Eff ect of tube-electrode inner diameter on electrochemical discharge machining of nickel-based superalloy

Zhang Yan,Xu Zhengyang,Xing Jun,Zhu Di

College of Mechanical and Electrical Engineering,Nanjing University of Aeronauticsamp;Astronautics,Nanjing 210016,China

Eff ect of tube-electrode inner diameter on electrochemical discharge machining of nickel-based superalloy

Zhang Yan,Xu Zhengyang*,Xing Jun,Zhu Di

College of Mechanical and Electrical Engineering,Nanjing University of Aeronauticsamp;Astronautics,Nanjing 210016,China

Nickel-based superalloys are widely employed in modern aircraft engines because of their excellent material characteristics,particularly in the fabrication of film cooling holes.However,the high machining requirement of a large number of film cooling holes can be extremely challenging.The hybrid machining technique of tube electrode high-speed electrochemical discharge drilling(TEHECDD)has been considered as a promising method for the production of film cooling holes.Compared with any single machining process,this hybrid technique requires the removal of more complex machining by-products,including debris produced in the electrical discharge machining process and hydroxide and bubbles generated in the electrochemical machining process.These by-products significantly affect the machining efficiency and surface quality of the machined products.In this study,tube electrodes in different inner diameters are designed and fabricated,and the effects of inner diameter on the machining efficiency and surface quality of TEHECDD are investigated.The results show that larger inner diameters could effectively improve the flushing condition and facilitate the removal of machining by-products.There fore,higher material removal efficiency,surface quality,and electrode wear rate could be achieved by increasing the inner diameter of the tube electrode.

1.Introduction

Nickel-based superalloys havefound several applications in modern aircraft engines,because of their superior strength and excellent temperature resistance.1Employed as the materials for the turbine blades and vanes,these superalloys have remarkably improved the operability and efficiency of turbines at extreme temperatures.2However,nickel-based superalloys are also difficult to machine,and the fabrication of some complex structures from these materials using the traditional machining processes can be quite problematic.3,4For example,film cooling holes are typical structures in turbine blades and are commonly tiny,numerous,and irregularly divergent.Because they need to be machined with high machining efficiency and surface quality,5,6the fabrication of film cooling holes in nickel-based superalloys has been a significant challenge in the aerospace manufacturing industry.7Hence,a reliable and efficient process is urgently required for producing these holes without surface defects like recast layers,heataffected layers,and cracks.

Tube electrode high-speed electrical discharge drilling(TEHECDD)has been proposed as a suitable process for the machining of film cooling holes.8In this process,using a tube electrode and low-conductivity salt solution,electrical discharge machining(EDM)and electrochemical machining(ECM)are combined.There fore,TEHECDD can obtain better machining performances in both machining efficiency and surface quality.In this hybrid process,because tube electrode high-speed electrical discharge erosion occurs in the frontal gap,a hole can be drilled with high speed,while the electrochemical reaction,occurring in the lateral gap,removes the surface defects generated in the EDM process,such as recast layers,cracks,and residual stress.9Because of these advantages,TEHECDD is considered as the perfect machining process for the fabrication of film cooling holes.

The greatest obstacle in the TEHECDD method is the removal of machining by-products.As it is a hybrid process,these include not only the melted and vaporized particles generated by EDM but also the hydroxide precipitates and bubbles produced by ECM.The volume of the hydroxide precipitates is several hundred times larger than that of the EDM particles.10,11Thus,the narrow machining gap can be more easily blocked by by-products in TEHECDD than in either EDM or ECM.Such blockage makes it difficult to remove the mixed machining by-products and the Joule heat from the machining gap.12Moreover, under hightemperature and sharp cooling conditions,the hydroxides and melting metal particles resolidify to form a thick recast layer on the surface of the hole.13The blockage of the machining gap also leads to an increase in the concentration of contaminants in the working fluid.14The poor decontamination of the working fluid may result in extra arc and secondary discharges,and these abnormal discharges cause instable machining,reducing the machining accuracy,surface quality,and machining efficiency.15–17Moreover,because of the poor decontamination of the narrow gap and the high residual Joule heat,the electrochemical dissolution reactions fatally deteriorate,decreasing the quality of the machined surface.18Hence,the removal of machining by-products is essential for achieving high machining accuracy and surface quality in TEHECDD.

