Identification of Damaged Teeth in Gears using Wavelet Transform Applied to the Angular Vibration Signal

P.A.Mero?o,F.C.Gómezand F.Marín

Identification of Damaged Teeth in Gears using Wavelet Transform Applied to the Angular Vibration Signal

P.A.Mero?o1,F.C.Gómez2and F.Marín1

This work represents a comparative study of Wavelet Transform of angular vibration signal and the traditional Fourier analysis applied to the signals of angular vibration,in one transmission which involve gears.How it is known,the elastic deformation of the material,together with the superficial irregularities of the teeth due to wear,provoke characteristic angular oscillations,which make it possible to distinguish between the regular functioning of a mechanism in good condition and the angular vibrations provoked by wear and the superficial irregularities of teeth in poor condition.However,the character of the vibrations produced in such circumstances means that Fourier’s analysis is not the most suitable processing technique for such cases.As the results of this work will show,wavelet transform applied to the angular vibration signal seems to be more suited to detecting and to identifying wear and other surface damage to the teeth of gears.

torsional vibrations,wavelet transform,Fourier Transform,laser vibrometry,damaged teeth.

1 Introduction

It is an indisputable fact that the technology that has dominated the analysis of vibrations in the diagnosis of machine faults is Fourier’s Transform.Nevertheless,since the 1990s,alternative analysis methods in the domain of the frequency-or of the time and frequency-of a signal have been gaining acceptance in this f i eld.Among such processing techniques are the Transformed Wigner-Ville Distribution(WVD),Wavelet Transform(WT),Choi-Williams Distribution(CWD)and Cone-Shaped Distribution(CSD)[Peng and Chu(2004)].

In the field of the diagnosis of gear damage,particularly,these transforms present certain advantages over the classic Fast Fourier Transform(FFT),due to their ability to deal successfully with signals that have a high non-stationary component.

In this field,early detection of damage is particularly important since in the initial condition it is difficult to locate and its evolution tends to be slow,although it speeds up when failure is near[Wang(1995)].

When the Fourier Transform is used for the analysis,the frequency characteristics of the complete temporal signal are clear,but the disturbances that take place during a short interval are not detected.This means that it is not a method particularly well adapted to such cases especially in light of the non-stationary characteristics of the signals produced by the gears(in every revolution transitory phenomena take place provoked by the randomness of the impacts due to the damages).That is,when the spectral content of the signal changes frequently with time,neither temporal signal nor its transformation by FFT is sufficient for the complete analysis of the same[Kara and Mohanty(2008)].Little more there can be done using this technique than detect the evolution of the harmonic frequency of meshes,which is insufficient for early detection of the problem.

So,FFT technique makes disappear the instantaneous events along the temporal wave to extract the frequency components of the signal.That is to say,when FFT is applied over a piece of signal,all the events into that temporal segment are,in some way,averaged together.So,little events,that could be significant,can be eliminated.In machines with gear transmissions,in addition to the meshing frequency,the meshing process of the teeth produces periodic events and random vibrations.Some studies pointing towards modal vibrations[Tiwari,Bordoloi,Bansal and Sahoo(2013)],Rayleigh distribution of probability[Gómez(1998);Valverde et al.(1997)],chaotic[Litak and Friswell(2003)],different kinds of noise[Bel?ak and Prezelj(2007)],among others;that is to say,mainly non-gaussian vibration.Therefore,by using WT,instead of FFT,those little events can be detected inside that random vibration.

In addition,one of the well known problems when gears defects are going to be monitored is that the FFT spectrum features of the defects in bearings and gears are very similar,usually random vibration and high frequencies produced by the impact metal-metal.By using WT,time and frequency are analyzed simultaneously;therefore,it is possible to observe when those impacts occur and the frequency range-scale,strictly-in which they are produced.This way,the gear meshing period can be detected and,so,the teeth damage can be distinguished from a bearing problem,whose sequence of impacts,i.e.,its period,is totally different.

When the frequency spectrogram is used to avoid this lacuna in the diagnosis,it is observed that,although it is suitable when all the analyzed phenomena take place in the same range on a large scale,it is not so well adapted to the problem when this is not the case–as in the case that concerns us here.This is because it is impossible to simultaneously achieve high resolution in both the time and frequency domains.

On the other hand,the initial damage to the gear teeth produces vibration signals of short duration that are shorter than a period of meshes between teeth.In later stages the damage provokes modulations with a duration that may be even greater than time taken by one whole revolution.To have to decide between good temporal or good frequency resolution implies losing information in either case,and it is for this reason that this technology does not seem to offer a good diagnostic solution.With the increased requirements for prolonged operative life and increased safety,the models used for the prediction and identification of failures have seen great advances.The methods used,which are based on the frequency analysis of the signals based on WVD[Baydar-1(2001);Gu and Ball(1992);Fan(2006);Fan(2004)]and on WT[Fan(2006);Jiawei and Ming(2011)construct a multi-scale wavelet finite element model using Hermite cubic spline Wavelet on the interval(HCSWI)to obtain damages in cantilever beam,that can be assimilated to the a gear tooth;Choi,Mugler and Zou(2003);Bing(2006);Boulahbal(1999);Li,Zhiyuan and Zheng(2002);Jun(2007);Li(2006);McFadden and Wang(1996);Sung(2000);Niola(2007);Wang(2004);Wang(1995);Wang(1996);Baydar-2(2001);Yourong(2005);Zheng(2002);Bing and Zhengjia(2013)show different methods of vibration-based crack identification problem,that can be applied to some gear teeth faults;Zhennan(2003)],provide instantaneous frequency spectra at several points of the rotating shaft and have achieved notable success in the detection of gear-located failures.

Nevertheless,all the above methods focus on analysis of the vibration signals in the radial and axial directions of the machine,and there has been no parallel development in the measurement of the angular vibration.In the preset study discuss the advantages of applying wavelet transform(WT)to the signal of angular vibration when carried out adopting a suitable Mother Function[Rafiee,Tse,Harifi and Sadeghi(2009)].

