An experimental study on shock wave mitigation capability of polyurea and shear thickening fluid based suspension pads

Andi Haris,Heow Pueh Lee,Vincent Beng Chye Tan

Department of Mechanical Engineering,National University of Singapore,9 Engineering Drive 1,Singapore 117576,Singapore

1.Introduction

Improvised explosive devices(IEDs)are mainly homemade bombs that are usually hidden in signboards,guardrails,roadside structures,debris,animal carcasses,containers,briefcases or back packs carried by suicide bombers,and vehicles driven by suicide bombers.These explosive devices can be detonated manually or remotely by a variety of triggering mechanisms or devices such as hand phones,satellite phones,radio,remote controllers,or garage door openers[1].The threat of IED hinders troop mobility as well as security forces and moving vehicles.Although their targets are primarily military personnel,IED attacks also routinely cause unintentional civilian injuries.

Besides high velocity shrapnel,injuries from IEDs could be due to shock waves.Despite improvements in combat helmets,propagation and reflection of shock waves(within the intracranial cavity)[2]produced by IEDs have caused traumatic brain injury(TBI)-the signature wound of the US armed forces in Iraq and Afghanistan.This type of TBI is referred to as primary TBI and has often no externally visible signs of trauma.As the design parameters for ballistic protection and shock wave mitigation are different,improved impact resistance has not led to improved pressure wave attenuation.Although improved ballistic protection by helmets has saved lives,many military survivors from Iraq and Afghanistan suffer irreversible traumatic brain injuries[3-6].

The commonly used combat helmets are the personnel armor system ground troops(PASGT),modular integrated communications helmet(MICH),lightweight helmet(LWH),advanced combat helmet(ACH),and enhanced combat helmet(ECH).In general,the helmets consist of a protective shell and a pad suspension system.The shell is usually made from multiple layers of anti-ballistic fabrics such as Kevlar,Twaron,Spectra and Dynemaa due to their excellent properties in defeating bullets and fragments[7-9].The suspension pad is often made from conventional foam materials[10].While current combat helmets have been successful in terms of providing an effective protection against penetrating ballistic injury,their protective performance against shock wave has yet to be established[3,12].Preliminary studies by Mott et al.[13]and Moss et al.[14]showed that the helmets tend to enhance local blast overpressure on the head by focused interactions of the blast waves.Ganpule et al.[11]computationally investigated the role of helmets in mitigating the effect of primary shock waves.In their work,the primary shock wave interactions for various helmet head configurations were evaluated,and the pressure and impulse intensification effects were elucidated as a function of geometry,head-helmet gap and surface curvature.Grujicic et al.[10]developed a simple “core-sample”finite element model of the helmet/head assembly to investigate computationally the potential of polyurea as a shock wave impact mitigating helmet suspension-pad material.Lately,they have extended the simple “core-sample”finite element model to a fully three dimensional(3D) finite element model[15].The simulation results of both simple and 3D models showed that the use of polyurea suspension pads is associated with a substantially greater decrease in the peak pressure experienced by the brain relative to that observed in the case of the conventional foam.Other computational studies by Radovitzky's group[16]and Karami's group[17]reported that wearing an advanced combat helmet(ACH)can reduce level of the blast induced traumatic brain injury.

Shock waves from IEDs can also interact with other body organs such as lungs and gastrointestinal tract causing primary blast injury[18].Used together with anti-trauma(suspension)pads which can reduce injury due to dynamic deformation of the armor into the wearer,ballistic vests and bomb suits made from multiple layers of anti-ballistic fabrics have been successful in providing an effective protection against the resulting high velocity shrapnel produced by IEDs.However,their protective performance is highly questionable when they are subjected to shock waves[19].Previous studies showed that the severity of primary blast injury(i.e.caused by the impact of a shock or blast wave generated by an explosion)is increased when protective fabrics are used since the transmitted over pressures are significantly amplified through the fabrics[19-23].Besides polyurea and conventional foams,shear thickening fluid(STF)may be used as suspension pad material.STF has huge potential for many industrial applications ranging from devices with adaptive stiffness and damping to body armour[24].In body armour,the application of STF has received substantial attention.Particularly,STF has been used in combination with high strength ballistic fabrics to enhance their stab,puncture and ballistic resistance properties with little or no increase in thickness or stiffness of the fabrics.A recent study by Haris et al.[25]found that STF treated fabrics have potential applications not only for ballistic protection but also for shock wave mitigation.The STF treated fabrics can provide lower peak pressure and lower maximum rate of pressure rise as compared to(untreated)neat fabric and fabric impregnated with PEG only revealing that STF contributes to the increase in performance.

