Effects of process parameters on mechanical properties of abrasive-assisted electroforming nickel

Ren Jianhua,Zhu Zengwei,Zhu Di

College of Mechanical and Electrical Engineering,Nanjing University of Aeronautics and Astronautics,Nanjing 210016,China

Effects of process parameters on mechanical properties of abrasive-assisted electroforming nickel

Ren Jianhua,Zhu Zengwei*,Zhu Di

College of Mechanical and Electrical Engineering,Nanjing University of Aeronautics and Astronautics,Nanjing 210016,China

A cathode mandrel with translational and rotational motion,which was supposed to obtain uniform friction effect on surface,was employed in abrasive-assisted electroforming for revolving parts with complex profile.The effects of current density,translational speed and rotational speed on the deposit properties were studied by orthogonal test.The tensile strength,elongation and micro hardness value were measured to find out how the factors affected the properties.The optimized results show that changes of current density affect the tensile strength of nickel layer most,while translational speed has the most remarkable influences on both elongation and micro hardness.The low rotational speed affects the properties least.In this experiment,a smooth nickel layer with tensile strength 581 MPa,elongation 17%and micro hardness 248HV is obtained by the orthogonal test.

1.Introduction

Metallic thin-wall parts of complex surface manufactured by electroforming are heavily required by modern industry, for electroforming is a precision manufacture technology or by far the most efficient way to produce these parts.By employing the principle of electrodeposition,electroforming can copy microscopic detail,reproduce accurate dimensions,and form components of controllable material property for desirablefunctions in applications such as precision mould,shaped charge liner,cryogenic upper stage main engine,1–5etc.

However,the applications of traditional electroforming process always go with some drawbacks at the electroforming layer, for example,pinholes and nodules on the surface,coarse grain size and long electroforming cycle.So far,a majority of researchers have been engaged in various kinds of additives,some of which could really reduce the grain size and enhance the strength of the deposits in electroforming process,and others could eliminate the pits and make the deposited layer surface smooth.6,7However,it is difficult to maintain the electrolyte baths because the additive agents are consumed during the electrodeposited process by decomposition and being absorbed on the cathode which leads to code position of sulfur and carbon.8,9Researchers have blamed the high-temperature ductility losses in nickel on sulfur and carbon that are supposed to give rise to the embrittlement of deposits.10

Studies made by researchers have shown that abrasiveassisted nick elelectroforming process could effectively eliminate pinholes,remove nodules,positively affect crystal nucleation,and refine the grains of layer,and thus nearmirror electroforming layer was obtained without any organic additives.11,12

Generally speaking,there are two independent cathode motions in the abrasive-assisted electroforming process to obtain friction effect on cathode surface.A pure rotational motion was designed for revolving parts electroforming,and a designed translational cathode in horizontal type was employed in complex shaped non-rotating parts electroforming.However, for revolving parts with complex surface in abrasive-assisted nickel electroforming process,neither of the two single cathode motions would be carried out.Firstly,there are different linear velocities along the axial direction of cathode because of diverse curvature radius in pure rotational motion.Secondly,the varying electric field intensity on cathode surface for pure translational motion should be taken into consideration because it will lead to the nonuniformity in thickness of deposits.Naturally,the friction effect would also be inhomogeneous.To solve the problems mentioned above,a horizontally positioned cathode with complicated movement in combination of translation and rotation is proposed in this paper.The complex effects of current density,translational speed and rotational speed on the deposit microstructure and properties were studied by orthogonal test.The tensile strength,elongation and micro hardness values were also measured.

2.Principle and experiments

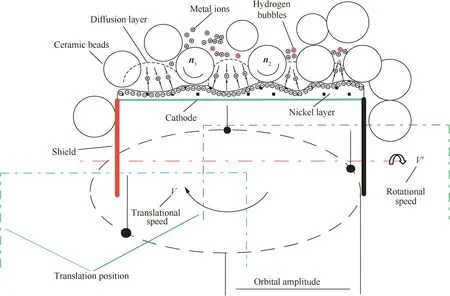

Fig.1 shows the scheme of experimental principle of abrasive assisted electro forming process with moving cathode.n1and n2are the rotation directions of ceramic beads.V is translational speed.V′is rotational speed.A cylinder mandrel is translated as well as rotated in horizontal type.In the nickel electr ofoZrming process,nonconductive hydrogen bubbles usually adhere to cathode surface impeding nickel ion deposition.The free ceramic beads filling in the space between cathode and anode were forced to polish the growing deposited layer slightly and uniformly,driving the hydrogen bubbles away,during the electroforming process.13,14The rotation of cathode was set at low speed,while the translational speed was set much higher and played the key role in driving the beads.The orbital movement of cathode mandrel was a circle.The reasons are presented below.11,12On one hand,different parts of the cathode have the same linear velocity during the cathode’s translation to make sure the polishing effect on the whole surface in uniformity.On the other hand,the rotation of cathode could maintain the cathode surface in the same electric field intensity,and achieve uniform polishing effect on circumference surface.

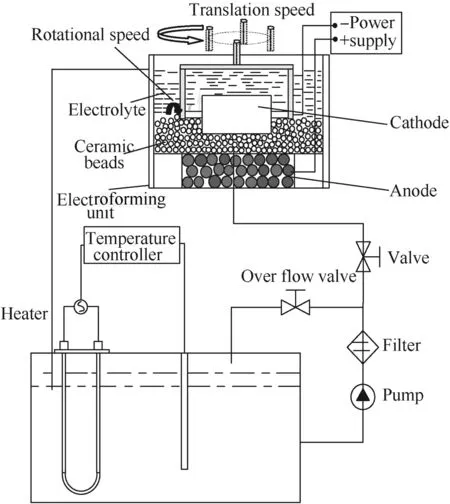

Fig.2 illustrates the schematic diagram of the experimental apparatus.The cathode’s translational movement was carried out by a planar worktable driven by stepper motor in X/Y axis linkage.And a speed control motor was employed to drive the rotation of the cathode via transmission mechanism.Nickel pellets were used as anode.A stainless steel cylinder mandrel was used as cathode in horizontal type whose deposit area was ?70 mm × 100 mm.Free ceramic beads in 0.8–1.2 mm diameter were chosen as the abrasive medium filling the space between the electrodes to maintain continuous friction on the cathode’s surface in the process of electroforming.The electrolyte was pumped from the storage bath to the electroforming unit and flowed through the gap between cathode and anode.Both the electrolyteflushing and the moving cathode motion served as the agitation of the electrolyte.The electrolyte’s temperature was controlled by a heater and temperature controller.Be fore deposition,the cathode was mechanically polished,degreased with organic solvent,and rinsed with ethanol.

