高低速?zèng)_擊下紡織品的抗沖擊防護(hù)

陳曉鋼

(曼徹斯特大學(xué) 材料學(xué)院, 曼徹斯特 英國 M13 9PL)

1 Introduction

Protective textiles against impact loading form an important part of protection for soldiers and police officers, and the threats they have to face include high velocity projectiles such as bullet and shrapnel from explosions as well as low velocity impact such as knife and spike stabbing and trauma impact. Despite the fact that high performance materials are used for creating personal protective gears, the total mass of body armour is still considerably heavy in order to effectively resist the various types of impact. Whilst a US soldier carries a 70 kg weight in a battlefield, full personal body armour could be as heavy as 14 to 17 kg[1]. Regarding the development of new generation of personal protective materials against mechanical impact, engineers are battling two problems, i.e. improvement of protection level and reduction of the material mass.

In the human history, different types of materials were used as protective clothing associated to the types of weapons used. High performance fibres are the major type materials in the modern time, but new types of materials are being actively sought for better protection and lower weight. Since the invention of Nylon body armour around the middle of last century, the creation of para-aramid fibres brought about a revolution in personal protection again ballistic impact because of their superb modulus (60~120 GPa) and strength (2.4~3.6 GPa)[2-3]. The use of fibre based armouring materials allows personal armour to be made lighter and flexible compared to those made from leather and metal in the past. The commercialisation of ultra high molecular weight polyethylene (UHMWPE) fibre in the later 1970s added hope for lightweight body armour because the specific volume density of UHMWPE fibre is only 0.97 g/cm3compared to 1.44 g/cm3for the aramid fibres. The strength of DSM Dyneema fibre is 2.2~3.9 GPa and the modulus is 52~132 GPa, which fulfills the need for protection[3]. Fibre M5 (also known as PIPD) poised to be an excellent fibre for ballistic protection[4]with average modulus of 271 GPa, strength of 3.96 GPa and volume density of 1.7 g/cm3. PBO fibre is another high strength (5.10 GPa) high modulus (320 GPa) fibre with volume density 1.56 g/cm3[5], but it was reported to degrade when exposed to moisture and heat[6].

The fibre-based technology currently plays the key role in engineering design of body armour. For any given type of fibre, the construction of the fibre assembly for ballistic protection determines the properties of the assembly as has demonstrated in textile materials research[7]. For ballistic applications, fibres are mainly used in the forms woven and unidirectional (UD) construction. In parallel to the development and utilisation of high performance fibres, new materials and new technologies are actively sought for improving the body armour performance with reduced weight.

This paper aims to describe the latest advancements in research and engineering of personal protective textiles against high and low velocity impacts. Experimental and numerical methods were adopted for the research introduced in this paper. Some important aspects including inter-yarn friction in fabrics, quasi-isotropic construction of panels, hybrid panel design, and shear thickening fluid for impact protection will be discussed.

2 Effectofinter-yarnfriction

2.1 Modeoffailure

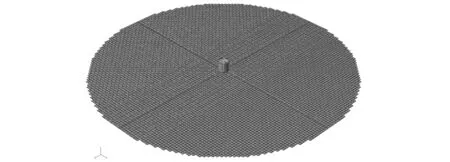

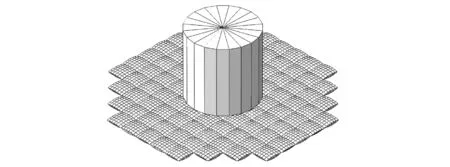

Friction between yarns in a woven fabric has been found to have a significant effect on ballistic impact resistance. Briscoe and Motamedi[8]studied various fabric weaves with three levels of inter-yarn frictional coefficients, and found that more energy was absorbed in the fabric with higher levels of inter-yarn friction. They concluded that fabrics with high inter-yarn friction absorb and dissipate energy more effectively than fabrics with low friction between yarns during a ballistic event. The investigation on the influence of inter-yarn friction was studied further at the University of Manchester for a more comprehensive understanding of the mechanism[9]. FE modeling was used for the investigation. Figure 1 shows the geometrical model of the impact system, where the plain woven fabric was made from an aramid yarn of 158 tex, and the fabric density is 7.5 threads/cm.

A fixed edge boundary condition is applied for all models. The projectile only moves in the direction perpendicular to the fabric plane, and the impact velocity of the projectile is assumed to be 500 m/s, the same as the impact velocity practically measured. The diameter of the circular fabric patch, as illustrated in Figure 1 (a), is 148 mm, following the aperture size of the clamp used for holding the fabric panels in experiment. Figure 1 (b) shows the detailed view of projectile-fabric system after meshing.

(a) An overview

(b) A detailed viewFigure 1 The geometrical model of the fabric and projectile

The ballistic impact performance of the fabrics was assessed by measuring the energy absorbed by the fabric panel on penetration. The energy dissipation due to projectile deformation, fibre intermolecular friction, air resistance and acoustic losses are all assumed to be negligible. Thus, it is taken that the loss of kinetic of the projectile equals to the energy absorption by the fabric. The loss in kinetic energy (E) of the projectile is determined using the expression below.

(1)

wheremis the mass of the projectile,VsandVrare the striking and residual velocities of the projectile, respectively.