As outlined above,research on this area is still limited and minimal.More studies are needed to improve the performance of current fabric ballistic vests and combat helmets for optimal protection;not only for protecting from projectiles,but also from shock waves.Most of the earlier studies are computational works which need experimental validation.In the present study,shock wave mitigation capabilities of potentially new suspension pads made of polyurea,shear thickening fluid(STF),and STF-infused foam is experimentally investigated and compared with conventional foam pad.

2.Materials and method

2.1.Flexible polyurethane foam

The foam pad used in this study is made of a flexible open cell polyurethane foam.The polyurethane foam has the following specifications:density of 22 kg/m3and an average pore diameter of 715μm.Fig.1 shows a photograph of the foam taken with a digital microscope.The thickness of the foam pad and other pads used in this study is limited to at most 20 mm as systems thicker than this are deemed to be too bulky for personnel protection purposes and may affect soldier performance like visual awareness,aiming of weapons and mobility.The foam pads of current combat helmets have thicknesses of approximately 0.75 in or~19.05 mm.

2.2.Polyurea

Polyurea is a multiblock polymer with alternating soft(linear hydrocarbon chain)and hard(aromatic moiety)segments along its backbone.At room temperature,the soft domains are above their Tgand impart polyurea its elastomeric properties,whereas the hard domains are below their Tgand impart polyurea its mechanical toughness and compressive stiffness,allowing polyurea to be used in a wide range of coating applications[26,27].In recent years,polyurea has attracted much attention due to its excellent dissipative properties and thus has been used as external and internal wall-slidings and foundation coating for buildings aimed at minimizing the degree of structure fragmentation and minimizing the extent of the associated collateral damage in the case of a bomb blast.Besides,it has been used as ballistic resistant and blast mitigating coating for military vehicles and structures[26].As mentioned earlier,the feasibility of using polyurea as a combat helmet pad was recently explored computationally in three studies[10,15,28].

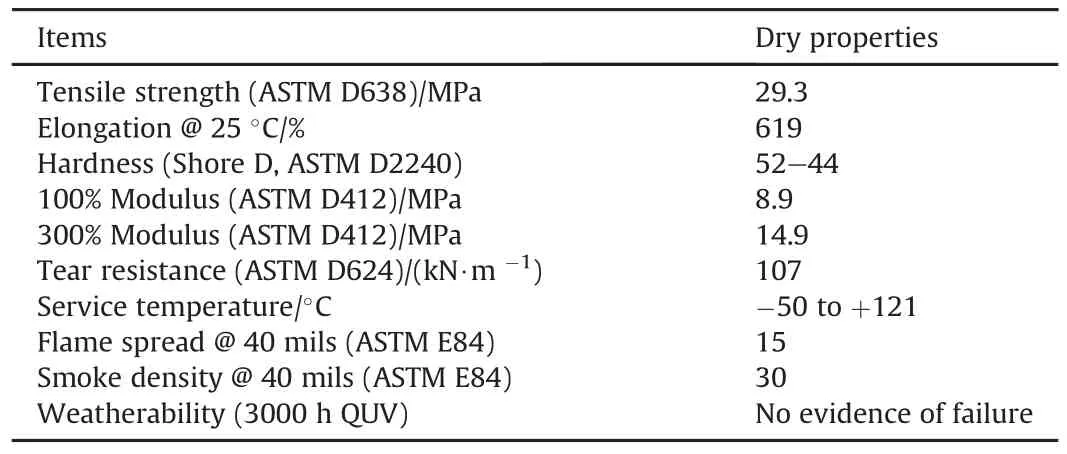

The polyurea used in the present study is Dragonshield-HT ERC with an elongation percentage of 619%and density of 1000 kg/m3.It was purchased from Specialty Products Incorporated(SPI).The manufacturer's specifications for the polyurea are presented in Table 1.Due to its high density,the thickness of the polyurea pad was set at 4 mm.Fig.2 shows the polyurea pad specimen.

