Modeling and analysis onoutput errors of precision linear vibration table

ZOU Zhong-xian,YU Zhi-wei,ZENG Ming,LIU Yu

(Space Control and Inertial Technology Research Center,Harbin Institute of Technology,Harbin150001,China)

The accuracy of Inertial Navigation System(INS)is mainly depended on the accuracy of Inertial Measure-ment Units(IMUs,including gyroscope and accelero-meter)[1-2].The navigation accuracy of the INS is signi-ficantly affected by IMUs’drift error which cumulates over time[3-4].The equatorial tumble test under gravity is usually utilized to identify the drift error,but it is not enough for the equipment used in missile and satellite while they often work under10~15g(g expresses the gravitational acceleration,g=9.8 m/s2),sometimes more than60gin re-entry stage.Special devices,which can generate high acceleration,should be adopted to test those IMUs.Vibration table is one of the special devices[3-7].

In the vibration test,the accuracy of the device under test(DUT)is determined by both the accuracy of vibration table and the identification method.In order to improve the accuracy of vibration table,Sun introduced an ultra-low-frequency vibration table,and a high-precision displacement feedback control system was applied to reduce the distortion of vibration table output[7].Uchiyama used a2degree-of-freedom controller and H∞filter to obtain robustness against the uncertainty,and good performance was achieved[8].Sawada utilized risk-sensi-tive tracking control to improve the accuracy of electric shaking tables[9].The above literatures focus on advancing the control method to improve the accuracy of the vibra-tion table.

On the other hand,the study on the output errors of vibration table can also provide an approach to advance the test accuracy of vibration table.Yao adopts BP neural network to develop a harmonic identification scheme for hydraulic shaking table[10].Zou analyzed the output errorcharacteristic of centrifuge[11].However,few people paid attention on the error characteristic of the precision linear vibration table.

In this paper,the error characteristic of precision linear vibration table is investigated.According to the investigation,the output error models of vibration table are established.Experiments are carried out to verify the validity of the established model.The established error model provides a potential approach for improving the test accuracy of vibration table.

1 Mechanical structure and working principle of vibration table

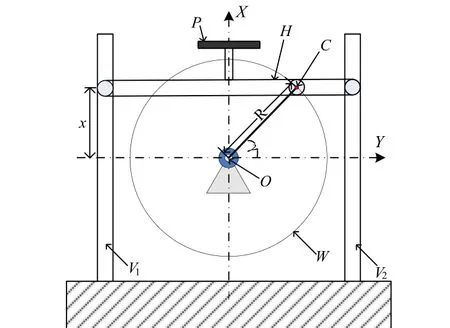

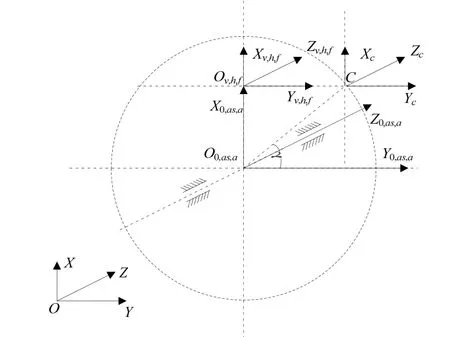

The mechanical structure of vibration table is shown in Fig.1.Based on the mechanical structure,the working principle and theoretical output of vibration table can be obtained.

Fig.1 Schematic diagram of vertical vibration table

The simplified schematic diagram of the vertical vibration table is illustrated in Fig.1.Circle W is a wheel.V1,V2and H are guide rails.Point O is the rotation center of wheel W.Point C is the center of roller on the edge of wheel.P is the platform used to fix objects.The center of wheel is connected to the motor spindle,and it is driven by DC torque motor.The platform P is mounted at the middle of horizontal guide rail H,which is moved along the vertical guide rail.The radius of circular motion for point C is R.In the vertical direction,the displacement along with vertical guide rail is defined as x.The angle between OC and horizontal direction OY isγ.Therefore,displacement x can be calculated by Eq.(1).

Whereγ=ωt+γ0,γ0is initial angle,ω is angular velocity and t is running time.It is clear that displacement x is the vertical travel of platform P,and it is defined as the output displacement of vibration table.In this paper,γ0is set to be0.The output acceleration a of vibration table is the sum of vibration accleration and gravitational accele-ration,it can be obtained according to Eq.(1)and it is shown in Eq.(2).

where g is gravitational acceleration;axis the vertical component of acceleration a;while ayand azare the components of acceleration a in other two directions.

Eq.(2)is the ideal output acceleration of vibration table.Due to mechanical errors,the output acceleration of vibration table is not the same as the ideal value of Eq.(2)and has some errors.It is necessary to more accurate values of the actual output acceleration of vibration table,which is important for the DUT.

2 Modeling the output of vibration table with error sources

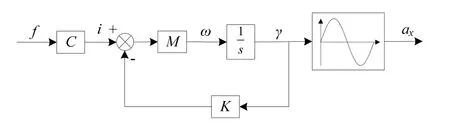

Fig.2is the block diagram of vibration table system.In this figure,f is the setting value of running frequency,C is the controller,i is the control current generated by the controller,M presents the motor and K is the feedback factor.The controlled output of vibration table system is the angular positionγ.The angular position,which is sensed by rotary encoder,feeds back to the controller and form a closed loop controlling system.Actually,one output displacement(x=Rsinγ)corresponds to two solutions(γ1= a rcsinx andγ2= 1 80° - a rcsinx),thus the output displacement can not be used as a feedback variable.The output displace-ment and acceleration are under open-loop control.

