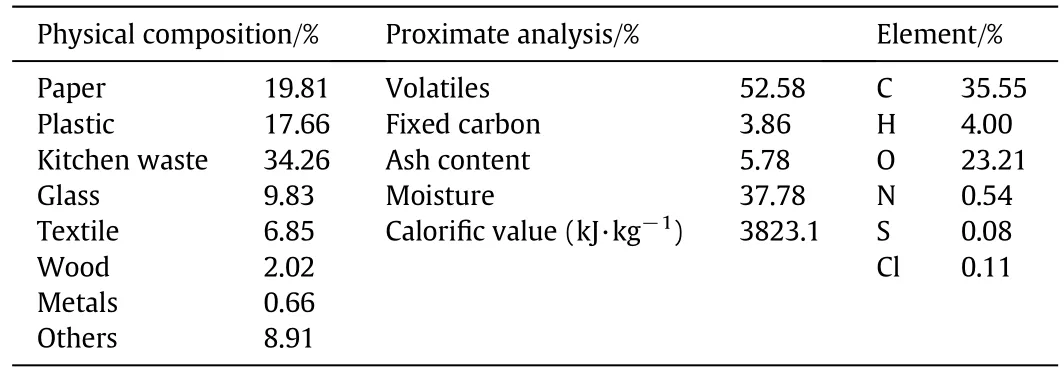

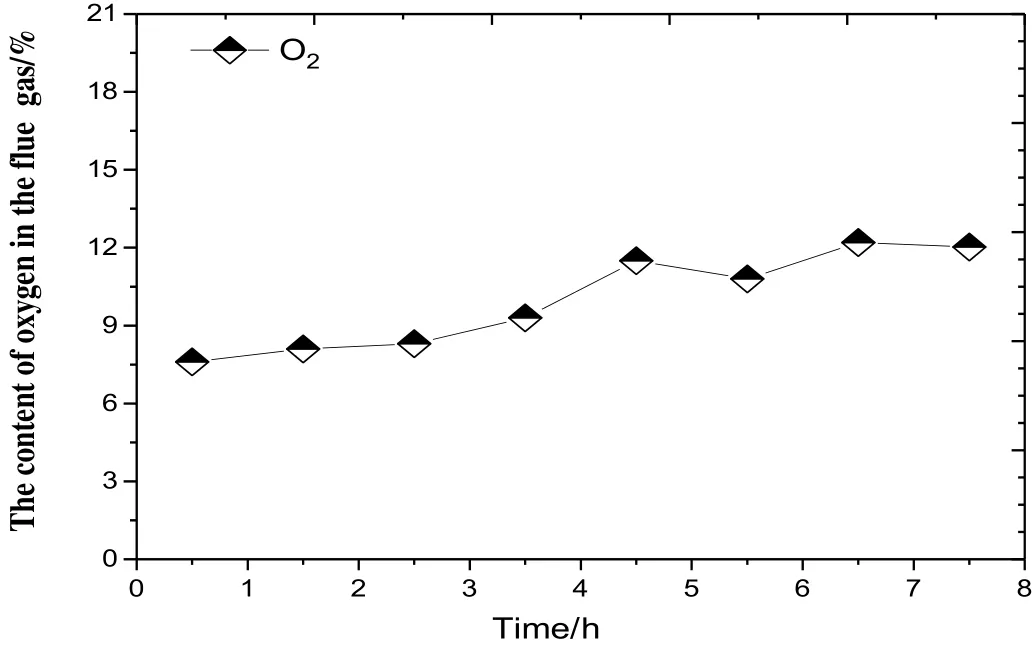

Oxygen plays an important role in the formation and transformation of pollutants during thermal treatment process of solid waste[8,9,11].As shown in Fig.2,the content of oxygen in flue gas gradually increased with time in the whole feeding cycle,with 7.6%and 12.0%at 0.5 and 7.5 h after feeding,respectively.This may attribute to the decreasing resistance for air flow resulted from the reduction in amount of raw solid waste within the gasifier chamber,and more air could easily flow into the chamber as the gasification went on(Fig.1).Fortunately,the increasing of oxygen did not increase the emission contents of toxic pollutants including NOx,SO2and CO in the flue as demonstrated in Fig.3.The contents of SO2,NOx,and HCl at the sampling point A were 86.50,83.75,and 2.20 mg·m?3at0.5 h afterfeeding and then decreased to 21.50,60.00,and 1.60 mg·m?3at 4.5 h,respectively.In solid waste gasification,sulfur in raw solid waste was mainly converted to H2S,COS and little SO2,nitrogen was mainly formed to NH3,N2and small amount of NOx,and the conversion rate of SO2and NOxincreased generally with the oxygen content[12,13].In this study,however,the contents of SO2and NO,decreased with the oxygen content in flue gas(Fig.3).Previous studies found that most of sulfur and chlorine in raw solid waste were volatilized at 550°C[14,15].Chlorine including organic chlorine and inorganic chlorine in raw solid waste began to release at temperature over 200°C,and most of organic chlorine mainly converted to HCl when heating temperature reached 550°C.For the inorganic chlorine,its release needed a more high temperature of 600°C and it is mainly converted into NaCl,KCl and small amount of HCl[16,17].Therefore the gradual decreasing of SO2and HCl in flue gas with gasifying time was resulted from the reduced amount of sulfur and chlorine at the later stage of gasification during a batch run.

As a main product of municipal solid waste gasification,emission of CO was very high and generally reached 50–150 g·m?3in flue gas[18,19],which was difficult in meeting the emission standard(100 mg·m?3,GB18485–2014)of China.However,the low CO in fluegas in this study was obtained and gradually decreased with the gasifying time(Fig.3),owing to the reactions:CO+H2O?CO2+H2and 2CO+O2?2CO2occurred within the electric heating device.

Table 1 Proximate and element analysis of the domestic rural solid waste

Fig.2.The variation of oxygen content in flue gas with time(sampling point A).