2.3.Shear thickening fluid and STF-infused foam

An STFis a non-Newtonian fluid and is often termed as a dilatant fluid.It is characterized by significant,and sometimes discontinuous,increase in viscosity when the applied shear rate reaches a critical value[29].The fluid has low viscosity at shear rates lower than a critical value and high viscosity when the shear rate exceeds the critical value.There are two main mechanisms of shear thickening behaviour which have been proposed:order-disorder theory and hydrocluster theory.The earlier theory postulates that the flow structure changes from ordered layers to a disordered structure with increasing shear rate resulting in an increase in lubrication drag forces between particles[30].According to the latter theory,the particles tend to push together into clusters under shear and the drag forces between particles increase due to this rearrangement[31].

In the present study,the shear thickening fluid comprising cornstarch particles of approximately 5-20μm in diameter suspended in water.The STF was prepared at a concentration of 55 wt%and synthesized using a combination of mechanical and ultrasonic mixing.This weight fraction was selected to ensure shear thickening behaviour while maintaining a workable solution[32].At weight fractions higher than 55 wt%,cornstarch-water suspension becomes less workable.At weight fractions lower than 55 wt%,its thickening effect becomes very weak.Crawford et al.[33]who studied cornstarch-water suspension at concentrations ranging from 0 to 55 wt%reported that only the suspensions containing at least 52.5 wt%thicken to high enough viscosities.This very narrow range of cornstarch weight fraction(52.5-55 wt%)limits the authors to investigate the effects of weight fraction of STF on the shock wave mitigation capability in this study.The mechanical mixing was carried out using a vortex mixer(Cole-Parmer vortex mixer)whereas the ultrasonic mixing was performed using an ultrasonic bath(Telsonic power cleaning TPC-25).Ultrasound sonication can help to enhance the distribution of particles within a suspension by reducing aggregation of the particles and expel entrained air bubbles[32].Figs.3 and 4 show the STF pad specimen and STF-infused foam pad specimen,respectively.The STF pad specimen was prepared by filling a thin rubber pouch with the STF.The STF-infused foam pad specimen was prepared by filling the foam with the STF and then sealing it in a ziplock bag.

Table 1Dry properties of Dragonshield-HT ERC(explosive resistant coating)@0.8 mm.

2.4.Twaron ballistic fabric

The ballistic fabric used in this study is a plain woven paraaramid(Twaron T717)ballistic fabric having an areal density of 285 g/m2and thickness of 0.4 mm purchased from Teijin Aramid BV.The weave densities of the warp and weft are 8.4 ends/cm and 8.2 ends/cm,respectively.Table 2 presents the manufacturer's specifications for Twaron T717 fibre and fabric.

2.5.Shock tube tests

Explosives and shock tubes are commonly used to produce blast loading.The shock tube is preferred for the laboratory scale tests over explosive testing because of simpler safety operating procedures and better control over the rate of explosive loading.A compressed gas-driven shock tube was built and used for the present study.The shock tube has a single diaphragm and a total length of 4.7 m.The driver,driven and muzzle sections of the shock tube all have a round cross-section of 58.4 mm inner diameter and 15.2 mm wall thickness.Stainless steel(316L grade)was used to build the sections.The shock tube is able to withstand a maximum pressure of 7.6 MPa.Hydrostatic testing was performed on the whole setup by filling the tube with water up to a pressure of 12 MPa for a duration of 20 min.The driven section is 3.3 m in length giving a length to inner diameter ratio of about 56.This would insure that the driven section is long enough for the full development of the shock wave.The driver section is 1.3 m long which is long enough to prevent the head of the expansion reflected wave from reaching the shock wave during its travel towards the driven end[34].The muzzle section is of length 0.1 m and is fastened securely inside a steel testing chamber.