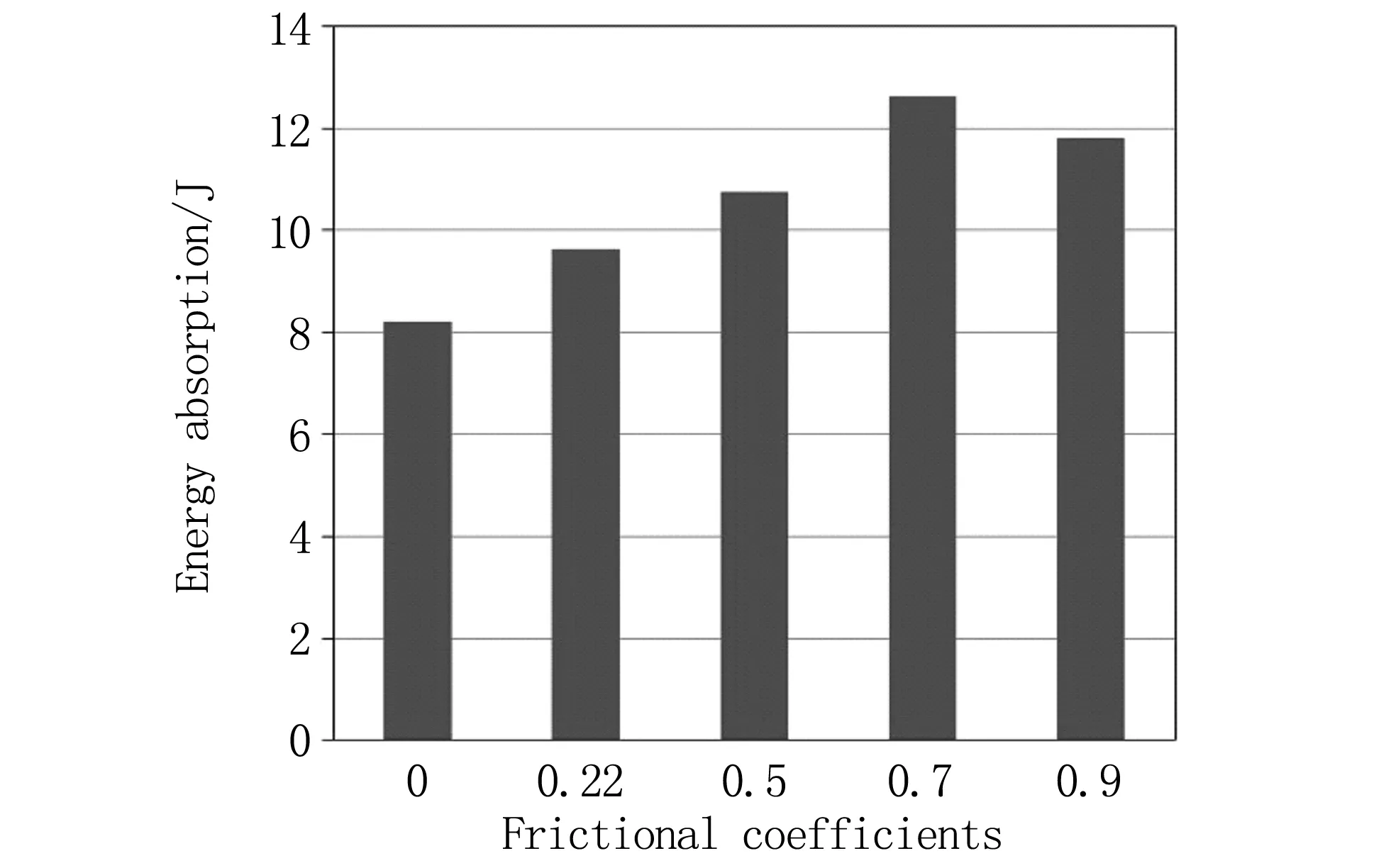

In order to investigate the influence of inter-yarn friction, different coefficients of friction was assigned between the contact yarns, ranging from 0, 0.22, 0.50, 0.70, and 0.90. Figure 2(a) shows a plot of projectile velocities against acting time with various frictional coefficients when impacting a single layer fabric. The residual velocity of the projectile decreases when the inter-yarn frictional coefficient goes higher. The time taken to penetrate the panel is also increased generally along with the increase of frictional coefficient. In other words, the fabric with higher friction between the yarns has a tendency to delays the time of fabric failure, and consequently the amount of materials involved in impact deformation is increased. Therefore, the energy absorbing capacity of the fabrics are increased for fabric with higher inter-yarn friction. The energy absorption of the fabric was calculated using Eq. (1) and the calculated results are depicted in Figure 2(b), which shows that the energy absorbed by fabrics with different levels of inter-yarn friction is increased when increasing the frictional coefficient up to 0.7 in this exercise.

(a) Time history of projectile velocities

(b) Energy absorptionFigure 2 Influence of frictional coefficients on ballistic event

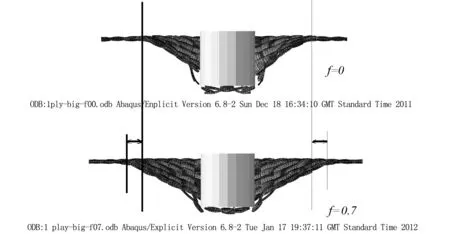

The numerical study also revealed the effect of frictional coefficient on the transverse deformation of the fabric. For different levels of the frictional coefficient between the yarns in the fabric, the maximum transverse displacement of the projectile remained to be the same in all cases, but the areas of the fabrics involved in the deformation were clearly different. Figure 3(a) illustrates that the larger is the frictional coefficient, the larger is the deformed fabric area. The increase of the deformed area with the increment of the frictional coefficient is also found through experiments, as indicated in Figure 3(b). This indicates that a suitable increase in the inter-yarn friction causes more yarns to absorb energy.

