Construction monitoring of lock head base plate using distributed optical fibre sensing technique

Song Zhanpu Shi Bin Zhu Honghu Shen Mengfen Zhang Dan Sun Yijie

(1School of Earth Sciences and Engineering, Nanjing University, Nanjing 210023, China)(2Glenn Department of Civil Engineering, Clemson University, Clemson, SC 29634, USA)

?

Construction monitoring of lock head base plate using distributed optical fibre sensing technique

Song Zhanpu1,2Shi Bin1Zhu Honghu1Shen Mengfen2Zhang Dan1Sun Yijie1

(1School of Earth Sciences and Engineering, Nanjing University, Nanjing 210023, China)(2Glenn Department of Civil Engineering, Clemson University, Clemson, SC 29634, USA)

Abstract:The concrete hydration heat release process of the base plate is monitored using Roman optical time domain reflectometry(ROTDR)sensing sensors. The monitoring data shows that the internal maximum temperature of the base plate is about 54 ℃ after the concrete was cured for 120 h. The fiber Bragg grating (FBG) temperature sensors are adopted to measure the surface temperature of the concrete and the temperature results are used to compensate the data measured by the pulse-prepump Brillouin optical time-domain analyzer(PPP-BOTDA) to obtain the real concrete surface strain of the base plate. The monitoring data is analyzed to obtain a clear understanding of the strain state of the base plate under the effect of concrete hydration heat release. The monitoring results demonstrate the potential of distributed optical fibre sensing techniques as a powerful tool in real-time construction monitoring, and also provide an important insight into the design, construction and maintenance of large hydraulic structures.

Key words:construction monitoring; lock head base plate; optical fibre sensing; lock engineering; concrete

Received 2015-03-17.

Biographies:Song Zhanpu (1989—), male, graduate; Shi Bin (corresponding author), male, doctor, professor, shibin@nju.edu.cn.

Foundation items:The National Key Technology R& D Program during the 12th Five-Year Plan Period (No.2012BAK10B05), the State Key Program of National Natural Science of China (No.41427801).

Citation:Song Zhanpu, Shi Bin, Zhu Honghu, et al. Construction monitoring of a lock head base plate using distributed optical fibre sensing technique[J].Journal of Southeast University (English Edition),2015,31(4):535-540.[doi:10.3969/j.issn.1003-7985.2015.04.018]

The safety of ship locks should be guaranteed to protect people and their properties downstream. Therefore, the health monitoring of ship lock structures is a critical issue[1]. The stress state of a ship lock structure depends on its type and structural complexity. In addition, the construction process and the control of hydration temperature have a significant influence on the structural quality. Thus, the monitoring of the structural temperature and strain during construction plays a significant role in ensuring the construction quality of ship locks[2].

At present, the traditional monitoring techniques can hardly meet the requirements of modern structural monitoring due to the following deficiencies[3]. Most of the sensors are single-point sensors with a relatively low survival rate and can hardly perform in real-time or automatic monitoring. Single-point sensors are integrated into an organized monitoring system with difficulty. As a result, it is necessary to develop and apply the innovative technologies and methods to structural monitoring. In recent years, the distributed optical fibre sensing-based construction monitoring and health diagnosis methods have been developed and widely adopted in different structural monitoring systems[4-10]. A study in this research area was carried out by Shi et al[11]. They utilized the Brillion scattering-based sensing optical fibres to measure the strain distribution of a tunnel in Nanjing, China. Matta et al.[12]installed optical fibre on steel bars to measure the strain distribution of a bridge. However, both of them focused on built structure health monitoring. In this paper, we employ three distributed optical fibre sensing techniques including FBG, ROTDR and PPP-BOTDA to monitor the construction stage of a ship lock head base plate. The monitoring results are presented and analyzed, which provide an insight into the design, construction and maintenance of large hydraulic structures. Herein, the working principles of three distributed optical fibre sensing techniques are introduced.