Fig.1 Scheme of experimental principle of abrasive-assisted electroforming process with moving cathode.

Fig.2 Schematic diagram of experimental apparatus.

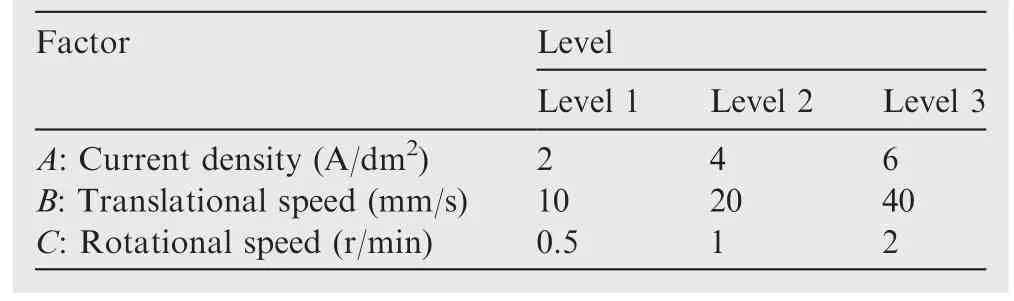

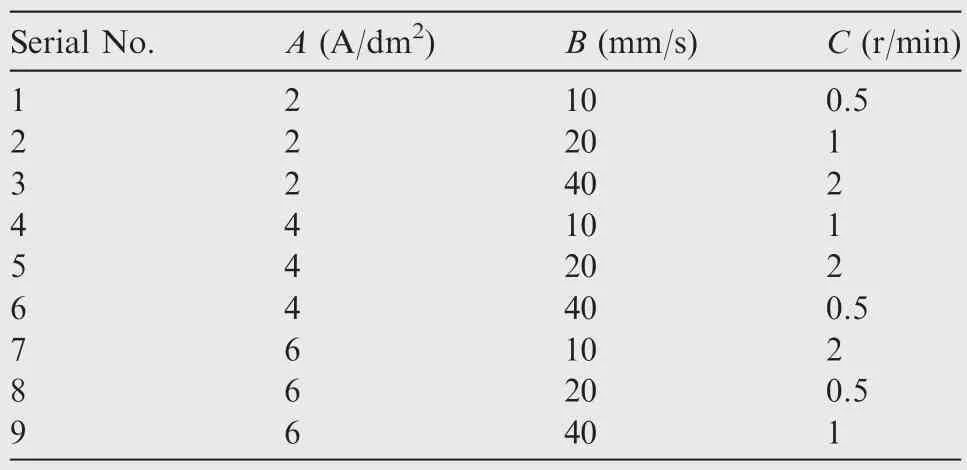

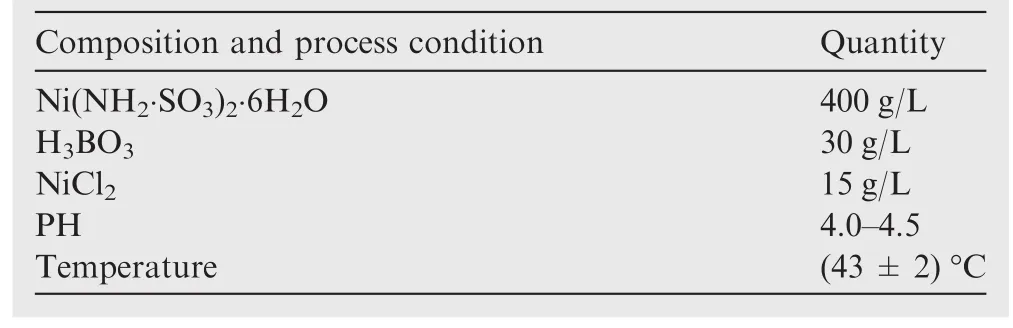

An orthogonal method was used to study the effects of the three factors:current density(A),translational speed(B)and rotational speed(C)on the mechanical properties of nickel layers,and each factor had three levels.Thus,the variable factors and levels formed an orthogonal array(Tables 1 and 2).A L9 orthogonal array was selected for optimization of the process parameters.15,16

All solutions were prepared by deionized water and analytical reagents were used.No additive was used.The solution content and the experiment condition are shown in Table 3.At the end of the process,the cathode was immediately withdrawn,rinsed with deionized water,dried and then detected.

A HITACHI S3400N SEM was used to observe the surface morphology of the samples.A HXS-1000A Vickers micro hardness tester was used to measure the micro hardness of the nickel deposits at room temperature.A load of 0.49 N was applied and kept for 15 s.Thefinal value quoted for the hardness of each deposit is the average of six times.A Instron 5566 tensile strength tester was used to measure the strength property,the thickness of the samples was kept at about 0.7 mm by controlling the current density and deposition time,and the tensile rate was kept at 0.2 mm/min.