The driven gas was ambient air while the driver section was pressurized with helium until the diaphragm burst releasing a shock wave through the driven and muzzle section towards the target specimen.A gasket with a thickness of 3 mm was placed on each side of the diaphragm to prevent leakage.Mylar sheet was selected as the diaphragm due to its strength and ability to burst at a consistent pressure.The burst pressure at which the mylar sheet ruptured was recorded using a digital pressure gauge(Ashcroft D1005PS).Different burst pressures and consequently shock wave strengths can be obtained by varying the thickness of the mylar diaphragm.

Table 2Properties of para-aramid Twaron T717 fiber and fabric.

Fig.5 shows a schematic of the shock tube setup and target specimen being clamped before the shock tube tests.The target specimens consisted of multiple layers of Twaron fabric and various suspension pads were prepared with dimensions of 120 mm(length)x 110 mm(width)and were mounted at the exit of the muzzle section.A circular plate with thickness of 30 mm made of stainless steel(316L grade)was used to support the specimens.Two pressure transducers,Kistler type 603B,were employed to monitor the pressure profile of the shock wave.One of them was mounted on the muzzle sidewall to record the side-on shock wave profile near the exit.The other was mounted on the support plate to record the face-on shock wave profile.The signals were sent through a signal conditioner and amplifier(Kistler 5015 charge meter)before being recorded by the GW Instek GDS-3154 oscilloscope.

3.Results and discussion

Based on limited available literature,the effect of pure primary air blast is estimated to occur in the range of 2-100 kg of explosive C4 when the object is in the range of 2-10 m away.The resulting peak pressure is in the range of 60-400 kPa and time duration of 2-8 ms[35].All specimens in our shock tube tests were subjected to the same incident peak pressure of 186 kPa produced by bursting a 0.1 mm thick mylar diaphragm.The measured incident shock speed was 651 m/s.The typical side-on and face-on pressure profiles for shock wave tests with no target specimen(bare surface)are presented in Fig.6.A step pressure rise resulting from head-on impact of a plane shock wave on a flat surface is observed in the figure.The face-on peak pressure of the bare surface is 748 kPa.A successive spike in the pressure wave due to the wave travelling back and forth through the shock tube is also observed.

The typical face-on pressure profiles for shock wave tests with target specimens are presented in Fig.7.In the presence of foam pad alone,the typical step pressure rise of bare surface is obviously amplified(Fig.7(a)).Its peak pressure is 1.68 MPa.The use of either STF pad alone or STF-infused alone appears to give roughly the same result with that of the foam alone.Differently,polyurea pad alone slightly attenuates the step pressure rise of the bare surface.The peak pressure of the polyurea pad alone is 681 kPa.The shock wave amplification due to the use of foam pad tends to increase when it is used in combination with multiple layers of Twaron fabric,i.e.,when the foam pad is positioned behind the fabric(Fig.7(b)-(e)).It can be seen that such a combination is highly undesirable in terms of protection against shock wave as peak pressure can reach values of more than 6 MPa.Interestingly,the potentially new suspension pads do not exhibit such property.When they are jointly used with the fabric,their face-on pressure profiles are only slightly affected by the thickness of the Twaron fabric.

The shock wave parameters considered in this study are:peak pressure and impulse.The peak pressure is defined as the maximum height of the signal.The impulse is defined as the area under the curve of the pressure-time signal within a time range from 0 to approximately 15 ms(before the second spike as illustrated in Fig.6).Based on experimental evidence reported in the past,peak pressure and impulse are some important parameters associated with the shock wave which governs blast-related injury.For example,Baker et al.[36]used peak pressure and impulse parameters to develop the human lethality curve.Previously,Bowen et al.[37]and White et al.[38]used peak pressure and duration parameters to develop the lethality curve.The peak pressure and impulse appear to be more appropriate because impulse is dependent on peak pressure as well as on duration and the tendency for peak pressure-impulse lethality curve to approach asymptotic limits is also very aesthetically appealing from a mathematical point of view[39].By increasing the peak pressure or its impulse,the severity of shock wave injury will also increase.