2.2 Increase of inter-yarn friction and effect

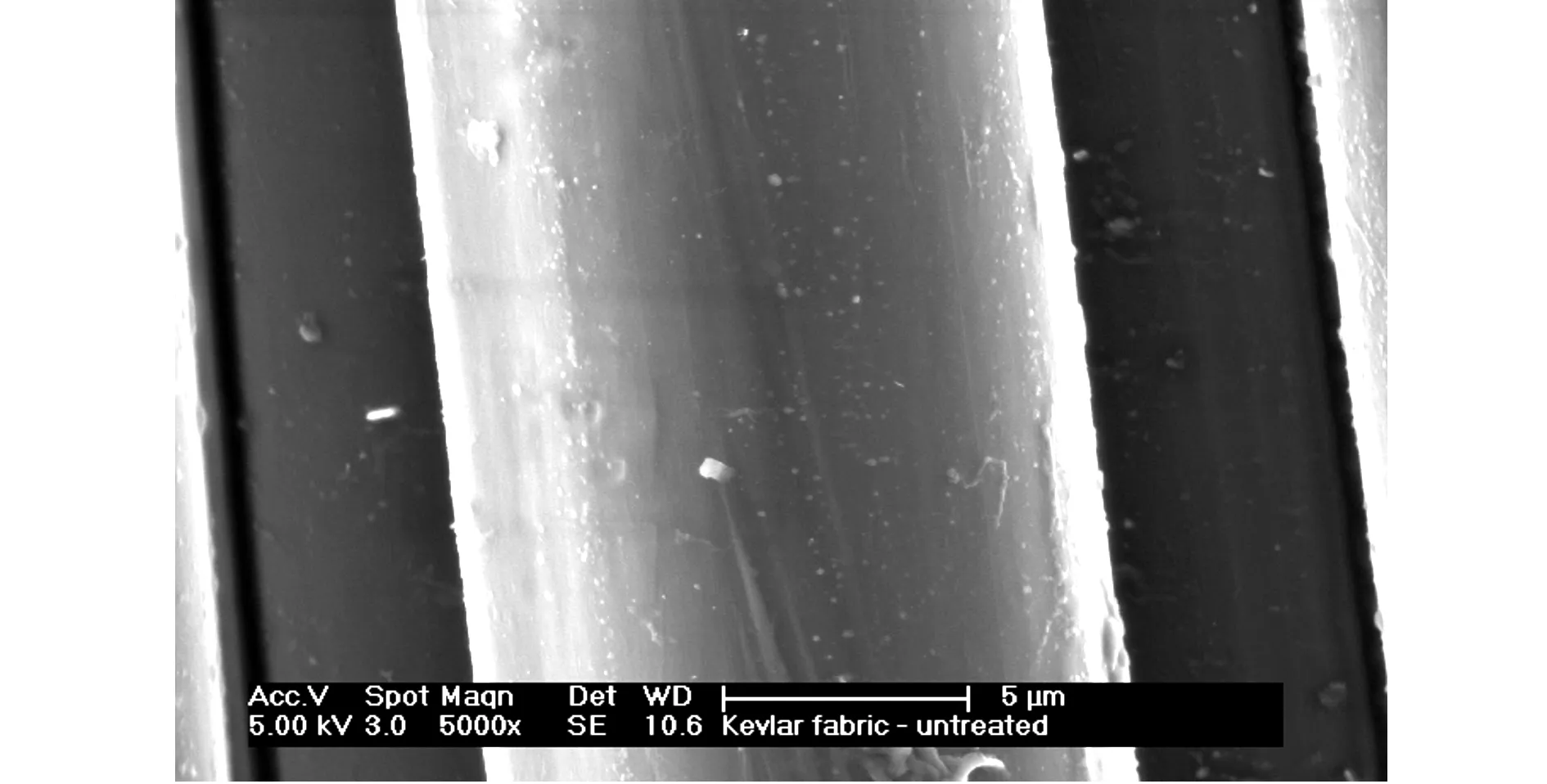

Inter-yarn friction in a woven fabric may be altered using various methods. Modifications of fibre surface through bombardment, particle deposition, as well as woven structure modification were used to increase the inter-yarn friction. Chemical vapour deposition (CVD) technology was used[10]to roughen the aramid fibre surface using (CH3)2Cl2Si group, and the comparison is illustrated in Figure 4. Experiment showed that the yarn pull-out resistance became 4 to 5 times higher over the untreated.

(a) Projectile displacement

(b) Fabric area involved in deformationFigure 3 Friction and fabric deformation

Sol-gel was used to modify the aramid fibre surface efficiently aiming to increase the inter-yarn friction[11]. The test results for coefficient of friction revealed that the coefficient of friction between the yarns treated by submicro-sized hydrosol was 54% higher than the non-treated, and the nano-sized hydrosol was associated to a 10% increase.