2 Fundamentals

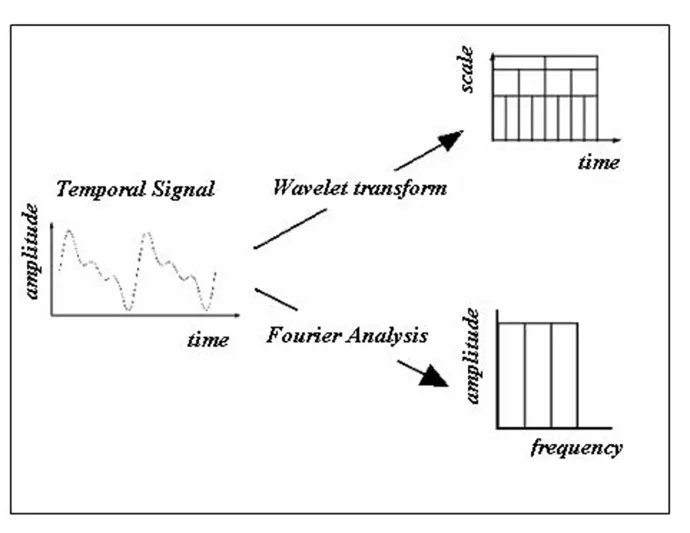

The wavelet transform provides a time-frequency analysis of the input signal.It has the advantage over FFT in that it shows the frequencies that are present in the signal and the exact instant at which they appear,which is not the case with FFT,in which the frequencies obtained are the mean for the whole period studied.This means,for example,that a resonant vibration of short duration compared with the temporal interval of the signal under study,may be overlooked even though its amplitude is considerable.This is precisely what happens with the impacts of the teeth of a gear.Fig.1 shows a schematic vision of this process.WT possesses the ability to detect temporal impulses of short duration in such a way that any possible failure can be detected in gear transmissions.

Figure 1:Comparison between Fourier Analysis and Wavelet Transform.

Just as the sinusoidal decomposition that Fourier analysis performs,Wavelet analysis separates the signal into scaled elements(the equivalent of frequencies in the Fourier’s Transform)that are shifted with regard to the original.It is easy to understand that this is a better way to analyze signals that change randomly and erratically.

The expression of the Wavelet transform in constant form is:

Wherea∈R+is the scale andb∈Ris the parameter change.

The integral evaluates the similarity between the signal x(t)and the wavelet function ψa,b(t),where:

For low values of a(a<1),ψa,b(t)is short and of high frequency,whereas for high values(a>1)it is long and of low frequency.

Considering different values for the scale parameter,the wavelet transform locates the transitory phenomena of the signal.

The initial damages in teeth produces vibration signals of short duration–shorter than that of the period of meshing teeth.In later states this damage leads these signals becoming longer-even longer than the meshing periods[Wang(1995)].Other types of failures,such as eccentricity or misalignment,on top of the wear suffered by the teeth,produce modulated vibrations whose period greatly exceeds that corresponding to the mesh frequency and even the fundamental turning frequency.To detect this wide range of possibilities,the use of the WT is so advisable.Adopting a series of different scales and moving along the temporal axis,a great variety of failures can be detected,regardless of how long they last.

The use of wavelets with a high number of null moments can also be useful for detecting purely frequency components in a signal.Depending on the smoothness conditions of the signal,Wavelets Mother Functions should be chosen that reflect a sufficient number of null moments.The number of these moments is related to the capacity of the wavelet to suppress signals that could be described by polynomials of a certain order.In this way,if a wavelet of n+1 null moments is chosen to calculate the transformed of a signal,we can cancel the components of the above mentioned signal that are polynomials of up to the nthdegree,that is all the polynomial signals up to the above mentioned degree will have null coefficients.

2.1 Wavelet function selection

Wavelet analysis uses as mother functions oscillating waveforms of finite duration and of average zero that tend to be irregular and asymmetric.These are the windowing functions used on signal to be analyzed.It is necessary to adopt a whole series of different scales and move the window along the time axis.In addition,it is necessary to determine which mother function is to be used and whether it is suitable for detecting a certain type of transitory phenomenon.That is to say,it is fundamental to properly choose the type of function that best suits the analysis of the mechanical failure that is being determined.The basic principle is to choose a wavelet function whose form is similar to that of the vibratory sign caused by the above mentioned failure.That is to say,it is really a question trying to confirm a hypothesis.In most of the studies carried out to date it is thought that when a mechanical failure occurs the vibratory signal possesses Morlet-type periodic impulses,for which reason this is the most commonly used function,although the Gabor and Mexican Hat type functions are also frequently used[Choi,Mugler and Zou(2003)].

The family of wavelets known as Daubechies or dbN wavelets is one of the most commonly used in f i ltering applications[Raf i ee,Tse,Harif iand Sadeghi(2009)].The reason lies in the excellent capacity of this type of wavelet to represent polynomial and/or not linear behaviors of diverse signals and,as a consequence,to estimate the fundamental signal of noisy measurements[Saravanan and Ramachandran(2009)].The different dbN functions are generated by increasing parameter N,which indicates their order.The resultant function becomes smoother as N in-creases(greater number of null moments).This means that,theoretically,low order dbN(N→1)will be better at treating pulsatory series or those with strong discontinuities,whereas high order dbN(N→∞)will be more adapted to treating smooth signals or those with weakly damped transitory vibrations.

The kind of irregularities produced by one damaged gear tooth in the signal of vibration is mainly a very narrow pulse,that is to say,very limited temporarily in respect to the period of the turning speed,usually once per revolution of the shaft.Since the amplitude of this pulse depends on the severity of the damage,when the defect is incipient that amplitude hardly exceeds the background level.Therefore,a high order of the Daubechies wavelet function,bigger than 6th order,makes those pulses disappear,acting like a filter to them.In the other side,if a low order is applied,below 3rd order,that background signal is not filtered enough,hiding often the pulses among the noise.So,4th or 5th order of Daubechies seems to be the best choice to detect damaged teeth in gears.

In our work,the most suitable type was seen to be 5th order Daubechies.The type of Wavelet Mother Function plays an important role in the final results,since the use of one type or another or the level of decomposition chosen may affect positively or negatively the task of identifying the pattern of failure in question.