3.Results and discussions

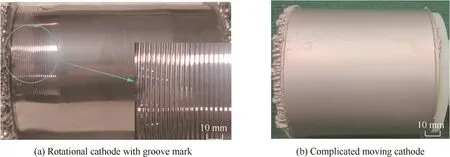

As Fig.3(a)shows,there are distinct groove marks on the surface of nickel deposit with purely rotating cathode in a very long electroforming cycle,while Fig.3(b)shows smoothsurface of nickel deposit with complicated moving cathode.The linear speed in Fig.3(a)is a little higher than that in Fig.3(b),so the surface in Fig.3(a)is brighter than Fig.3(b).17,18There is no doubt that the friction effect of ceramic beads with ordinary rotating cathode is too strong to obtain smooth-surfaced deposit layer when the cathode linear speed is at about 20–100 mm/s.The marks on the surface are just the same as the purely rotational movement of cathode.However,when a complicated moving cathode was employed,the ceramic beads were forced to move in a complicated way,achieving uniform polishing effect on circumference surface.

Table 1 Orthogonal factors and levels.

Table 2 L9 orthogonal array.

Table 3 Bath composition and process conditions of nickel electroforming.

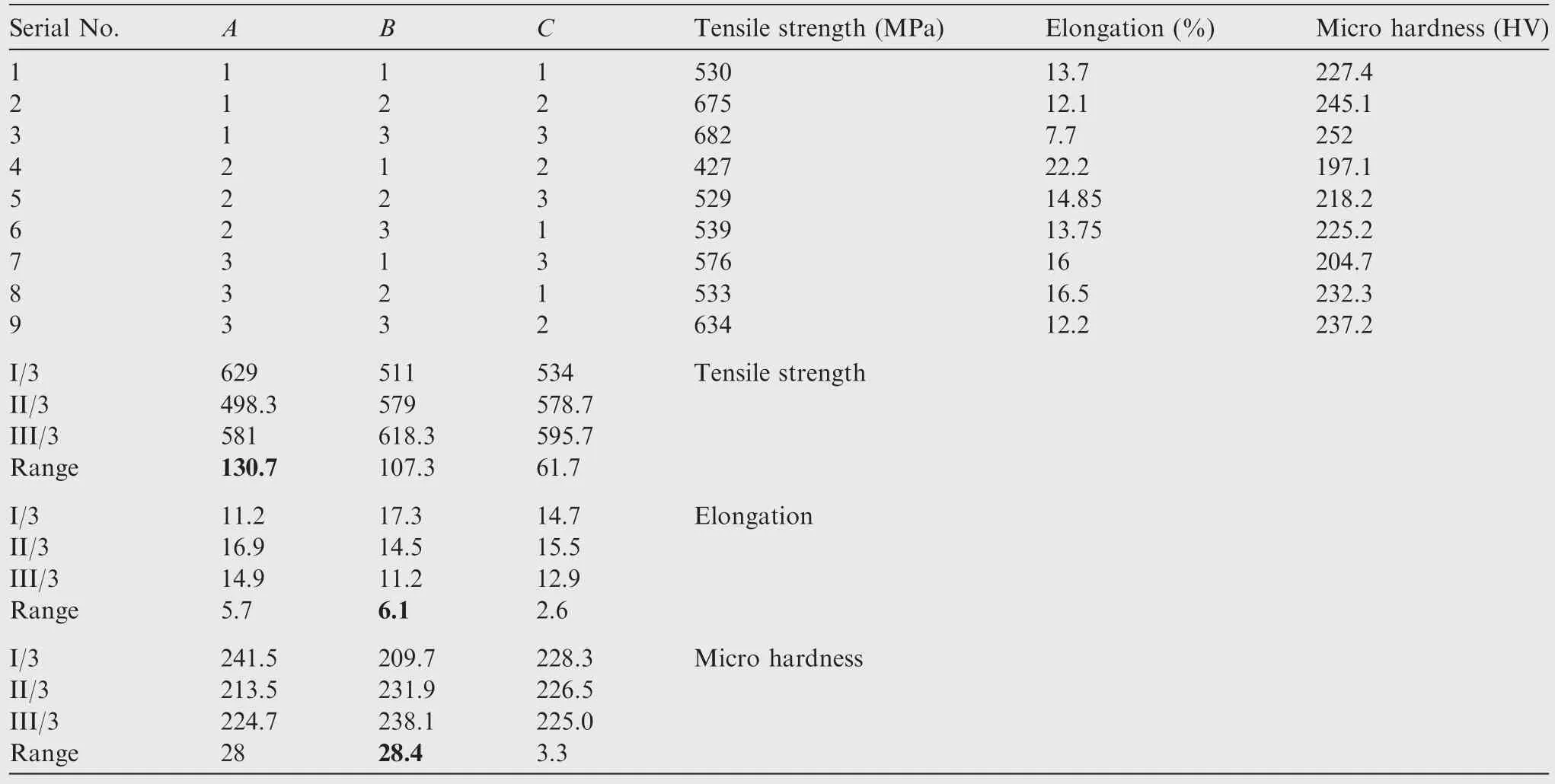

Then the results of orthogonal test are shown in Table 4,among which I,II,III show the average value of each factor under different levels respectively.The range value in Table 4 shows the degree of the effect of factors on mechanical properties;the maximum value is written in bold;the larger the value is,the more significant the effect is.Table 4 shows the tensile strength,elongation and micro hardness values of each orthogonal array group.As can be seen from Table 4,the factors influencing tensile strength arranged by the order from major to minor are current density,translational speed,and rotational speed,namely A,B,and C.In addition,the influence of current density is the most significant,and translational speed is the second.As to influence on elongation,translational speed is the most significant factor,current density is the second,and rotational speed is the last,namely B,A,and C.There is no significant difference between the first two factors.The factors with their influence on micro hardness listed from the most to the least important are translational speed,current density,and rotational speed,namely B,A,and C,and also the significance levels of first two factors are nearly equal.

The effects of current density,translational speed and rotational speed on the properties of nickel deposits are discussed as follows.

Fig.3 Abrasive-assisted nickel electroforming process when deposit grows thick at current density of 3 A/dm2.

Table 4 Tensile strength,elongation and micro hardness of electroformed nickel orthogonal array.