To evaluate the performance of the suspension pads,their shock wave test result is directly compared with that of the conventional foam pad.As shown in Fig.8(b)-(e),it is clear that the replacement of the foam pad with the STF,STF-infused foam and polyurea pads within the fabric thickness range of 2 mm-18 mm has a favourable effect since the normalized peak pressure is greatly reduced(by about 72%,72%and 74%,respectively).Unfortunately,this great reduction in the normalized peak pressure for STF and STF-infused foam pads is not accompanied by a reduction in the normalized impulse.As shown in Fig.9(b)-(e),the two pads may increase the normalized impulse by about 78%and 131%,respectively.This may reduce their shock wave mitigation.Interestingly,this does not happen when the polyurea pad is used.The normalized impulse can also be reduced by about 49%or at least remain the same.

The above results show that among the potentially new suspension pads tested,the polyurea pad displays the best shock wave mitigation performance.This experimental finding is in good agreement with the numerical one reported previously[10,15,28].According to Grujicic et al.[28,40]who performed detailed examination of the molecular-level microstructure evolution in the shock wave wake,this superior shock wave mitigation behavior of polyurea is believed to be closely related to its micro-phase segregated microstructure consisting of the so-called hard domains and a soft matrix.Their simulation results revealed that shock loading causes extensive hydrogen bond breaking in the micro-phase segregated polyurea in which these processes are associated with substantial energy absorption and dissipation and are believed to be related to the experimentally observed high blast mitigation potential of polyurea.

Moreover,in contrast to flexible polyurethane foam which is highly compressible,polyurea is a bulk and nearly incompressible material[10].Gibson[23]who studied the dynamics of shock wave propagation and reflection in flexible and porous materials both analytically and experimentally by using an air driven shock tube reported that the shock wave slows down as porous and compressible materials are compressed, which allows more compression waves to add to the shock wave strength,thereby increasing the peak pressure.As a consequence of this,compared to the flexible foam,polyurea has lower peak pressure and impulse because no compression waves are added to the shock wave strength.

4.Conclusions

This study demonstrates that polyurea exhibits the best shock wave mitigation capability among the potentially new suspension pad materials tested.For different Twaron fabric thicknesses ranging from 2 mm to 18 mm,the replacement of 20 mm thick conventional foam pad made from a flexible polyurethane foam with 4 mm thick polyurea pad can reduce the normalized peak pressure and impulse by about 74%and 49%,respectively.The other pads(20 mm thick STF pad and STF-infused foam pad)perform better than the conventional foam pad in terms of peak pressure but worse in terms of impulse.Therefore,polyurea has potential to replace conventional flexible foam for use as a suspension pad in PPE requiring shock wave mitigation capability such as cloth ballistic vests,bomb suits and combat helmets.

Acknowledgements

This work has been supported by the Ministry of Education,Singapore(R265000533112).

[1]Wilson C.Improvised explosive devices in Iraq:effects and countermeasures.CRS Report for Congress.2005.http://www.dtic.mil/dtic/tr/fulltext/u2/a443388.pdf/[Accessed 13 December 2016].

[2]Cernak I,Wang Z,Jiang J,Bian X,Savic J.Ultrastructural and functional characteristics of blast injury-induced neurotrauma.J Trauma 2001;50(4):695-706.

[3]Lew HL,Poole JH,Alvarez S,Moore W.Soldiers with occult traumatic brain injury.Amer J Phys Med Rehab 2005;84:393-8.

[4]Peota C.Invisible wounds.Minn Med 2005;88(1):13-4.