This study focuses on the improvement of the machining accuracy and surface quality of TEHECDD by the enhanced removal of by-products.To achieve these objectives,tube electrodes of different inner diameters are fabricated for use in TEHECDD,and the effects of the inner diameter on the material removal efficiency,machining accuracy,and surface quality are analyzed.Finally,the inner diameter of the tube electrode is optimized to ensure better machining accuracy and surface quality.

2.Experimental details

2.1.Machine tool

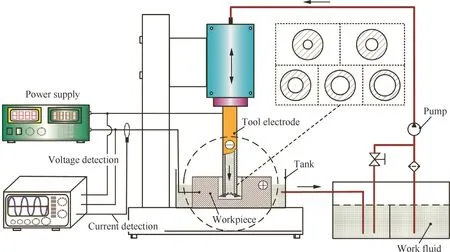

The experimental system specially developed for TEHECDD with different electrode structures is schematically illustrated in Fig.1.All the experiments in this study were conducted in this system,which consists of tube electrode clamp and flushing units,power supply cell,current/voltage detection unit,and machining region.In this study,a series of electrodes,including five tube electrodes,was investigated.The electrode was fixed on the machine head and could be moved in the feeding directions along a linear guide using motors.By operating the pump,the working fluid could be supplied continuously and steadily to the machining zone through the interior of the tube electrode.The pulse generator placed on the machining channel supplies energy for the entire machining process.The voltage detection unit enables the machining voltage and current to be determined simultaneously,so the process could be controlled in real time.

2.2.Materials

Fig.1 Schematic diagram of experimental system developed for TEHECDD with different tube electrodes.

Table 1 Properties of electrode and workpiece materials.

Currently,DZ125L is one of the most commonly used nickelbased superalloys,and it is employed as the material for turbine blades and vanes.19A typical directionally solidified nickel-based superalloy,DZ125L has good physical and mechanical properties,including high melting point,rigidity,and good corrosion and wear resistances,but it is also difficult to machine.20In this study,all the experiments were conducted on the DZ125L superalloy,and plate pieces of dimensions 40 mm(length)× 15 mm(width)× 3 mm(thickness)were used as the workpieces.In addition,a brass tube was employed as the tool electrode.The properties of the workpiece and electrode materials are listed in Table 1.

2.3.Design of tube electrodes with different inner diameters

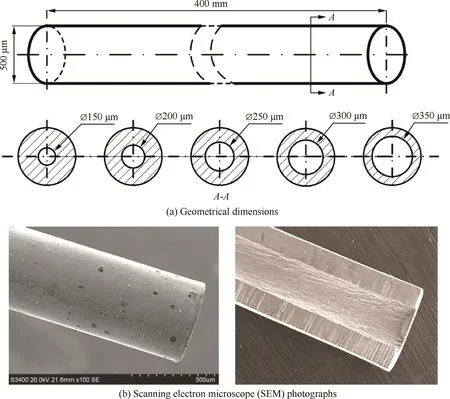

Different inner diameters of the tube electrode would facilitate the flow of the working fluid to different degrees,which would in turn affect the machining accuracy and surface quality of the TEHECDD.This study mainly aimed to investigate the effect of the inner diameter on the machining performance,so the tube electrodes of different inner diameters were designed and manufactured(see Fig.2).In order to exclude the effects of external diameter on the machining performance,all outer diameters were set as 500 μm.The smaller inner diameter could limit the flow rate of working fluid,while the larger inner diameter could decrease the rigidity of tube electrode and machining stability.Neither the larger diameter nor smaller inner diameter was suitable to obtain better machining performances,so the five different interior diameters were set as 150,200,250,300,350 μm,respectively.

2.4.Machining procedures and conditions

In the experiments,the machining time and enlargement of the lateral gap,surface quality of the holes,thickness of the recast layer(TRC),and electrode wear rate(EWR)were investigated.The main machining conditions are listed in Table 2.First,the tube electrodes of different inner diameters were studied.Then,the effects of the inner diameter on the machining performances were analyzed by comparative experiments.Finally,the optimal inner diameter for improving the machining performance of TEHECDD was identified,and film cooling holes were fabricated using the tube electrode with this optimal inner diameter.