(a) Untreated

(b) (CH3)2Cl2Si treatedFigure 4 CVD treatment to aramid fibre

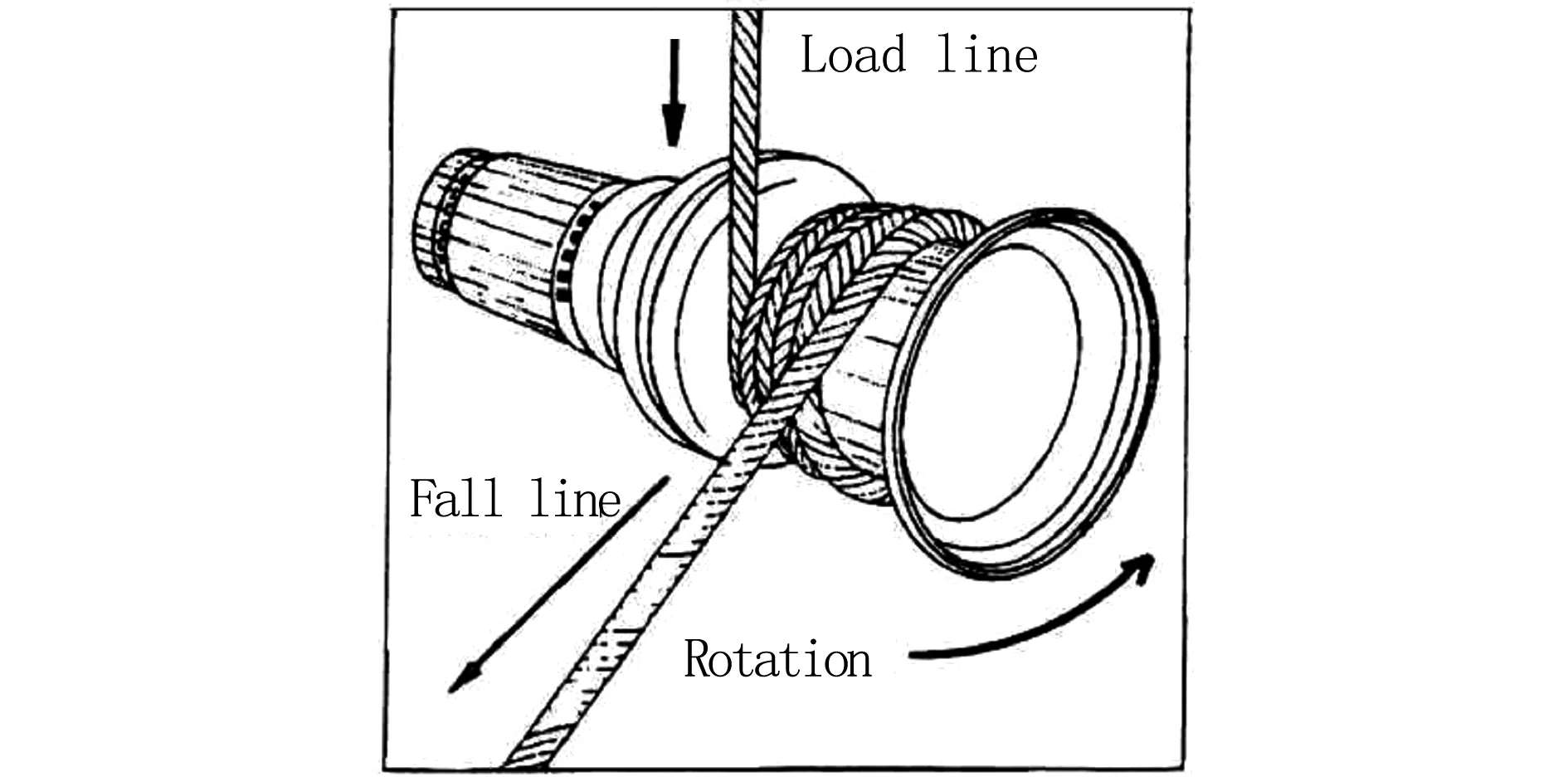

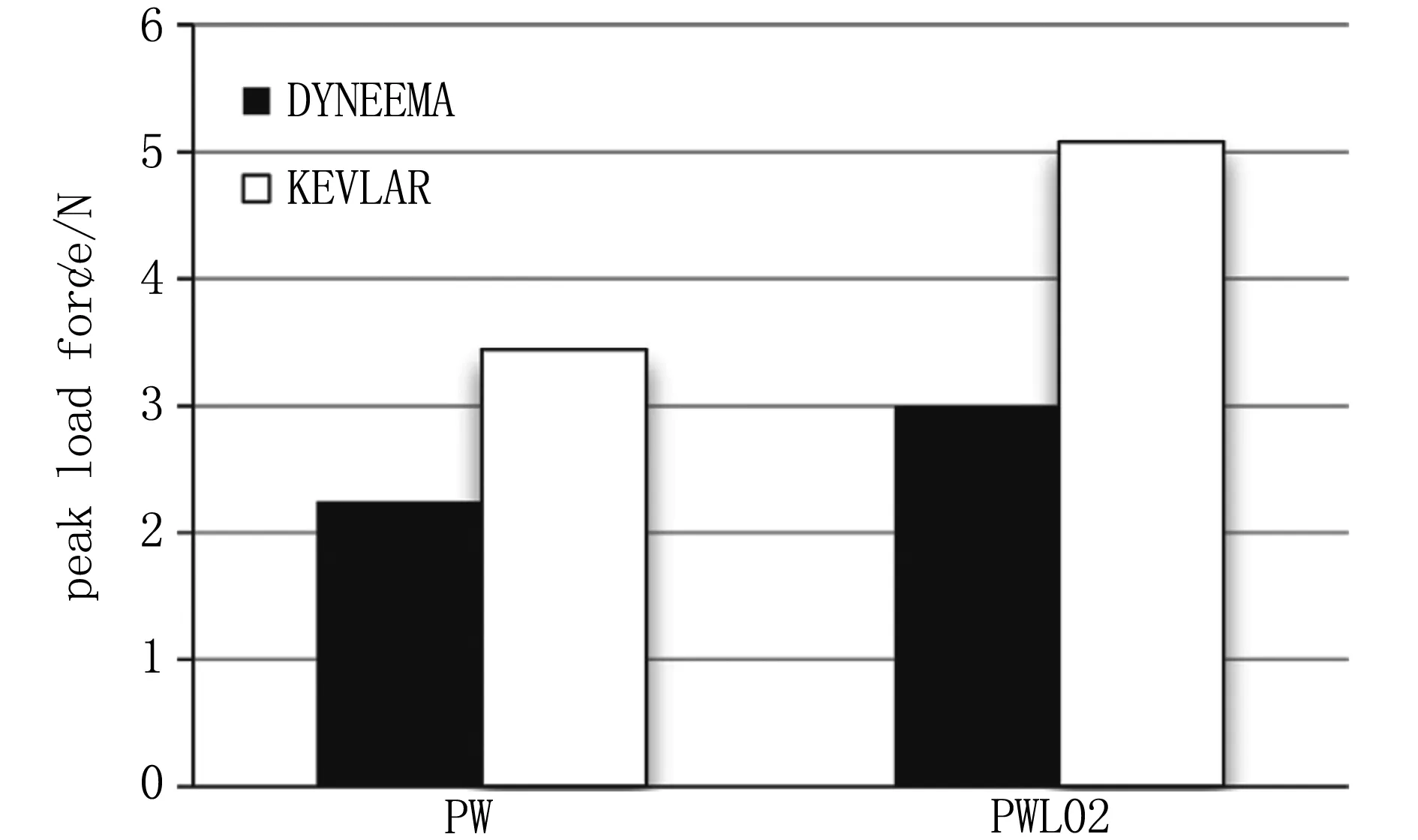

Increasing the gripping between yarns in a woven fabric was also found to increase the inter-yarn friction and therefore the ballistic performance for both woven fabrics made from aramid and UHMWPE fibres[12-15]. The enhanced gripping of yarns in a fabric was achieved by the use of leno insertion, cramming in weaving, and double-pick weft insertion based on the capstan principle, as shown in Figure 5(a). The yarn pull-out resistance of fabrics made from aramid and UHMWPE fibres was shown in Figure 5(b), where the PW are the fabrics constructed in plain weave and the PWL02 fabrics are plain woven fabrics with 2 cm gaps between the neighbouring leno lines.

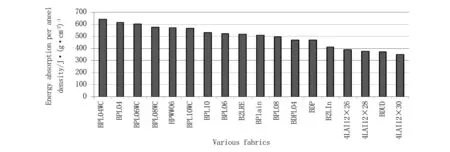

Experiments were also designed to investigate influence of the formation of ballistic panels[12]. The results of the comprehensive study using various methods to enhance the inter-yarn friction revealed that plain fabrics with leno insertions were associated with higher normalized energy absorption with respect to the panel areal density. Comparing the plain woven fabric BPlain and the plain woven fabric with leno insertions with 4cm interval, the latter absorbed more than 20% impact energy than the latter, as demonstrated in Figure 6.

(a) Capstan principle

(b) Yarn pull-out resistanceFigure 5 Yarn gripping principle and effect on yarn pull-out force