3.1.Effects of process parameters on tensile strength of nickel deposits

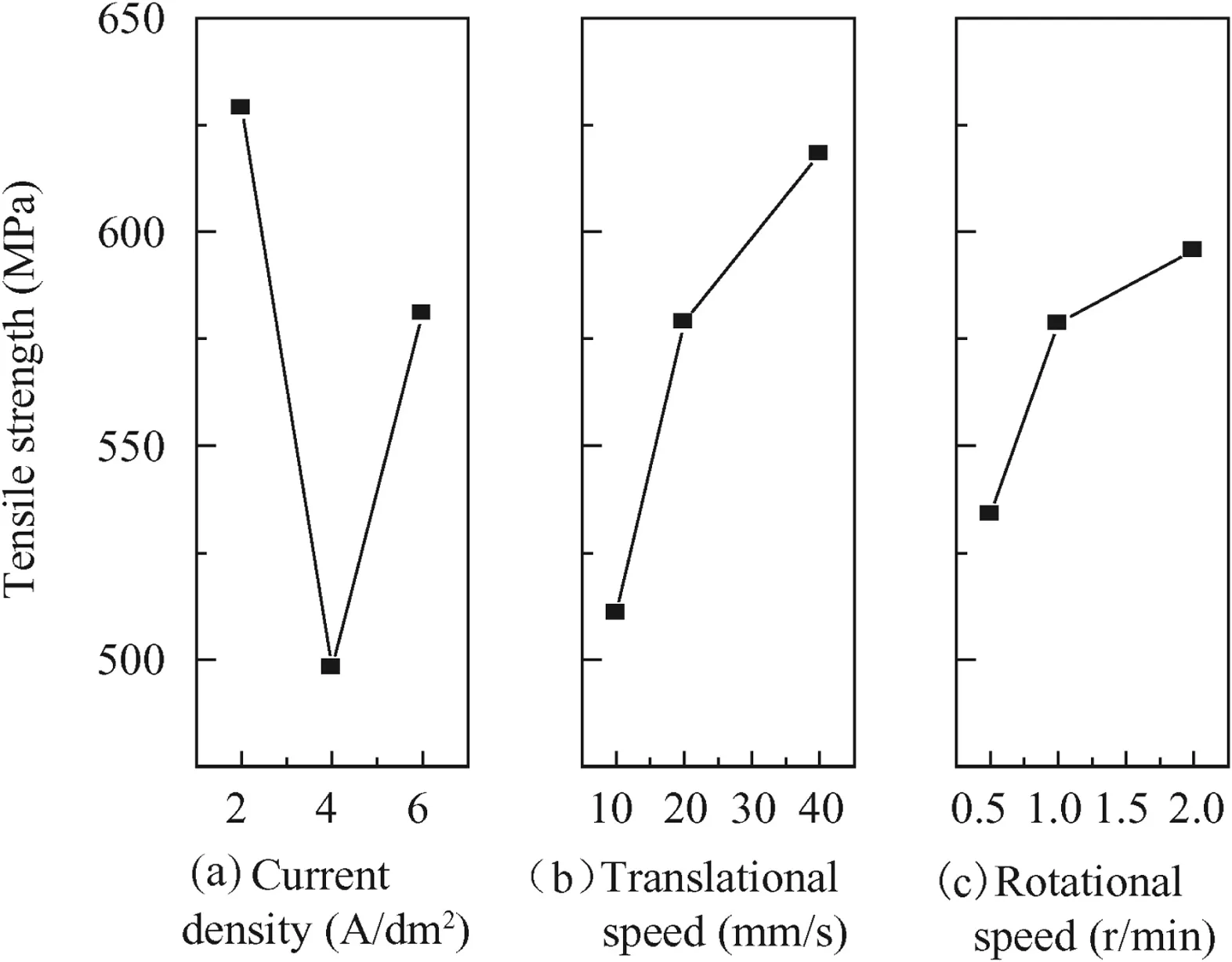

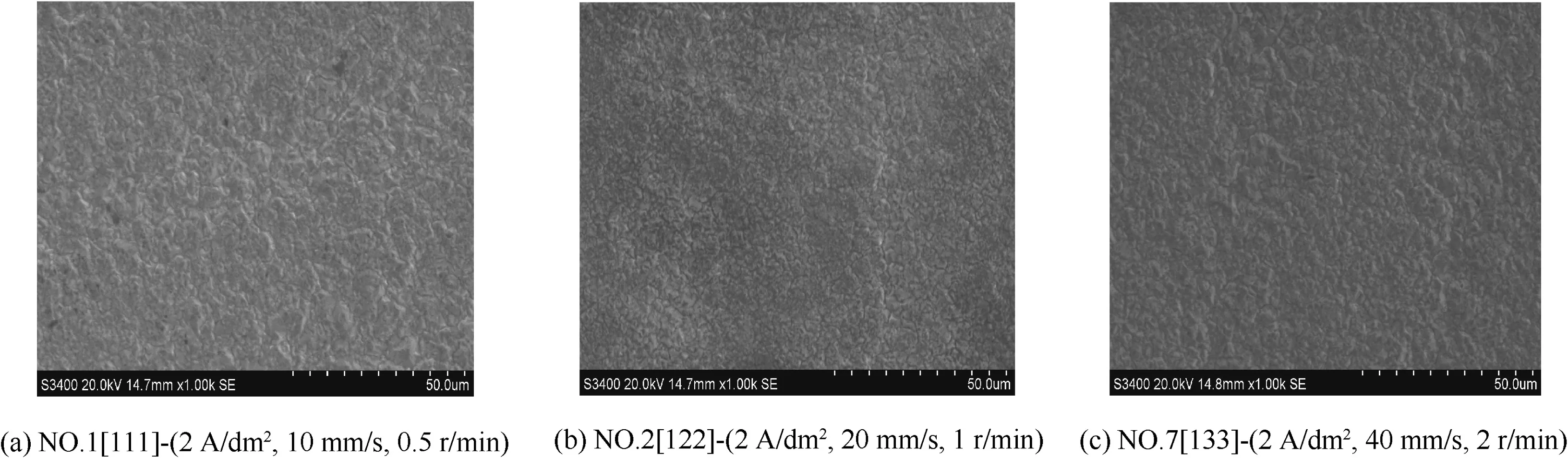

Fig.4 shows the effect of each factor on tensile strength of electroformed nickel with moving cathode that is obtained from the results of Table 4.As Fig.4(a)presents,tensile strength value of nickel electroformed decreases at first,and then rises when current density increases from 2 A/dm2to 6 A/dm2.There is a big fluctuation in the tensile strength values with the increase of current density.At the same time,there is a quick increase of tensile strength value with the increase of translational speed,as plotted in Fig.4(b).In addition,there is a positive correlation between tensile strength and rotational speed in Fig.4(c).It seems that current density is the most significant factor influencing the variation of tensile strength,either increase or decrease.However,the translational speed might be another significantly positive factor to increase the tensile strength.As shown in Fig.5,when the moving speed of cathode increases,the abrasion strength becomes more distinguishable and grains grow smaller where current density stays the same.When the cathode speed increases,the polishing can be strengthened and help to obtain smooth nickel layers with fine mechanical properties by increasing the activated points on cathode and refine the grain size.Thus,the tensile strength increases with increasing translational speed as well as rotational speed because there is a negative