Fig.2 Schematic Block Diagram of vibration table

Because the angular and the angular velocity are controlled by close-loop,while the nonlinear translation from angular to sine vibration is in open-loop,the angle and the angular velocity are easier to achieve higher accuracy.The errors in the nonlinear translation,which mainly consist of mechanical errors,are uncontrollable.Thus mechanical errors are more responsible for the production of output errors.

2.1 Establishment of coordinate systems

Analyzing the transformation of motion from exciting component to receiving component is important for the application of equipment[12].Here the motion transformation and error propagation are analyzed by homogeneous transformation.

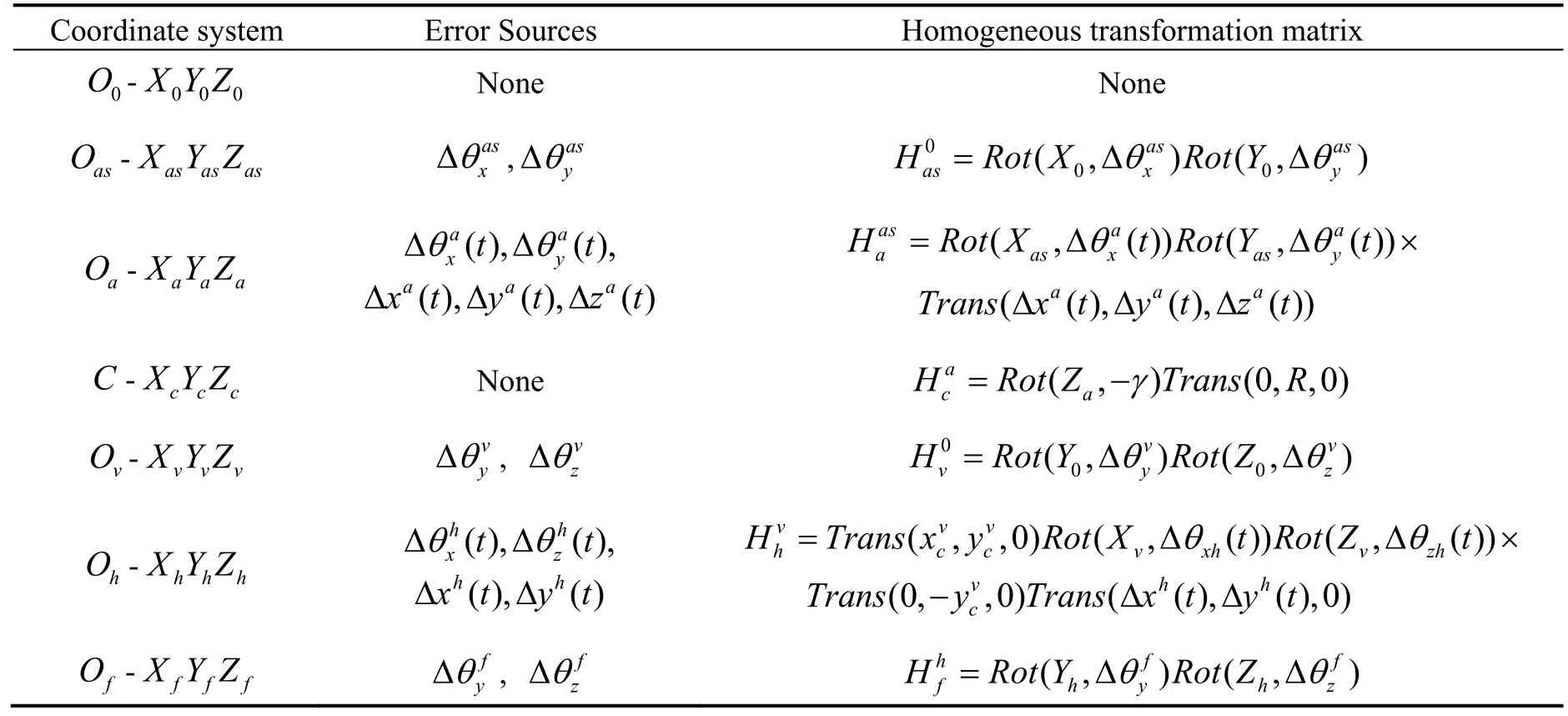

Fig.3 The coordinate systems of vibration table

Fig.3shows the coordinate systems in vibration table.O0-X0Y0Z0is geographic coordinate;Oas-XasYasZasis axle sleeve coordinate,translated from geographic coordinate system;Oa-XaYaZais principle axis coordinate,translated from axle sleeve coordinate;C-XcYcZcis roller coordinate,translated from principle axis coordinate;Ov-XvYvZvis vertical guides coordinate,the vertical guides fixed in the base and conected to the crank wheel only by a roller,thus this coordinate is directly translated from geographic coordinate;Oh-XhYhZhis horizontal guide coordinate, translated from vertical guides coordinate;Of-XfYfZfis fixture coordinate,translated from horizontal guide coordinate,the DUT fixed on the plant,thus the fixture coordinate is the output coordinate of vibration table.

2.2 Structure errors of vibration table

The error sources in vibration table are classified into statistic ones and dynamic ones by its characteristic.The statistic error sources are concerned with fixed structures and are constant,while the dynamic ones are concerned with motive structures and are time-varying.

The statistic error sources of vibration table contain:the levelness errors of spindle axis;the non-perpendicularitybetween vertical motion axis and level axis;the perpendicularity errorof the platform.

The dynamic error sources of vibration table contain:the rotary errors of the spindle axisΔ ya(t )andΔ za(t );the straightness errorΔ xh(t)of vertical guide rails;the straightness errorΔ yh(t)of horizontal guide rail;the rotation errors(t )and(t )generated from the clearances of guide rails.