3 Laboratory test programs,technology and equipment used

3.1 Test bench

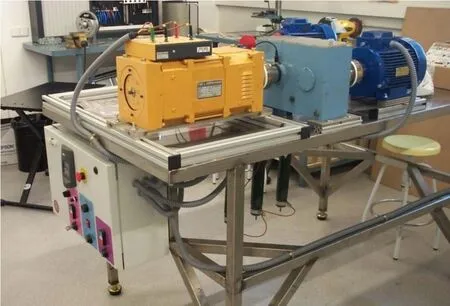

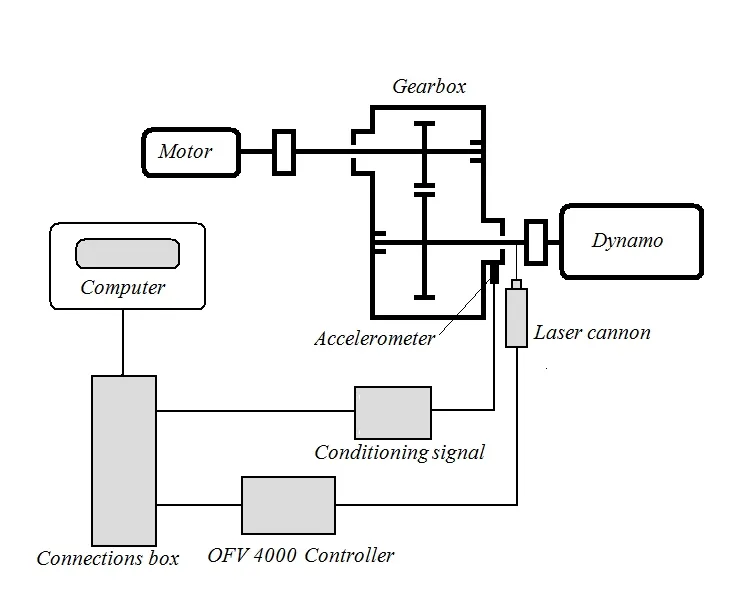

The test bench used test consists of the following elements:

-Asynchronous electrical three-phase engine.Power of 3 kW and 1,475 rpm.The speed can be controlled by means of a frequency variator.

-One step gears train composed of a pinion with 20 teeth and a driven wheel with 40 teeth.

-3 kW Shunt Dynamo with rheostat-controlled load.

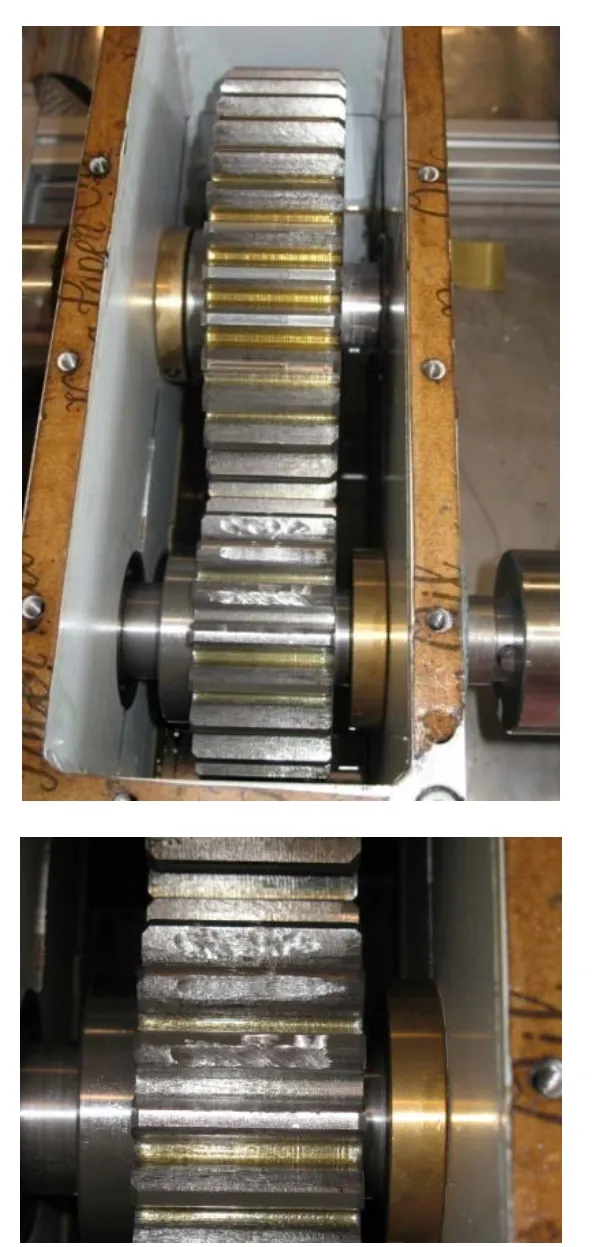

The damage was initiated by machining the contact flank of one,two and up to three teeth,with a material gradually taken off until the deterioration was noticeable in the measurements.Fig.3 shows a detail of the damaged teeth.

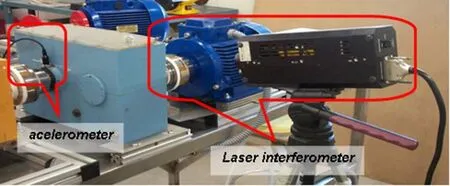

The radial vibration measurements were made under acceleration(mm/s2)and those of angular vibration by measuring variations in angular speed(Δω in rpm),this latter by parallel beam laser interferometry,using a rotational vibrometer with a Helium-Neon laser beam source.The set-up the obtaining these measurements is depicted in Fig.4 and Fig.5.

For data storage and treatment a laptop was used.The software used for processing the signal was Matlab? and Labview? as redundant measuring system.

Figure 2:Test bench.

Figure 3:Gears with damaged teeth and detail of the damage.

Figure 4:View of accelerometer and laser interferometer.

Figure 5:Schematic set-up.