3 Quasi-isotropicpanels

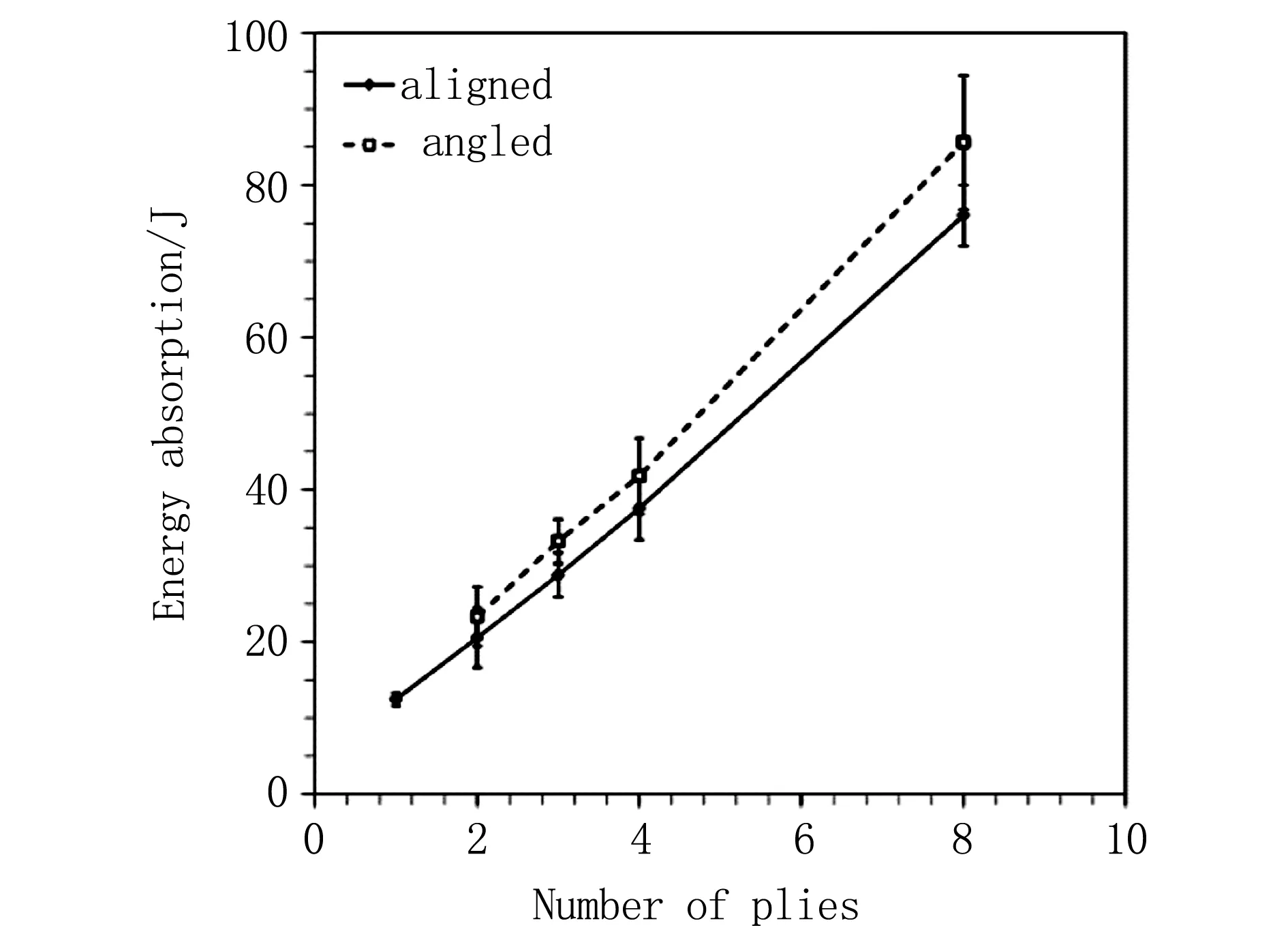

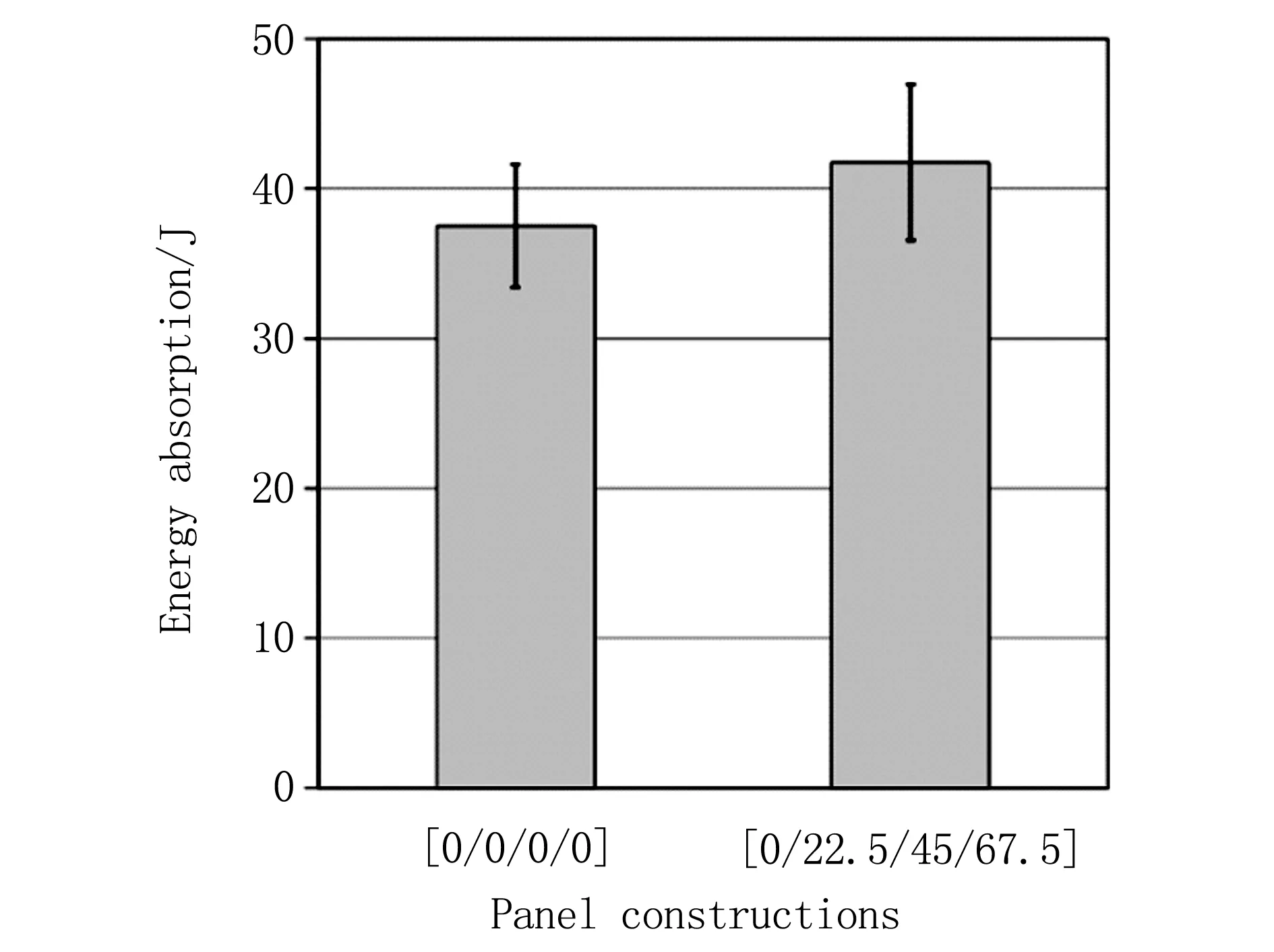

It has been reported that ballistic panels formed by angle-laying woven fabric layers affect the deformation area caused by high velocity impact. This exercise produces ballistic panels to approach a quasi-isotropic panel structure, instead of being orthotropic. Hearle et al. experimented on the shape of the transverse wave front of two-layers and found that the shape of the transverse deflection was octagonal when the two fabric plies were put together 45° apart, which indicated some degree of interlayer interaction[16]. In a more recent study, Wang et al. systematically investigated through experiments the effect of ply angle-laying on the performance of the ballistic panels[17-18]from the three perspectives: (i) the effect of ply orientation; (ii) the effect of the ply sequence; and (iii) the effect of ply grouping. The results showed that the angle laid fabric panels had consistently higher energy-absorbing capacity over the align-laid fabric panels. Even distribution of angles among the layers seemed to lead to higher performance. For the panels with a large number of plies, such as the eight-ply panels, panel performance appears to be deter-mined by the performance of the sub-level ply group. Figure 7 shows the effect of panel angle-laying on energy absorption of the panel.

Figure 6 Normalised energy absorption of fabrics with different inter-yarn friction

(a) Effect of angle-laying

(b) Effect of ply sequenceFigure 7 Performance of quasi-isotropic panels

The quasi-isotropic was also applied to the panel design from fabrics with leno insertions in the warp direction[14]. However, results showed that panels made from fabric layers with off-set leno lines between adjacent layers gave the highest energy absorption, and panels with cross laid fabric layers with leno lines demonstrated the lowest energy absorption. The difference in energy absorption between the two was as high as 33.5%.

4 Hybridpaneldesign

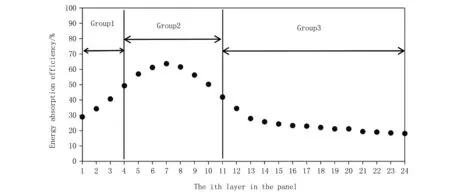

To enhance the ballistic performance of the fabric panel for body armour, various construction methods have been developed, including the use of combinations of materials with different properties in the panel. Cunniff demonstrated this effect using a double-ply system[19], and reported different ballistic performance when used in different layer sequence. In a study by Chen et al.[20], it was confirmed that different layers of fabrics in a laminate ballistic panel react dramatically differently in a ballistic impact event. Yang and Chen[21]studied the response of each layer of a 25 layer woven fabric panel and divided the 24 layers of fabrics into three groups according their energy absorption efficiency, and this is illustrated in Figure 8 A new panel was designed from three different types of materials (13F3/11F7/U14) accordingly, and the average depth of backface signature was 31.5% less compared to the uniform panel (11F24) at almost the same areal density (4 750 and 4 724 g/cm3respectively). In these fabric codes, F and U refer to woven and UD fabrics, the digit before F is the thread density in threads/cm, the digits after F and U indicate the number of fabric layers grouped together.

