Study on Preparation and Properties of Grease Based on Ultra fi ne Bentonite Powder

(Department of Military Oil Application & Management Engineering, Logistical Engineering University, Chongqing 401311)

Study on Preparation and Properties of Grease Based on Ultra fi ne Bentonite Powder

Wang Jing; Guo Xiaochuan; Jiang Mingjun; He Yan

(Department of Military Oil Application & Management Engineering, Logistical Engineering University, Chongqing 401311)

The feasibility for preparation of ultra fi ne bentonite powder by different milling methods was studied. And the comparison of comprehensive performance between ultra fi ne bentonite grease and traditional bentonite grease was also investigated. The results indicated that the statistic Z-average size of ultra fi ne bentonite prepared by sand milling was 250 nm with a narrow size distribution and the lattice structure of ultra fi ne bentonite maintained good character despite a slight distortion occasioned. The mechanical stability, colloid stability, antiwear ability and friction-reducing property of ultra fi ne bentonite grease were superior to the traditional one.

ultra fi ne bentonite; preparation; grease; mechanical stability; tribology

1 Introduction

In the critical period of military revolution, a series of new equipment are urgently needed by the military which can improve the working condition of military equipment to operate at high temperature and high speed and under heavy load which should raise the requirements for lubricating grease with excellent performance, covering especially the high-temperature, anti-wear and frictionreducing properties and the anti-shear performance.

Bentonite grease with high dropping point, good heat resistance and chemical stability can satisfy the needs of different working conditions. Especially in aviation lubricating grease products, bentonite grease occupies an important position. For example, there are fi ve bentonite grease products made by Shell among its seven aerial lubricating grease products. At the same time bentonite grease is also widely used in the equipment of metallurgy, casting and rolling, papermaking machinery and cement production[1].

But the existing bentonite grease has some disadvantages, such as poor performance of anti-shear and thickening ability[2-3], which can greatly restrict the promotion and application of bentonite grease.

At the same time, with the rapid development of nano materials and nano technology, ultra fi ne powder thanks to its excellent physical and chemical properties of speci fi c surface area, high surface activity, strong adsorption capacity, low sintering temperature and high sintering strength[4-5]makes the ultrafine processing of mineral raw materials in new high-tech industry more and more indispensable. In the lubrication field, a large scale investigation of ultrafine powder used as lubricating oil additive has been reported[6-10]. The excellent extreme pressure, anti-wear and friction-reducing performance of ultrafine powder has captured more and more attention, and, nevertheless, the ultrafine powder used as grease thickener has rarely been reported[11-15].

In this paper, the feasibility for preparation of ultrafine bentonite powder by different milling methods was studied. And the effect of ultrafine bentonite powder serving as a thickener on the performance of grease has been investigated, which has overcome the shortcomings of traditional bentonite grease, improved its performance and broadened the range of application with greater theoretical and practical signi fi cance.

2 Experimental

2.1 Materials

The organic bentonite modi fi ed with octadecyltrimethylammonium chloride (OTAC) was commercially obtained from the Fenghong New Material Co., Ltd (Zhejiang, China). The ethanol (analytical reagent) was purchased from the Kelong Chemical Co., Ltd (Chengdu, China). Naphthenic oil T110 was purchased from Nynas (Sweden). The paraf fi nic oil MVI 500 and synthetic oil PAO8 were purchased from SINOPEC Corp.

2.2 Preparation of ultra fi ne bentonite (UB)

(1) Preparation of UB by ball milling method

The organic bentonite was mixed with ethanol under mechanical stirring for 30 min. Then the mixture was ground in the ball mill with a slurry concentration of 20% for 4 h by applying a milling speed of 350 r/ min. Finally, the slurry was poured out in a sealed bottle for further use.

(2) Preparation of UB by sand milling method

After drying, the organic bentonite and ethanol were mechanically mixed in 30 min to obtain a slurry of required concentration. Then the slurry was ground by a sand mill (Yinjun Machinery Co., Ltd., Shanghai, China) for a scheduled time. Finally, the slurry was poured out in a sealed bottle for further use.

2.3 Characterization of the UB

The size distribution of UB was taken for analysis by a nanoparticle size and zeta potential analyzer (Malvern Instrument Ltd., the United Kingdom).

Infrared spectroscopic measurements of UB samples were obtained using a 577 Fourier infrared spectrometer (resolution: 4 cm-1; wavenumber range from 400 to 4 000 cm-1; PerkinElmer, USA) by the KBr pellets method.

Powder X-ray diffraction (XRD) patterns of UB samples were recorded on a Shimadzu Lab XRD 6100 diffractometer with Cu Kα radiation (λ =1.540 56?; Shimadzu Corporation, Japan) operating at 40 kV and 30 mA and scanning from 2° to 60° of 2θat a rate of 2(°)/min. The corresponding basal (d001) spacing was derived from the first order reflections by applying the Bragg law.

2.4 Preparation of ultra fi ne bentonite grease (UBG)

The UBG was prepared according to the following procedure. Firstly, about 60% of the total base oil and the UB (prepared by sand milling method) slurry were added into a stirred vessel. Then the mixture was heated to 90 ℃ under stirring for about 1 h to evaporate all ethanol and make the mixture homogeneous. Secondly, when the mixture was slowly cooled down to room temperature, a certain amount of ethanol was added and the mixture was continuously stirred for about 20 min. And then the remaining base oil was added to the vessel. After that, the mixture was stirred for about 20 min before being heated up to 140 ℃ and the mixture was maintained at this temperature for about 10 min. The grease was obtained after being homogenized three times by a triple-roller mill.