Fig.2 Design of tube electrodes of different inner diameters.

Table 2 Machining parameters and conditions.

During the comparative experiments,the machining results,including the material removal rate(MRR),accuracy and quality of the holes,TRC,and EWR were examined.The MRR is considered as the linear rate and is calculated as MRR=L/t,whereas the EWR is determined by the formula EWR=(Tb-Ta)/(Gb-Ga).In these equations,L is the depth of drilling(μm),t is the machining time(min),Tband Taare the weights of the tube electrode be fore and after machining(mg),respectively,and Gband Gaare the weights of the workpiece be fore and after machining(mg).The weight of the tube electrode was measured three times using an analytical balance(AE240,METTLER,Switzerland),and then the average weight was calculated.The geometrical form and inner wall of the holes were observed using a scanning electron microscope(SEM),and the inner and external diameters of the tube electrodes were measured using a Leica digital microscope.The energy-dispersive X-ray spectroscopy(EDX)system integrated in the SEM was utilized to analyze the material composition of the machining surface and tool electrode surface.

3.Experimental results and discussion

In this section,the effects of inner-hole diameter on machining speed,dimensional accuracy,surface quality,recast layer,and electrode wear rate have been studied.The machining time,which is measured to drilling though a hole in the feed direction,is used to evaluate the machining speed.The dimensional accuracy has been evaluated from expanding of lateral machining gap and the roundness of entrances.The recast layer is examined by per forming a metallography experiment,which includes cutting,polishing,and etching.Then,the recast layers of cross sections are analyzed under a metallographic microscope.

3.1.Effects of inner-hole diameter on lateral gap and machining time

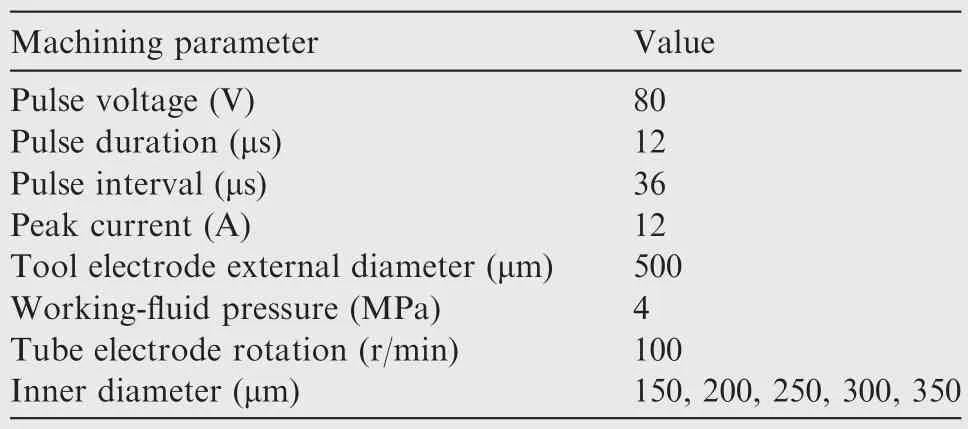

Fig.3 Effect of inner diameter on lateral gap and machining time.

The lateral gap and machining time at different inner diameters are shown in Fig.3.It can be observed that as the inner diameter of the tube electrode increases,the lateral gap first decreases and then increases,with the minimum lateral gap at ?250 μm.This can be explained by the fact that,when the inner diameter is as small as 150 μm,the machining byproducts cannot be washed out of the narrow gap immediately,resulting in massive secondary discharges and arcs,which increase the size of the lateral machining gap.On the other hand,when the inner diameter is as large as 350 μm,the flushing condition is improved,which facilitates the EDM and ECM processes significantly,and thus,a large lateral gap is obtained and the dimensional accuracy becomes poor.Hence,it implied that the TEHECDD could improve the dimensional accuracy by using ?250 μm tube electrode to constrain the thickness of material layer further dissolving from lateral gap.

Furthermore,it can be seen that as the inner diameter increases,the machining time decreases sharply,demonstrating that larger inner diameters lead to higher drilling efficiency.This is because the better decontamination of the frontal gap associated with tube electrodes of large inner diameters enhances the EDM and ECM processes,resulting in higher material removal efficiency in the drilling direction.