3.2.Emission variation of dioxins

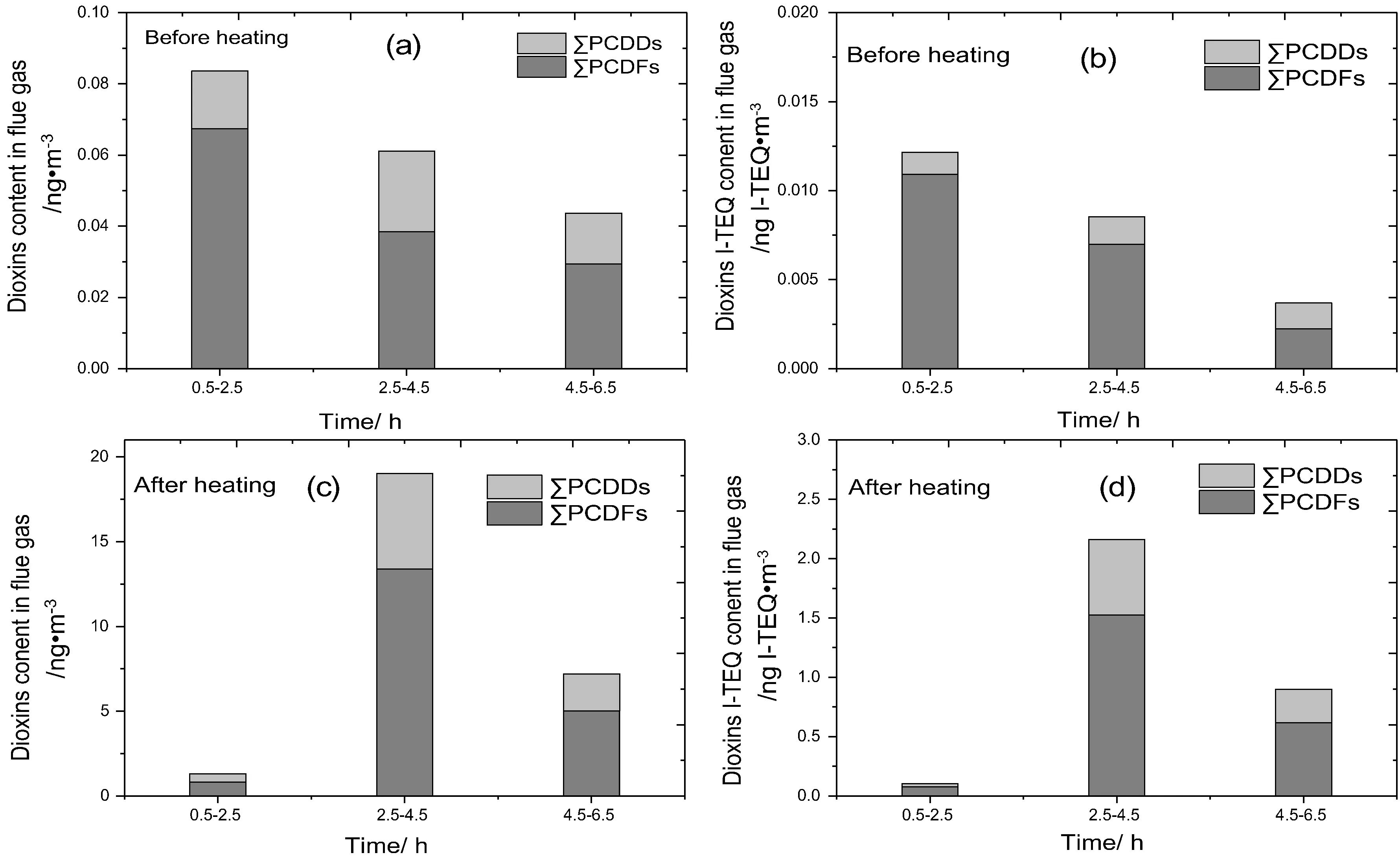

Oxygen could promote the synthesis ofdioxins during the solid waste thermal treatment[20].In the present work,the concentration of dioxins was not increased but decreased with oxygen in the flue gas[Fig.4(a)],and the content of dioxins was 0.084,0.061,0.044 ng·m?3at 0.5–2.5,2.5–4.5,4.5–6.5 h after feeding,respectively.This was probably due to the reduced release of chlorine as discussed above.

In different sampling time,the PCDF congeners in flue gas were higher than PCDDs,demonstrating that PCDF was easy to form during gasifying.This was similar to that of solid waste incineration[10].For the I-TEQ content of dioxins,their contents were 0.012,0.009,and 0.004 ng I-TEQ·m?3at 0.5–2.5,2.5–4.5,and 4.5–6.5 h after feeding[Fig.4(b)],respectively,obviously lower than the emission standard value(0.1 ng I-TEQ·m?3)of China(GB18485-2014).Although some previous studies reported that the wet scrubbing had very low removal efficiency[21,22],low content of dioxins in flue gas in this study was obtained by the wet scrubbing coupled with electronic tar precipitator.This is because the thick solid waste layer within the gasifier chamber may filter particulate matters containing dioxins,and the re-synthesis of dioxins may not occur in wet scrubber and electrostatic tar precipitator(ETP)due to the low temperature of flue gas[23–25].Notably,in the scrabble water and tar,relative high contents of dioxins were found up to 5295 ng I-TEQ·L?1and 8260 ng I-TEQ·kg?1,respectively,suggesting that large parts of PCDD/Fs might be transferred into the scrubbing water and tar under low temperature and high humidity[26].

Fig.3.The variations of SO2,NO x,HCl and CO in flue gas with time(sampling point A).

Fig.4.The content of dioxins in flue gas before(a,b)and after heating(c,d).

Fig.4(c)and(d)showed that the content of dioxins in flue gas increased after heating with the electric heating device,and the I-TEQ content of dioxins increased 8.51,253.19,and 244.00 times,reaching 0.10,2.16,and 0.90 ng I-TEQ·m?3at 0.5–2.5,2.5–4.5,and 4.5–6.5 h,respectively.The increase in dioxins may mainly come from the re-synthesis in the cooling process of flue gas in the post zone of electric heating rather than within the electric heating device because the high temperature(850°C)and great residence time of flue gas over 2.5 s within the electric heating device were not suitable for the synthesis of dioxins[8,27].

