Microstructural observations on the terminal penetration of long rod projectile

Krushna Kumbhar,P.Ponguru Senthil,A.K.Gogia

Armour Design and Development Division,Defence Metallurgical Research Laboratory,Hyderabad 500058,India

Microstructural observations on the terminal penetration of long rod projectile

Krushna Kumbhar*,P.Ponguru Senthil,A.K.Gogia

Armour Design and Development Division,Defence Metallurgical Research Laboratory,Hyderabad 500058,India

Long rod projectile Terminal penetration Shear localization Adiabatic shear band Tungsten heavy alloy Armour steel

Present study focuses on the terminal penetration of tungsten heavy alloy(WHA)long rod penetrator impacted against armour steel at an impact velocity of 1600 m/s.The residual penetrator and armour steel target recovered after the ballistic test have been characterized using optical microscope,scanning electron microscope(SEM)and electron probe micro analyzer(EPMA).Metallurgical changes in target steel and WHA remnant have been analysed.Large shear stresses and shear localization have resulted in local failure and formation of erosion products.Severe plastic deformation acts as precursor for formation of adiabatic shear band(ASB)induced cracks in target steel.Recovered WHA penetrator remnant also exhibits severe plastic deformation forming localized shear bands,ASB induced cracks and shock induced cracks.

1.Introduction

Penetration of long rod projectile is a complex phenomenon which involves erosion and deceleration of the rod and erosion and acceleration of the target[1-3].The projectile material,density,impact velocity and the aspect ratio of the projectile are the main factors which affect performance of the projectile against a given target[4].Similarly target material properties and density also influence the penetration.Projectile erosion begins when impact velocity exceeds a critical velocity[2,3].In erosion regime,both the projectile and target are consumed during the course of penetration.Because of erosion,length of the projectile continuously decreases with increasing penetration.When the eroding projectile reaches a minimum L/D ratio,the projectile erosion comes to an end for a given impact velocity[3,5].After reaching this minimum L/D ratio,projectile penetrates the target as a rigid rod.Several experimental and simulation studies have been carried out with different combinations of target and projectile materials and impact velocity to understand the penetration of long rod projectiles[1-9].

Penetration of long rod projectile in a target takes place mainly in three phases namely transient,steady state(primary)and non steady state(terminal)penetration[8].Transient phase occurs during the initial impact of the projectile with the target generating high pressure and shock waves and lasts for a very short time[3,8].Primary(steady state)penetration contributes almost the entire penetration of the projectile.In this regime,projectile kinetic energy is dissipated in the target as well as the projectile.Failure and flow of target and projectile materials(erosion)opposite to the direction of the penetration occurs creating the final crater.Both the penetration and projectile consumption occur at a constant rate resembling a steady state flow.However,experimental observations have concluded that while this stage is characterised by a steady state,it is not completely hydrodynamic[10].Though contribution of steady state penetration is dominant in long rod penetration,significant length of the penetrator undergoes rigid or terminal penetration at the end[11,12].In terminal phase,projectile erosion stops and the projectile penetrates as a rigid rod.Projectile deceleration occurs and the penetration continues until the projectile kinetic energy is consumed completely.Due to deceleration of the projectile,the pressure at target-projectile interface reduces continuously[3].When the pressure drops below the dynamic yield strength of the target material,penetration comes to an end.Strength of the material plays a major role in this phase of penetration.

For projectiles with large aspect ratio,the transient phase can be neglected and total penetration can be given by Ref.[3].

Psis the depth of penetration corresponding to the length(Ls)of the projectile that undergoes erosion andPris the depth of penetration corresponding to the rigid length of the projectile(Lr).At a given impact velocity,the projectile with a certain initial lengthL(L>Lr)starts eroding until it reduces to lengthLr.Upon its length reachingLr,it behaves as a rigid projectile.This rigid penetration resembles penetration of small arms projectiles where the penetration shows a high dependence on strength of the target.

Though lot of studies have been carried out on steady state and terminal penetration using scaled down tests,experiments involving full scale tests are rare in open literature.Metallurgical changes that occur during penetration can give some insights and clues about the mechanisms of deformation and failure at such high rates of loading.The post ballistic metallurgical studies on the long rod penetration are also limited in literature[4,5,7,13].Present study describes metallurgical observations on recovered tungsten heavy alloy long rod remnant and target steel corresponding to terminal penetration and outlines possible deformation and failure mechanisms in both projectile and target.