3.2.Effects of inner-hole diameter on entrance of hole

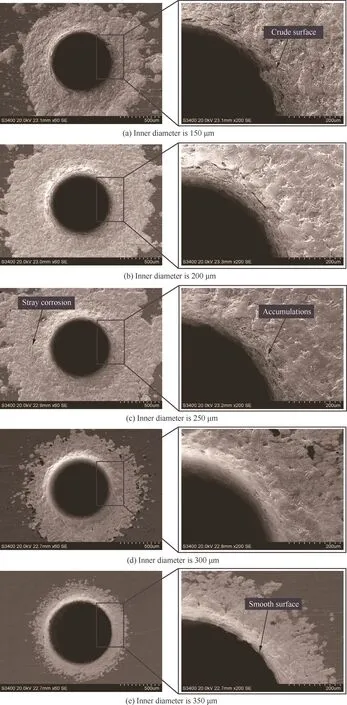

In Fig.4,the holes obtained using the tube electrodes with different inner diameters are presented,and the rims of the hole entrances are magnified.It can be seen that the hole obtained using the tube electrode with the largest inner diameter of 350 μm has better roundness of entrance compared with the other holes.Moreover,as the inner diameter increases,the stray corrosion is considerably reduced.This demonstrates that tube electrodes with larger inner diameters could improve the machining performance in terms of roundness of the hole as well as stray corrosion.On the other hand,the poor flushing condition resulting from a small inner diameter causes accumulation of the by-products generated in the EDM and ECM processes.The by-products trapped in the lateral gap then cause unstable machining and irregular material removal,thereby reducing the roundness of the hole.Hence,in order to obtain better roundness accuracy,a larger inner diameter should be chosen.In addition,the materials accumulated over the rim of the entrance result in secondary discharge and stray erosion,which can be identified in the magnified images in Fig.4.Massive accumulations could be observed on the inner surfaces of the holes machined by the tube electrodes with smaller inner diameters.Moreover,because of the poor flushing condition,the by-products cover the machined surface as well.When tube electrodes with larger inner diameters are used,the blockage is improved significantly,and no machining by-products can befound on the machined surface.It is implied that the blockage of machining productions leads to the increase of the concentration of contaminant in work fluid.The poor decontamination of work fluid probably results in extra arc and secondary discharge,while these abnormal discharges cause the instable machining,and then reduce the machining accuracy,entrance quality.

Fig.4 SEM images of microholes machined by tube electrodes with different inner diameters.

Fig.5 SEM photographs of machined lateral surfaces using tube electrodes with different inner diameters.

3.3.Effects of inner-hole diameter on surface quality

According to the aforementioned analyzes,there is a significant difference in the surface quality of the side wall,especially between the holes with ?150 μm and ?350 μm inner diameters.In order to further study the effect of inner diameter on surface quality,the lateral surfaces of the holes machined by TEHECDD using the tube electrodes with ?150 μm and ?350 μm inner diameters are analyzed in detail.In Fig.5,the machined surface using the tube electrode with ?150 μm inner diameter is seen to be crude and covered with a recast layer,which includes cracks,globules,and caves.This is because the unsatisfactory flushing condition due to the small inner diameter affects the removal of the machining byproducts,some of which cohere on the surface under hightemperature and rapid cooling conditions.When the tube electrode with ?350 μm inner diameter is used,the quality of the machined surface is improved significantly,and the entire machined area is smoother.The surface defects,such as cracks,scaly appendages,and recast layer,are not observed because of the electrochemical dissolution properties of TEHECDD.It is demonstrated that due to the poor decontamination of narrow gap and mass residual Joule heat,the electrochemical dissolution reactions are fatally deteriorated,and then the better machined surface cannot be obtained.

