十氫萘/空氣混合物高溫著火延遲的激波管測量

何九寧 李有亮 張昌華 李 萍,* 李象遠

(1四川大學原子與分子物理研究所,成都610065;2四川大學化學工程學院,成都610065)

1 lntroduction

Real hydrocarbon fuels are complex mixtures containing hundreds of chemical constituents.The chemical species contained in these fuels belongs to only four classes:alkanes,alkenes,cycloalkanes,and aromatics.1The oxidation characteristics of alkanes have been well investigated.2,3However,only a few studies were performed on the oxidation characteristics of cycloalkanes.4,5Decalin,C10H18,is a typical bicyclic compound in liquid hydrocarbon fuels.It is usually chosen as a representative component of cycloalkanes for surrogate diesel fuels.6-8Decalin is a primary constituent of petroleum feedstocks and found in automotive fuels,aircraft fuels,and proposed additive package for these various fuels.9Moreover,it is also considered as an endothermic fuel with potential capability for engine cooling.10Therefore,investigations on the oxidation property of decalin are necessary.

Previous experimental studies of decalin mostly involved in its oxidation and pyrolysis characteristics.Zhuet al.9studied the pyrolysis and oxidation of decalin in a shock tube between 769-1202 K,for pressures of 11.82×105-51.71×105Pa and equivalence ratios(Φ)of 0.5,1.0,and 2.0.They observed the negative temperature coefficient behavior of decalin auto-ignition at temperature below 920 K.Dagautet al.11investigated the decalin oxidation and pyrolysis in a jet-stirred reactor at pressures of 1.01×105and 10.10×105Pa.They measured the stable species concentration profiles from the oxidation of decalin.Stewartet al.12investigated the supercritical decalin pyrolysis in terms of product distribution and probable reaction pathways in a flow reactor.Pressures and temperatures varied over ranges from 2.02×105to 10.10×106Pa and 700 to 810 K.The oxidation chemistry of decalin was investigated by Yang and Boehman13in a motored engine at low to intermediate temperatures,and decalin showed significant low temperature reactivity.Ignition delay time measurements of decalin at elevated pressures were performed in a shock tube for temperatures ranging from 990 to 1300 K by Oehlschlaegeret al.14For kinetic study,a semi-detailed kinetic sub-mechanism was proposed for describing the high temperature pyrolysis and oxidation of decalin by Oehlschlaegeret al.14The mechanism is the only one available for decalin from literature.The validation of this mechanism was performed in high pressures by Zhuet al.9and the experimental data were overpredicted.Up to now,the ignition delay data of decalin at low pressures are scarce.

In order to understand the ignition delay characteristics of decalin and validate its kinetic mechanism,ignition delay time of decalin/air mixtures was measured behind reflected shock waves in a heated shock tube.The experimental conditions are as follows:temperatures of 950-1395 K,pressures of 1.82×105-16.56×105Pa,and equivalence ratios of 0.5,1.0,and 2.0.The effects of temperature,pressure,and equivalence ratio on the ignition delay time were investigated.Comparisons between the measured data and predictions of available kinetic mechanism were conducted.Furthermore,sensitivity analysis was performed to identify important reactions in the decalin/air ignition process.

2 Experimental

Ignition delay time measurements were carried out in a heated stainless-steel shock tube with an internal diameter of 10 cm,which consists of a 6 m driver and a 5 m driven sections.Two sections were separated by a double diaphragm section.Diaphragms of different gauges were chosen to obtain various reflected shock pressures.The details of the shock tube facility have been described elsewhere.15,16High-purity helium(>99.99%purity)was used as the driver gas.Prior to each run,the shock tube was evacuated down to 10 Pa or better using a vacuum pump system.Meanwhile,the initial temperature of driven section was uniformly heated to 120°C using six electro-thermal circuits and controllers with uncertainty within±3 °C.Mixtures of gas phase decalin/synthesis air(21%O2and 79%N2)mixtures were prepared in a stainless-steel mixing tank of 40 L.Purities of N2and O2are higher than 99.99%.The mixing tank can be pumped down to pressures below 10 Pa.In order to prevent condensation of the fuel,the mixing tank was preheated and maintained at 150°C.Additionally,all connecting delivery lines were also evaporated below 10 Pa by the vacuum system before preparing the mixtures to be investigated.Neat decalin was directly injected into the tank,after evaporation,synthesis air was added to prepare the desired mixtures.Pressures of gas phase decalin in the tank were monitored by a thin-film capacitance manometer.Oxygen and nitrogen were measured by a pressure gauge.