Fig.5.Distributions of 17 dioxin congeners in flue gas before(b)and after heating(a).

Fig.4(c)and(d)further demonstrated that the dioxins in flue gas increased firstly and then deceased after heating,itis possibly due to the effect of variation in oxygen and chlorine in flue gas[20,28].It can be inferred from Figs.2 and 3 that both the high oxygen of 8.3%–11.5%and high chlorine of 1.90 mg·m?3resulted in large re-synthesis of dioxins at 2.5–4.5 h after feeding,but at 4.5–6.5 h,with further reducing in chlorine release,the synthesis of dioxins was decreased.Obviously,at 0.5–2.5 h after feeding,the emission content of dioxins was low with oxygen content of 7.6%–8.3%in flue gas,however,at 2.5–4.5 h and 4.5–6.5 h,with further increase in oxygen(9.3%–12.20%),dioxins were largely synthesized and difficult to meet the emission standard value of China(0.1 ng I-TEQ·m?3).Therefore,in order to keep the emission of dioxins within the standard limited value(0.1 ng I-TEQ·m?3),the oxygen content in flue gas should be controlled below 8.3%by reducing the air intake in the later stage of feeding,such as turning the valve of air inlet small open which is located at the bottom of gasifier chamber,or reducing the feeding cycle to within 3 h.Fig.4 also showed that PCDF content was obviously higher than PCDDs in flue gas in different sampling times,revealing that PCDFs were easier to generate than PCDDs during the heating process of flue gas.

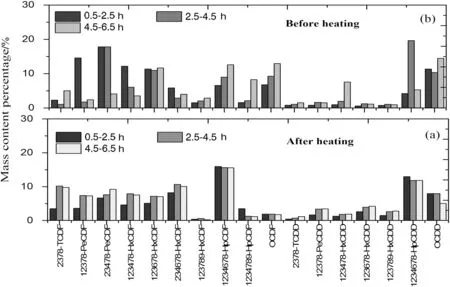

3.3.Distribution characteristics of 17 dioxin congeners

The distribution characteristics of 17 dioxin congeners in flue gas were much different between prior to and after electric heating device(Fig.5),showing the re-synthesis of PCDD/Fs after electric heating.Prior to electric heating,the percentage distributions of 17 dioxin congeners varied much in the different sampling time[Fig.5(a)],however,the percentage characteristics of dioxin congeners in flue gas remained almost unchanged after heating regardless of these three sampling time[Fig.5(b)].The content of 1234678-HpCDF was the highest after heating and reached 15.98%,15.57%,and 15.56%in different sampling time,respectively,indicating oxygen may not obviously influence on the percentage distribution of dioxin congeners during the flue gas heating.In terms of I-TEQ distribution of dioxin congeners(Fig.6),the 23478-PeCDF was the highest in different sampling time,and the range of percentage content of 23478-PeCDF was 22.41%–63.86%and 32.24%–53.23%before and after the flue gas heating,respectively,which was similar to that of MSWI[29,30].