In Fig.6,the compositions of the aforementioned two lateral surfaces are identified by the EDX spectrum.In Fig.6(a), for the sample machined by the tube electrode with ?150 μm inner diameter,it is observed that the oxygen composition is 15.88%.However,on the surface machined by the tube electrode with ?350 μm inner diameter,there exists no oxygen,as shown in Fig.6(b).This is because,during the TEHECDD with the smaller inner diameter,the poor flushing condition causes the melting and vaporization of metal as well as the decomposition of water at high temperatures into hydrogen and oxygen.Thus,the molten metal and the oxygen rapidly combine to form an oxide layer on the machined surface,resulting in the presence of oxygen on the lateral surface.However,when the tube electrode with the larger inner diameter is used,the oxygen compounds disappear from the surface.Furthermore,it can be observed that compared with the surface machined by the ?150 μm inner diameter tube electrode,the amount of carbon on the surface produced by the ?350 μm inner diameter tube electrode is reduced by 4.08%.This can be attributed to the poor flushing condition due to the smaller inner diameter,which causes the carbon debris to eject from the workpiece material by melting and evaporation to redeposit on the workpiece surface.On the other hand,when the larger inner diameter tube electrode is used,the flushing condition is remarkably improved.There fore,most of the debris particles are washed out from the machining gap,and those deposited on the surface are removed by the electrochemical reaction.Thus,using a larger inner diameter,the electrochemical reaction in the TEHECDD can be enhanced by better expulsion of the machining by-products and Joule heat,and a smooth machined surface,free of recast layers and surface defects,can be obtained.

Fig.6 EDX spectra of machined surfaces using tube electrodes with different inner diameters.