correlation between tensile strength and grain size.The rotational speed is so low that it can be supposed to have uniform abrasion effect on revolving parts with complicated profiles and maintain the circumference surface in the same electric field intensity.

Fig.4 Effect of each factor on tensile strength of electroformed nickel.

Fig.5 Effect of moving speed on SEM morphology of electroforming nickel with increasing translational speed and rotational speed at the same current density(No.1,2,3 from orthogonal array of Table 2).

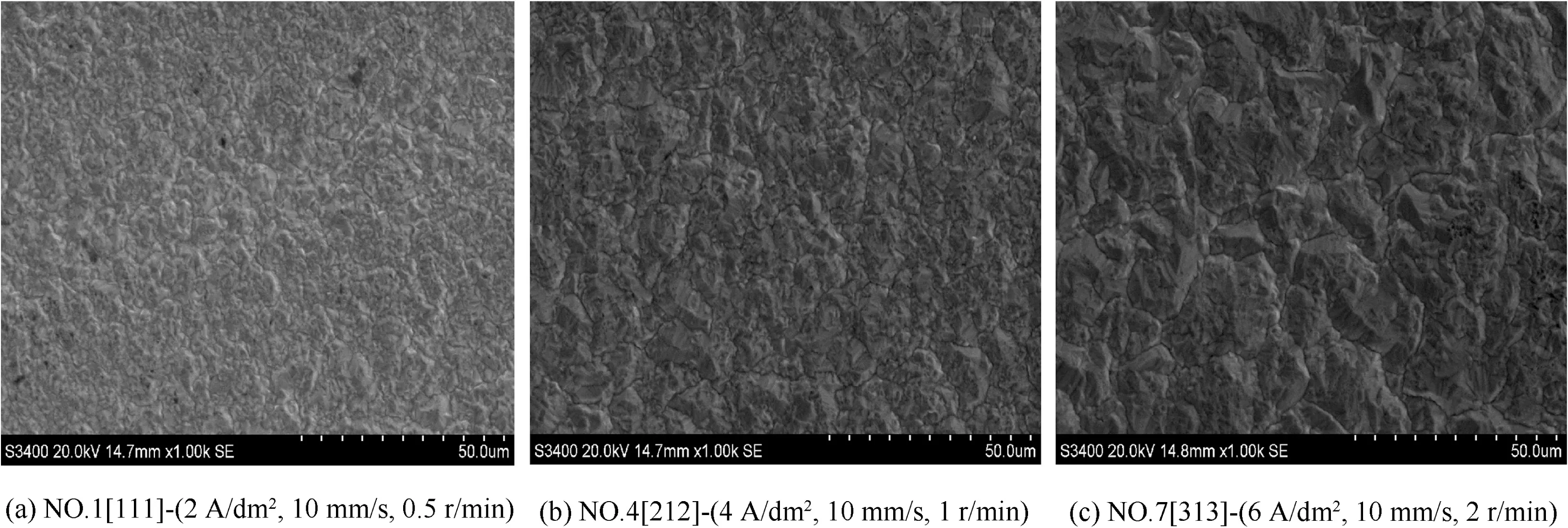

Fig.6 Effect of current density on SEM morphology of electroformed nickel with the same translational speed but increasing rotational speed(No.1,4,7 from orthogonal array of Table 2).

As shown from Fig.6,higher current density may lead to coarser crystal grains and loose structure.When current density increases,the abrasion effect is not really obvious and the grains grow bigger.So the SEM Simages are the evidence that low tensile strength can be sourced in coarse crystal grains and loose structure.Tensile strength of 4 A/dm2is lower than that of 6 A/dm2in Fig.4(a)maybe because the moving speed at 6 A/dm2is higher than that at 4 A/dm2.The tensile strength is strengthened by the free beads’polishing effect.The influence of current density on property of electroforming nickel is remarkable.Hence, for obtaining nickel layer with proper property,the current density requires tight control for slight change in it will cause much change in tensile strength.