4 Experimental results

4.1 FFT analysis

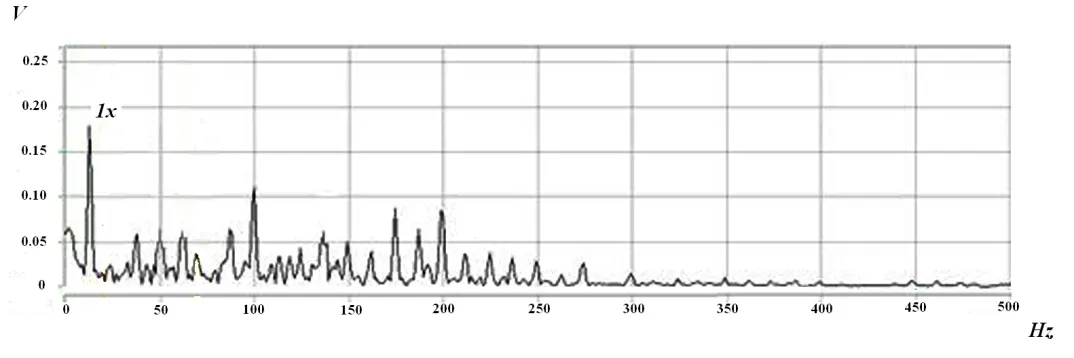

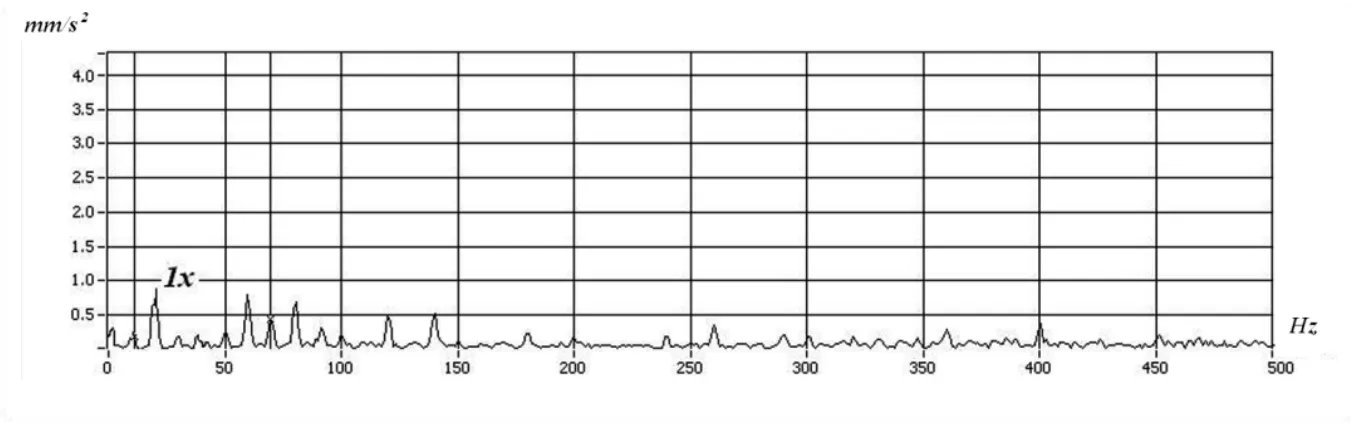

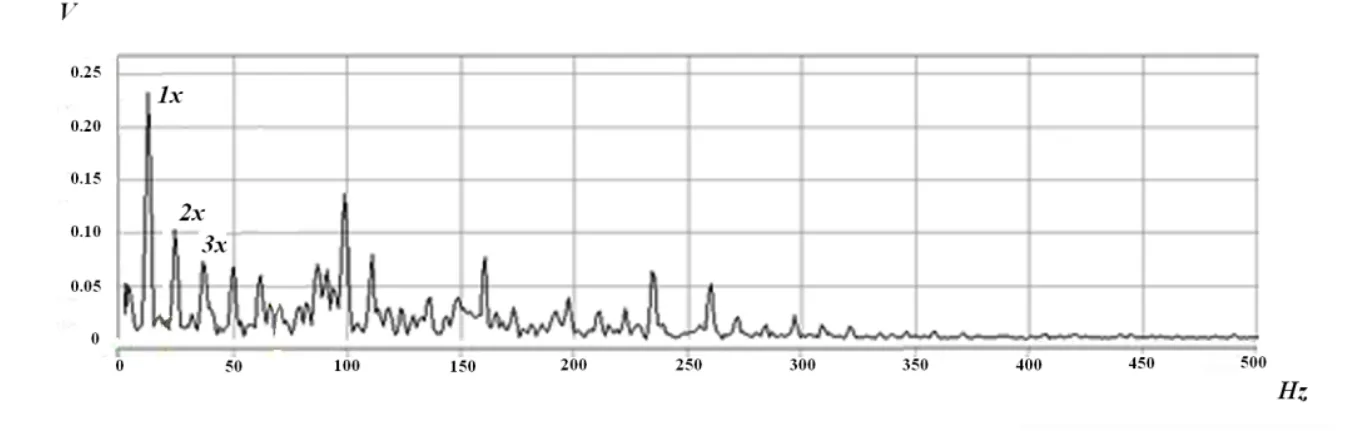

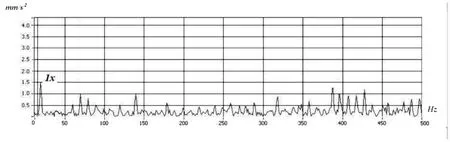

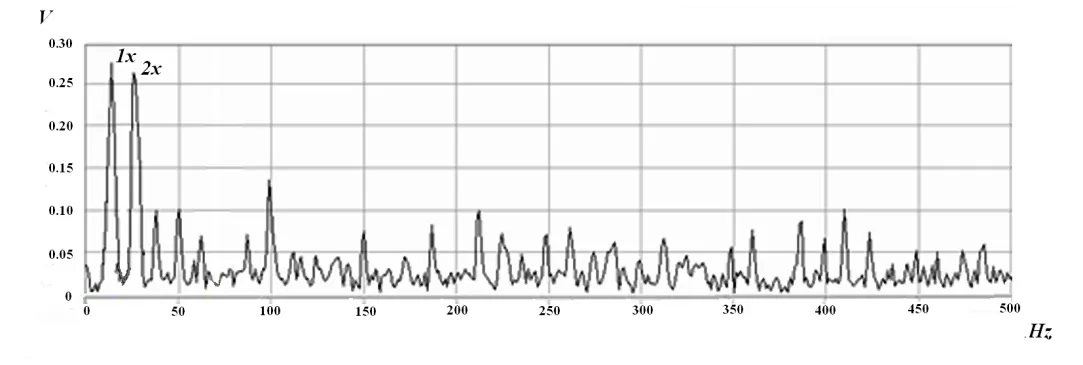

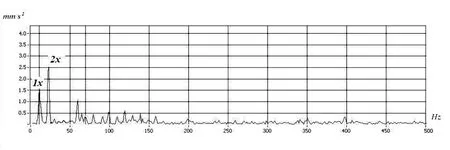

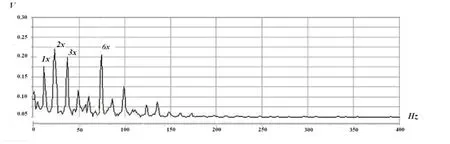

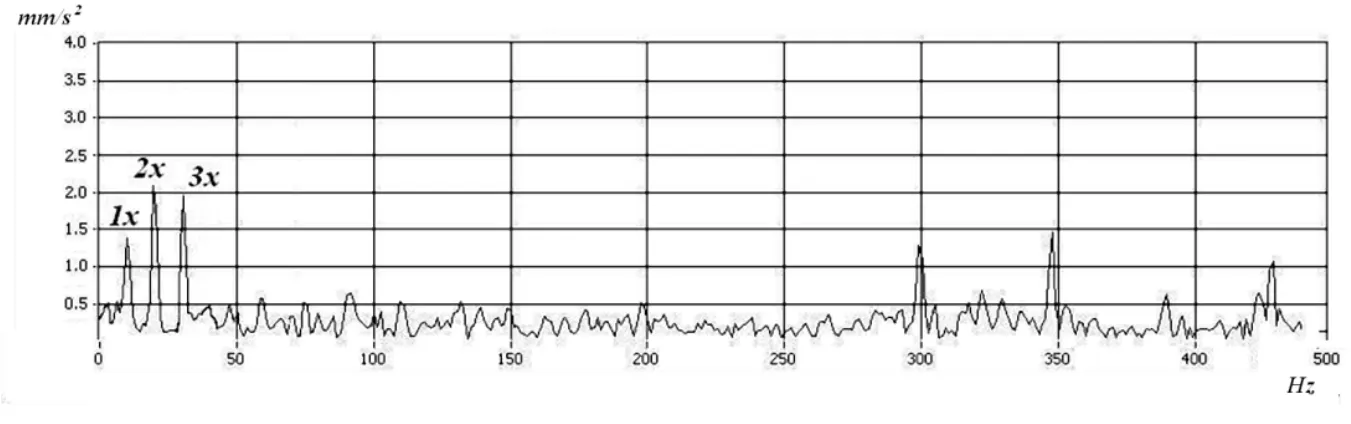

Fig.6a to Fig.6h show Fourier’s spectra of angular and radial vibration with a different number of damaged teeth.Although a clear trend can be observed in the increase in the levels and the components at different frequencies related with the number of damaged teeth,making a diagnosis with this type of transform is complicated,whether analyzing the signals of radial vibration or those of angular vibration,since they may be confused with other types of anomaly that show similar spectral behavior(mechanical looseness,misalignment,...).This is because the waveform of the vibratory signal is not similar to the sinusoidal form,so that their Fourier spectral decomposition gives rise to a whole series of multiples of the principal frequency,which are highly random and which do not correspond to specif i c events.Although the mesh frequency can still be appreciated in the early stages of deterioration of the teeth,as the damage progresses a broad band of frequencies appears,masking the frequency of interest.