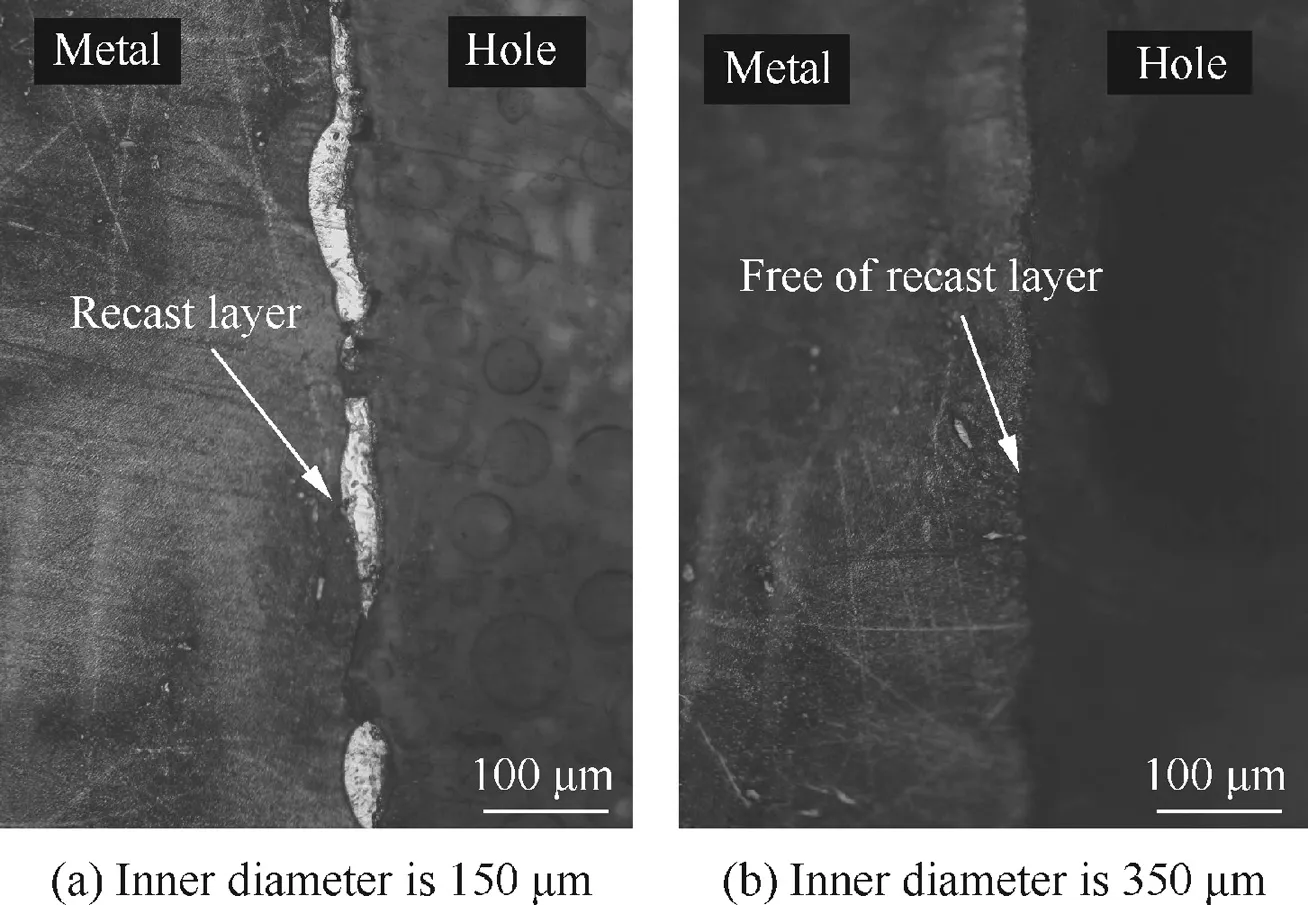

Fig.7 Comparison of recastlayers with differentinner diameters.

For the inner diameters of ?150 μm and ?350 μm,the removal of the recast layer in TEHECDD was further analyzed by the metallography experiment.The recast layer thickness was observed under a metallographic microscope after appropriate metallurgical procedures,including cutting,polishing,etching,and microscopic analysis of cross sections.The comparative results are shown in Fig.7.As seen in Fig.7(a),the machined surfacefrom the tube electrode of inner diameter ?150 μm,is irregularly covered by the recast layer,which includes many cracks,especially at the exit of the hole.In Fig.7(b),the surface of the hole obtained using the tube electrode of ?350 μm inner diameter is free of the recast layer.These results are in accordance with those from the aforementioned analyzes of the lateral surfaces.It is implied that in this hybrids process,the machining productions not only include the melted and vaporized particles generated in the EDM,but also contain hydroxide precipitates and bubbles produced by ECM.Especially for the hydroxides precipitates,the volume is several hundred-fold larger than the EDMed particles.Thus,then arrow machining gap of TEHECDD is easier to be blocked than any single process of EDM or ECM.Due to the blockage,mixed machining productions and Joule heat are difficult to be swept away from the machining gap.Under the high temperature and sharp cooling,the mixed productions including hydroxide and melting metal particles are re-solidified formed thick recast layer on the surface of the hole.Thus,using a larger inner diameter in the tube electrode,the surface quality and accuracy of TEHECDD could be remarkably improved.

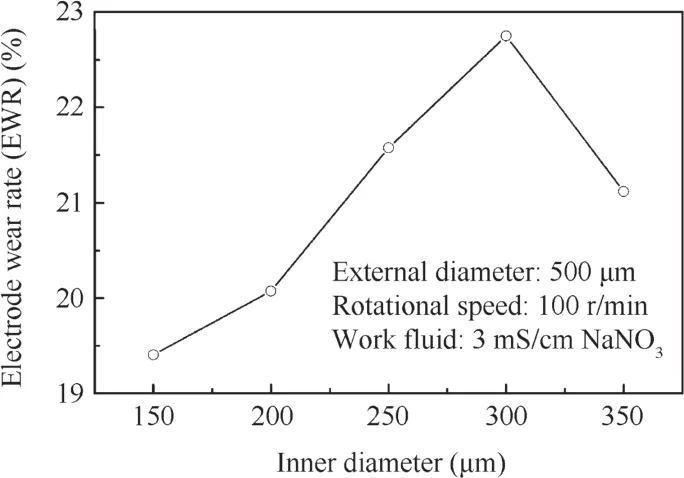

Fig.8 Effect of inner diameter on electrode wear rate(EWR).

3.4.Effects of inner-hole diameter on electrode wear rate

The EWR for different inner diameters is shown in Fig.8.It can be seen that as the inner diameter increases,the EWR increases almost linearly within the range ?150–300 μm and then decreases.That is because, for the same outer diameter,the increase in the inner diameter results in the reduction of the wall thickness of the tube electrode.Hence, for the same duration,the length of electrode wear is higher in tube electrodes with larger inner diameters.However,when the electrode of inner diameter 350 μm is employed,the MRR increases sharply,and the large lateral gap is rapidly expanded to be a large scale,as shown in Fig.3.The Joule and secondary discharge resulting to electrode wear could be dissipated in the larger machining gap.Thus,the EWR is decreased in this case.