1Working Principles of Distributed Optical Fibre Sensing Techniques

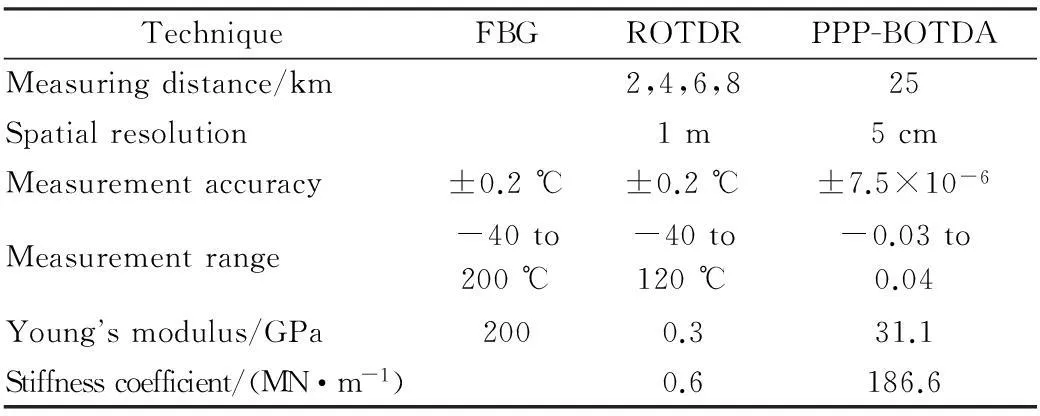

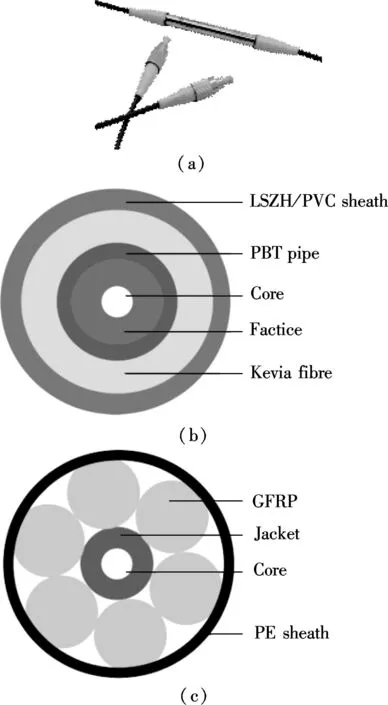

In the past few decades, several distributed optical fibre sensing techniques have been developed. FBG, ROTDR and PPP-BOTDA are the most frequently used distributed optical fibre sensing techniques. Tab.1 lists the features of the three techniques, and the structures of the sensors used in monitoring are shown in Fig.1. The ROTDR temperature sensing cable is only sensitive to temperature. The PPP-BOTDA strain sensing cable is cross sensitive to strain and temperature.

Tab.1Features of three distributed optical fibre sensing techniques

TechniqueFBGROTDRPPP-BOTDAMeasuringdistance/km2,4,6,825Spatialresolution1m5cmMeasurementaccuracy±0.2℃±0.2℃±7.5×10-6Measurementrange-40to200℃-40to120℃-0.03to0.04Young smodulus/GPa2000.331.1Stiffnesscoefficient/(MN·m-1)0.6186.6

The sensing function of FBG was first discovered in the formation of photo-generated optical fibres by Hill et al[13].

Fig.1 Structure of the sensors.(a) FBG sensor; (b) ROTDR sensing cable; (c) PPP-BOTDA sensing cable

The Bragg grating is written into a segment of Ge-doped single-mode fibre, in which a periodic modulation of the core refractive index is formed by exposure to a spatial pattern of ultraviolet (UV) light[14]. According to Bragg’s law, when a broadband source of light has been injected into the fibre, FBG reflects a narrow spectral part of light at a certain wavelength[15]. FBG can accurately measure strain and temperature by use of its wavelength shift. FBG sensors with different wavelengths can be connected to construct a quasi-distributed sensing array.