2.Materials and experimental procedure

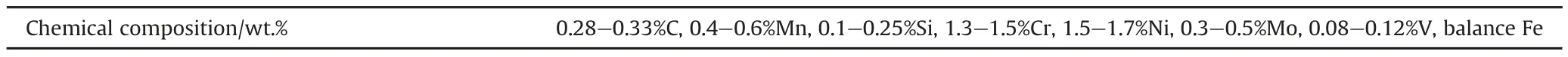

Armour steel used in the present study is a medium carbon low alloy steel.The chemical composition of the steel is given inTable 1.Mechanical properties of the steel are shown in Table 2.Projectile used in the test is made of tungsten heavy alloy(WHA)projectile with anL/Dratio of 16.Density and hardness of the WHA projectile are 17.5 g/cc and 510 VHN respectively.The ballistic test was conducted at an impact velocity of 1600 m/s and zero degree angle of attack.Target was a composite of ceramic(Alumina)and steel in front followed by stack of armour steel plates at back.The steel plates in the stack were sufficient in number to provide semiinfinite thickness.The thickness of the composite was kept such that the stack of armour plate at the back side was able to experience steady state penetration.It was also ensured that the transition from steady state to terminal phase occurs in the semi-infinite backing of armour steel.Residual penetrator and the steel crater were cut longitudinally and prepared for metallurgical characterization.2%Nital was used as etchant for etching steel.Different locations in residual penetrator and armour steel crater were observed using optical microscope(OLYMPUS GS-51)and Scanning Electron Microscope)(FEI QUANTA 400)to understand the deformation and failure mechanism.Electron probe micro analysis(EPMA)also has been carried out to understand the compositional changes caused by the penetration in WHA.Micro hardness has been measured with OMNI TECH(MVH-SAUTO-550)at a load of 300 gm.

3.Results and discussion

3.1.Initial microstructure of WHA projectile and target steel

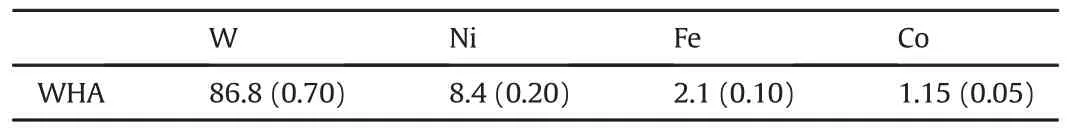

The initial microstructure of the WHA projectile is shown in Fig.1.It consists of tungsten particles embedded in a ductile matrix of W-Ni-Fe-Co.Average size of tungsten particles distributed in the matrix has been estimated as 46±13μm by utilising the image analysis software Image tool 2.0.The average chemical composition of the WHA is given in Table 3.The SEM microstructure of armour steel used for this study is shown in Fig.2.The microstructure exhibits tempered martensite which is characteristic of quenched and tempered heat treatment condition.Fine cementite particles precipitated in the decomposed martensite matrix caused by tempering can also be seen.

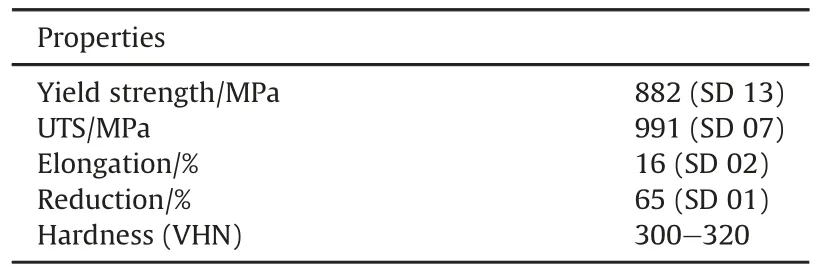

Table 2Mechanical properties of armour steel.

Table 3Chemical composition of WHA(wt%).

Table 1Chemical composition of armour steel.

3.2.General observations at terminal phase

The cross-section of the crater corresponding to the terminal phase of penetration is shown in Fig.3.It can be seen that the major part of the projectile has been consumed by erosion and a small part of the tail end is left in the crater.TheL/Dratio of the remnant projectile is 1.77.The region of crater surrounding the remnant has been filled with fragments of WHA and steel along with the residues of the fin of projectile.The diameter of the crater surrounding the remnant is smaller compared to the steady state crater diameter.The ratio of crater diameter to that of projectile diameter(Dc/Dp)is observed to be 2.11 and 1.76 for steady state and terminal phase respectively.The stress at the target-projectile interface during steady state penetration is very high and the stress field extends to large distance surrounding the interface leading to target material failure over a large radius and correspondingly increased crater radius.The reduction in crater diameter in terminal phase is due tothe commencement of deceleration of tail end of the projectile and consequent drop in stress at the target-projectile interface[3].This drop leads to reduction in the target erosion and reduced crater diameter.