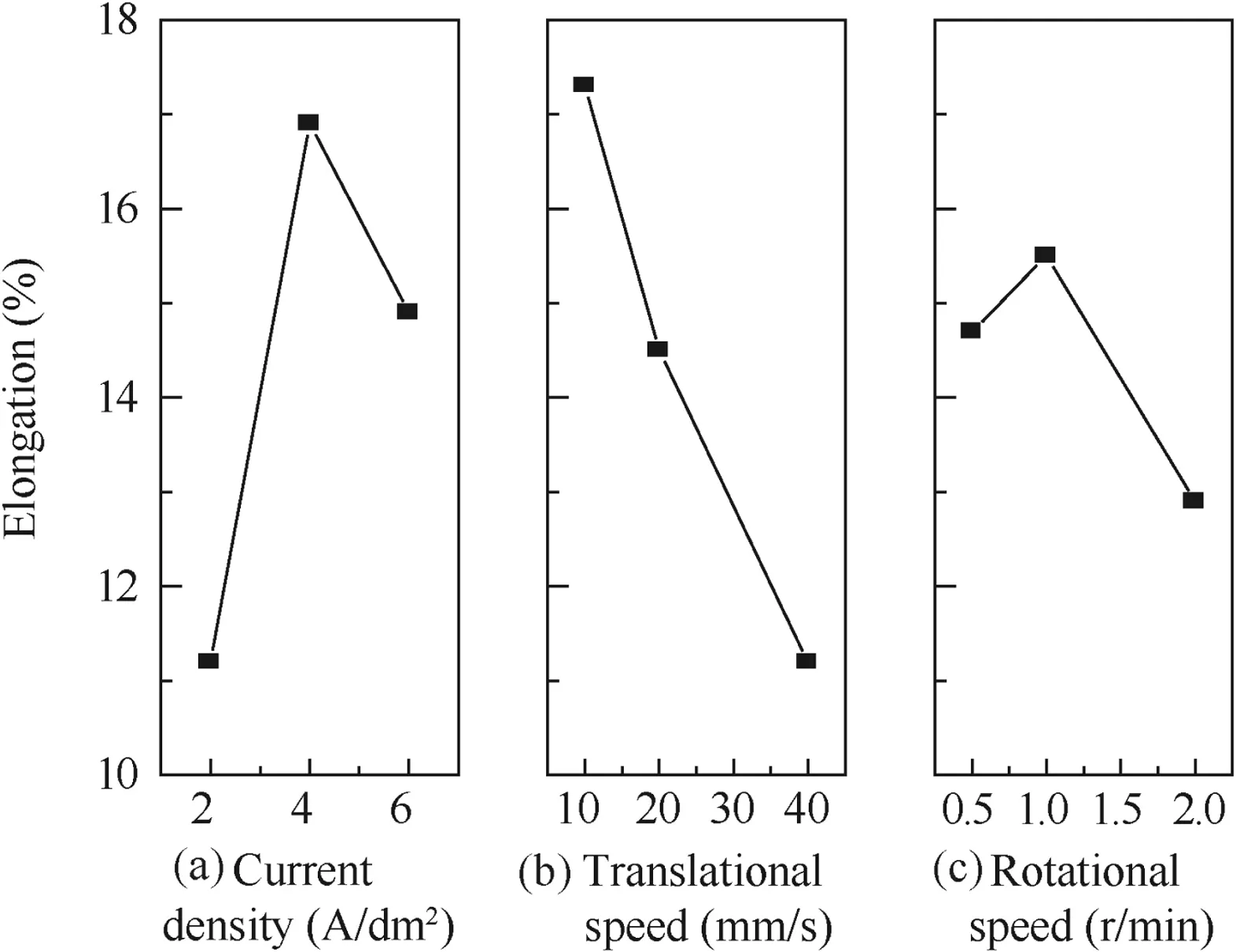

3.2.Effects of process parameters on elongation of nickel deposits

Fig.7 shows the effect of each factor on elongation of electroformed nickel with moving cathode that is obtained from the results of Table 4.As plotted in Fig.7(a),the elongation of electroformed nickel first goes up,and then goes down with current density increasing from 2 A/dm2to 6 A/dm2,just contrary to the influence on tensile strength in Fig.4(a).As shown in Fig.6,higher current density may lead to coarser crystal grains and loose structure.When tensile strength goes low,the elongation will increase.Data on the effect of current density show that a 4 A/dm2current density should be used for good elongation and high tensile strength.

When translational speed increases,the dominant trend of effect on deposits is a quick decrease of the elongation in Fig.7(b).The influence of translational speed on elongation of electroforming nickel is remarkable.As shown in Figs.4 and 5,faster translational speed may lead to higher tensile strength,and the corresponding elongation gets lower.Hence, for obtaining nickel layer with proper property,the translational speed requires tight control because slight change in it will cause much change in elongation.

In Fig.7(c),there is a small positive and then a small negative correlation between elongation and rotational speed.Data on the effect of rotational speed are so small that the rotational speed has really loose correlation with elongation.Well,the rotational speed at low range is supposed to have uniform abrasion effect.The rotational speed should be controlled low enough to get higher elongation.