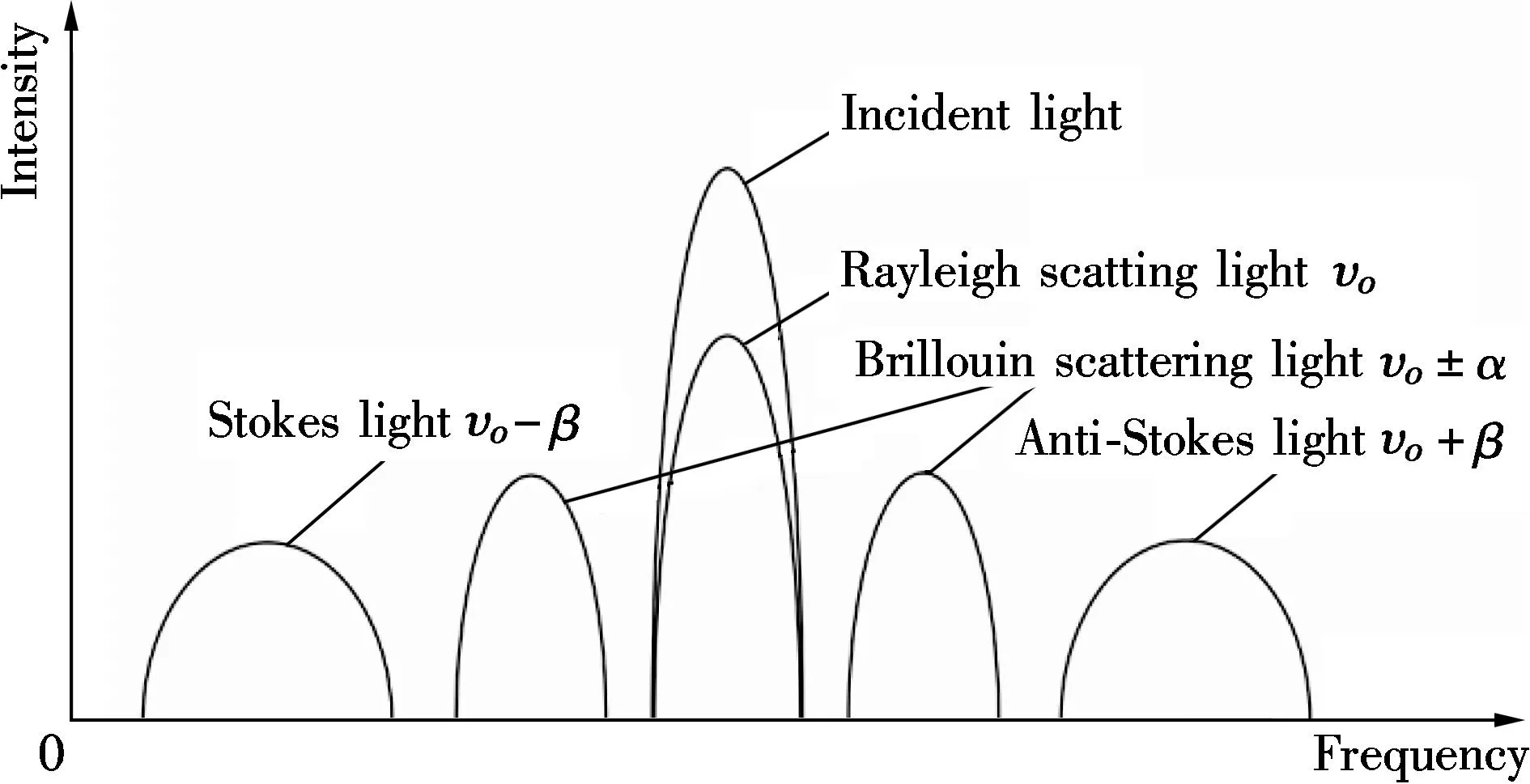

In the measurement process of ROTDR, an intense laser pulse is launched into a sensing fibre. Due to collision between photon and optical fibre molecules, the back scattering light is yielded. The back scattering light can be divided into Rayleigh scattering light, Raman scattering light and Brillouin scattering light[16]. The frequency spectrum characteristics of Rayleigh and Raman scattering lights are influenced by a variety of factors, such as strain, pressure, electric magnetic and so on. According to the frequency spectrum of Rayleigh scattering light, it can be divided into anti-Stokes light and Stoke light, as shown in Fig.2. ROTDR can measure the temperature distribution if the frequency spectrum of Rayleigh scattering light is captured.

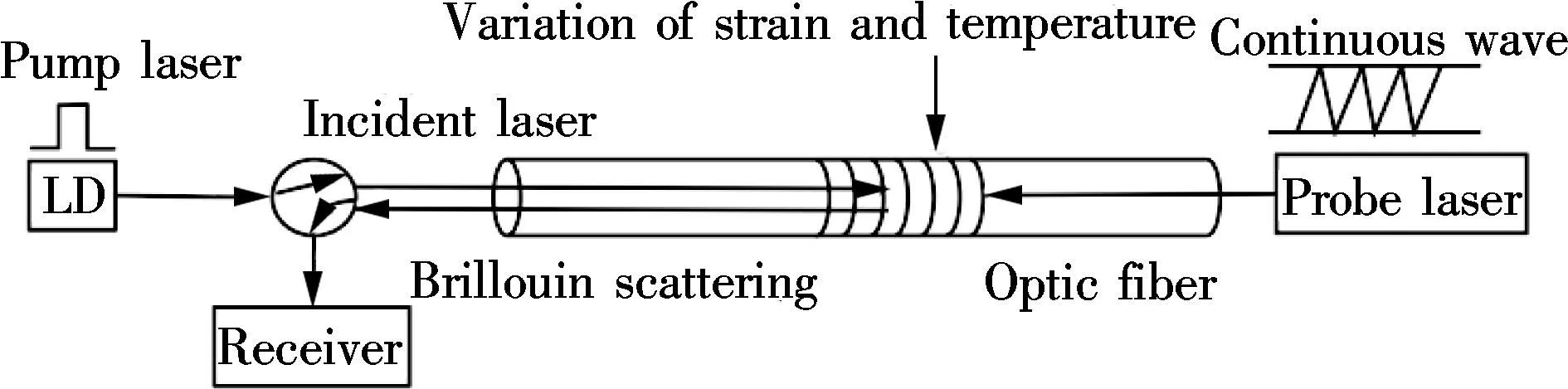

The PPP-BOTDA sensing technique is based on stimulated Brillouin backscattering. During measurement, the pulse laser (pump laser) and probe continuous wave are injected into an optical fibre from two ends. When the

Fig.2 Scattering lights in a sensing optical fibre[16]

frequency difference between the two lasers equals the Brillouin frequency shift, the Brillouin backscattering will be stimulated and the energy transfer will be generated between the two lasers[17]. As shown in Fig.3, a new method using a pre-pump pulse in front of a traditional laser pulse to enhance the accuracy and spatial resolution was introduced by Kishida et al.[18], which can enhance the accuracy and spatial resolution of the sensing technique.

Fig.3 Working principle of PPP-BOTDA

According to the linear relationship between the Brillouin frequency shift and the strain or temperature, the strain or temperature can be measured by detecting the frequency change of stimulated Brillouin scattering and the equation is given as[19]

VB(T,ε)=Cεε+CTT

whereCεandCTare the strain and temperature coefficients;νBis the Brillouin frequency shift;εandTare the strain variation and temperature variation, respectively. To accurately obtain the stress-strain field of the structure under load, we must correct the strain, which was affected by temperature. In this paper, the authors adopt the FBG temperature sensors to measure the surface temperature of the concrete and the temperature results are used to compensate the data measured by PPP-BOTDA to obtain the real concrete surface strain of the base plate.