Figure 6a:Angular spectrum without damaged teeth.

Figure 6b:Radial spectrum without damaged teeth.

4.2 Wavelet analysis

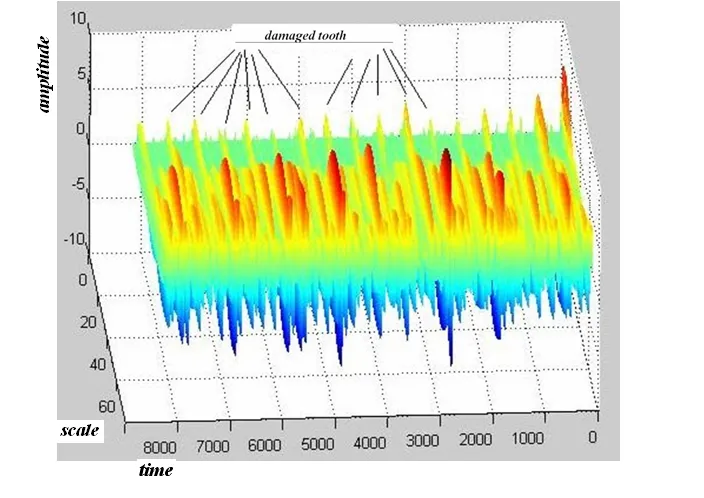

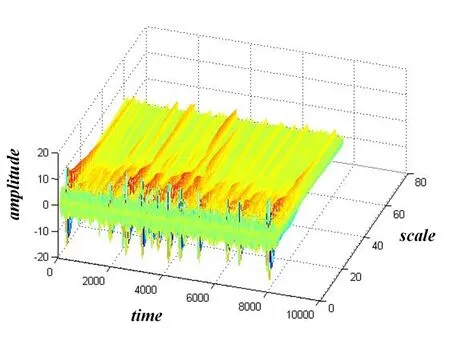

Fig.7 shows the Wavelet Transform of the angular vibration signal corresponding to one damaged tooth in the pinion,using as"mother"the 5th order Daubechies.The graph represents 16 complete turns of the shaft,with a sampling frequency of 5 kHz and 8,192 sampled points.

Figure 6c:Angular spectrum with one damaged tooth.

Figure 6d:Radial spectrum with one damaged tooth.

Figure 6e:Angular spectrum with two damaged teeth.

Figure 6f:Radial spectrum with two damaged teeth.

Figure 6g:Angular spectrum with three damaged teeth.

Figure 6h:Radial spectrum with three damaged teeth.

Figure 7:Wavelet Transform(Db5)of the angular vibration signal with one damaged tooth.

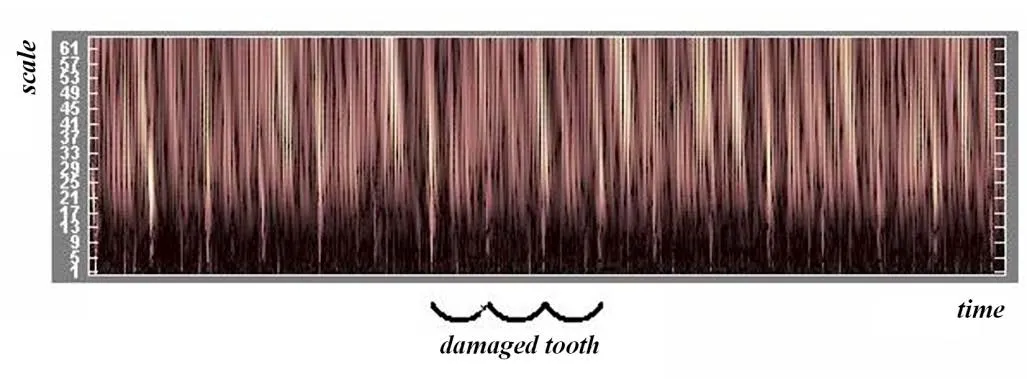

The peaks corresponding to the passage of the damaged tooth as it turns can be observed.The peaks are provoked by a variation in the angular oscillation in the gear as the defective tooth meshes.The graphical evidence shown in Fig.7 can be compared with that depicted in Fig.6c,which represents the same situation but seen by FFT.Fig.8 shows the same situation but with the graph in two dimensions(scale-time).

Figure 8:Wavelet Transform(Db5)of the angular vibration signal with one damaged tooth-2D view.