For better understanding of projectile-target interaction and failure mechanism in terminal phase,crater has been divided into three different zones for observations as shown in Fig.3.The remnant projectile zone,fragmentation or interaction zone and target deformation zone.The fragmentation zone consists of a mixture of target and projectile fragments.The projectile fragments are the residues of the mushroom head that has formed at the end of the steady state or at the transition from steady state to terminal phase penetration.The detailed microstructural analysis of each zone has been carried out and is discussed below.

3.3.Microstructure of WHA remnant

The remnant WHA projectile recovered from the crater is shown in Fig.4(a).Two types of failure mechanisms have been observed in remnant projectile,one due to severe plastic deformation and another due to shock wave propagation.

3.3.1.Severe plastic deformation and adiabatic shear band induced failure

The remnant has undergone bulk deformation at the front due to the interaction with the target.Going away from the head,the deformation gradually reduces reaching initial microstructure of the WHA.Fig.4(b)-(e)shows the enlarged view of deformation at different locations of the remnant.The spherically shaped tungsten particles have deformed and elongated into a fibrous shape in the regions of heavy plastic flow.These observations are comparable to the results reported by other investigators[5,9,14,15].

There were also regions of shear localization in the deformed remnant.Fig.4(b)shows the regions of shear localization in WHA wherelargelocalized strainhas been observed.Many of these shear localized regions have undergone further plastic straining and resulted in adiabatic shear bands as shown in Fig.5.The crack nucleation and propagation in adiabatic shear bands have resulted in fragmentation of the WHA.Similar adiabatic shear band formation has been observed in high strain rate deformation of WHA[16-18].High velocity penetration has induced high strain rate deformation leading to adiabatic shear localization and cracking in remnant WHA.

Electron Probe Micro Analysis(EPMA)has been done in deformed regionsof WHA remnant.Elemental mappingof different alloying elements in the deformed region of the remnant is shown in Fig.6.The distribution of W,Fe,Ni and Co is given in Fig.6(b)and(c),(d)and(e)respectively.It can be seen that the matrix is made of Fe,Ni,Co and small amount of W which illustrates that there is no change in composition of WHA after severe plastic deformation.Thin layer of Fe rich regions in the front end of the remnant have been observed as shown in Fig.6(c)This is perhaps due to the interaction of the WHA and steel target during penetration.Elemental mapping also helps to visualize the deformation of matrix and tungsten particles separately.The flow of tungsten and matrix can be clearly observed.

3.3.2.Shock induced cracking and failure

Fig.7 show cracks which are different from the shear band induced cracks.These cracks have been initiated at the surface of the remnant projectile and propagated inward.They have propagated through the matrix as well as tungsten particles by nucleation and coalescence of voids.This type of failure is observed during shock wave propagation where there is a sudden rise of stress to values higher than the strength of both the tungsten particle and the matrix.These observations are similar to the spall failure observed during shock loading experiments[19].It is likely that the shock waves generated during the initial impact of the projectile on target have travelled along the projectile length and caused this shock induced cracking.The stress decreases during subsequent reverberations of thewave.Similar shock wave induced cracks have also been observed to originate from the tail of the remnant.These cracks are much larger than the cracks that are originating from the sides of the projectile.

Nucleation of voids during spall failure has been divided in to homogeneous and heterogeneous.Heterogeneous nucleation occurs at heterogeneities in the microstructure such as inclusions,second phase particles etc.The nucleation can happen by fracture of the inclusion,separation of the interface between the matrix and second phase and by fracture or void nucleation in the matrix.Homogeneous nucleation happens at sub microscopic heterogeneities such as low-angle grain boundaries,dislocation tangles etc[20].

The threshold stress required for heterogeneous nucleation is lower than that of homogeneous nucleation but if the stress is sufficiently high both type of nucleation can occur simultaneously[20].In WHA remnant voids and cracks have been observed in both tungsten particle and matrix.So it is apparent that stress has been high enough to nucleate crack in both tungsten particle and matrix.When the stress drops the failure happens by void nucleation in matrix.Crack propagation takes place by void coalescence.

3.4.Microstructural changes in penetration debris

Theregionin-betweentheremnantpenetratorandthe deformed steel target have been filled with WHA and steel fragments as shown in Fig.8.These are erosion debris and have formed at the target projectile interface during steady state erosion and transition from steady state to terminal penetration.