[5]DePalma RG,Burris DG,Champion HR,Hodgson MJ.Blast injuries.N Engl J Med 2005;352:1335-42.

[6]Gawande A.Casualties of war-military care for the wounded from Iraq and Afghanistan.N Eng J Med 2004;351(24):2471-5.

[7]Liu S,Wang J,Wang Y,Wang Y.Improving the ballistic performance of ultra high molecular weight polyethylene fiber reinforced composites using conch particles.Mater Des 2010;31(4):1711-5.

[8]Tham CY,Tan VBC,Lee HP.Ballistic impact of a Kevlar?helmet:experiment and simulation.Int J Impact Eng 2008;35(5):304-18.

[9]David NV,Gao XL,Zheng JQ.Ballistic resistance body armor:contemporary and prospective materials and related protection mechanisms.Appl Mech Rev 2009;62(5):50802.

[10]Grujicic M,Bell WC,Pandurangan B,He T.Blast-wave impact-mitigation capability of polyurea when used as helmet suspension-pad material.Mater Des 2010;31(9):4050-65.

[11]Ganpule S,Gu L,Alai A,Chandra N.Role of helmet in the mechanics of shock wave propagation under blast loading conditions.Comput Meth Biomech Biomed Eng 2012;15(11):1233-44.

[12]Bhattacharjee Y.Shell shock revisited:solving the puzzle of blast trauma.Science 2008;319(5862):406-8.

[13]Mott DR,Schwer DA,Young TR,Levine J,Dionne JP,Makris A,et al.Blastinduced pressure fields beneath a military helmet.Oslo,Norway.In:Proceedings of the 20th international symposium on military aspects of blast and shock;September 2008.

[14]Moss WC,King MJ,Blackman EG.Skull flexure from blast waves:a mechanism for brain injury with implications for helmet design.Phys Rev Lett 2009;103(10):108702.

[15]Grujicic A,LaBerge M,Grujicic M,Pandurangan B,Runt J,Tarter J,et al.Potential improvements in shock-mitigation efficacy of a polyurea-augmented advanced combat helmet.J Mater Eng Perform 2012;21(8):1562-79.

[16]Nyein MK,Jason AM,Yu L,Pita CM,Joannopoulos JD,Moore DF,Radovitzky R.Reply to Moss et al.:military and medically relevant models of blast-induced traumatic brain injury vs.ellipsoidal heads and helmets.Proc Natl Acad Sci 2011;108:E83.

[17]Jazi MS,Rezaei A,Karami G,Azarmi F.Biomechanical parameters of the brain under blast loads with and without helmets.Int J Exp Comput Biomech 2014;2:223-44.

[18]Owers C,Morgan JL,Garner JP.Abdominal trauma in primary blast injury.Br J Surg 2011;98:168-79.

[19]Zhu F,Chou CC,Yang KH.Shock enhancement effect of lightweight composite structures and materials.Compos part B 2011;42(5):1202-11.

[20]Cripps NPJ,Cooper GJ.The influence of personal blast protection on the distribution and severity of primary blast gut injury.J Trauma 1996;40(3):S206-11.

[21]Phillips YY,Mundie TG,Yelverton JT,Richmond DR.Cloth ballistic vest alters response to blast.J Trauma 1988;28(suppl):S149-52.

[22]Skews BW,Bugarin S.Blast pressure amplification due to textile coverings.Text Res J 2006;76(4):328-35.

[23]Gibson PW.Amplification of air shock waves by textile materials.J Text Inst 1995;86(1):119-28.

[24]Ding J,Tracey P,Li WH,Peng GR,Whitten PG,Wallace GG.Review on shear thickening fluids and applications.TLIST 2013;2(4):161-73.

[25]Haris A,Lee HP,Tay TE,Tan VBC.Shear thickening fluid impregnated ballistic fabric composites for shock wave mitigation.Int J Impact Eng 2015;80:143-51.

[26]Arman B,Reddy AS,Arya G.Viscoelastic properties and shock response of coarse-grained models of multiblock versus diblock copolymers:insights into dissipative properties of polyurea.Macromolecules 2012;45(7):3247-55.