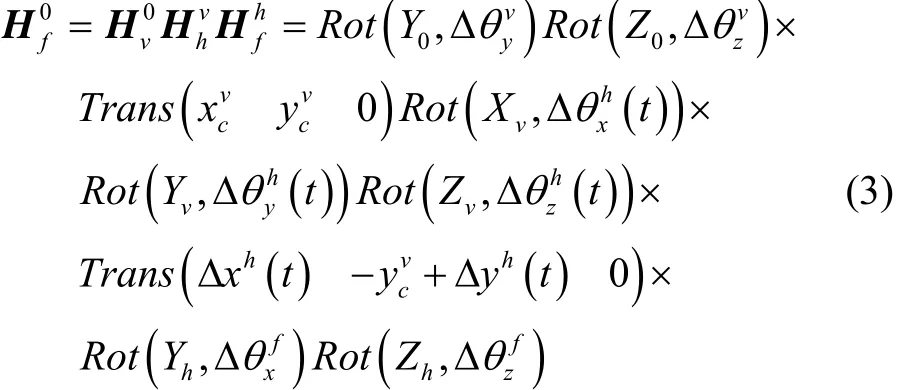

Tab.1 Error sources, coordinate systems and homogeneous transformation matrix amongcoordinate systems in vibration table

The gyroscope is fixed on the platform P and moved with platform P.Thus the acceleration projection in fixture coordinate is the output of vibration table and it is also the input of the gyroscope.Homogeneous transformation matrix is used to express the transformation relationship among coordinate systems.For example,is the homogeneous transformation matrix of axle sleeve coordi-nate related to geographic coordinate.

The error sources and the coordinate systems in vibra-tion table and the homogeneous transformation matrix among coordinate systems are summarized in Table1.

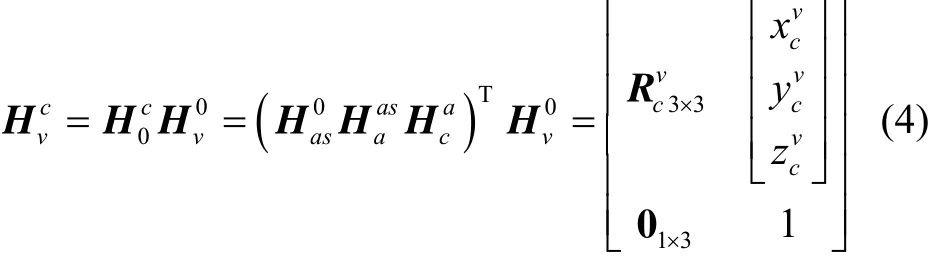

Based on the above analysis,the homogeneous trans-formation matrix of fixture coordinate related to geogra-phic coordinate can be obtained,and then the actual output acceleration of vibration table can be computed.

2.3 Mechanism model of vibration table output

Due to mechanical errors in vibration table,the projections of vibration table output are not the same as the ideal value and have some errors.It is necessary to obtain the precision projections which are important for the gyroscope.Therefore,it is very essential to obtain more accurate values for the vibration table output acceleration projectionswhich includeerror sources.

Based on the relationships among coordinate sys-tems in Table1,homogeneous transformation matrixof fixture coordinate relative to geographic coordi-nate is computed.

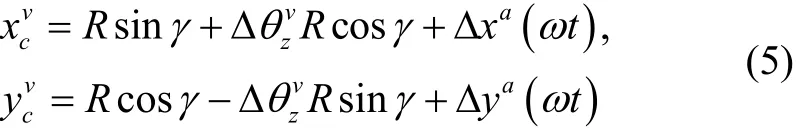

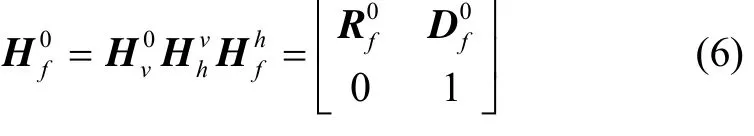

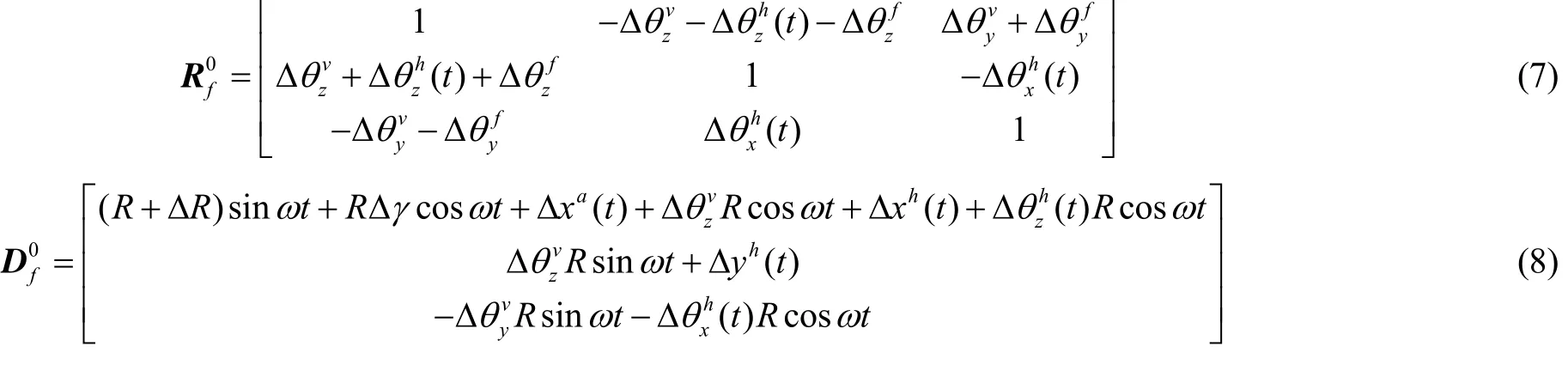

From Eq.(4),it can be obtained that:

And then,the homogeneous transformation matrixof fixture coordinate relative to geographic coordi-nate can be obtained.

where

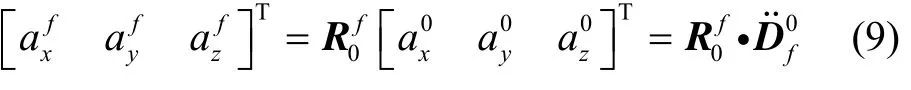

According to the definition of the homogenous transformation in Annex B,are the rotation transformation matrix and displacement transformation matrix of fixture coordinate related to geographic coordinate,respectively.expresses the motioncurve of the origin Ofof fixture coordinate in the platform P,thus the vibration acceleration is obtained from twice derivation of.The total output in fixture coordinate,which is the output of vibration table,can be obtained by Eq.(9).

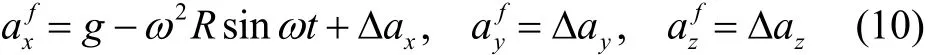

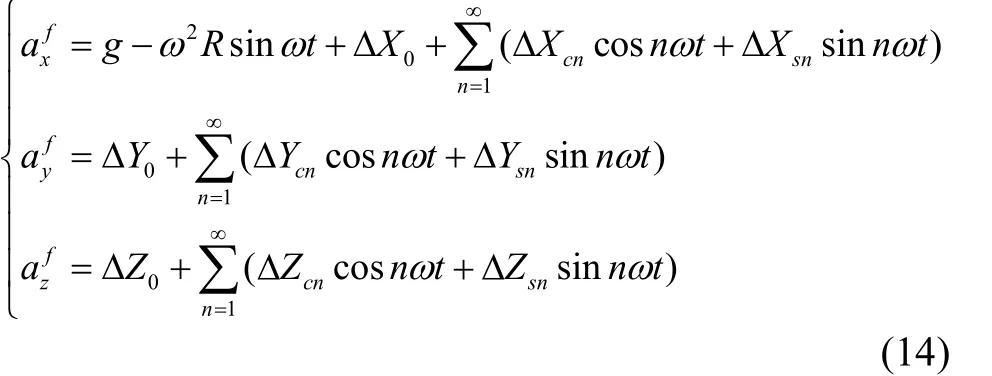

And then the output acceleration model of vibration table is obtained and shwon in Eq.(10).

wherexaΔ,yaΔandzaΔare the output acceleration errors,they are:

Eq.(10)is the mechanism model of vibration table output.According to the error sources given in Table1and the output error model in Eq.(11)-Eq.(13),the error sources with an effect on vibration table output are:from the driving system mentioned in Table1are not contained in Eq.(11)-Eq.(13),hence they have little influences on vibration table output.It means that,the errors of driving system(axis system and axle sleeve system)have little influence,and the errors of motion transform system(horizontal and vertical guide rails system)and fixed system(the fixed platform)have a lot of influences.Based on the measuring of these errors,especially for the constant parts,the vibration table output can be compensated and improved.

The vibration table motions periodically,and any periodic function or periodic signal can be decomposed into Fourier series,thus the output model of vibration table should be rewriten into the Fourier series form,that is

The error sources of vibration table is determined by the mechanical structure of vibration table.Once thevibration table is assembled,the error sources are permanent.In combination with the output model in Eq.(10),the scale factors of output acceleration as shown in Eq.(11)-Eq.(13)should be the fuction of frequency f(ω=2πf).That is to say,the scale factors(ΔXi, ΔYiandΔ Zi)are constants when the running frequency is certain value.These standpoints will be verified in next section by experiments.

3 Verification of output acceleration model

In order to verify the validity of the established model and the proposed standpoints,the tests based on the high precision vibration table system were carried out.According to the analysis of measured acceleration,the features of acceleration output error can be obtained.These obtained features are used to compare with the features from the established model in Section2.4.Then the validity of established model can be demonstrated.