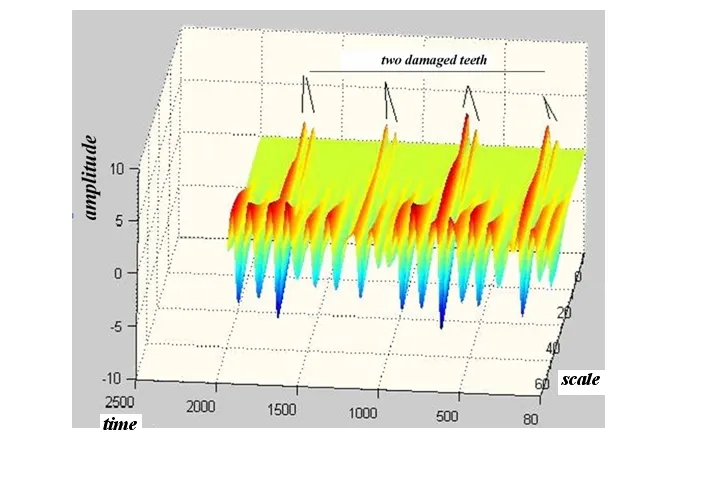

Figure 9:Wavelet Transform(Db5)of the angular vibration signal with two damaged teeth.

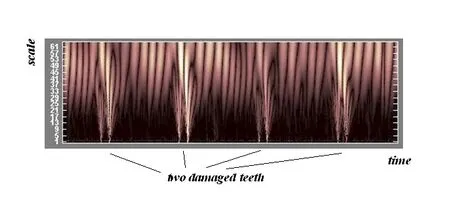

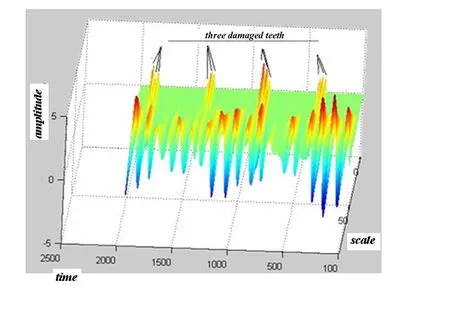

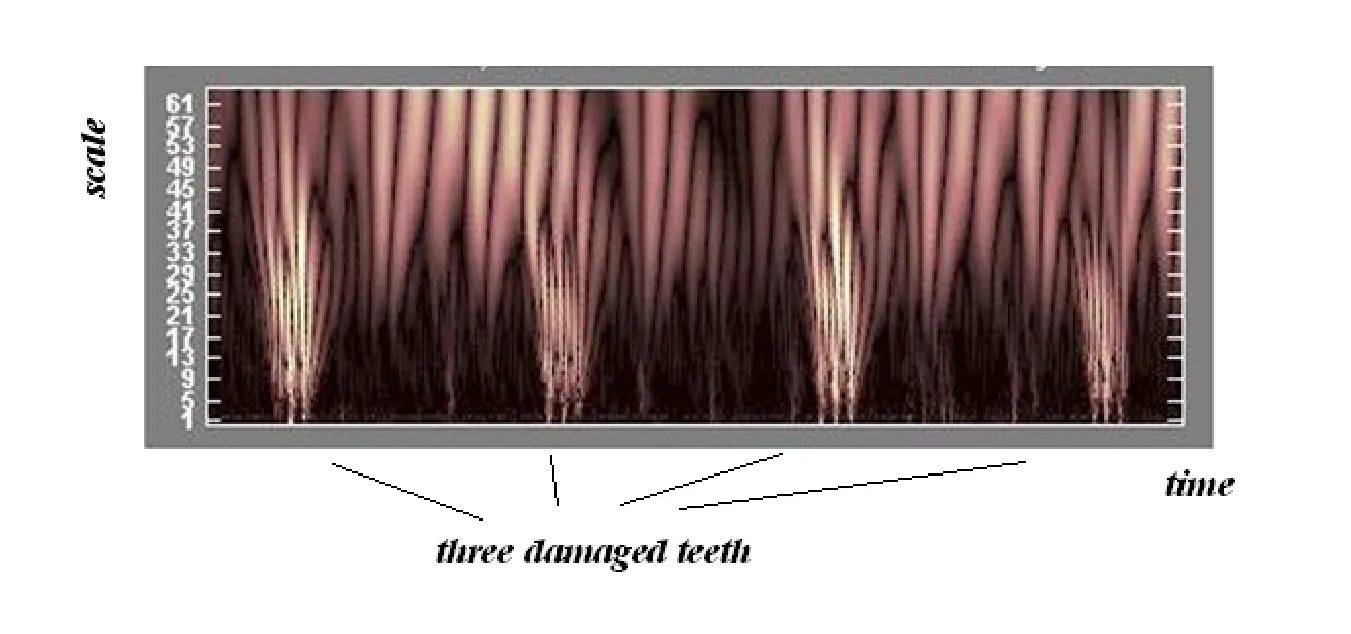

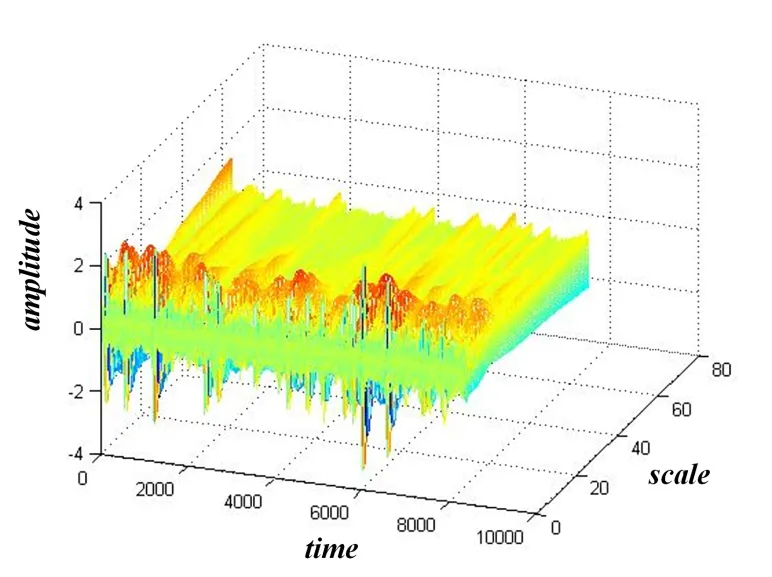

In the case of two and three damaged teeth the effect is similar,as can be observed in the following graphs where the peaks correspond to the sequence and number of damaged teeth.Fig.9 and Fig.10 correspond to the case of two non-consecutive damaged teeth,with an undamaged tooth between them:in this case,the graph represents four consecutive turns of the shaft Fig.11 and Fig.12 correspond to the case of three consecutive damaged teeth.