The traditional bentonite greases (abbreviated as TBG) was prepared following the same procedure mentioned above in order to exclude the influence of preparation process on the properties of grease.

2.5 Characterization of UBG and TBG

The dropping point, penetration and oil separation of the UBG and TBG samples were characterized according to the standard methods GB/T 3498—2008, GB/T 269—1991 and SH/T 0324—2010, which were similar to ASTM D2265, ASTM D217 and FED-STD-791(method 321), respectively. The physicochemical properties of the UBG and TBG samples are outlined in Table 1.

The mechanical stability, antiwear ability and frictionreducing property of UBG and TBG were characterized according to the standard methods GB/T 269—1991 and SH/T 0204—2004, which were similar to FED-STD-791(method 313) and ASTM-D2266, respectively.

3 Results and Discussion

3.1 Effect of different milling methods on particle size and structure of bentonite

3.1.1 Characterization of the UB samples prepared by ball milling method

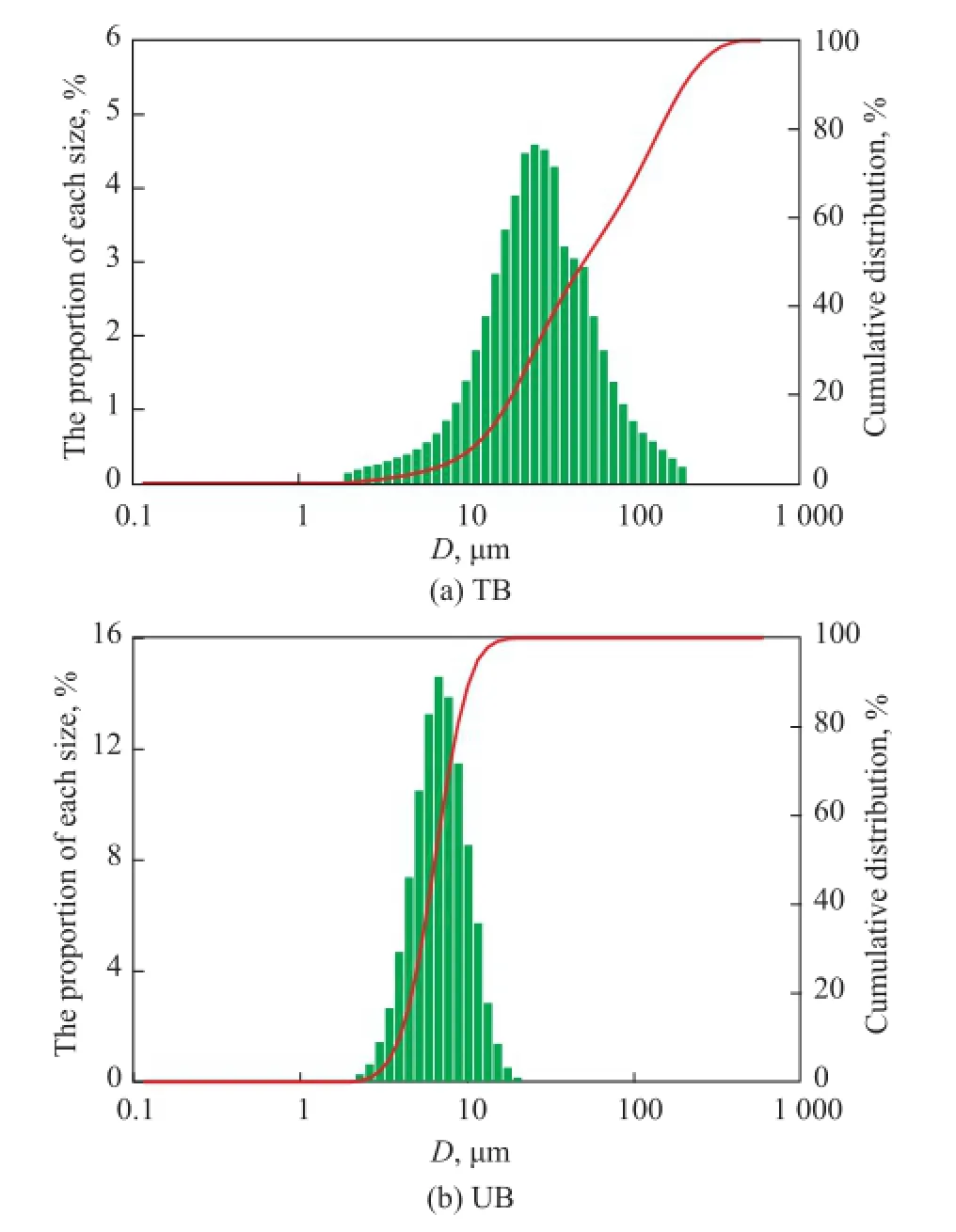

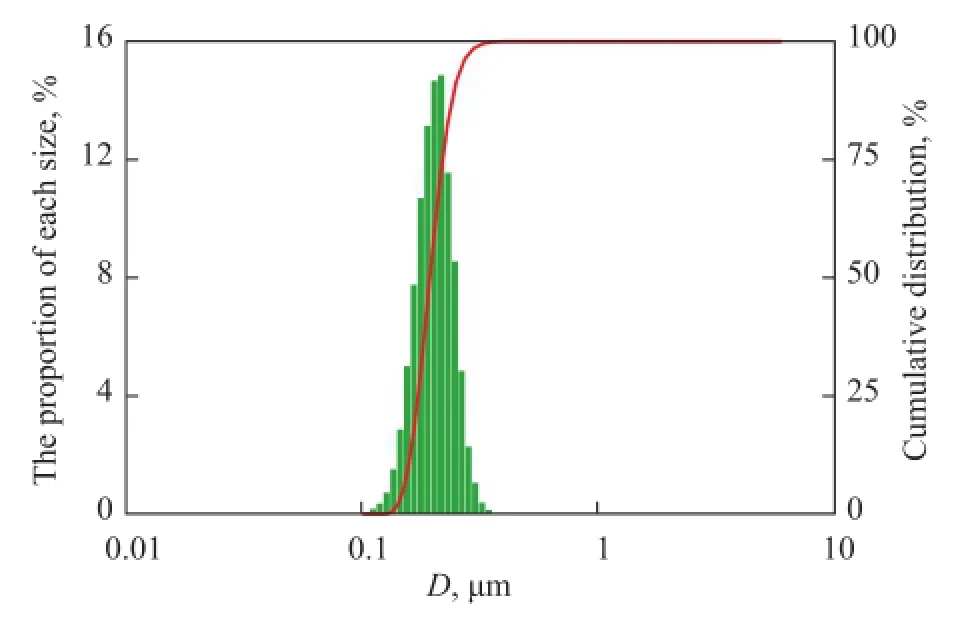