In a parallel research, Yang and Chen[22]reported that for the combined use of woven and UD fabrics, placing the woven before UD fabric in different designs resulted in better results in terms of both specific energy absorption and depth of backface signature, and these are shown in Figure 9 (a) and (b) respectively.

Figure 8 Responses of different fabric layers in a 24-layer ballistic panel 11F24 to impact

5 STFenhancedpanelsforprotection

Despite the fact that fibre-based technology dominates the development of protective materials against impact, new materials and new technology have been actively sought for protective purposes. Shear thickening fluid (STF), a type of non-Newtonian fluid, is one of the new materials that have attracted much attention for its protective potentials. The shear thickening behaviour is triggered by sudden increase of shear rate to the STF, which causes the colloidal dispersions to be concentrated exhibiting abrupt increase in viscosity. The shear thickening behaviour of an STF is influenced by many factors including the particle size and size distribution, particle shape, polydispersity of the particles, particle concentration, interactions among particles, as well as the properties of the dispersion medium[23].

(a) Specific energy absorption

(b) Depth of backface signatureFigure 9 Performance of hybrid panels

STF was studied for protection against stabbing impact at the University of Manchester[24]. STFs were created from silica (SiO2) particles of 12 and 650 nm with polyethylene glycol (PEG200) with various concentration levels. The manufactured STFs were used to impregnate the aramid plain-woven fabrics with a mass ratio of 50:50 to achieve the minimal involvement of STF which ensures the STF continuity in the fabric-STF assembly. The plain aramid woven fabric was constructed from a 93 tex yarn and the thread density of the fabric was 8 threads/cm. The fabric-STF assemblies were stabbed perpendicular to the plane of the specimens with a P1 knife with 22.54 J, which produces a impact velocity of 3 m/s.

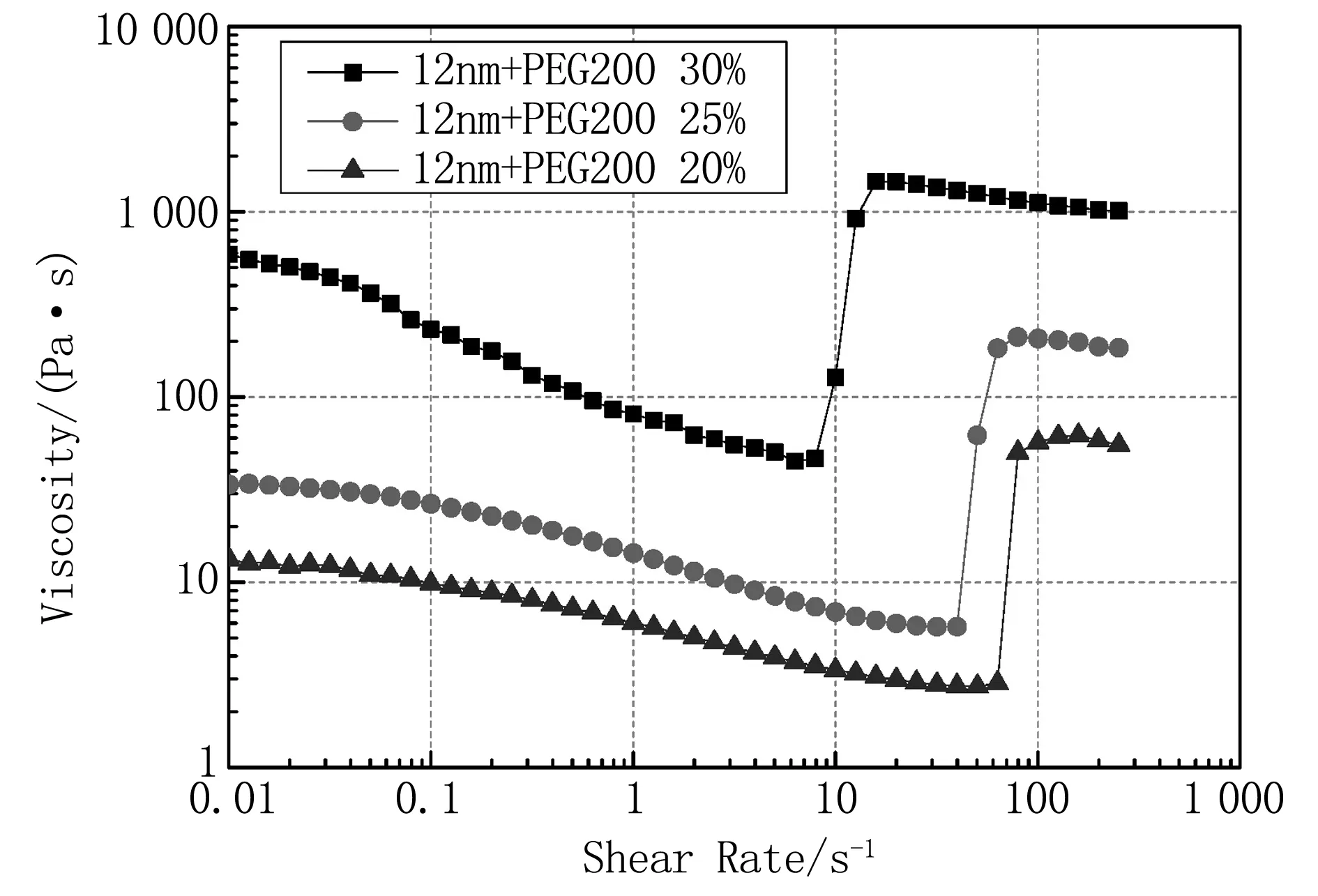

The research results indicated that STF properties are affected by the mass concentration. STFs made from both 12 and 650 nm silica particles showed lower critical shear rate and sharper increase in STF viscosity as the particle concentration goes higher, and that the larger particle size led to more obvious shear thickening behaviour and lower critical shear rate. These are shown is Figure 10.