In summary,using tube electrode with a larger inner diameter,theflushing can be improved.Whereby,the machining products can be rushed out of a narrow machining gap smoothly.Thus,with the inner diameter of tube electrode increasing,a high machining speed and larger lateral gap will be produced.Besides,a better dimensional accuracy and surface quality and considerably thin recast layer can be obtained.However,a larger inner diameter will cause a higher electrode wear rate.Hence,the optimum parameters should be selected at the set of 350 μm inner diameter based on a considerably high machining speed,surface quality,and a considerably low EWR.

4.Conclusions

In this study,a nickel-based superalloy(DZ125L)was used to investigate the machining performances of the TEHECDD technique.Tube electrodes with the same outer diameter of 500 μm but with different inner diameters of 150,200,250,300,350 μm were fabricated and used in the TEHECDD.Based on the comparison experiments,the effects of the inner diameter on the machining efficiency and surface quality of TEHECDD were investigated,and the following conclusions were drawn:

(1)The removal of the machining by-products from the lateral gap was investigated.It was found that using a tube electrode with a larger inner diameter,the by-products could be washed out more effectively.

(2)The machined surfaces were analyzed for quality,composition,and thickness of recast layer.Compared with the ?150 μm tube electrode,the ?350 μm tube electrode could be used to significantly improve the surface quality and obtain a smooth surface without defects such as cracks,scaly appendages,and recast layer.

(3)The effects of the tube electrode inner diameter on the lateral gap,machining time,and electrode wear rate were studied.When the inner diameter is as large as 350 μm,theflushing condition is improved,and higher material removal efficiency can be obtained in the drilling direction,but the length of electrode wear is higher.

Acknowledgements

The authors acknowledge thefinancial support provided by the National Natural Science Foundation of China(No.51475237),the National High-Tech Research and Development Program of China(No.2013AA040101),the Program forNew Century Excellent Talents in University(No.NCET-12-0627)of China,and the Funding of Jiangsu Innovation Program for Graduate Education(No.KYLX_0232)of China.

1.Akhtar W,Sun JF,Sun PF,Chen WY,Saleem Z.Tool wear mechanisms in the machining of Nickel based super-alloys:a review.Front Mech Eng 2014;9(2):106–19.

2.Xiong JC,Li JR,Liu SZ.Surface recrystallization in nickel base single crystal superalloy DD6.Chin J Aeronaut 2010;23(4):478–85.

3.Ding WF,Xu JH,Chen ZZ,Su HH,Fu YC.Grindability and surface integrity of cast nickel-based superalloy in creep feed grinding with brazed CBN abrasive wheels.Chin J Aeronaut 2010;23(4):501–10.

4.Wang KD,Duan WQ,Mei XS,Wang WJ.Technology to drill micro-holes without recast layer by laser on nickel-based alloy.Adv Mater Res 2012;459:303–7.

5.Fang XL,Qu NS,Zhang YD,Xu ZY,Zhu D.Improvement of hole exit accuracy in electrochemical drilling by applying a potential difference between an auxiliary electrode and the anode.J Mater Process Technol 2014;214(3):556–64.

6.Shi HH,Sasa SY.Study of turbulent flow of film cooling holes with lateral expanded exits.Chin J Aeronaut 2002;15(4):200–7.

7.Wang W,Zhu D,Qu NS,Huang SF,Fang XL.Electrochemical drilling inclined holes using wedged electrodes.Int J Adv Manuf Technol 2010;47:1129–36.

8.Zhang Y,Xu ZY,Zhu D,Xing J.Tube electrode high-speed electrochemical discharge drilling using low-conductivity salt solution.Int J Mach Tools Manuf 2015;92:10–8.

9.Coteat?a?M,Schulze HP,Sla?tineanu L.Drilling of difficult-to-cut steel by electrochemical discharge machining.Mater Manuf Processes 2011;26(12):1466–72.

10.Kitamura T,Kunieda M,Abe K.Observation of relationship between bubbles and discharge locations in EDM using transparent electrodes.Precis Eng 2015;40:26–32.

11.Lohrengel MM,Rosenkranz C.Microelectrochemical surface and product investigations during electrochemical machining(ECM)in NaNO3.Corros Sci 2005;47(3):785–94.