Figure 1 shows the size distribution of UB prepared by ball milling method. The curve represents cumulative distribution of the particle size and the histograms represent the proportion of each particle size. It can be seen from the graph that the size distribution of traditional bentonite (abbreviated as TB) is very wide with a statistic median particle diameter (D50) of 36.89 μm. After ball milling, the particle size distributes in a range of 2—20 μm and theD50is 5.3 μm.

Figure 1 Particle size distribution of bentonite samples

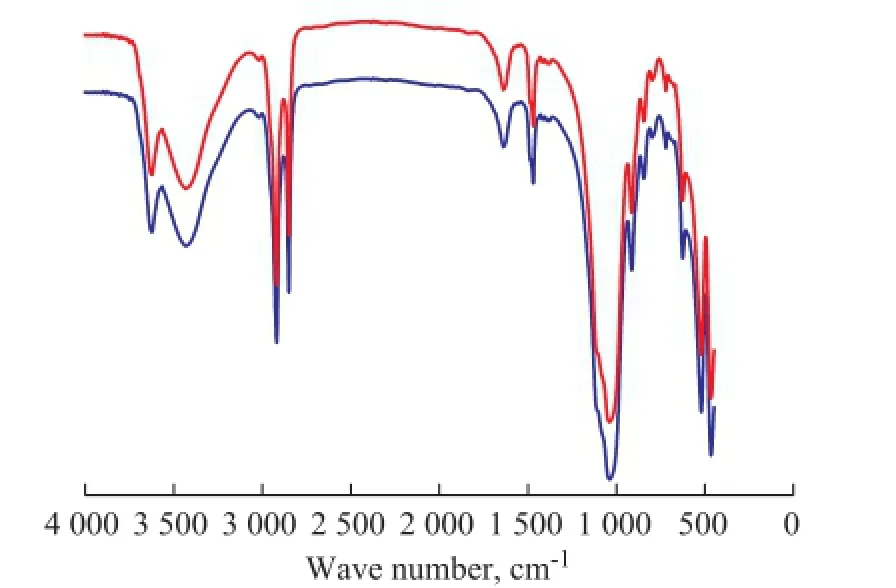

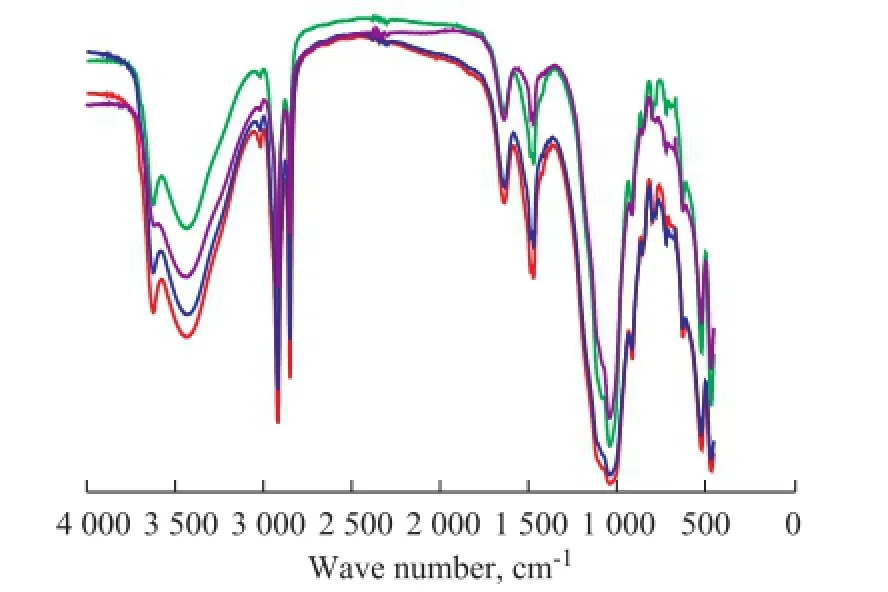

The Fourier transform infrared spectra of TB and UB samples are shown in Figure 2. Adsorption peaks at 3 624 cm?1and 3 431 cm?1are assigned to the stretching vibration of —OH units which are the characteristic peaks of water molecules within the bentonite interlayer, while the adsorption peak at 1 645 cm?1is assigned to the flexural vibration of water molecules. A big sharp peak at 1 050 cm-1corresponding to the asymmetric stretching vibration of Si—O—Si groups is the typical infrared peak of bentonite. The peaks near 794 cm-1and 524 cm-1are attributed to stretching vibrations of SiO4and Si—O—Mg groups, respectively.