Comparatively much larger WHA particles were found in the erosion debris than those observed during steady state penetration debris reported[6].This may be due tothe fact that during terminal penetration WHA fragments were seized immediately after it got detached from the WHA rod and did not undergo further flow.The WHA fragments in the debris have shear localized regions,adiabatic shear bands and cracks.These confirm that shear localization occurred in WHA before separation from the main body of penetrator in fragmentation process.There are also steel fragments surrounding the remnant projectile with large deformations which are shown in Fig.8(a)-(d).Severely deformed and disintegrated tungsten particles are present in the interface between fragments as shown in Fig.8(e)and(f).The deformation of steel fragments after etching is shown in Fig.9.Heavy plastic flow has been observed in the steel fragments.The high magnification BSE image of the deformed region is shown in Fig.9(f).Very fine grains have been observed with grain size< 2μm.The large plastic strain associated with temperature rise would have caused dynamic recrystalization leading to grain refinement[13].

3.5.Microstructural changes in target steel

During penetration,the target material in front of the mushroom head experiences severe plastic flow and fragmentation leading to the formation of crater.However,target material surrounding the crater also has experienced substantial plastic deformation and it extended radially to a significant distance.This target material surrounding the craterhas undergone severe plastic deformation leading to shear localization and adiabatic shear band induced cracks.The regions immediatelyadjacent to the crater wall have experienced largest strain and going awayfromthe crater wall the target deformation gradually reduces.The optical microstructure of the deformed target is given in Fig.10.The cracks are predominantly initiated due to adiabatic shear bands.Adiabatic shear bands have been observed in high rate loading of high strength steels[21-23].

Hardness measurements have been taken from the target steel adjacent to the crater wall.In deformed steel the hardness has increased from 320 VHN to 410 VHN.It confirms severe plastic deformation and strain hardening of target steel due to the penetration.Hardness of the adiabatic shear band(ASB)has been measured to be around 520(SD:13)VHN.These adiabatic shear bands does not get etched and thus appear white after etching because of the very fine grains caused by the localized deformation.Similar observations have been reported with AISI 4340 steel during high strain rate testing[24].Existence of very fine grain size caused by the large deformation leads to increase in hardness within the adiabatic shear band due to higher dislocation density and grain boundary area[24].

4.Conclusion

Terminal penetration of a tungsten heavy alloy against armour steel has been investigated using remnant projectile and debris recovered from the crater bottom.The metallurgical observations on the terminal penetration is summarised below.

1)Crater diameter reduced upon entering in to terminal phase from steady state and ratio of crater diameter to that of projectile diameter is 2.11 and 1.76 for steady state and terminal phase respectively.

2)Crater can be considered to be composed of three different zones such as remnant projectile,fragmentation zone(consisting mixture of WHA and steel debris)and target deformation zone.

3)In remnant projectile adiabatic shear band induced cracks and shock wave induced crack propagation are the major failure mechanisms.

4)Fragmentation zone consists of mixture of WHA and steel fragments.LargeWHA fragments arepresent in both sides of the projectile which have probably been part of mushroom head and later got disintegrated into fragments.

5)The WHA debris in fragmentation zone containing adiabatic shear bands and cracks suggests adiabatic shear induced failure tobeaprominentprojectilefailuremechanism during mushrooming.

6)Target steel microstructure in fragmentation zone shows evidence of dynamic recrystalization.Target material adjacent to the crater wall experienced heavy plastic deformation and fragmentation due to adiabatic shear band induced cracking.

Acknowledgements

The authors are grateful to Defence Research Development Organization(DRDO)for financial support to carry out this work at Defence Metallurgical Research Laboratory,Hyderabad.Also the authors wish to express their gratitude to the Director,DMRL for granting permission to publish this paper.

[1]Grace FI.Long rod penetration in to targets of finite thickness at normal impact.Int J Impact Eng 1995;16:419-33.

[2]Tate A.A theory for the deceleration of long rods after impact.J Mech Phys Solids 1967;15:387-99.

[3]Anderson Jr CE.Dennis Orphal.Analysis of terminal phase of penetration.Int J Impact Eng 2003;29:69-80.

[4]Gerlach U.Microstructural analysis of residual projectiles-a new method to explain penetration mechanisms.Metall Trans A 1986;17A:435-42.

[5]Lankford J,Anderson Jr CE,Royal SA,Reigel III JP.Penetration erosion phenomenology.Int J Impact Eng 1996;18:565-78.

[6]Ponguru Senthil P,Bhav Singh B,Siva Kumar K,Gogia AK.Effect of heat treatment on ballistic performance of an armour steel against long rod projectile.Int J Impact Eng 2015;80:13-23.