12.Meena VK,Azad MS,Mitra S.Effect of flushing condition on deep hole micro-EDM drilling.Int J Mach Mach Mater 2012;12(4):308–20.

13.Ekmekci B,Sayar A.Debris and consequences in micro electric discharge machining of micro-holes.Int J Mach Tools Manuf 2013;65:58–67.

14.Qu NS,Fang XL,Li W,Zeng YB,Zhu D.Wire electrochemical machining with axial electrolyteflushing for titanium alloy.Chin J Aeronaut 2013;26(1):224–9.

15.Guu YH,Hocheng H.Effects of workpiece rotation on machinability during electrical-discharge machining.Mater Manuf Processes 2001;16(1):91–101.

16.Wang J,Han FZ,Cheng G,Zhao FL.Debris and bubble movements during electrical discharge machining.Int J Mach Tools Manuf 2012;58:11–8.

17.Murray J,Zdebski D,Clare AT.Workpiece debris deposition on tool electrodes and secondary discharge phenomena in micro-EDM.J Mater Process Technol 2012;212(7):1537–47.

18.Zhang H,Xu JW.Modeling and experimental investigation of laser drilling with jet electrochemical machining.Chin J Aeronaut 2010;23(4):454–60.

19.He B,Li DC,Zhang AF,Lu Z,Ge JB,Khoa DT.Influence of oxidation on the cracks of DZ125L nickel-based superalloy thinwalled parts in laser metal direct forming.Rapid Prototyping J 2013;19(6):446–51.

20.Yang FX,Liu EZ,Zhi Z,Tong J,Ning LK.Influence of Ti content on microstructure,mechanical properties and castability of directionally solidified superalloy DZ125L.Mater Des 2014;61:41–9.

Zhang Yan is a Ph.D.candidate at the College of Mechanical and Electrical Engineering,Nanjing University of Aeronauticsand Astronautics,China.His areas of research include electrochemical machining and electrical discharge machining.

Xu Zhengyang is a prof essor at the College of Mechanical and Electrical Engineering,Nanjing University of Aeronautics and Astronautics,China.He received his Ph.D.degreefrom the same university.His current research interests are electrochemical machining,electro forming,electrical discharge machining and micro electrochemical machining.

25 July 2015;revised 21 September 2015;accepted 28 September 2015 Available online 21 December 2015

Electrical discharge

machining;

Electrochemical machining;Film-cooling hole;

Inner diameter;

Nickel-based superalloys;

Tube electrode

?2015 The Authors.Production and hosting by Elsevier Ltd.on behalf of Chinese Society of Aeronautics and Astronautics.This is an open access article under the CC BY-NC-ND license(http://creativecommons.org/licenses/by-nc-nd/4.0/).

*Corresponding author.Tel.:+86 25 84895912.

E-mail addresses:zhangyanzy@nuaa.edu.cn(Y.Zhang),xuzhy@nuaa.edu.cn(Z.Xu),xingzjun@163.com(J.Xing),dzhu@nuaa.edu.cn(D.Zhu).

Peer review under responsibility of Editorial Committee of CJA.

Production and hosting by Elsevier

http://dx.doi.org/10.1016/j.cja.2015.12.016

1000-9361?2015 The Authors.Production and hosting by Elsevier Ltd.on behalf of Chinese Society of Aeronautics and Astronautics.

This is an open access article under the CC BY-NC-ND license(http://creativecommons.org/licenses/by-nc-nd/4.0/).

CHINESE JOURNAL OF AERONAUTICS2016年4期

CHINESE JOURNAL OF AERONAUTICS2016年4期

- CHINESE JOURNAL OF AERONAUTICS的其它文章

- E ff ect of sodium tartrate concentrations on morphology and characteristics of anodic oxidefilm on titanium alloy Ti–10V–2Fe–3Al

- Eff ect of temperature on corrosion behavior of 3003 aluminum alloy in ethylene glycol–water solution

- New design of a compact aero-robotic drilling end eff ector:An experimental analysis

- Coupling behavior between adhesive and abrasive wear mechanism of aero-hydraulic spool valves

- Cathode design investigation based on iterative correction of predicted profile errors in electrochemical machining of compressor blades

- Effects of process parameters on mechanical properties of abrasive-assisted electroforming nickel