The strong absorption peaks at 2 920 cm-1, 2 851 cm-1and 722 cm-1which indicate the stretching vibrations of—CH—CH3— and —C—(CH2)n—C— groups suggest few changes in the infrared spectra of organic bentonite before and after ball milling. The various characteristic peaks show that the UB can still keep its functional groups, which can reflect its structural integrity on one side.

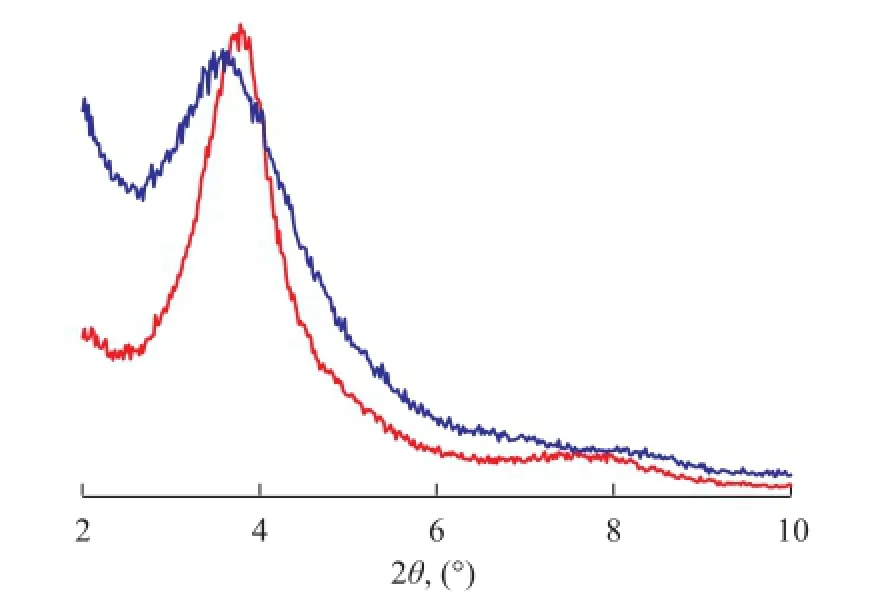

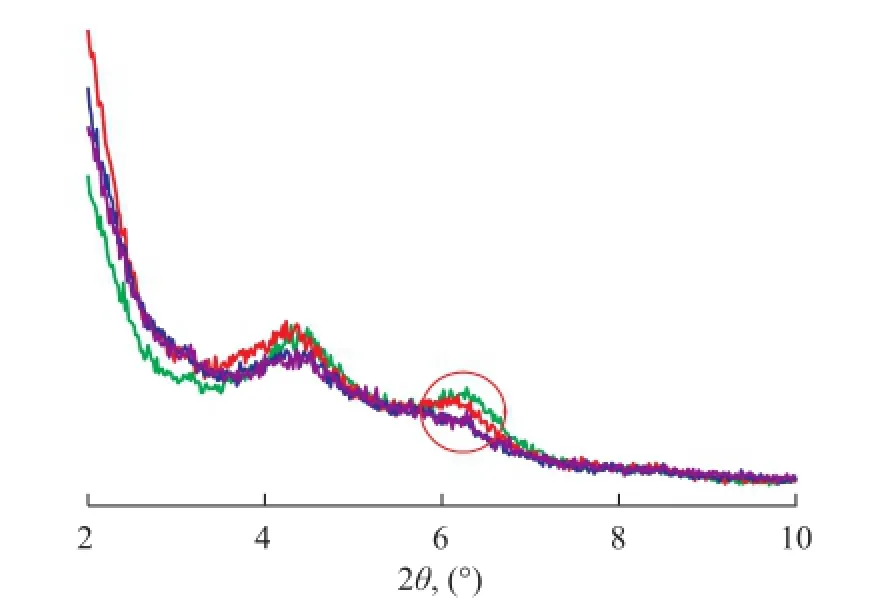

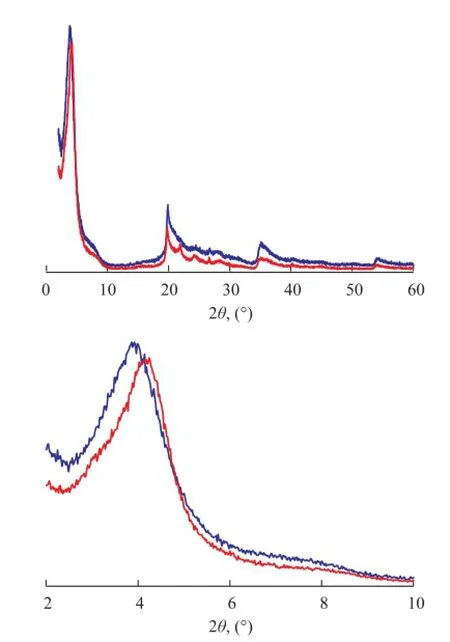

Figure 3 illustrates the XRD spectra of TB and UB samples. In comparison with the traditional bentonite, the fi rst peak position, sharpness and symmetry of UB’s diffraction peak are changed. The 2θof fi rst peak changes from 4.02° to 3.84°. According to the Bragg equation, the interlayer spacing of UB expands from the original 2.19 nm of TB up to 2.30 nm because of insertion of ethanol into the interlayer. Compared with XRD spectra of the traditional bentonite, there is obviously passivation of the fi rst peak of UB, which occurs owing to the decrease of its order degree of crystal structure and lattice distortion during the mechanical ball-milling process. During the mechanical ball-milling process, the decrease of particle size leads to the broadening of UB’s diffraction peaks and reduction of the symmetry of XRD spectra of UB. But the ultra fi ne bentonite can keep its crystal structure which is also confirmed by the infrared spectroscopic analysis mentioned above.

Figure 2 The FT-IR spectra of organic bentonite

Figure 3 The XRD spectra of organic bentonite

The above-mentioned results show that the ultrafine organic bentonite powder can be obtained by the ball milling method. But the particle diameter is quite large that cannot meet the requirements. Therefore, theinfluence of different grinding time on the particle size and structure of organic bentonite was investigated to obtain the UB samples with smaller particle size and more uniform size distribution.

As shown in Figure 4, with the increase of grinding time, the characteristic peaks of organic bentonite are gradually passivated. For instance, the stretching vibration peak of —OH radical at 3 624 cm-1has basically disappeared after 20 h. This phenomenon indicates the delamination of organic bentonite leading to the reduction of interlayer water and gradual disappearance of characteristic peaks.