2Project Background

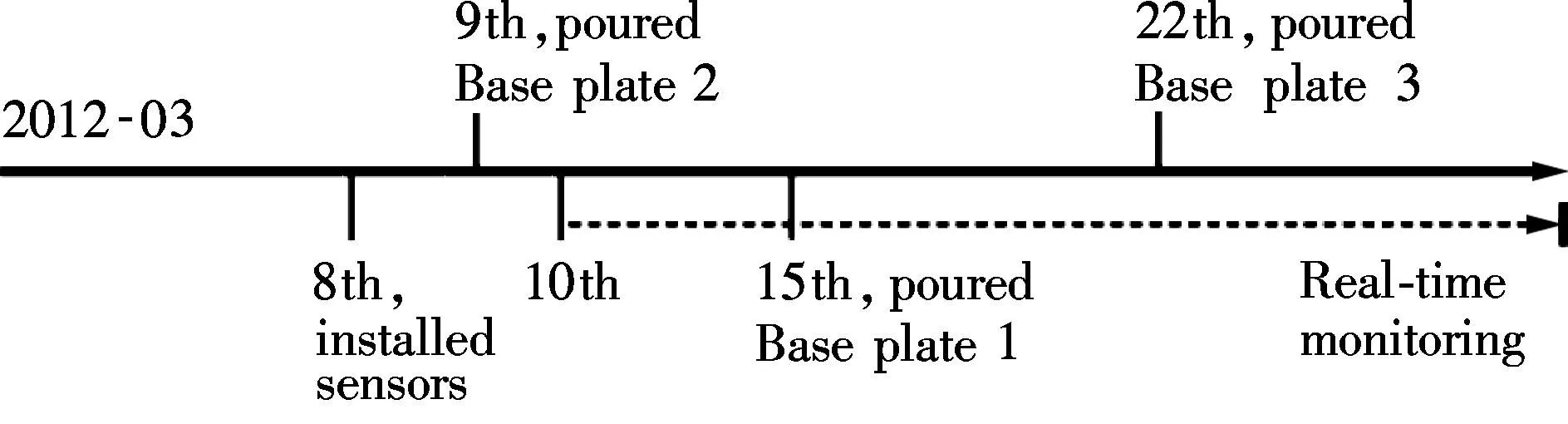

The ship lock as a case study is located in Jiangsu province, China. The size of the lock head base plate is 53.8 m×29.2 m×3.0 m. In order to control the concrete hydration temperature of the base plate, two post-cast strips (width: 1 m) were used to separate the base plate into three blocks of a similar size, defined as base plate 1, 2, 3, respectively. The blocks were poured with concrete one by one and the construction process is shown in Fig.4.