3.1 Test rig and test procedure

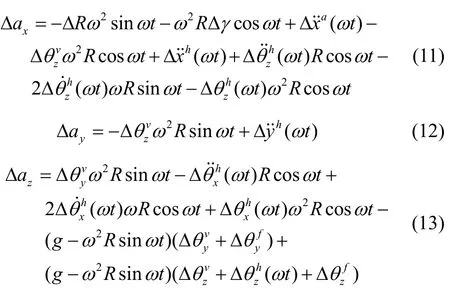

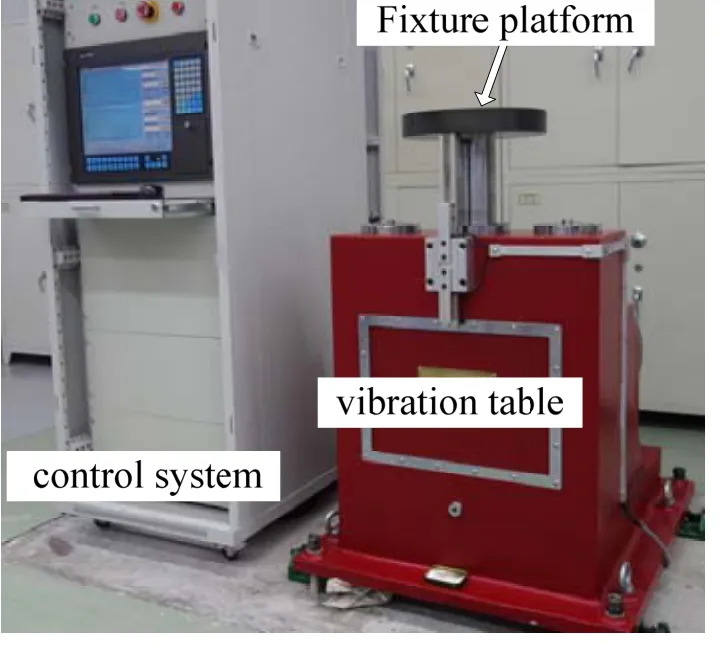

Fig.4shows the high precision vibration table system.It is mainly consisted by two parts:control sys-tem and vibration table.Dust can cause additional error and abrasion,affecting the precision of vibration table.In order to keep dust out,the main structure of vibration table is covered by stainless steel case.

Fig.4 The vibration table system

Based on the high precision vibration table system,displacement data are acquired by displacement mea-suring system when the rotation frequencies of motor are1Hz,2Hz,4Hz and10Hz,and the sampling rate is5kHz.Then the calculated acceleration can be obtained.

3.2 Results and discussions

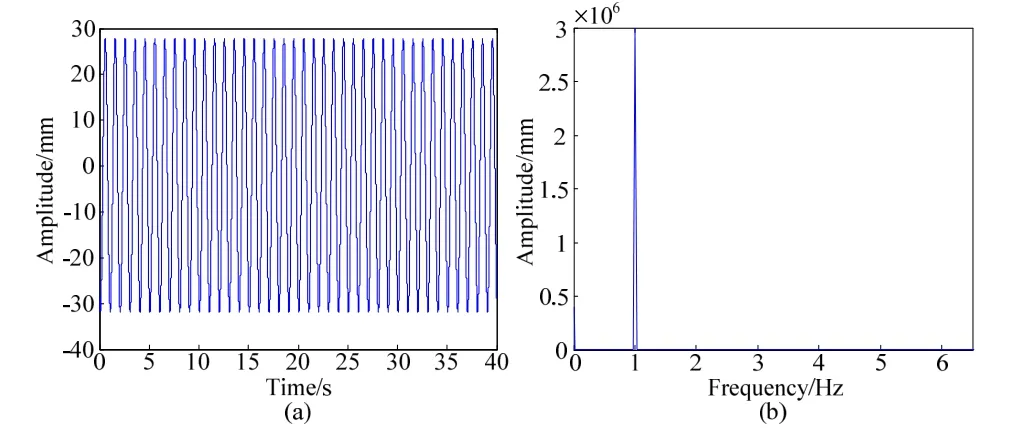

In order to verify the validity of established model,the obtained features from measured signals are com-pared with the features from the established model.The signals are analyzed with different motor rotation fre-quencies.Fig.5a shows the output displacement of vibra-tion table when the rotation frequency of motor is1 Hz,and this signal includes40rotation periods of motor.The frequency spectrum of this signal is shown in Fig.5b.

Fig.5 Rotation frequency at1Hz:(a)displacement signal and(b)frequency spectrum

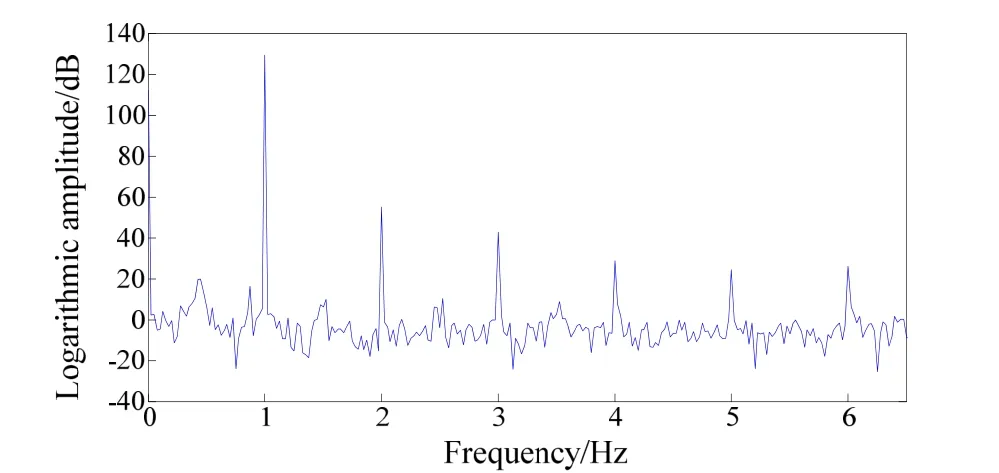

It is clear that the signal has the obvious base frequency with1Hz,and it is the same as the rotation frequency of motor.Unfortunately,we cannot see the frequency components from the errors.The reason is that the frequency components from the errors are too small and cannot be displayed.Therefore,a logarithmic scale for frequency is calculated,and the improved results are shown in Fig.6.