Figure 4 The FT-IR spectra of organic bentonite samples prepared at different grinding time

The XRD spectra of organic bentonite samples prepared at different grinding time are shown in Figure 5. It can be seen from Figure 4 that after being milled for 8 h the organic bentonite has shown significant change of the fi rst peak position, sharpness and symmetry of its spectral line. The peak at 6° has completely disappeared after being milled for 16 h, indicating to the lattice distortion and a decreased crystal structure order degree because of mechanical force during the ball milling process. The results of FT-IR spectrometry and XRD spectroscopy con fi rm the damage of organic bentonite structure caused by ball milling for an overlong grinding time.

Figure 5 The XRD spectra of organic bentonite samples prepared at different grinding time

3.1.2 Characterization of the UB prepared by sand milling method

It can be learned from the above experiment that the decrease of particle size of organic bentonite can be achieved by the ball milling method. But due to the design limitation of ball mill, the particle size of the prepared organic bentonite is still greater than 1 μm which cannot meet the requirement. And the results of FT-IR spectra and XRD spectra indicate the damage of organic bentonite structure caused by ball milling for an overlong grinding time. Therefore, the sand milling method was investigated to obtain the UB with a smaller particle size of less than 500 nm and a more uniform size distribution. Figure 6 shows the size distribution of UB prepared by the sand milling method. It can be seen from Figure 6 that the particle size distribution of UB reaches 100—400 nm along with a narrow size distribution and a D50of 250 nm so that the sand milling method can decrease the bentonite particle size signi fi cantly.

Figure 6 Particle size distribution of UB

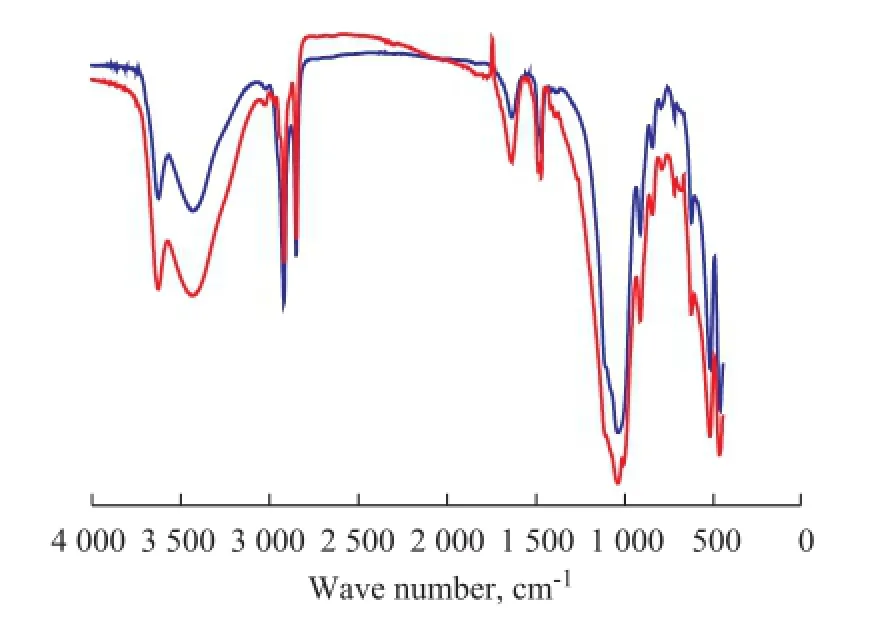

As shown in Figure 7, the FT-IR spectra of TB and UB samples prepared by the sand milling method suggest that there is little difference between the FT-IR spectra of TB and UB. And the emergence of all kinds of characteristic peaks shows that organic bentonite can still retain its functional characteristics during the sand milling process, which also re fl ects its structural integrity.