Fig.4 The construction process of the base plate

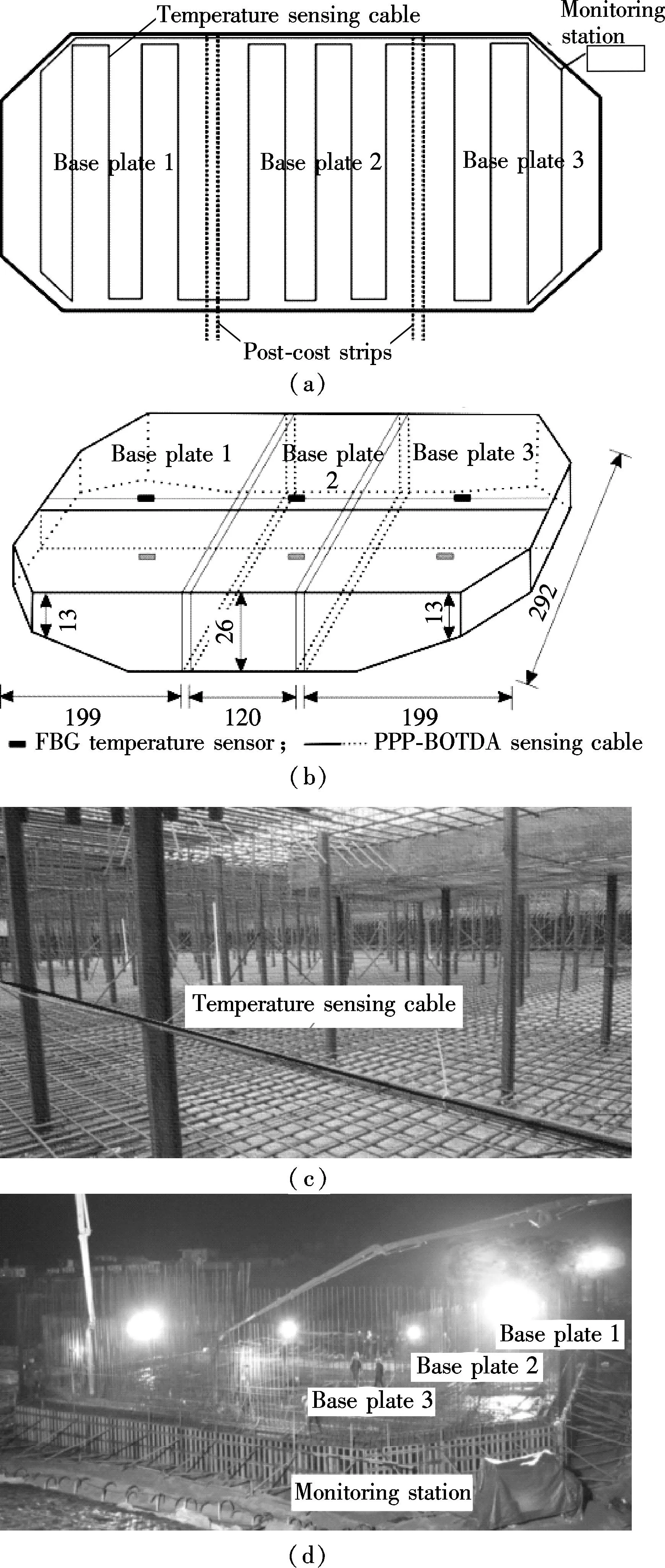

The ROTDR distributed temperature optical fibre sensing cable was laid on the central parts of base plate 1, 2, 3 with a U-shaped distribution,as shown in Fig.5(a).

Fig.5 Layout of the distributed optical fibre sensing system(unit:dm).(a) ROTDR temperature measurement; (b) FBG/PPP-BOTDA strain measurement; (c) Work filed ROTDR temperature measurement; (d) Work field monitoring station

According to the structural characteristics of the ship lock, distributed optical fibre sensing cable based on PPP-BOTDA was laid to real-time monitor the concrete strain and six FBG temperature sensors were installed along with the PPP-BOTDA sensing cable to monitor its temperature, as shown in Fig.5(b). The distance from the cable to the base plate surface is 10 cm. Fig.5(c) shows the layout of the ROTDR sensing cable in the work field. The construction of the three blocks of the base plate and the monitoring station are shown in Fig.5(d).