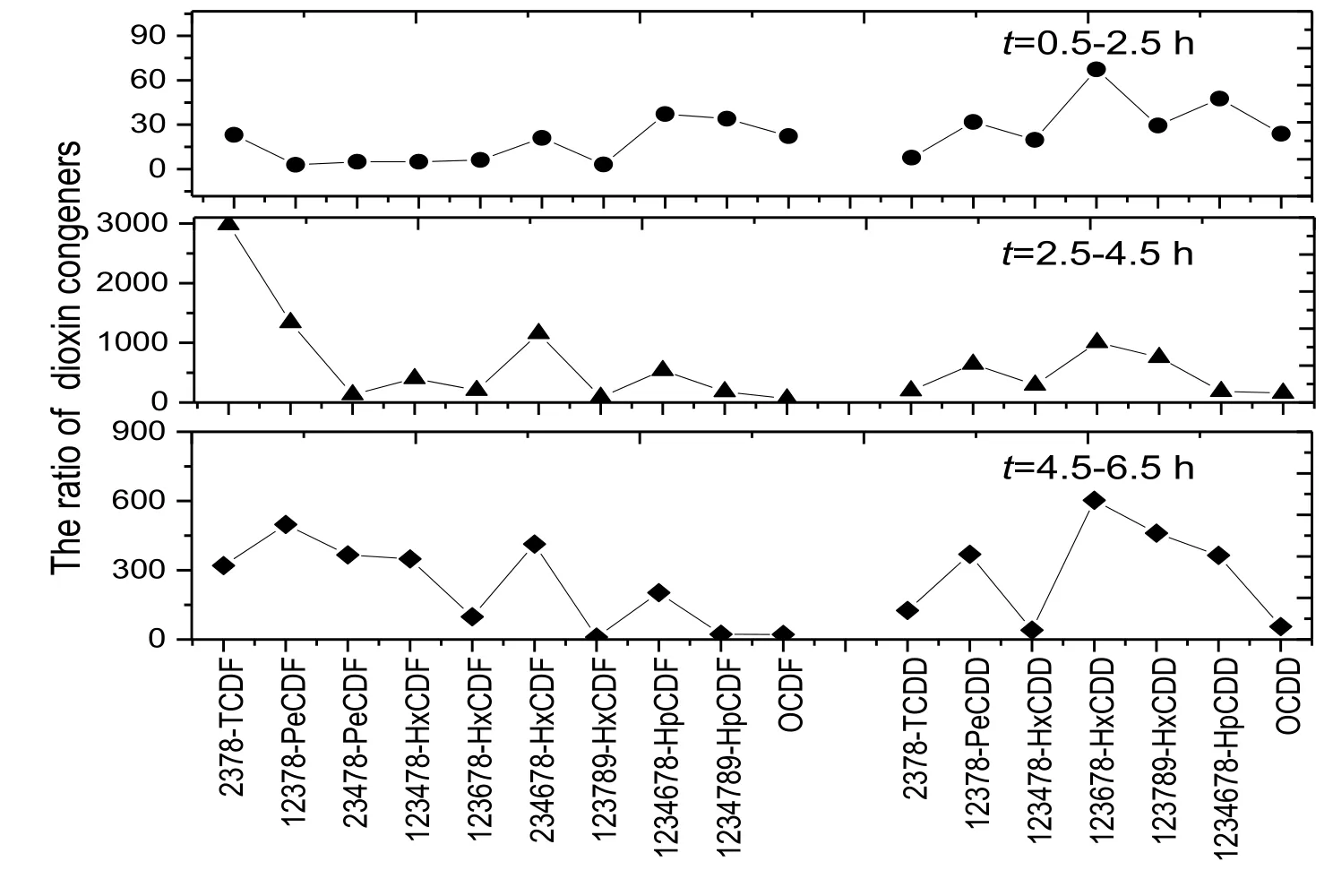

Fig.7 showed the variation of increase ratio(the ratio of the content of dioxin congener after heating to that before heating)of 17 dioxin congeners in flue gas in different sampling time after feeding.The highest increase ratio of dioxin congeners occurred at 2.5–4.5 h after feeding.For the 7 PCDDs congeners,the increase ratio of 123,678-HxCDD was the highest and reached 67.40,520.33,1957.00 at 0.5–2.5,2.5–4.5,4.5–6.5 h after feeding,respectively.In term of the 10 PCDFs congeners,the increase ratio of high chlorine PCDFs congener was greater than that of low chlorine PCDFs at 0.5–2.5 h after feeding,but opposite at 2.5–4.5 h and 4.5–6.5 h,indicating high chlorine PCDFs were easily synthesized at low oxygen condition,while the low chlorine PCDFs formed under high oxygen atmosphere.