Figure 7 The FT-IR spectra of organic bentonite

Figure 8 shows the XRD spectra of TB and UB prepared by the sand milling method. The 2θof the first peak changes from 4.26° of TB to 3.92° of UB, which means that the interlayer spacing of UB expands from the original 2.07 nm of TB up to 2.25 nm because of the insertion of ethanol into the interlayer. In general, the inconspicuous change of the XRD spectra of TB and UB indicate that UB can keep its crystal structure in spite of the milling process which was also confirmed by the infrared spectroscopic tests mentioned above.

3.1.3 Comprehensive performance of UBG and TBG

Figure 8 The XRD spectra of organic bentonite

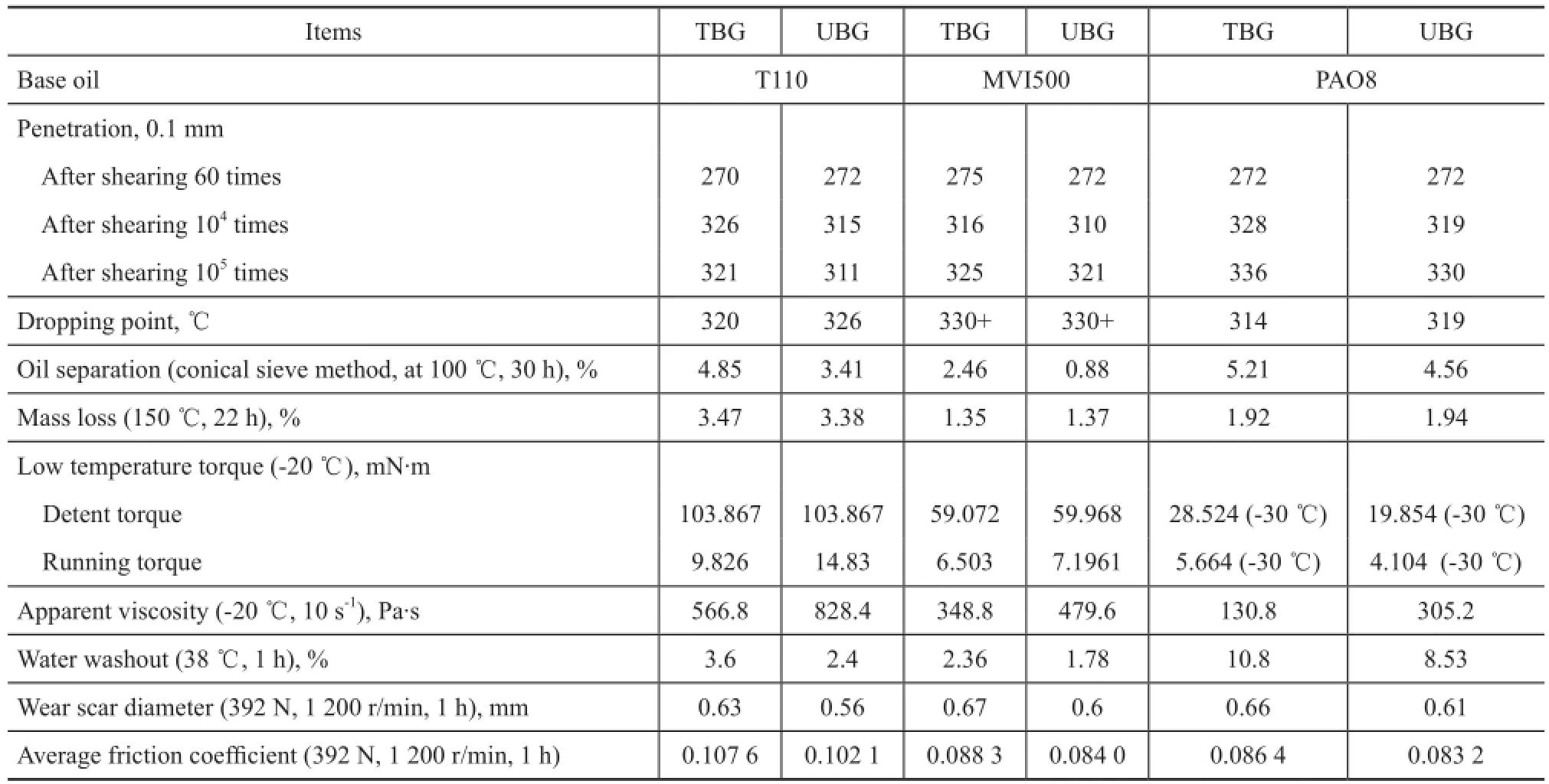

The comprehensive performance of UBG and TBG formulated with different base oils is shown in Table 1. It can be seen from Table 1 that the mechanical stability of UBG is superior to the traditional one. In comparison with TB, the UB has smaller particle size, larger surface and end surface area, which can lead to adsorption of more hydroxyl radicals and cause the increase of hydrogen bonds formed between the particles. Thus the recoverability of hydrogen bonds in UBG are strongerthan in the traditional one in the shearing process which would decrease the difference between the recovery rate and the destruction rate and improve the mechanical stability of UBG.