The incident shock velocity was measured through four piezoelectric pressure transducers(PCB113B),which are equally spaced alongside the test section.The distance of each two pressure transducers was 18.9 cm.The velocity at the end wall was obtained by extrapolating the three wave velocities.The ignition temperature(T)and pressure(p)behind the reflected shock wave were obtained using the one-dimensional(1D)normal shock equations with respect to the measured initial temperature in the driven section,the measured incident shock wave velocity,and the thermodynamic properties of the reactant mixtures.Light emission was detected through a quartz optical fiber located at side wall 15 mm away from the end wall.The fiber was connected with a grating monochromator(Zolix Omni-λ3009)coupled with photomultiplier tubes(PMT).The monochromator was set to 431 nm to capture electronically excited CH*emission from theA2Δ-X2Пtransition.The optical signal was recorded by a digital phosphor oscilloscope(Tektronix TDS5054B),and four pressure signals transmitted through pressure transducers were recorded by another oscilloscope(Tektronix DPO5054).

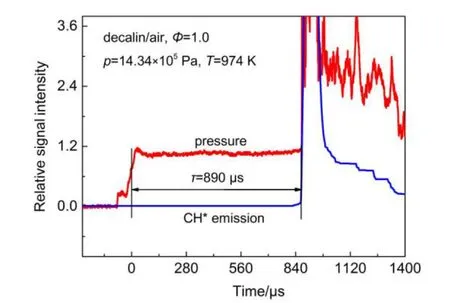

The ignition delay time(τ)is defined as the time interval between arrival of the reflected shock wave and the onset of ignition at the side-wall observation location(15 mm from the end wall).The arrival of the reflected shock wave is determined by the jump of pressure signal,while the steepest increase of the CH*emission means the onset of ignition.Fig.1 shows an example of ignition delay time determination.The uncertainty in measured ignition delay time is estimated within±20%based on combined uncertainties in reflected shock temperature and pressure measurement,and uncertainty in the ignition delay time determination from the measured pressure and emission signals.

3 Results and discussion

3.1 lgnition delay time

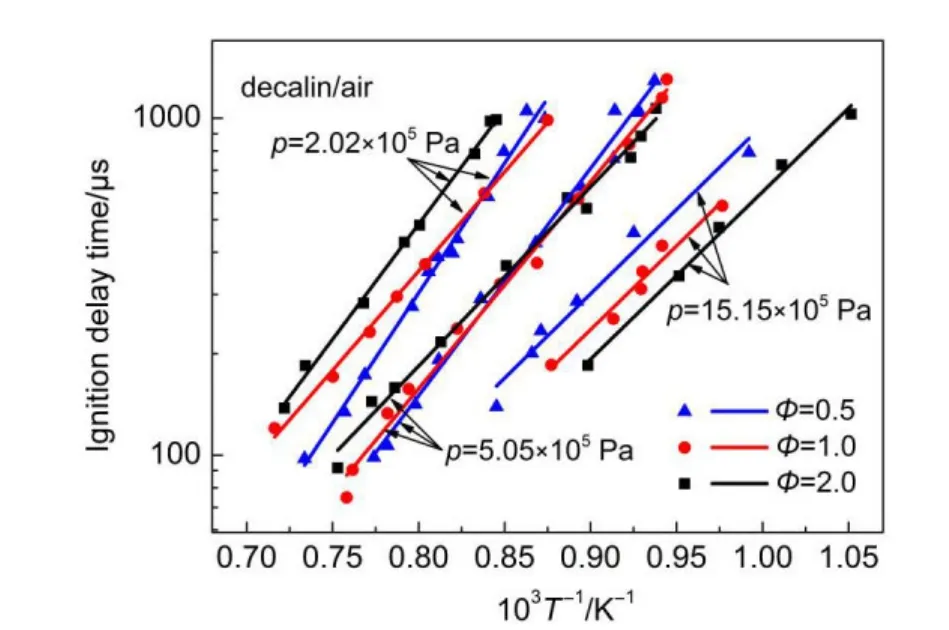

Ignition delay time of decalin/air mixtures was obtained for pressures of 1.82×105-16.56×105Pa,temperatures of 950-1395 K,equivalence ratios of 0.5,1.0,and 2.0.The measured data are listed in Table 1 and shown in Fig.2.The data in Fig.2 are scaled to 2.02×105,5.05×105,and 15.15×105Pa using the power-law relationship(τ∝p-1),thisp-1dependence has been observed in many previous studies with different experimental facilities.17Present results show that an increasing temperature or pressure results in a decrease in ignition delay time.However,there is no law to describe the effect of equivalence ratio on the ignition delay time directly,and an opposite behavior of the ignition delay dependence on equivalence ratio at pressures of 2.02×105and 15.15×105Pa was observed.