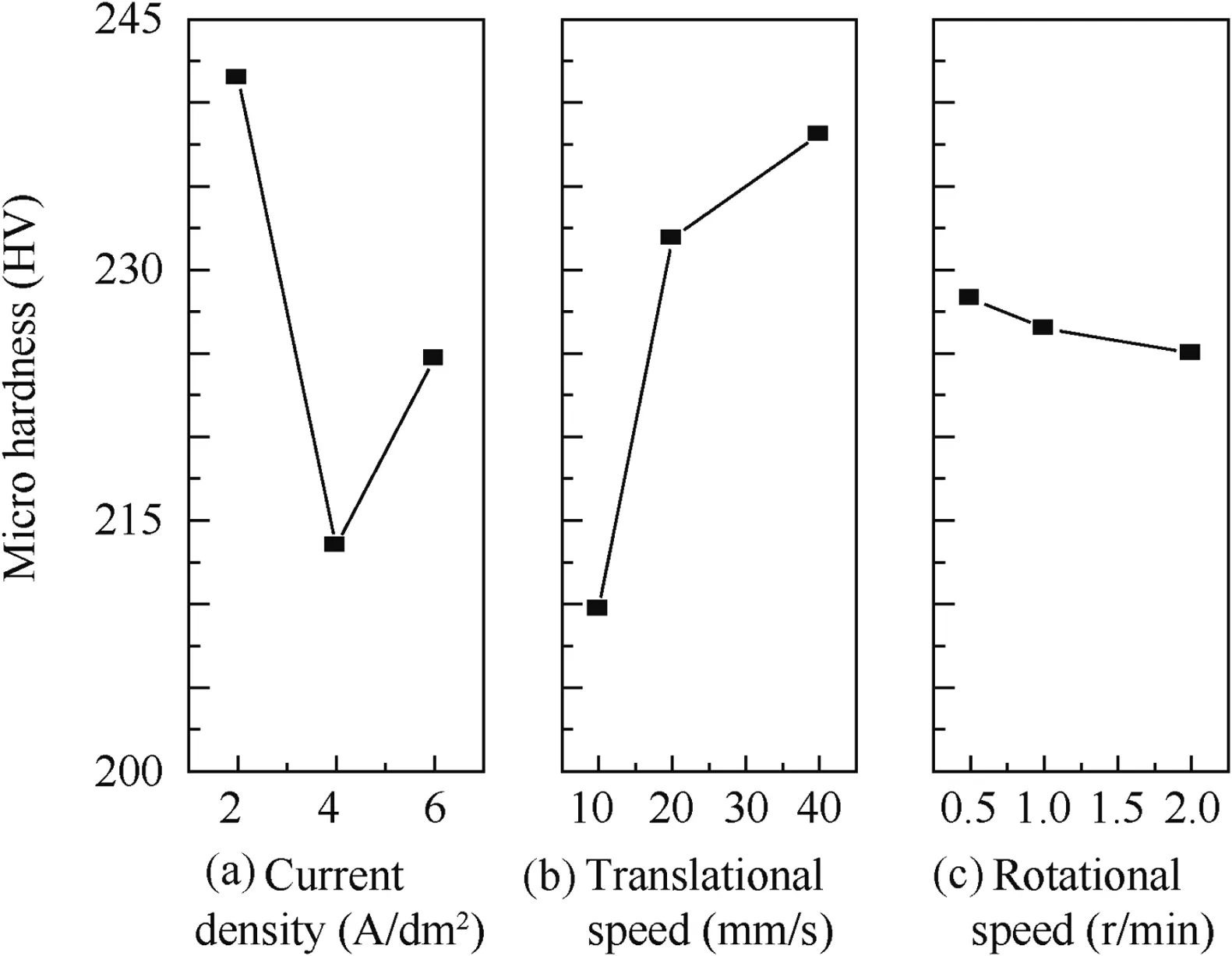

3.3.Effects of process parameters on micro hardness of nickel deposits

Fig.7 Effect of each factor on elongation of electroforming nickel.

Fig.8 Effect of each factor on micro hardness of electroforming nickel.

As Fig.8(a)presents,micro hardness values of electroformed nickel decrease at first,and then rise when current density increases from 2 A/dm2to 6 A/dm2.But there is a downward trend overall.In Fig.8(b),the dominant trend is a quick increase of micro hardness value of electroforming nickel with the increase of translational speed.Generally,hardness has the same effect tendency as tensile strength does.And there is a negative correlation between tensile strength and grain size.So the higher hardness might be attributed to the compact and fine-grained deposit structure.There is a small negative correlation between micro hardness and rotational speed in Fig.8(c).The effect of rotational speed is non-significant and negligible.

3.4.Process parameters optimization procedure

The optimization analysis process by overall equilibrium of the properties19,20is shown as follows.

As Table 4,Figs.3,6 and 7 show,translational speed has the most remarkable influences both on elongation and micro hardness.Level 20 mm/s is good in factor B in view of relatively high elongation value.To tensile strength,the influence of translational speed is not the largest,so level 20 mm/s is also the best.

Rotational speed is not a remarkable influence to any of the three properties.As shown in Figs.3,6 and 7,level 1 r/min is good in factor C in view of tensile strength and elongation.Furthermore,level 1 r/min in factor C is not the lowest to micro hardness,so level 1 r/min is the best in factor C.

Current density is the most remarkable influencefactor to tensile strength as shown in Table 4.Fig.3(a)shows that level 2 A/dm2is the best in factor A,and 6 A/dm2is the second.But level 6 A/dm2is better to elongation and it is not the lowest to micro hardness.Thus,level 6 A/dm2is the best in factor A.

4.Conclusions

(1)An orthogonal test of abrasive-assisted nickel electroforming process was carried out with moving cathode in combination of translation and rotation.The influences of current density,translational speed and rotational speed on the microstructure and properties of deposits were studied.

(2)In order to realize high-speed nickel electroforming by using high current density,faster translational speed should be applied to obtain higher mechanical properties,such as tensile strength and micro hardness.

(3)To achieve uniform friction effect on deposits for the abrasive-assisted electroforming of revolving parts with complex surface profile,both translational and rotational motion are necessary.For most of the friction effects were attributed to translational cathode,the rotation could achieve uniform polishing effect at circumferential direction of cathode surface and maintain the surface in the same electric field intensity.

(4)Changes of current density affected the tensile strength of nickel layer most,while translational speed had the most remarkable influences both on elongation and micro hardness.Slow rotational speed had the smallest influence on properties of deposits.In this experiment,best factors with A3B2C2(6 A/dm2,20 mm/s,1 r/min)were obtained by using the optimized analysis:overall equilibrium of the properties.A smooth nickel layer with comprehensive propertiesof tensile strength 581 MPa,elongation 17%and micro hardness 248HV was obtained.

Acknowledgement

Authors acknowledge financial support from the Program for New Century Excellent Talents in University of China(No.NCET-10-0074).

1.Brousseau EB,Dimov SS,Pham DT.Some recent advances in multi-material micro-and nano-manufacturing.Int J Adv Manuf Technol 2010;47(1–4):161–80.