Table 1 The comprehensive performance of UBG and TBG

It can be seen from Table 1 that the oil separation of UBG is less than TBG, which demonstrates a better colloidal stability of UBG than TBG. This occurs owing to the decrease of bentonite particle size which enhances the interaction force itself coupled with the increase of specific surface area and the number of hydrogen bonds. All of these factors can enhance the adsorption capacity of UB in base oil and the structural strength of UBG, leading to the reduction of oil separation under the in fl uence of heat and pressure.

The average friction coefficient and wear scar diameter (WSD) under lubrication of base oil containing UB and TB are shown in Table 1. It can be seen that the UBG samples show better antiwear ability and friction-reducing property than the TBG samples.

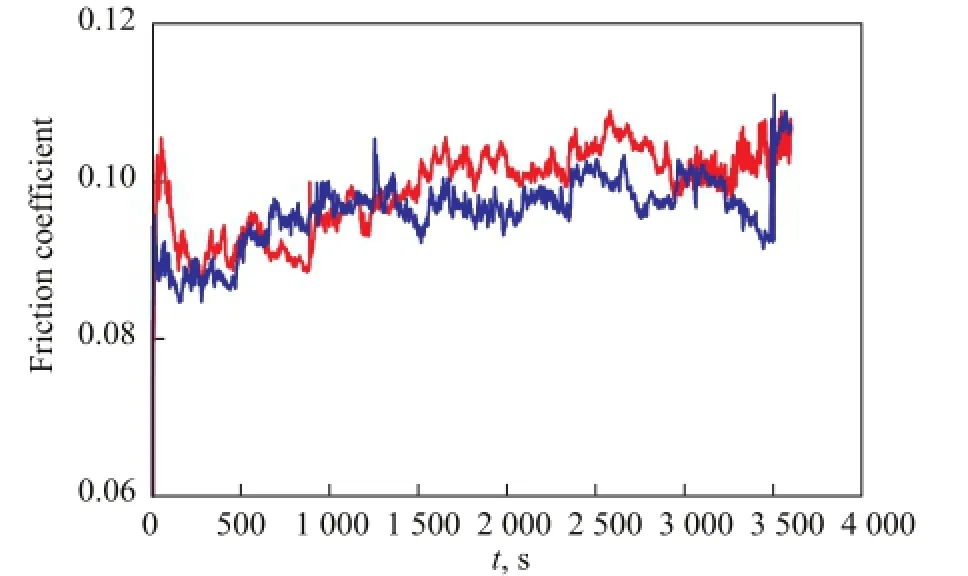

Although there is inconspicuous difference in the average friction coefficients between the two bentonite greases, the change in friction coefficients with time under lubrication of T110 used as base oil containing UB is more stable (Figure 9). As we all know that the bentonite crystal structure is anisotropic, which will experience cleavage along different crystal planes under external force. As the Si—O tetrahedral sheets are made of parallel superposition layers in nature, the lone pair electrons of lower oxygen atoms in the superstratum layer can stretch into the negatively charged holes containing the lone pair electrons of upper oxygen atoms in the substratum layer[16]. Thus the force in layers is weak due to electrostatic repulsion between the above-mentioned electrons. And the force tends toward further weakening after sand milling, leading to easier slide along the bentonite lamellas under a tangential force. As a result, the friction coefficients of UBG would decrease and become more stable.

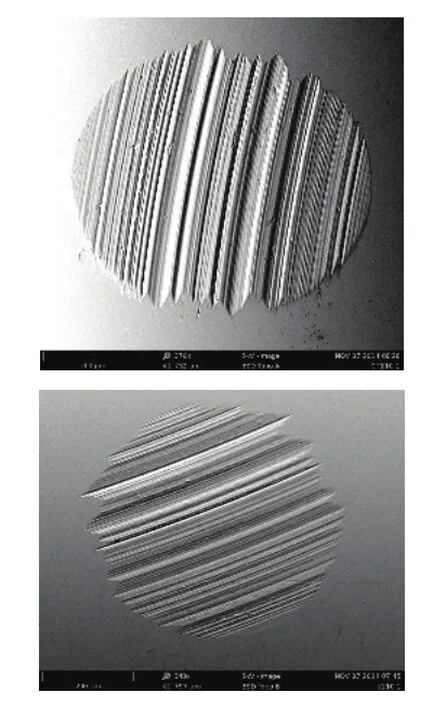

The WSD of steel balls lubricated by T110 used as base oil containing UB is decreased by more than 10%. As shown in Figure 10, the deeper grinding crack, more obvious bruises and scratches and irregular abrasions can be found on steel balls lubricated by base oil containing TB, while the WSD of steel balls lubricated by base oil containing UB is smaller and the appearance of worn surface is more uniform and smooth along with minor scrapes and shallow scratches.

The friction coefficients and worn surface appearance of steel balls under lubrication of MVI500 and PAO8 serving as base oils containing UB and TB, respectively, can be found in the literature[17].

Figure 9 Variations of friction coef fi cients as a function of friction time under lubrication by T110 used as base oil containing TB and UB, respectively

Figure 10 The worn surface of steel ball: (upper) lubricated by T110 serving as base oil containing TB; (under) lubricated by T110 serving as base oil containing UB

4 Conclusions

In this paper, the feasibility for preparation of ultrafine bentonite powder by different milling methods was studied. And the comparison of comprehensive performance between ultrafine bentonite grease and traditional bentonite grease were also investigated. The conclusion is as follows:

(1) The statistic Z-average size of ultrafine bentonite prepared by sand milling is 250 nm with a narrow size distribution. The lattice structure of ultrafine bentonite retains its good characteristics albeit with a slight distortion. The ultrafine bentonite powder can be produced by the sand milling method.