Fig.6 Logarithmic frequency spectrum of displacement signal

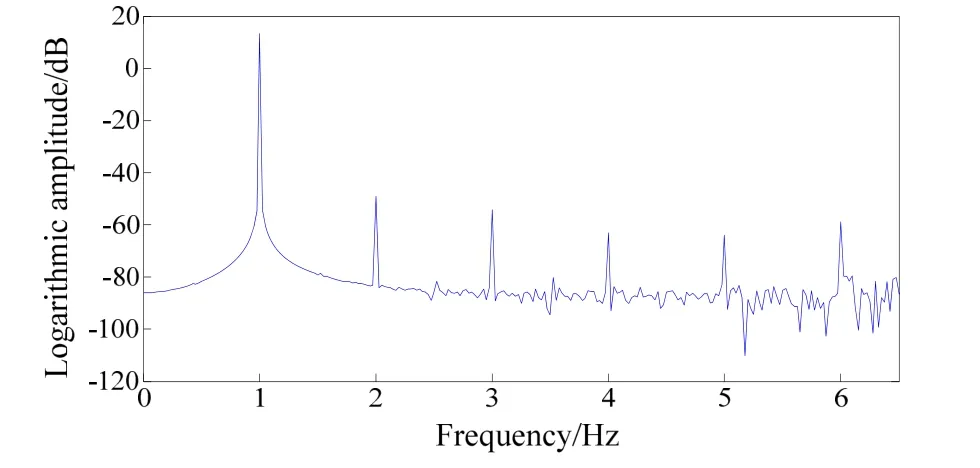

In addition to the base frequency component,the high-frequency components from errors are very distinct in Fig.6.Exactly,these high-frequency components are integral multiple of base frequency,such as2Hz,3Hz and so on.Similarly,the logarithmic frequency spectrum of output acceleration is shown in Fig.7when the rotation frequency of motor is1 Hz,and it has the same features as that of output displacement.

Fig.7 Logarithmic frequency spectrum of acceleration signal

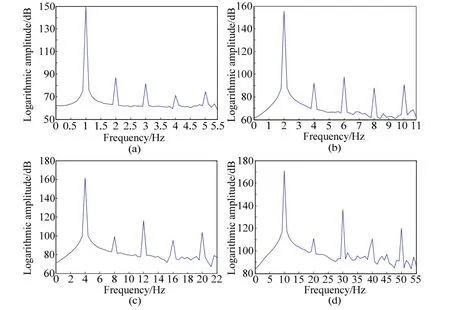

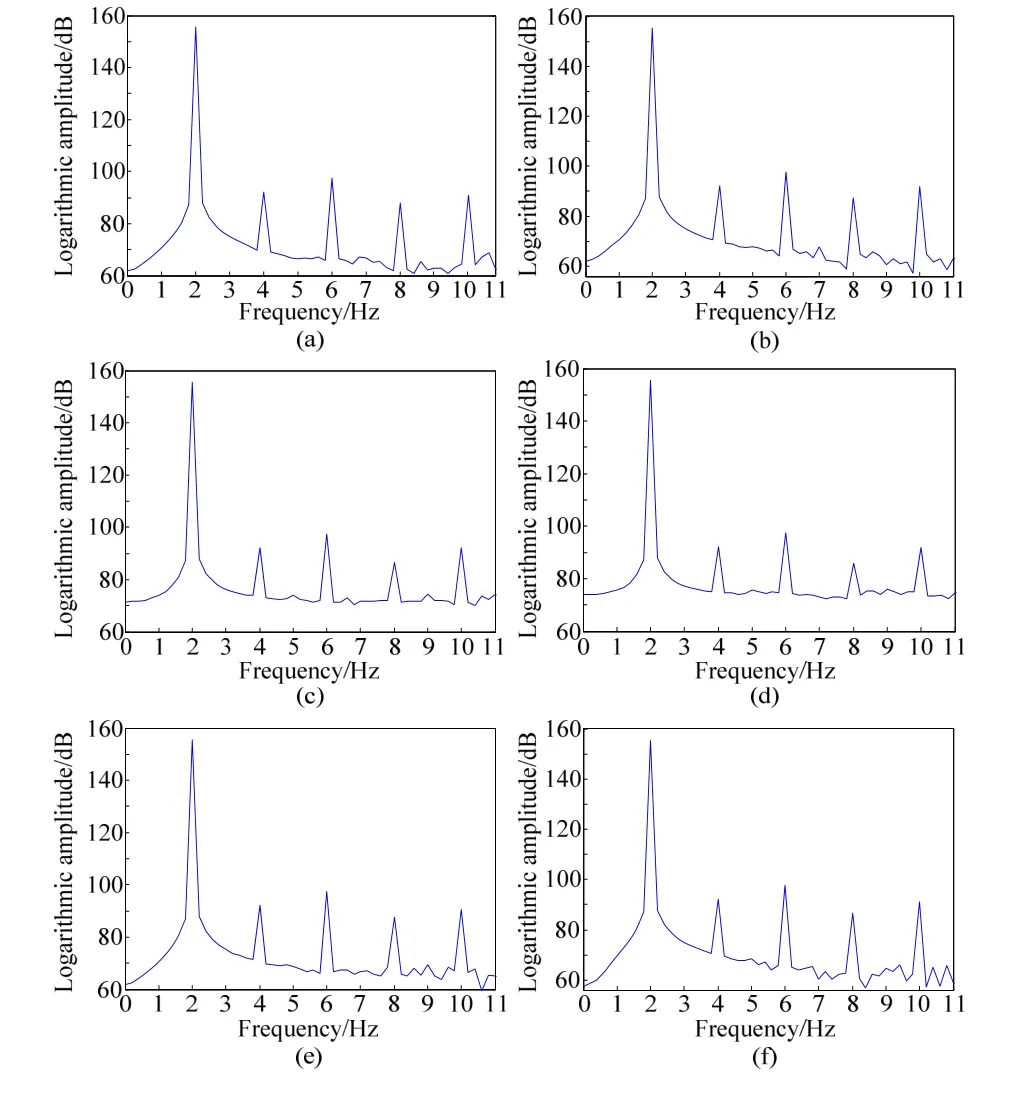

Furthermore,logarithmic frequency spectrums of output acceleration are shown in Fig.8a-Fig.8d when the rotation frequencies of motor are1Hz,2Hz,4Hz and10Hz,respectively.Each signal includes10rotation periods of motor.