3Real-Time Monitoring Results

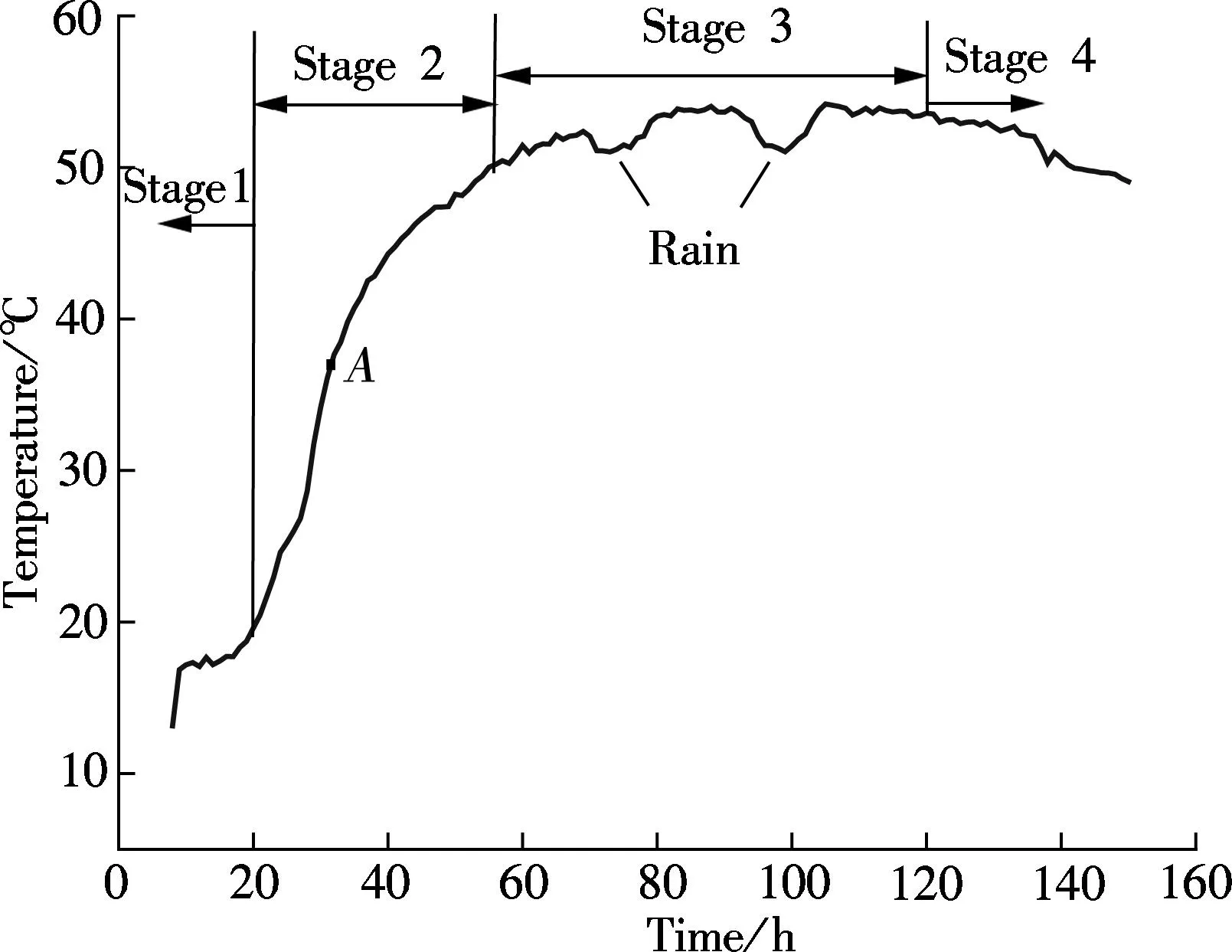

Base plate 2 was poured with concrete on March 9, 2012. The internal concrete temperature of the base plate was real-time monitored by the ROTDR technique and the monitoring data of the base plate geometric centre temperature is shown in Fig.6. It can be seen that the concrete hydration of base plate 2 produced a violent reaction and the peak temperature of the internal concrete block reached 53.7 ℃ after the concrete had been cured for 120 h. The change process of the concrete temperature can be divided into four stages: ① 0 to 20 h is defined as the beginning stage of the concrete hydration, in the end of which the concrete pouring was completed; ② From 20 to 55 h, the hydration was energetic and the concrete temperature of the base plate increased rapidly and the rate of the hydration exothermic reached a maximum in the 30th hour, which was marked as pointAin the figure; ③ From 55 to 120 h, the hydration reaction and the heat dissipation from the base plate surface reached a dynamic balance and the internal temperature of the base plate was affected by rain; ④ after 120 h, the hydration reaction was substantially completed and the internal concrete temperature began to decrease, as a result of dissipating heat from the base plate surface.

Fig.6 The temperature vs. time of base plate 2

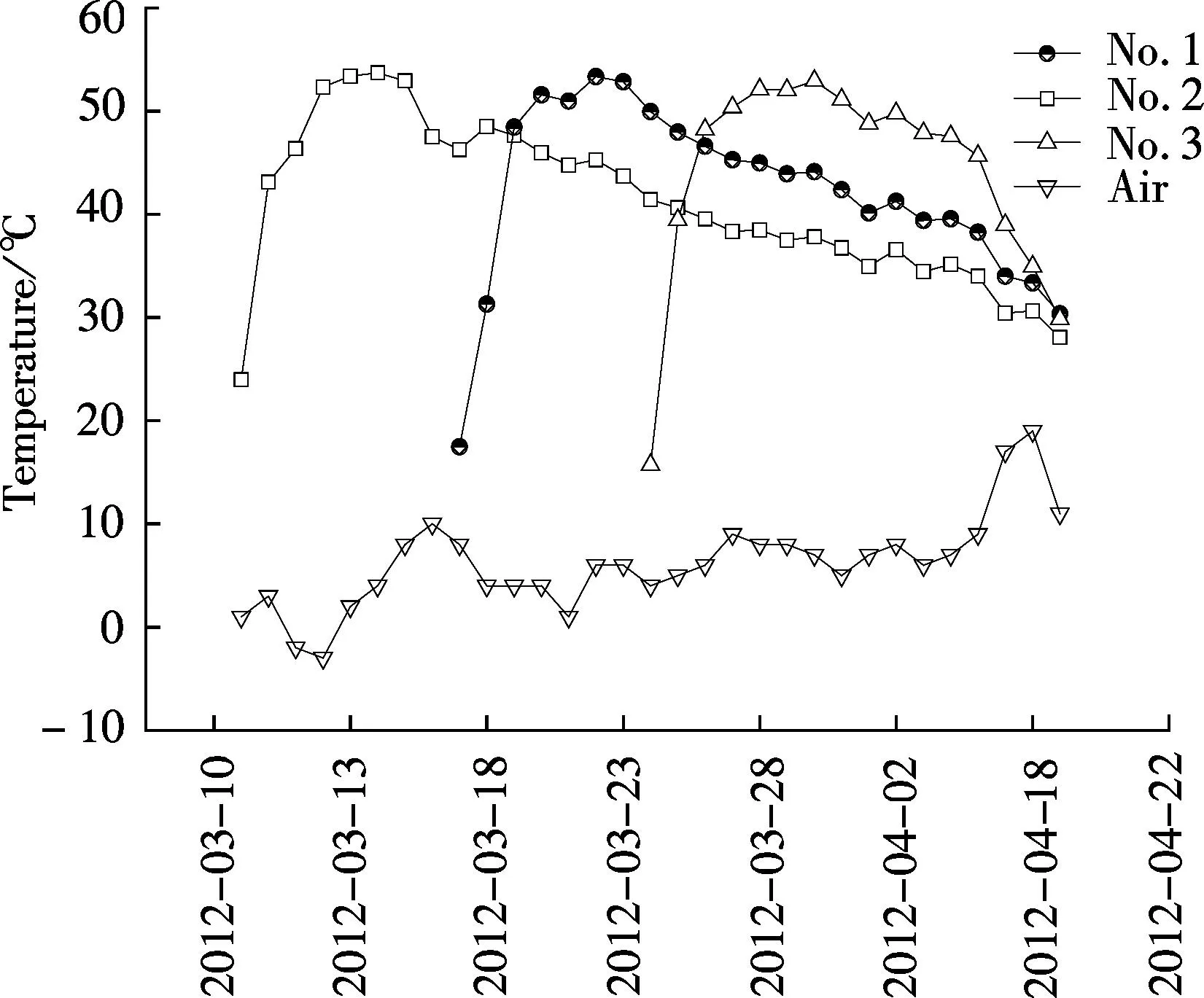

The central temperature of the three base plates is shown in Fig.7. The internal concrete temperature of three base plates reached a maximum on the 5th day and all of them were approximately 54 ℃. Overall, the change trend in the central temperature of the three base plates is similar.