Figure 10:Wavelet Transform(Db5)of the angular vibration signal with two damaged teeth–2-D view.

Figure 11:Wavelet Transform(Db5)of the angular vibration signal with three damaged teeth.

Figure 12:Wavelet Transform(Db5)of the angular vibration signal with three damaged teeth-2-D view.

Figure 13:Wavelet Transform(Db5)of the radial vibrations signal with one damaged tooth.

Figure 14:Wavelet Transform(Db5)of the radial vibration signal with two damaged teeth.

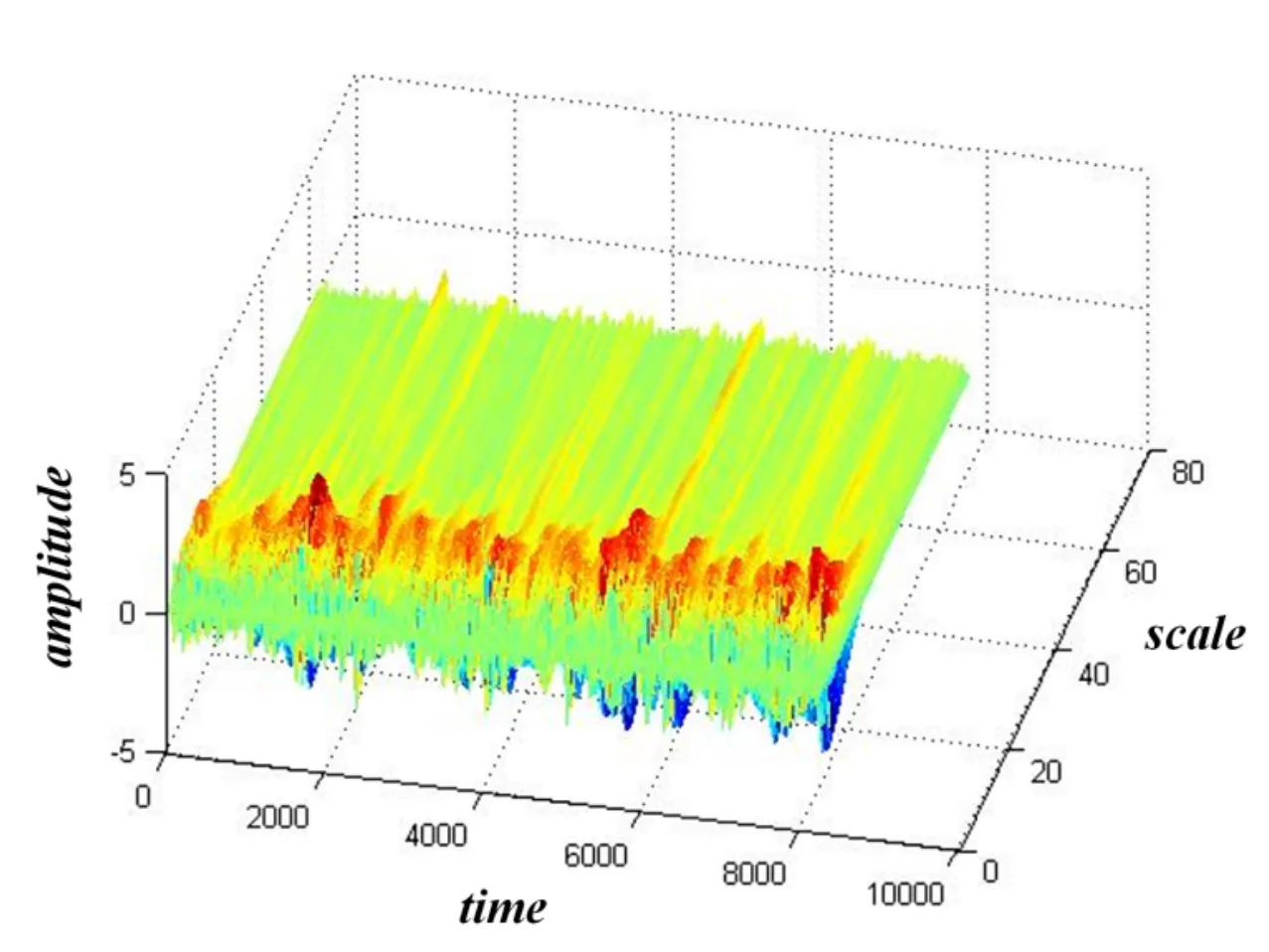

Figure 15:Wavelet transform(Db5)radial vibration signal with three damaged teeth.

An important observation is that as the damage to the teeth a rise,so does the severity of the angular vibration,as is to be expected and the detail of the fault can be clearly observed by WT.This is,although the vibration signal of becomes more random,the WT continues being very effective at extracting the scale-time components that reveal the failure.

In all cases equidistant peaks coinciding with the passage of the damaged tooth/teeth can be observed.This effect is also clear in the 2-D graphs corresponding to the scale-time axes.

However,this effect was not observed to the same extent in the radial vibration signal,despite the fact that its level of severity also increased.The peaks that appear in the graphs do not bare any relation with the temporal sequence of meshing or with the number of damaged teeth.As Fig.13,Fig.14 and Fig.15 show,although a sequence of peaks can be observed in 3-D,they were changeable did not in any way correspond to the expected frequencies.

This is due to the fact that the damage modifies the involute tooth profile,and thus the change in the instantaneous angular velocity is inevitable during the process of meshing,while the radial effect is not so pronounced,so no highlights with respect to other random vibration background,and goes unnoticed especially in the early stages of default.

5 Conclusions

The joint analysis of the angular vibration signal and its Wavelet transform was seen to be a very effective diagnostic procedure,particularly when the 5th order Daubechies Wavelet was used to detect defective teeth in transmissions gears.The vibration caused by one or more damaged teeth is of the stationary impulsive type,that is,far from a sinusoidal waveform,meaning that the Fourier Transform is not the most suitable procedure for such an analysis.

When the level of severity of the angular vibration identifies the existence of damage in the gear,WT permits specif i c diagnosis of the same,and it is possible to ascertain whether the fault appears in one or more teeth.

Any deterioration in the teeth,accompanied by an increase in the levels of angular vibration,can be clearly observed in the temporal sequence of the angular vibration signal in WT,whereas making a diagnosis with FFT is complicated since they may be confused with other types of anomaly that show similar spectral behavior(mechanical looseness,misalignment,...).FFT provides unspecific results in this respect.

Baydar,N.(2001):A comparative study of acoustic and vibration signals in detection of gear failures using Wigner-Ville Distribution.Mechanical Systems and Signal Processing,vol.15,no.6,pp.1091-1107.