Fig.8 Logarithmic frequency spectrums of output acceleration with different frequencies:(a)1Hz;(b)2Hz;(c)4Hz;and(d)10Hz.

Fig.9 Logarithmic frequency spectrums of6output acceleration signals with2Hz:(a)signal1;(b)signal2;(c)signal3;(d)signal4;(e)signal5;and(f)signal6.

These acceleration signals with different frequen-cies also have the error frequencies with integral multiple of base frequency.Based on the features of above figures,it is obviously that all of the acceleration signals with different frequencies have errors and these errors can be partitioned into harmonic components which conform to the results of the model in Eq.(14).The model form of the output error is verified.

Furthermore,the repeatability of error character-ristics is investigated and it is used to demonstrate whe-ther the errors of acceleration signals have uniform and stable frequency features which conform to the results of the model in Eq.(14).For the same rotation frequency of motor,the acceleration signals are measured by6times,and the motor has a start and stop in each time.Then,6signals are obtained,and each signal has10running periods of motor rotation.For example,the logarithmic frequency spectrums of the signals with rotation fre-quency2 Hz are shown in Fig.9.It is clear that6signals all have the same error frequency components which are integral multiple of base frequency.

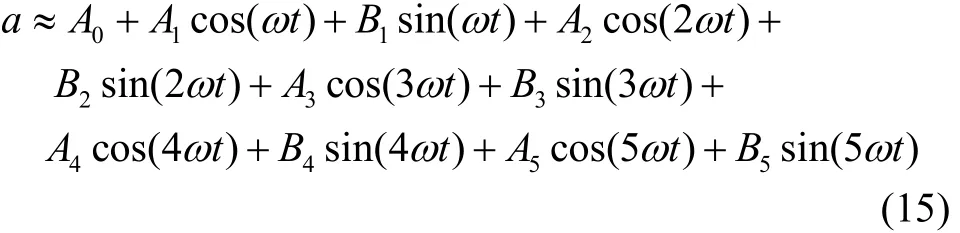

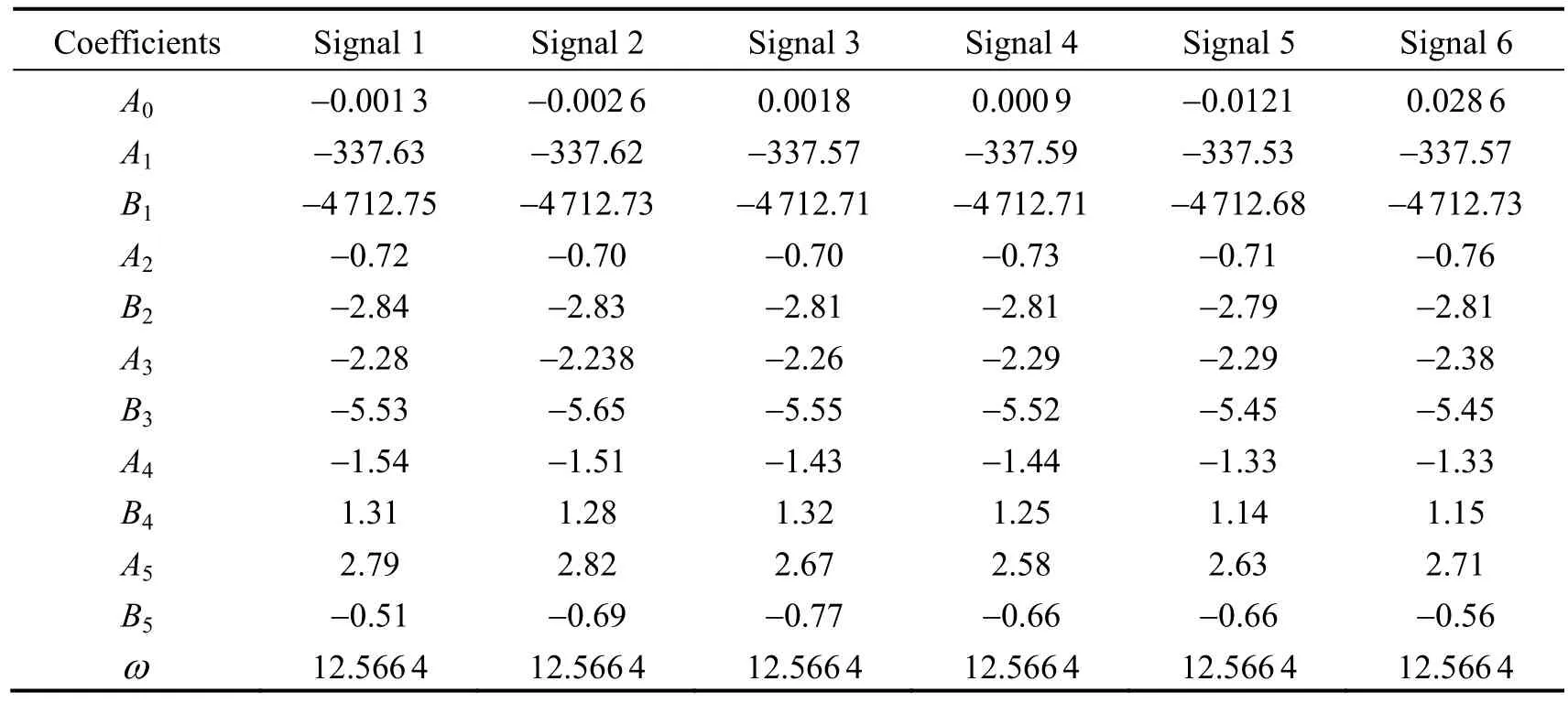

In order to analyze the features of errors further,Fourier fitting is used to these acceleration signals,and fitting coefficients are obtained.The fitting coefficients of these6signals are investigated to demonstrate whether the errors have similar amplitudes to corresponding error frequency.If these signals have very approximate fitting coefficients for each error frequency component,the errors have uniform and stable features,and the error character-ristics are repeatable on fixed frequency.Based on the analysis of errors features,the results of the model in Eq.(14)can be verified.The formula of Fourier fitting is shown in Eq.(15),and the fitting order is5.