[27]Chattopadhyay DK,Raju KVSN.Structural engineering of polyurethane coatings for high performance applications.Prog Polym Sci 2007;32(3):352-418.

[28]Grujicic M,Pandurangan B,Bell WC,Cheeseman BA,Yen CF,Randow CL.Molecular-level simulations of shock generation and propagation in polyurea.Mat Sci Eng A-Stuct 2011;528(10-11):3799-808.

[29]Barnes HA.Shear-thickening(‘Dilatancy’)in suspensions of non aggregating solid particles dispersed in Newtonian liquids.J Rheol 1989;33:329-66.

[30]Hoffman RL.Discontinuous and dilatant viscosity behaviour in concentrated suspensions.II.Theory and experimental tests.J Coll Int Sci 1974;46:491-506.

[31]Brady JF,Bossis G.The rheology of concentrated suspensions of spheres in simple shear flow by numerical simulation.J Fluid Mech 1985;155:105-29.

[32]Bischoff White EE,Chellamuthu M,Rothstein JP.Extensional rheology of a shear-thickening cornstarch and water suspension.Rheol Acta 2010;49:119-29.

[33]Crawford NC,Popp LB,Johns KE,Caire LM,Peterson BN,Liberatore MW.Shear thickening of corn starch suspensions:does concentration matter?J Colloid Interface Sci 2013;396:83-9.

[34]Colombo M,di Prisco M,Martinelli P.A new shock tube facility for tunnel safety.Exp Mech 2011;51(7):1143-54.

[35]Chandra N,Ganpule S,KleinschmitNN,Feng R,Holmberg AD,Sundaramurthy A,et al.Evolution of blast wave profiles in simulated air blasts:experiment and computational modelling.Shock Waves 2012;22(5):403-15.

[36]Baker WE,Kulesz JJ,Ricker RE,Bessey RL,Westine PS,Parr VB,et al.Workbook for predicting pressure wave and fragment effects of exploding propellant tanks and gas storage vessels.Technical Report.NASA;1977.https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19760012208.pdf/ [Accessed 13 December 2016].

[37]Bowen IG,Fletcher ER,Richmond DR.Estimate of man's tolerance to the direct effects of air blast.Technical Report.Defense Atomic Support Agency and Lovelace Foundation for Medical Education and Research;1969.http://www.dtic.mil/dtic/tr/fulltext/u2/693105.pdf/[Accessed 13 December 2016].

[38]White CS,Jones RK,Damon EG,Fletcher ER,Richmond DR.The biodynamics of air blast.Technical Report.Defense Nuclear Agency and Lovelace Foundation for Medical Education and Research;1971.http://www.dtic.mil/dtic/tr/fulltext/u2/a384508.pdf[Accessed 13 December 2016].

[39]Baker WE,Westine PS,Kulesz JJ,Wilbeck JS,Cox PA.A manual for the prediction of blast and fragment loadings on structure.Technical Report.US Department of Energy;1981.http://www.dtic.mil/dtic/tr/fulltext/u2/a476207.pdf[Accessed 13 December 2016].

[40]Grujicic M,Yavari R,Snipes JS,Ramaswami S,Runt J,Tarter J,et al.Molecularlevel computational investigation of shock-wave mitigation capability of polyurea.J Mater Sci 2012;47(23):8197-215.

- Defence Technology的其它文章

- Experimental study of the effect of wear parameters on the wear behavior of A356 alloy/cow horn particulate composites

- Chemical stability,thermal behavior,and shelf life assessment of extruded modified double-base propellants

- Experimental study on the microstructural and anti-corrosion behaviour of Co-deposition Ni-Co-SiO2composite coating on mild steel

- Modification of RDX and HMX crystals in procedure of solvent/anti-solvent by statistical methods of Taguchi analysis design and MLR technique

- Microstructure,properties and hot workability of M300 grade maraging steel

- Numerical and experimental study of wave shaper effects on detonation wave front