4.Conclusions

The emission variations of toxic pollutants during a feeding cycle from a batch feeding updraft fixed bed gasifier were studied.Results showed that the content of oxygen in flue gas gradually increased from 7.6%to 12.0%with gasification time increasing from 0.5 h to 7.5 h after feeding,however,SO2,HCl decreased owing to gradually reduced release of sulfur and chlorine in solid waste within the gasifier chamber.By the purification of wet scrubber coupled with electrostatic tar precipitator(ETP),low content of dioxins in the flue gas before electric heating was observed and gradually decreased with time after feeding.The distribution characteristics of dioxins congeners before and after flue gas heating indicated the re-synthesis of dioxins after flue gas heating.However,the dioxins content can meet the emission standard of 0.1 ng I-TEQ·m?3(GB18485-2014)of China under low oxygen atmosphere of below 8.3%during flue gas heating,suggesting that less oxygen atmosphere should be maintained by reducing the air intake at the later stage of feeding or reducing the feeding cycle to within 3 h.High chlorine PCDFs congeners were more readily synthesized under low oxygen condition during flue gas heating,while low chlorine PCDFs congeners tend to form in high oxygen atmosphere.

Fig.6.The I-TEQ content percentage distributions of 17 dioxin congeners in flue gas before(b)and after heating(a).

Fig.7.The ratio of dioxin congeners in flue gas.

[1]C.Zeng,D.Niu,Y.Zhao,A comprehensive overview of rural solid waste management in China,Front.Environ.Sci.Eng.9(6)(2015)949–961.

[2]Y.Guan,Y.Zhang,D.Zhao,X.Huang,H.Li,Rural domestic waste management in Zhejiang Province,China:Characteristics,current practices,and an improved strategy,J.Air Waste Manage.Assoc.65(6)(2015)721–731.

[3]Z.Han,D.Liu,Y.Lei,J.Wu,S.Li,Characteristics and management of domestic waste in the rural area of Southwest China,Waste Manag.Res.33(1)(2015)39–47.

[4]X.Yang,100 Pyrolysis-Gasification Furnace Disposing Rural Domesitic Waste will be Built in Baoshan City,Yunnan Provice,in China,2014([2014-06-06].http://www.baoshan.cn/561/2014/06/06/61@71770.htm.(in Chinese)).

[5]Z.Jiang,54 Small-Scale ThermalTreatment Furnaces for Disposing RuralSolid Waste had Built in Tengchong City,Yunnan Province,in China,2014([2014–1-17].http://www.cn-hw.net/html/china/201401/44064.html.(in Chinese)).

[6]H.Fiedler,Thermal formation of PCDD/PCDF:A survey,Environ.Eng.Sci.15(1)(1998)49–58.

[7]G.Mckay,Dioxin characterisation,formation and minimisation during municipal solid waste(MSW)incineration:review,Chem.Eng.J.86(3)(2002)343–368.

[8]X.U.Xu,J.H.Yan,K.F.Cen,Formation mechanism of dioxins in MSW incineration,Energy Eng.24(4)(2004)42–45.

[9]H.J.Zhang,Y.W.Ni,J.P.Chen,Q.Zhang,In fluence of variation in the operating conditions on PCDD/F distribution in a full-scale MSW incinerator,Chemosphere 70(4)(2008)721–730.

[10]G.Zhang,J.Hai,J.Cheng,Z.Cai,M.Ren,S.Zhang,J.Zhang,Evaluation of PCDD/Fs and metals emission from a circulating fluidized bed incinerator co-combusting sewage sludge with coal,J.Environ.Sci.25(1)(2013)231–235.

[11]K.Tuppurainen,I.Halonen,P.A.I.Ruokojarvi,J.Tarhanen,J.Ruuskanen,Formation of PCDDs and PCDFs in municipal waste incineration and its inhibition mechanisms:A review,Chemosphere 36(7)(1998)1493–1511.

[12]P.Mondal,G.S.Dang,M.O.Garg,Syngas production through gasification and cleanup for downstream applications—Recent developments,Fuel Process.Technol.92(8)(2011)1395–1410.

[13]V.Wilk,H.Hofbauer,Conversion of fuel nitrogen in a dual fluidized bed steam gasifier,Fuel 106(9)(2013)793–801.

[14]Q.Q.Ren,C.S.Zhao,C.Liang,J.Z.Shen,Experimental research on formation behavior of fuel-nitrogen during wheat straw pyrolysis,Proc.Chin.Soc.Electr.Eng.28(23)(2008)99–104(in Chinese).