Baydar,N.(2001):Detection of gear failures using wavelet transform and improving its capability by principal component analysis.Condition Monitoring and Diagnostic Engineering Management,pp.411-418.

Bel?ak,A.;Prezelj,J.(2007):Analysis of noise sources produced by faulty small gear units.Structural Durability&Health Monitoring,vol.3,no.4,pp.239-246.

Bing,L.;Zhengjia,H.((2013):A Benchmark Problem for Comparison of Vibration-Based Crack Identification Methods.Computer Modeling in Engineering&Sciences,vol.93,no.4,pp.293-316

Bing,S.(2006):Gear faults diagnosis based on wavelet packet and fuzzy pattern recognition.Chinese Control Conference,vol.1-5,pp.304-307.

Boulahbal,D.(1999):Amplitude and phase wavelet maps for the detection of cracks in geared systems.Mechanical Systems and Signal Processing,vol.13,no.3,pp.423-436.

Choi,F.K.;Mugler,D.H.;Zou J.(2003):Damage Identification of a Gear Transmission Using Vibration Signatures.Journal of Mechanical Design,vol.125,pp.395-403.

Fan,Z.(2004):Application of wavelet transform and FFT methods in the analysis of gear signals.Proceedings of the International Computer Congress on Wavelet Analysis and its Applications,and Active Media Technology.

Fan,Z.M.(2006):Application of the wavelet packet analysis in the gear vibration characteristic.Wavelet Active Media Technology and Information Processing,vol.1-2,pp.1019-1024.

Gómez,F.C.(1998):Tecnología del Mantenimiento Industrial.Servicio de Publicaciones de la Universidad de Murcia.University of Murcia.

Gu,F;Ball,A.(1992):Use of the Wigner Ville distribution in the interpretation of monitored vibration data.Maintenance,vol.10,pp.16-23.

Jiawei,X.;Ming L.(2011):Multiple Damage Detection Method for Beams Based

on Multi-Scale Elements Using Hermite Cubic Spline Wavelet.Computer Modeling in Engineering&Sciences,vol.73,no.3,pp.267-298.

Jun,G.(2007):Application of wavelet packet transform on fault diagnosis of snapped bolt in gear box.Journal of Beijing University of Technology,vol.33,no.3,pp.240-244.

Kara,C.;Mohanty,A.R.(2008):Vibration and current transient monitoring for gearbox fault detection using multiresolution Fourier transform.Journal of Sound and Vibration,vol.311,pp.109–132.

Li,H.(2006):Angle domain average and continuous wavelet transform for gear fault detection.Current Development in Abrasive Technology,Proceedings,pp.618-623.

Li,H.;Zhiyuan,C.;Zheng,X.(2002):Fault diagnosis for gearbox gear based on continuous wavelet transform.Ji Xie Gong Cheng Xue Bao,vol.38,no.3,pp.69-73.

Litak,G.;Friswell,M.I.(2003):Vibration in gear systems.Chaos,Solitons and Fractals16,pp.795–800.

McFadden,P.D.;Wang,W.J.(1996):Application of the wavelets to gearbox vibration signals for fault detection.Journal of Sound and Vibration,vol.192,no.5,pp.927-939.

Niola,V.(2007):A wavelet application for improving the kinematical quality of gear transmission.WSEAS Transactions on Systems,vol.6,no.1,pp.47-53.

Peng,Z.K.;Chu,F.L.(2004):Application of the wavelet transform in machine condition monitoring and fault diagnostic:a review with bibliography.Mechanical Systems and Signal Processing,vol.18,pp.199-221.

Rafiee,J.;Tse,P.W.;Harifi,A.;Sadeghi,M.H.(2009):A novel technique for selecting mother wavelet function using an intelligent fault diagnosis system.Expert Systems with Applications,vol.36,pp.4862–4875.

Saravanan,N.;Ramachandran,K.I.(2009):Fault diagnosis of spur bevel gear box using discrete wavelet features and decision tree classification.Expert Systems with Applications,vol.36,pp.9564–9573.

Sung,C.K.(2000):Locating defects of a gear system by the technique of wavelet transform.Mechanism and Machine Theory,vol.35,no.8,pp.1169-1182.

Tiwari,R.;Bordoloi,D.J.;Bansal,S.;Sahoo,S.(2013):Application of Wavelet Analysis in Multi-class Fault Diagnosis of Gear using SVM.International Journal of Condition Monitoring&Diagnostic Engineering,vol.16,no.3,pp.17-24.

Valverde,A.;Sánchez,J.J.;Gómez,F.C.(1997):Formulación de un modelo lógico de discriminación del estado de maquinas rotativas mediante normalización del nivel de vibración.Anales de Ingeniería Mecánica.Bilbao(Spain),vol.1,pp.341-348.

Wang,K.(2004):Feature extraction of gear fault based on improved wavelet arithmetic.Progress in Safety Science and Technology,vol.4(A-B),pp.2400-2404.

Wang,W.J.(1995):Application of orthogonal wavelets to early fear damage detection.Mechanical System and Signal Processing,vol.9,no.5,pp.497-507.

Wang,W.J.(1995):Application of orthogonal wavelets to early fear damage detection.Mechanical System and Signal Processing,vol.9,no.5,pp.497-507.

Wang,W.J.(1996):Application of wavelets to gearbox vibration signal for fault detection.Journal of Sound and Vibration,vol.192,no.5,pp.927-939.

Yourong,Z.(2005):Application of wavelet packet analysis to gear fault diagnosis.Zhen Dong Yu Chong Ji,vol.24,no.5,pp.101-103.

Zheng,H.(2002):Gear fault diagnosis based on continuous wavelet transform.Mechanical Systems and Signal Processing,vol.16,no.2-3,pp.447-457.

Zhennan,X.(2003):Detection of incipient localized gear faults in gearbox by complex continuous wavelet transform.Chinese Journal of Mechanical Engineering,vol.16,no.4,pp.363-366.

1Universidad Politécnica de Cartagena(UPCT),Cartagena,Spain.

2Universidad de Murcia,Murcia,Spain.

Computers Materials&Continua2015年8期

Computers Materials&Continua2015年8期

- Computers Materials&Continua的其它文章

- Research on damage distribution and permeability distribution of coal seam with slotted borehole

- Evaluating Water Vapor Permeance Measurement Techniques for Highly Permeable Membranes

- Static and Dynamic Analysis of Laminated Thick and Thin Plates and Shells by a Very Simple Displacement-based 3-D Hexahedral Element with Over-Integration