(2) The ultra fi ne bentonite grease had better mechanical stability than the traditional one. The phenomenon may be concluded that the recoverability of hydrogen bonds in UBG were stronger than in the traditional one during the shearing process which decreased the difference between the recovery rate and the destruction rate because of the smaller particles size and larger surface area of ultra fi ne bentonite. And the ultrafine bentonite grease had better antiwear ability and friction reducing property than the traditional one.

Acknowledgements: This work is fi nancially supported by the program of the General Logistics Department (AX214C002)

[1] Zhu Tingbin. Grease Technology[M]. Beijing: China Petrochemical Press, 2009: 681 (in Chinese)

[2] Mi Hongying, Guo Xiaochuan, Yang Tingdong, et al. The development of a new bentonite grease[J]. Acta Petrolei Sinica (Petroleum Processing Section), 2009, 25(S): 26-31 (in Chinese)

[3] Mi Hongying, Guo Xiaochuan, Yang Tingdong. Study on the shearing stability of bentonite grease[J]. Lubrication Engineering, 2007, 32(6): 109-111 (in Chinese)

[4] Zhang Zhi, Cui Zuolin. Nanometer Technology and Nanometer Materials[M]. Beijing: National Defence Industry Press, 2000 (in Chinese)

[5] Wang Shimin, Xu Zuxun, Fu Jing. The Technology for Preparation of Nano Materials[M]. Beijing: Chemical Industry Press, 2002 (in Chinese)

[6] Yang Changjiang. Effect of nano zinc additives on the wear performance of online repair surface[D]. Chongqing: Logistics Engineering University, 2010 (in Chinese)

[7] Wang Peng, Zhao Fangxia, Zhang Zhenzhong, et al. Tribological properties and initial exploration mechanism of composite grease with nano bismuth particles and ultra fi ne serpentine powder[J]. Acta Petrolei Sinica (Petroleum Processing Section), 2011, 27(4):643-648 (in Chinese)

[8] Chen Wengang, Zhou Gaoyu, Chen Zhanghui. Anti-wear mechanism of the serpentine powder as self-repairing additive[J]. Tribology, 2008, 28 (5): 463-468 (in Chinese)

[9] Sun Yuqiu, Guo Xiaochuan, Jiang Mingjun. Study on friction function of some stratified silicate material in lubricating additive[J]. Journal of Chongqing University of Science and Technology (Natural Science Edition), 2005, 7 (1): 55-57 (in Chinese)

[10] He Zhuocheng, Guo Xiaochuan, Li Jianhua, et al. The tribological properties of layered disilicate in greases[J]. Lubrication Engineering, 2005, 6 (172): 100-102 (in Chinese)

[11] Qin Xiaodong, Jiang Xiaoming, Chen Yuezhu. Preparation of lubricating grease for high temperature with nanometer SiO2powder[J]. Acta Petrolei Sinica (Petroleum Processing Section), 2002, 18 (3): 80-85 (in Chinese)

[12] Du Shouqin, Ke Yangchuan, Liu Qinglian, et al. Preparation and properties of SiO2grease by nano scale SiO2with large specific surface area[J]. Acta Petrolei Sinica (Petroleum Processing Section), 2007, 23 (4): 111-115 (in Chinese)

[13] Pogosian, A. K., and Martirosyan, T. R. Effect of thickener modi fi cation on bentonite-based plastic lubricant properties[C]//Proc. of 14th Inter. Colloquium, Tribology and Lubrication Engineering, Esslingen, 2004: 729-731.

[14] Pogosian, A. K., and Martirosyan, T. R. Impact of surfactant structure on the tribological properties of bentonite-based greases[J]. Journal of Tribology, 2007, 129(4): 920-922.

[15] Pogosian A K, Martirosyan T R. Tribological properties of bentonite thickener-containing greases[J]. Journal of Friction and Wear, 2008, 29(3): 205-209.

[16] Shan Changbing, Chen Guoxu, Li Huafeng, et al. Research on tribological behaviors of modified layered sodium silicate under surface contact condition[J]. Lubricating Oil, 2008, 23 (6): 42-45 (in Chinese)

[17] Wang J, Guo X C, He Y, et al. Impact of base oil on the performance of ultrafine bentonite grease[J]. Petroleum Processing & Petrochemicals, 2015, 46(7): 83-88 (in Chinese)

Received date: 2016-03-12; Accepted date: 2016-05-24.

Professor Guo Xiaochuan, E-mail: 1418718262@qq.com.

- 中國煉油與石油化工的其它文章

- Preparation and Tribological Properties of Lanthanumdoped Muscovite Composite Particles as Lubricant Additives in Lithium Grease

- Preparation and Tribological Behavior of Hydrophobic Lanthanum Borate Nanosheets in Rapeseed Oil

- Synthesis and Evaluation of Environmentally Friendly Calcium Isostearate Detergent with Excellent Oil Solubility

- Experimental and Molecular Simulations for Evaluating the Effect of Lubricity Improvers on the Property of Jet Fuel

- Analysis and Modeling of Wangqing Oil Shale Drying Characteristics in a Novel Fluidized Bed Dryer with Asynchronous Rotating Air Distributor

- Modeling of Isobutane/Butene Alkylation Using Solid Acid Catalysts in a Fixed Bed Reactor