[15]L.Tang,Study on the Properties of Pyrolysis Products and Elements Distribution during Minicipal Solid Waste Pyrolysis,Master Thesis,Chongqing University,2015(in Chinese).

[16]W.Ma,G.Hoffmann,M.Schirmer,G.Chen,V.S.Rotter,Chlorine characterization and thermal behavior in MSW and RDF,J.Hazard.Mater.178(1–3)(2010)489–498.

[17]Q.Xie,J.M.Shen,X.S.Zhang,L.I.Wei,Behavior of chlorine in municipal solid waste during heat treatment,J.China Univ.Min.Technol.32(6)(2003)641–645.

[18]J.Dong,Y.Chi,Y.Tang,M.Ni,A.Nzihou,E.Weisshortala,Q.Huang,Effect of operating parameters and moisture content on municipal solid waste pyrolysis and gasi fication,Energy Fuel 30(5)(2016)3994–4001.

[19]M.L.Mastellone,L.Zaccariello,U.Arena,Co-gasification of coal,plastic waste and wood in a bubbling fluidized bed reactor,Fuel 89(10)(2010)2991–3000.

[20]M.Yan,X.Li,T.Chen,S.Lu,J.Yan,Effect of temperature and oxygen on the formation of chlorobenzene as the indicator of PCDD/Fs,J.Environ.Sci.22(10)(2010)1624–1637.

[21]C.Ki-In,L.Dong-Hoon,O.Masahiro,K.Sam-Cwan,The prediction of PCDD/DF levels in wet scrubbers associated with waste incinerators,Chemosphere 66(6)(2007)1131–1137.

[22]H.Hunsinger,S.Kreisz,H.Seifert,PCDD/F behavior in wet scrubbing systems of waste incineration plants,Chemosphere 37(9–12)(1998)2293–2297.

[23]G.Mckay,Dioxin characterisation,formation and minimisation during municipal solid waste(MSW)incineration:review,Chem.Eng.J.86(01)(2002)343–368.

[24]H.Liu,S.Kong,Y.Liu,H.Zeng,Pollution control technologies of dioxins in municipal solid waste incinerator,Procedia Environ Sci 16(4)(2012)661–668.

[25]Y.Zhang,D.Zhang,J.Gao,J.Zhan,C.Liu,New understanding of the formation of PCDD/Fs from chlorophenol precursors:a mechanistic and kinetic study,J.Phys.Chem.A 118(2)(2014)449–456.

[26]K.Mohr,C.Nonn,J.Jager,Behaviour of PCDD/F under pyrolysis conditions,Chemosphere 34(5)(1997)1053–1064.

[27]V.I.Babushok,W.Tsang,Gas-phase mechanism for dioxin formation,Chemosphere 51(10)(2003)1023–1029.

[28]M.B.Chang,T.F.Huang,The effects of temperature and oxygen content on the PCDD/PCDFs formation in MSW fly ash,Chemosphere 40(2)(2000)159–164.

[29]G.Zhang,J.Hai,J.Cheng,Characterization and mass balance of dioxin from a largescale municipal solid waste incinerator in China,Waste Manag.32(6)(2012)1156–1162.

[30]Z.Hui,A.Meng,Y.Long,Q.Li,Y.Zhang,A review of dioxin-related substances during municipal solid waste incineration,Waste Manag.36(3)(2014)106–118.

Chinese Journal of Chemical Engineering2018年3期

Chinese Journal of Chemical Engineering2018年3期

- Chinese Journal of Chemical Engineering的其它文章

- Synthesis of butter fly-like BiVO4/RGO nanocomposites and their photocatalytic activities☆

- Fabrication of chitosan microspheres for efficient adsorption of methyl orange☆

- The combined effects of lysozyme and ascorbic acid on microstructure and properties of zein-based films☆

- Effects of nitrogen doping on surface-enhanced Raman scattering(SERS)performance of bicrystalline TiO2 nano fibres☆

- Parametric study and effect of calcination and carbonation conditions on the CO2 capture performance of lithium orthosilicate sorbent

- Effect of heat flux and inlet temperature on the fouling characteristics of nanoparticles☆