[7]Chen XW,Wei LM,Li JC.Experimental research on the long rod penetration of tungsten-fiber/Zr-based metallic glass matrix composite into Q235 steel target.Int J Impact Eng 2015;79:102-16.

[8]Cristman DR,Gehring JW.Analysis of high-velocity projectile penetration mechanics.J Appl Phys 1996;37:1579-87.

[9]Magness Jr LS.High strain rate deformation behaviours of kinetic energy penetrator materials during ballistic impact.Mech Mater 1994;17:147-54.

[10]Stenberg J,Orphal DL.A note on the high velocity penetration of aluminum nitride.Int J Impact Eng 1997;19:647-51.

[11]Anderson CE,Walker JD,Bless SJ,R Sharron T.On the velocity dependence of the L/D effect for long rod penetrators.Int J Impact Eng 1995;17:13-24.

[12]Orphal DL,Franzen RR,Charters AC,Menna TL,Piekutowski AJ.Penetration of confined boron carbide targets by tungsten long rods at impact velocities from 1.5-5km/s.Int J Impact Eng 1997;19:15-29.

[13]Murr LE,Trillo EA,Pappu S,Kennedy C.Adiabatic shear bands and examples of their role in severe plastic deformation.J Mater Sci 2002;37:3337-60.

[14]Xiaoqing Z,Shukui Li.Liu Jinxu,Self sharpening behaviour during ballistic impact of the tungsten heavy alloy rod penetrators processed by hothydrostatic extrusion and hot torsion.Mater Sci Eng A 2010;527:4881-6.

[15]Das Jiten,Appa Rao G,Pabi SK,Sankaranarayana M,Sarma Bijoy.Deformation behaviour of a newer tungsten heavy alloy.Mater Sci Eng A 2011;528:6235-47.

[16]Kim DS,Nemat-Nasser S,Isaacs JB,Lischer D.Adiabatic shear band in WHA in high strain rate compression.Mech Mater 1998;28:227-36.

[17]Wei Zhigang,Yu Jilin,Hu Shisheng,Li Yongchi.Influence of microstructure on adiabatic shear localization of pre-twisted tungsten heavy alloys.Int J Impact Eng 2000;24:747-58.

[18]Wenqi Guo,Jinxu Liu,Jia Yang,Shukui Li.Effect of initial tempetature on dynamic recrystallization of tungsten and matrix within adiabatic shear band of tungsten heavy alloy.Mater Sci Eng A 2011;528:6248-52.

[19]Bless SJ,Tarcza K,Chau R,Taleff E,Persad C.Dynamic fracture of tungsten heavy alloys.Int J Impact Eng 2006;33:100-8.

[20]Meyers MA,Aimone CT.Dynamic fracture(spalling)of metals.Prog Mater Sci.1983;28:1-96.

[21]Odeshi AG,Bassim MN,Al-Ameeri S.Effect of heat treatment on adiabatic shear bands in a high strength low alloy steel.Mater Sci Eng A 2006;419:69-75.

[22]Meyers MA,Wittman CL.Effect of metallurgical parameters on shear band formation in low carbon(0.2 Wt Pct)steels.Metall Trans A 1990;21:3153-64.

[23]Zurek AK.The study of adiabatic shear band instability in a pearlitic 4340 steel using a dynamic punch test.Metall Mater Trans A 1994;25A:2483-9.

[24]Polyzois Ioannis.Nabil Bassim.An examination of the formation of adiabatic shear bands in AISI 4340 steel through analysis of grains and grain deformation.Mater Sci Eng A 2015;631:18-26.

2 February 2017

in revised form 30 April 2017 Accepted 23 May 2017 Available online 25 May 2017

?2017 Production and hosting by Elsevier B.V.on behalf of China Ordnance Society(http://creativecommons.org/licenses/by-nc-nd/4.0/).

*Corresponding author.Armour Design and Development Division,Defence Metallurgical Research Laboratory,Kanchanbagh,Hyderabad 500058,India.

E-mail address:krushna@dmrl.drdo.in(K.Kumbhar).

Peer review under responsibility of China Ordnance Society.

- Defence Technology的其它文章

- Influence of electric current intensity on the performance of electroformed copper liner for shaped charge application

- Split warhead simultaneous impact

- Effects of Al/O on pressure properties of confined explosion from aluminized explosives

- The effect of wax coating,aluminum and ammonium perchlorate on impact sensitivity of HMX

- Spectrally adapted red flare tracers with superior spectral performance

- Control system design of flying-wing UAV based on nonlinear methodology