(a) STFs with 650 nm particles

(b) STF with 12 nm particlesFigure 10 Viscosity against shear rate for STFs with different particle weight fraction

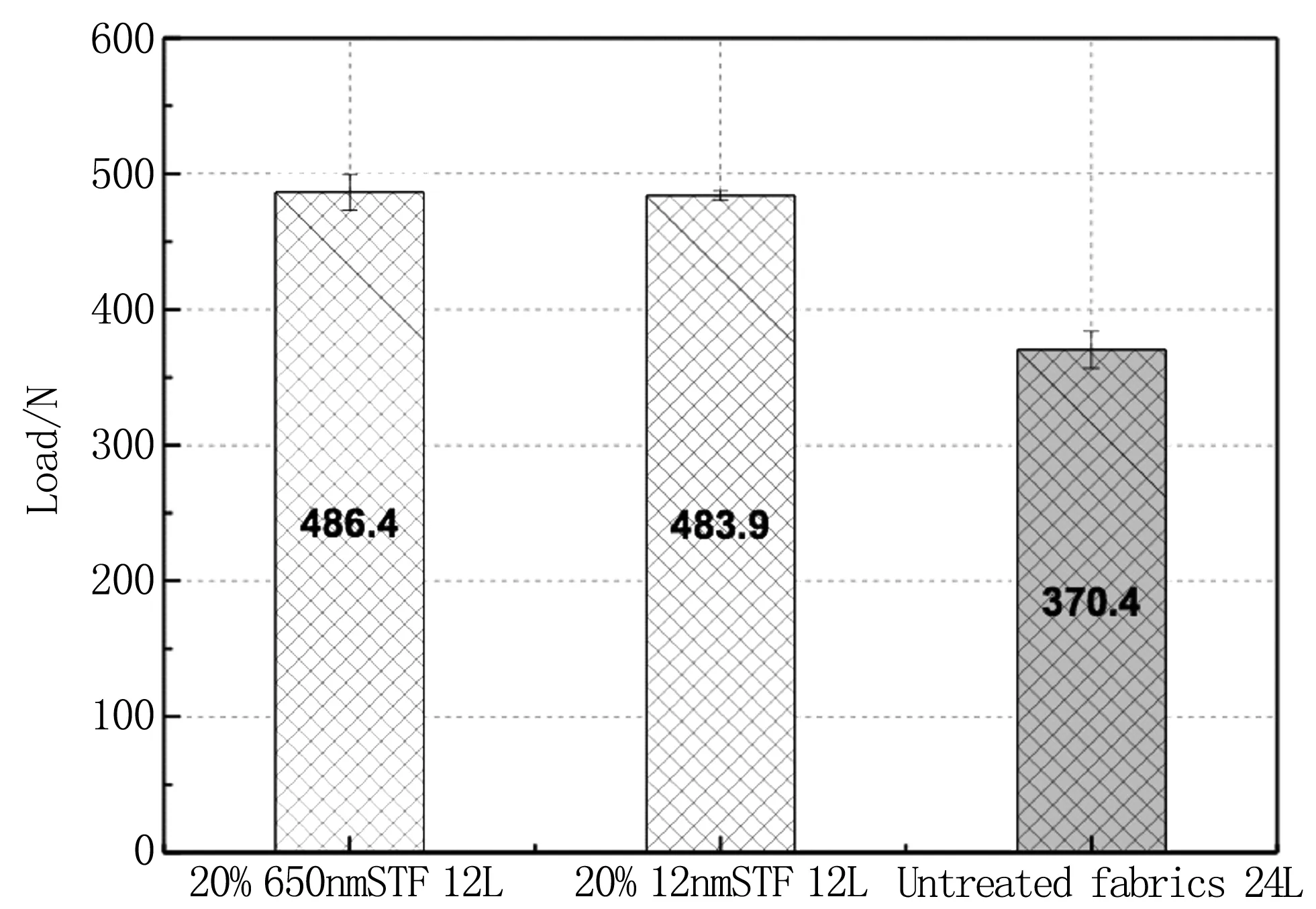

It is clear from Figure 11 that for stabbing panels with same areal density, the STF impregnated panels demonstrated superior performance over the untreated panel in terms of both the maximum load and the total energy absorption. In this experiment, it was found that the 12-layer impregnated panels demonstrated at least 31% increase in maximum load and at least 26% enhancement in total energy absorption than the 24-layer untreated panel.

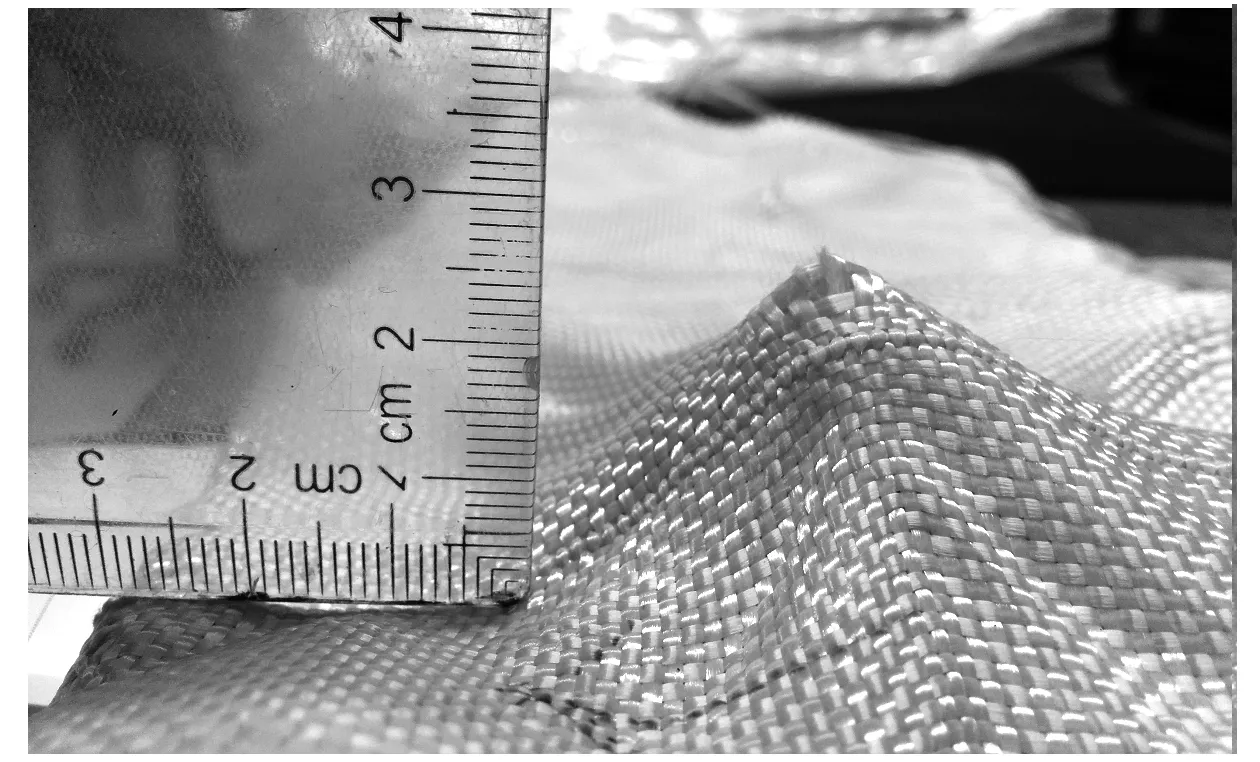

Improvements in backface deformation of the STF impregnated panel are evident in comparison with the untreated fabric panel, noting that both panels share similar areal density in the vicinity of 3 840 g/cm2. The deformation of 24-layer untreated fabric panel formed a cone with a 2.7 cm depth, whereas the back-face deformation of the 650 nm-30%-STF impregnated 12-layer panel was hardly noticeable. Figure 12 shows the backface deformation of the STF impregnated and untreated panels.