2.Qu NS,Qian WH,Hu XY,Zhu ZW.Preparation of a microprism Ni-Ceo2 nanocomposite mold by electroforming.Mater Manuf Processes 2014;29(1):37–41.

3.Huang MS,Ku HH.Microinjection molding of light-guided plates using LIGA-likefabricated stampers.J Appl Polym Sci 2011;122(5):3446–55.

4.Larson C,Smith JR.Recent trends in metal alloy electrolytic and electrolessplating research:a review.TransIMF 2011;89(6):333–41.

5.Zhong ZW.Recent advances in polishing of advanced materials.Mater Manuf Processes 2008;23(5):449–56.

6.Oliveira EM,Finazzi GA,Carlos IA.Influence of glycerol,mannitol and sorbitol on electrodeposition of nickel from a Watts bath and on the nickel film morphology.Surf Coat Technol 2006;200(20):5978–85.

7.Stoychev D,Vitanova I,Buyukliev R,Petkova N,Popova I,Pojarliev I.Effect of the structure of aromatic disulphides on some physico-mechanical properties of electrodeposited copper coatings.J Appl Electrochem 1992;22(10):987–90.

8.Dini JW,Johnson HR,Saxton HJ.Influence of sulfur content on the impact strength of electroforming nickel.Electrodeposition Surf Treat 1974;2(3):165–76.

9.Dini JW,Johnson HR.Electroforming of a throat nozzle for a combustion facility.Plat Surf Finish 1977;64(8):44–51.

10.Dini JW,Johnson HR.High-temperature ductility of electrodeposited nickel.Sandia Laboratories;1977 Aug.Report No.:SAND 77–8020.

11.Zhu ZW,Zhu D,Qu NS,Wang K,Yang JM.Electroforming of revolving parts with near-polished surface and uniform thickness.Int J Adv Manuf Technol 2008;39(11–12):1164–70.

12.Li XL,Zhu ZW,Zhu D,Zhang Y.Orbital-abrasion-assisted electroforming of non-rotating parts.J Wuhan Univ Technol Mater 2011;26(5):827–31.

13.Watanabe T.Nanoplating–microstructure formation theory of plated films and a database of plated films.Nano plating–microstructure formation theory of plated films and a database of plated films.Elsevier Science;2004.p.118–56.

14.Zhu D,Zhu ZW,Qu NS.Abrasive polishing assisted nickel electroforming process.CIRP AnnManufTechnol2006;55(7):193–6.

15.Zhao F,Zhu D,Xue YJ,Zhang WF.Effects of process parameters on composite electrodeposition of Ni-nano-La2O3.Surf Technol 2004;33(2):52–4[Chinese].

16.Surekar SH,Bhatwadekar SG,Kharche WG,Bilgi DS.Determination of principle component affecting material removal rate in electrochemical machining process.IntJEngSciTechnol 2012;4:2402–8.

17.Zhu ZW,Zhu D,Qu NS,Lei W.Electrodeposition of bright nickel coating under perturbation of hard particles.Mater Des 2007;28(6):1776–9.

18.Zhang Y,Zhu ZW,Zhu D.Effect of attrition on mechanical properties of electroforming nickel.Chin J Nonferrous Metals 2012;22(5):1377–82[Chinese].

19.Montgomery DC.Design and analysis of experiments.New York:John Wileyamp;Sons;2008.p.4–50.

20.Yu Q,Zeng Y,Xu K,Qu NS,Zhu D.Research on anode vibration and wire electrode travelling in micro wire electrochemical machining.China Mech Eng 2014;25(3):295–9[Chinese].

REN Jianhua is currently a Ph.D.candidate at College of Mechanical and Electrical Engineering,Nanjing University of Aeronautics and Astronautics.His research interests include electrochemical machining,electroforming,and micro-electrochemical machining.

ZHU Zengwei is currently a prof essor in Nanjing University of Aeronautics and Astronautics.His research interests include electrochemicalmachining,electroforming,and micro-electrochemical machining.

ZHU Di is currently a prof essor in Nanjing University of Aeronautics and Astronautics.His research interests include electrochemical machining,electroforming,and micro-electrochemical machining.

11 January 2016;revised 16 February 2016;accepted 28 March 2016

Available online 22 June 2016

Abrasive;

Cathode compound motion;Electroforming;

Mechanical properties;

Nickel

?2016 Chinese Society of Aeronautics and Astronautics.Production and hosting by Elsevier Ltd.Thisisan open access article under the CC BY-NC-ND license(http://creativecommons.org/licenses/by-nc-nd/4.0/).

*Corresponding author.

E-mail addresses:renjianrun@163.com(J.Ren),zhuzw@nuaa.edu.cn(Z.Zhu),dzhu@nuaa.edu.cn(D.Zhu).

Peer review under responsibility of Editorial Committee of CJA.

Production and hosting by Elsevier

http://dx.doi.org/10.1016/j.cja.2016.05.001

1000-9361?2016 Chinese Society of Aeronautics and Astronautics.Production and hosting by Elsevier Ltd.

This is an open access article under the CC BY-NC-ND license(http://creativecommons.org/licenses/by-nc-nd/4.0/).

CHINESE JOURNAL OF AERONAUTICS2016年4期

CHINESE JOURNAL OF AERONAUTICS2016年4期

- CHINESE JOURNAL OF AERONAUTICS的其它文章

- E ff ect of sodium tartrate concentrations on morphology and characteristics of anodic oxidefilm on titanium alloy Ti–10V–2Fe–3Al

- Eff ect of temperature on corrosion behavior of 3003 aluminum alloy in ethylene glycol–water solution

- New design of a compact aero-robotic drilling end eff ector:An experimental analysis

- Coupling behavior between adhesive and abrasive wear mechanism of aero-hydraulic spool valves

- Cathode design investigation based on iterative correction of predicted profile errors in electrochemical machining of compressor blades

- Eff ect of tube-electrode inner diameter on electrochemical discharge machining of nickel-based superalloy