The fitting coefficients of6signals with rotation frequency2 Hz are given in Table2.The calculated angular velocityωof these signals is12.566 4 rad/s.From Table2,it is clear that the fitting coefficients of6signals are very similar for each order only except the constant error A0,and the bias of A0is mostly about the misalignment of measurement zero position.This simila-rity evidences that the errors have uniform and stable coefficients for each frequency component,and the error characteristics are repeatable.Similarly,the signals with other rotation frequencies also have the same rule.

Based on the above analysis,it is clear that the errors are the harmonic errors with the form of Fourier series,the frequency components of errors are integral multiple of base frequency,the errors have uniform and stable coefficients for each frequency component,and the error characteristics are repeatable.These results conform to standpoints proposed in Section2.4.It is demonstrated that the proposed model is valid.

The proposed inference about the output error is verified by the practical acceleration data along axis X.The output error along axis X can be calculated from the sampled displacement data of the fixture platform.However,it is much harder to obtain the output errors along the other two directions.External test equipment(such as two laser interferometers)and specially designed measurement tests are needed[13-14].The measurement experiments are complex,time-consuming and manpower-consuming.It is unrealistic to run the measurement at each experiment which is carried out on the vibration table.Based on the above consideration,the output errors along axes Y and Z can be identified by a group of specially designed measurement experiments according to the mathematical model proposed in Section2.4,and then the identified errors can be used in the later experiments to improve the accuracy of the experiments.

Tab.2 The fitting coefficients of 6 output acceleration signals with 2 Hz

4 Conclusion

This paper models the output acceleration error of vibration table for advancing the test accuracy.Based on the mechanical structure analysis and error sources transaction of the vibration table,the relationship between error sources and vibration table output error is established by homogeneous transformation.The established output error model shows that the error is the harmonic error with the form of Fourier series,the scale factors are constant value for certain frequency,and the output errors are repeatable in multiple tests.And then,experiments are carried out,and the measured signals are utilized to verify the validity of the established model.The experimental results are identical to those of the model analysis.The established error model provides a potential approach to improve the test accuracy of vibration table.

[1] Baird W H.An introduction to inertial navigation[J].American Journal of Physics,2009,77(9):844-847.

[2] Armenise M N,Ciminelli C,Dell'Olio F,et al.Advances in gyroscope technologies[M].Springer Berlin Heidelberg,2011.

[3] IEEE Std836TM-2009.IEEE standard specification format guide and test procedure for linear single-axis,nongyroscopic accelerometers[S].New York:IEEE Aero-space Electronics System Society,2009.

[4] IEEE Std514TM-1974.IEEE standard specification format guide and test procedure for single-degree-of-freedom rate-integrating gyros[S].New York:IEEE Aero-space Electronics System Society,1974.

[5] Zeng M,Zou Z,Yu Z,et al.An investigation on the second-order drift error coefficient calibration of gyro-scope by vibration table[C]//201534th Chinese Control Conference.2015:5374-5380.

[6] Zou Z,Zeng M,Zhang X,et al.Study on calibration algorithms of gyroscopic drift error that affected by the acceleration harmonic errors of vibration table[C]//IEEE International Instrumentation and Measurement Techno-logy Conference.2017:1-6.

[7] Sun C,Ren S,Shi S,et al.Measurement method for PIGA precession during integer periods on linear vibration table[J].Journal of Chinese Inertial Technology,2016,24(5):672-676.

[8] He W,Zhu C P,Ma F.Realization of low-distortion ultra-low-frequency vibration based on feedback control tech-nology[C]//2005IEEE Networking,Sensing and Control Proceeding,2005:795-798.

[9] Uchiyama Y,Mukai M,Fujita M.Robust control of electro-dynamic shaker with2dof control using H∞filter[J].Journal of Sound Vibration,2009,326(1-2):75-87.

[10] Sawada Y,Ohgawara N.Risk-sensitive tracking control of uniaxial electric shaking tables with preview action[C]//Proceedings of the European Control Conference.2007:3173-3178.

[11] Yao J J,Niu Q T,Wang T,et al.Acceleration harmonic identification for an electro-hydraulic shaking table based on BP network[C]//2016Chinese Control and Decision Conference.2016:3328-3332.

[12] Zou Z X,Zeng M,Liu Y.Error analysis on centrifuge with precise linear vibration[J].Journal of Chinese Inertial Technology,2014,22(6):839-844.

[13] Rixen D J,Boogaard A,Seijs M V V D,et al.Vibration source description in substructuring:a theoretical depic-tion[J].Mechanical Systems Signal Processing,2015, s60-61:498-511.

[14] Shyu L H,Wang Y C,Chang C P,et al.A signal interpolation method for Fabry-Perot interferometer utilized in mechanical vibration measurement[J].Measurement,2016,92:83-88.

[15] Yasuda A,Hasegawa S,Pohtala J V,et al.Amplitude measurement of micro-vibration with robust optical inter-ferometer systems[J].Optik-International Journal for Light and Electron Optics,2015,126(23):4577-4580.