Fig.7 The center temperature change trends of three base plates

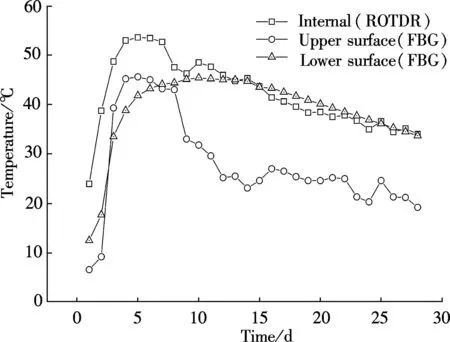

The concrete internal temperature of base plate 2 was monitored by the ROTDR sensing cable and the upper/lower surface temperatures were monitored by FBG thermometers. The monitoring results are shown in Fig.8, which indicate that the temperature of the internal and upper surface of the base plate reached a maximum almost at the same time (5 d after the concrete poured) and the maximum central temperature was 54 ℃. The temperature of the lower surface reached a maximal value of 46.3 ℃. The temperature of the lower surface changed slowly after reached the peak value. This can be attributed to the energetic hydration, which led to the rapid increase of the internal temperature. The hydration reaction essentially completed after 7 d, and the internal temperature gradually decreased and tended towards stability. Due to the better cooling condition near the upper surface, the temperature difference between the internal and the upper surface was much higher than the lower surface temperature. It suggests that the hydration heat of the base plate mainly dissipated through the upper surface.

Fig.8 The concrete temperature of base plate 2

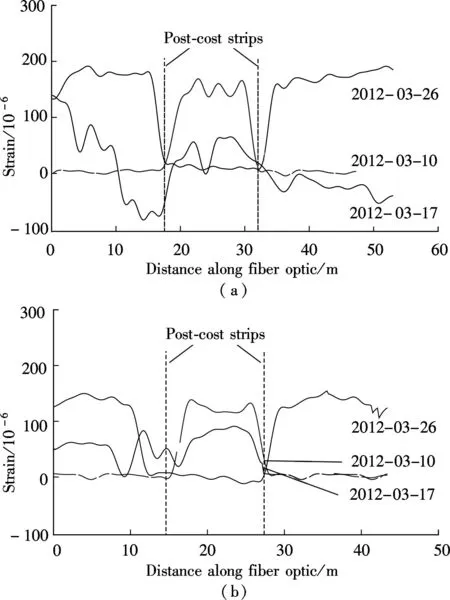

The PPP-BOTDA technique was employed to monitore the concrete surface strain of three base plates after each of them was poured. The concrete surface temperature, monitored by the FBG sensors, was used to compensate the strain values obtained by Eq.(1). The corrected concrete strain monitoring results are shown in Fig.9.

Fig.9 The strain of three base plates.(a) The upper surface strain; (b) The lower surface strain

It can be seen from Fig.9 that, 2 d after the concrete pouring (2012-03-10), the upper and lower surfaces of concrete of base plate 2 were subjected to tensile strain, and both of their strains were about 170×10-6. This was mainly because the concrete hydration heat was being released and the structure of the base plate was affected by thermal stress. Then, the concrete hydration heat was weakened and the temperature of the surface concrete decreased 8 d after the concrete pouring. At the same time, the thermal stress decreased and the concrete strain of the upper surface was reduced to about 50×10-6, as shown in Fig.9(a). However, the concrete strain of the lower surface was maintained at approximately 90×10-6, as shown in Fig.8(b). This was mainly because the lower surface concrete was based on the foundation and its temperature dropped more slowly than that of the upper surface. Therefore, the effect of thermal stress on the internal concrete was much greater than that of the upper surface concrete. In addition, the upper surface concrete strain of base plate 1 had an irregular distribution 2 d after the concrete pouring, as shown in Fig.9(a). The authors considered the monitoring data to be an instrumental error. On March 26, 2012, 18 d after the concrete had been poured, the concrete heat hydration had finished and the base plate was weakly affected by the structural thermal stress. The concrete strains of the upper and lower surface were reduced to zero. Compared with the concrete strain of base plates 1 and 3, similar trends were observed. Thus, it can be concluded that the base plate structure is mainly affected by the thermal stress of the concrete hydration heat release at the early construction stage.

4Conclusion

The concrete hydration heat temperature of the ship lock base plate was real-time monitored by the ROTDR technique. The results show that the central temperature of the base plate reached a maximum after the concrete had cured for 120 h and the maximum was about 54 ℃.

According to the monitoring data of the PPP-BOTDA and FBG sensors, the concrete of the base plate showed tensile stress during its construction and the base plate structure is mainly affected by temperature stress of the concrete hydration heat release in the early construction stage.