(a) Maximum load

(b) Total energy absorptionFigure 11 Performance of panels with the same areal density

(a) 24-layer of untreated panels

(b) 12-layer STF-impregnated panelFigure 12 Comparison of back-face deformation

STF impregnated panels have also been used for ballistic protection. However, literature indicates that STF impregnation was more effective for ballistic protection when the impact velocity is lower than 250 m/s. Therefore, creating STFs that have quicker response to high velocity impact is imperative.

6 Conclusions

This paper reports on the recent protective textile research at the University of Manchester. Whilst new materials and technologies are actively sought for improving personal protection, the conventional fibre-based technology still plays the major part in body armour engineering. Efforts and achievements have been made in the following areas:

(1) Understanding the working mechanism of inter-yarn friction in protective textile against impact. Enhancement in inter-yarn friction in ballistic fabric has been proven to be effective in involving more secondary yarns and therefore larger panel area for absorbing kinetic energy carried by the impacting projectile. Practical methods have been devised to increase the friction between yarns and layers of fabrics and they are proven to be effective.

(2) Quasi-isotropy has been brought in the design of ballistic protective materials. This is achieved by angle-laying fabric layers to form the ballistic panel, and the quasi-isotropic panels demonstrate improved ballistic performance compared to the conventional method for forming the ballistic panels. This finding could be used to guide the engineering multi-directional fibre laying fabrics (as compared to unidirectional fabrics), as well as engineering polymer membranes against impact loading.

(3) The research proves that different layers in the panel respond differently in relation to their positions in the panel. This has led to systematic investigation in hybrid design of ballistic panels. Understanding of the functions of the layers are better established which led to the grouping of fabric layers according to their functions. This results in effective use of materials and reduction of materials mass to satisfy the lightweight requirement of personal protective materials.

(4) Shear thickening fluid (STF) materials were systematically investigated for characterisation and for implementation in relation to low velocity impact loading. Based on the use of silica particles and PEG medium for making STF, the work demonstrates that large particle size and high particle concentration in STF result in lower critical shear rate and more effective shear thickening effect. An optimal impregnation procedure is established ensuring the lowest intake of STF in to the fabric and STF continuity in the assembly. Positive results are reported on the use of STF with woven fabrics for stabbing protection.

7 Acknowledgements

The author acknowledges the support from the EPSRC and MOD (EP/G042829/1, RT/COM/5/030, RT/COM/7/073) for finance support to the series of research, from Teijin Aramid and DSM for providing Twaron fibre and Dyneema fibres and UD fabric. The paper is written using materials produced by the following former postdocs and PhD students in the research group: Ying Wang, Danmei Sun, Yi Zhou, Yanyan Chu, Yanfei Yang, Shengnan Min, Yue Xu and Nan Wang.

[1] Chen X. PPE for increased body and head protection[C]//Defence Iq Conference on Soldier Survivability and Personal Protection,The Cafe Royal, London:[s.n.], 2008

[3] Twaron -a versatile high-performance fiber, Teijin[DB/OL].[2017-11-10].http://www.teijinaramid.com/wp-content/uploads/2016/07/Product-Brochure-Twaron.pdf?utm_medium=email&utm_source=sharpspring&sslid=MzQwMrEwMTazMLYwBwA&sseid=MzM3Nzcw NjcEAA&jobid=a3413e44-9084-43c6-a3cd-d77928c36a2c

[4] Cunniff P M, Auerbach M A, Vetter E, et al. High performance “m5” fiber for ballistics structural composites[C]//23rd Army Science Conference, Orlando, FL:[s.n.], 2002.

[5] Holmes G A, Rice K, Snyder CR. Ballistic fibers: a review of the thermal, ultraviolet and hydrolytic stability of benzoxazone ring structure[J]. Journal of Material Science,2006,41:4105-4116.

[6] Chae H G, Kumar S. Rigid-rod polymeric fibers[J]. Journal of Applied Polymer Science, 2006,100 : 791-802.

[7] Haerle J W S, Grosberg P, Baker S. Structural mechanics of fibres, Yarns and Fabrics[M]. New York: Wiley & Sons Inc, 1969.

[8] Briscoe B J, Motamedi F. The ballistic impact characteristics of aramid fabrics: the influence of interface friction[J]. Wear, 1992,158(1-2):229-47.

[9] Wang Y, Chen X, Young R, et al. Finite element analysis of effect of inter-yarn friction on ballistic impact response of woven fabrics[J]. Composite Structures, 2016,135: 8-16.

[10] Sun D, Chen X. Plasma modification of Kevlar fabrics for ballistic applications[J]. Textile Research Journal, 2012,82(18): 1928-1934.

[11] Chu Y, Chen X, Wang Q, et al. An investigation on sol-gel treatment to aramid yarns to increase inter-yarn friction[J]. Applied Surface Science, 2014,320: 710-717.

[12] Sun D, Chen X, Wells G. Engineering and analysis of gripping fabrics for improved ballistic performance[J]. Journal of Composite Materials, 2014 , 48(11):1355-1364.

[13] Zhou Y, Chen X, Wells G. Influence of yarn gripping on the ballistic performance of woven fabrics from ultra-high molecular weight polyethylene fibre[J]. Composites Part B: Engineering, 2014, 62: 198-204.

[14] Wang N. The effect of extra yarn gripping on ballistic performance, PhD Thesis, School of Materials[D]. Manchester:The University of Manchester, 2017.

[15] Chen X, Sun D, Wells G M. Effect of inter-yarn friction on ballistic performance of woven fabrics[M]. UK:Research Gate,2013.

[16] Hearle J W S, Leech C M, Adeyefa A, et al. Ballistic impact resistance of multilayer textile fabrics[M]. UK:Research Gate, 1981.

[17] Wang Y, Chen X, Young R, et al. An experimental study of the effect of ply orientation on ballistic impact performance of multi-ply fabric panels[J]. Tex Res J, 2016, 86(1): 34-43.

[18] Min S, Chu Y, Chen X. Numerical study on mechanisms of angle-plied panels for ballistic protection[J]. Materials & Design,2016, 90:896-905.

[19] Cunniff P M. Analysis of the system effects in woven fabrics under ballistic impact[J]. Textile Research Journal, 1992,62: 495-509.

[20] Chen X, Zhou Y, Wells G. Numerical and experimental investigations into ballistic performance of hybrid fabric panels[J]. Composite Part B: Engineering, 2014, 58(3): 35-42.

[21] Yang Y, Chen X. Investigation on energy absorption efficiency of each layer in ballistic armour panel for applications in hybrid design[J]. Composite Structures, 2017,164: 1-9.

[22] Yang Y, Chen X. Investigation of failure modes and influence on ballistic performance of Ultra-High Molecular Weight Polyethylene (UHMWPE) uni-directional laminate for hybrid design[J]. Composite Structures, 2017,174:233-243.

[23] Barnes H. Shear-thickening (Dilatancy) in suspensions of nonaggregating solid particles dispersed in Newtonian liquids[J]. Journal Rheology, 1989,33(2): 329-66.

[24] Xu Y, Chen X, Wang Y, et al. Stabbing resistance of body armour panels impregnated with shear thickening fluid[J]. Composite Structures, 2017,163: 465-473.