These monitoring results indicate above that the distributed optical fibre sensing technique used in this paper is a powerful and useful tool to real-time monitor the base plate construction of a ship lock structure. The distributed optical fibre sensing can be applied to infrastructural engineering construction monitoring.

References

[1]Song Z P, Zhang D, Shi B, et al. A study on distributed measurement in ship lock structural construction monitoring using fibre optic sensing [C]//GlobalViewofEngineeringGeologyandtheEnvironmentTechnologies. Beijing, 2012: 605-610.

[3]Shi B, Xu H Z, Zhang D, et al. Feasibility study on application of BOTDR to health monitoring for large infrastructure engineering [J].ChineseJournalofRockMechanics&Engineering, 2004, 23(3): 493-499. (in Chinese)

[4]Zhang D, Shi B, Wu Z S, et al. Distributed optical fibre sensor based on BOTDR and its application to structural health monitoring [J].ChinaCivilEngineeringJournal, 2005, 36(11): 83-87. (in Chinese)

[5]Bastianini F, Matta F, Galati N, et al. A Brillouin smart FRP material and a strain data post processing software for structural health monitoring through laboratory testing and field application on a highway bridge[C]//ProcSPIE. San Diego, CA, USA, 2005, 5765: 600-611.

[6]Bao X Y, Dhliwayo J, Heron N, et al. Experimental and theoretical studies on a distributed temperature sensor based on Brollouin scattering [J].LightwaveTechnology, 1995, 13(7):1340-1348.

[7]Wu Z S, Shi B, Harada T, et al. An experimental study on the measuring characteristics of BOTDR for structure health monitoring [J].ChinaCivilEngineeringJournal, 2005, 6(11): 83-87. (in Chinese)

[8]Zhu H H, Yin J H, Zhang L, et al. Monitoring internal displacements of a model dam using FBG sensing bars [J].AdvancesinStructuralEngineering, 2010, 13(2): 249-261.

[9]Zhu H H, Yin J H, Jin W, et al. Health monitoring of foundations using fibre Bragg grating sensing technology [J].ChinaCivilEngineeringJournal, 2010, 43(6): 109-115. (in Chinese)

[10]Fei B, Shi B, Zhu H H, et al. Study on the temperature field reconstruction for mass concrete based on DTS-GS method [C]//NewFrontiersinGeotechnicalEngineering. Shanghai, 2014: 150-159.

[11]Shi B, Xu H Z, Chen B, et al. A feasibility study on the application of fibre-optic distributed sensors for strain measurement in the Taiwan strait tunnel project [J].MarineGeoresources&Geotechnology, 2003, 21(3/4): 333-343.

[12]Matta F, Bastianini F, Galati N, et al. Distributed strain measurement in steel bridge with fibre optic sensors: validation through diagnostic load test [J].JournalofPerformanceofConstructedFacilities, 2008, 22(4): 264-273.

[13]Hill K O, Fujii Y, Johnson D C, et al. Photosensitivity in optical fiber waveguides: application to reflection filter fabrication [J].ApplPhysLett, 1978, 32(10): 647-649.

[14]Zhu H H, Ho A L, Yin J H, et al. An optical fibre monitoring system for evaluating the performance of a soil nailed slope [J].SmartStructures&Systems, 2012, 9(5): 393-410.

[15]Morey W W, Meltz G, Glenn W H. Fibre optic Bragg grating sensors [J].ProceedingsofSPIE, 1989, 1169(96): 98-107.

[16]Grattan K T V, Sun T. Fiber optic sensor technology: an overview [J].Sensors&Actuators, 2000, 82(1):40-61.

[17]Horiguchi T, Tateda M. BOTDA—nondestructive measurement of single-mode optical fiber attenuation characteristics using Brillouin interaction: theory [J].JournalofLightwaveTechnology, 1989, 7(8): 1170-1176.

[18]Kishida K, Li C H. Pulse pre-pump-BOTDA technology for new generation of distributed strain measuring system [J].StructuralHealthMonitoringandIntelligentInfrastructure, 2005, 5855: 471-477.

[19]Bernini R, Minardo A, Zeni L. Reconstruction technique for stimulated Brillouin scattering distributed fiber-optic sensors [J].OpticalEngineering, 2002, 41(9): 2186-2194.

doi:10.3969/j.issn.1003-7985.2015.04.018

Journal of Southeast University(English Edition)2015年4期

Journal of Southeast University(English Edition)2015年4期

- Journal of Southeast University(English Edition)的其它文章

- 廣義H-Hom-李代數(shù)的包絡(luò)代數(shù)

- 基于默認(rèn)網(wǎng)絡(luò)貝葉斯模型的輕微型肝性腦病的判別方法

- 微囊藻毒素-LR對大鼠海馬組織中N-乙酰門冬氨酸及神經(jīng)行為的作用

- 丁烯氧化脫氫制丁二烯反應(yīng)擴(kuò)散過程的數(shù)值模擬

- 用作熱穩(wěn)定劑的有色層狀氫氧化物的合成與表征

- 長江深水航道工程后特征物種的生態(tài)評價(jià)