At pressure of 2.02×105Pa,fuel-rich mixture(Φ=2.0)gives the longest ignition delay time,and ignition delay time of stoichiometric and fuel-lean mixtures(Φ=1.0,0.5)exhibit a crossover at temperature of~1200 K.The fuel-lean mixture has the shortest ignition delay time in excess of 1200 K.This indicates that the ignition delay time increases with the increase of the fuel concentration at relatively high temperatures,showing a positive dependence on the equivalence ratio.The phenomenon was also found for 2,4-dimethylpentane,2,5-dimethylhexane,and isooctane at high temperature and low pressure.18At these conditions,the ignition delay is mostly controlled by the chain-branching reaction H+O2=OH+O.The reaction has a promoting influence on the ignition delay time,which will be discussed later.

At pressure of 15.15×105Pa,contrary to the results at 2.02×105Pa,the fuel-rich mixture gives the shortest ignition delay time,and fuel-lean mixture presents the longest one.It demonstrates that the ignition delay time decreases with increase of the fuel concentration,and exhibits a negative dependence on equivalence ratio.Similar behavior for fuels at high temperatures was commonly found.9,19,20

Fig.1 Example of decalin/air ignition delay time(τ)determination

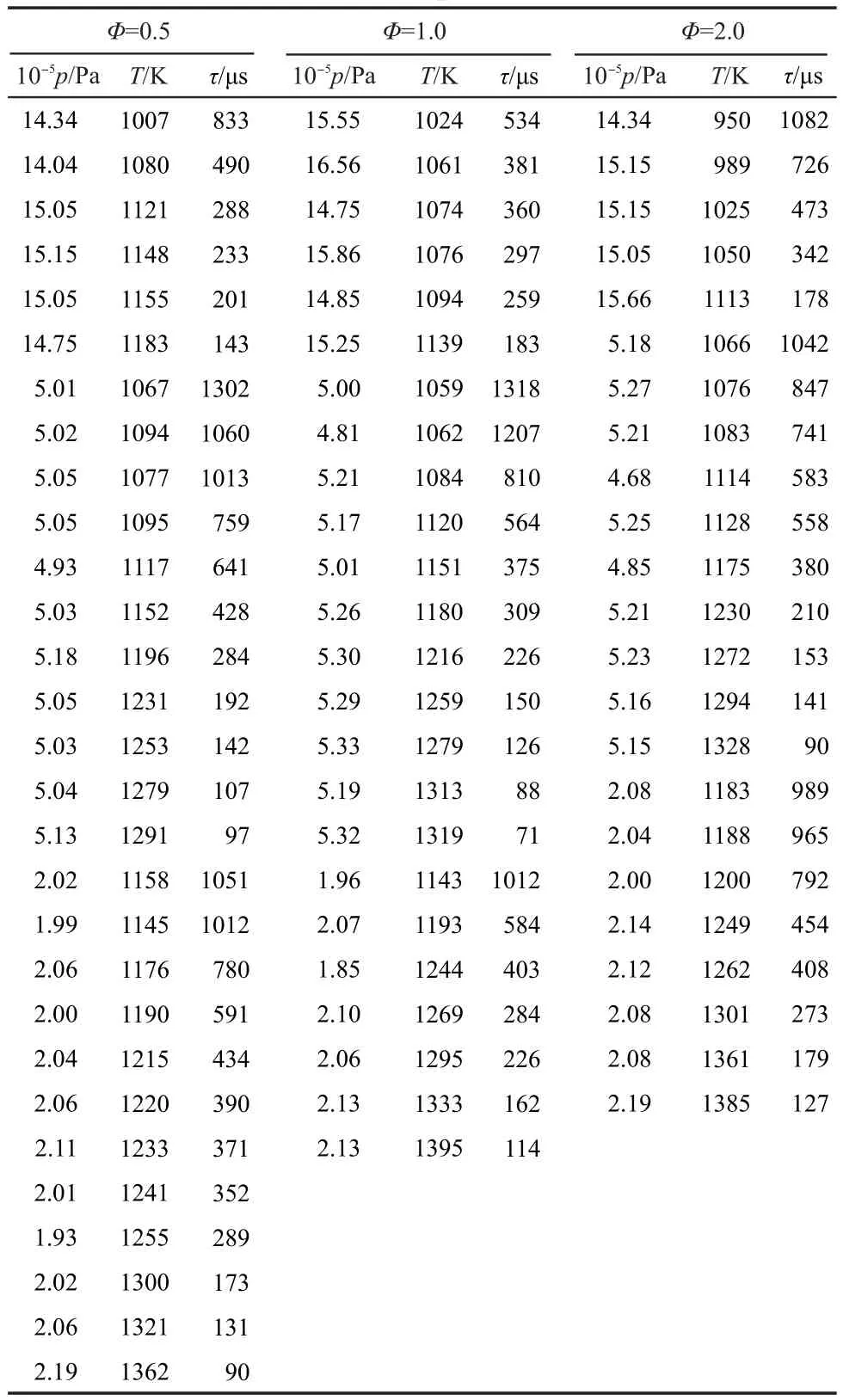

Table 1 Measured ignition delay time(τ)data of decalin/air mixtures at different equivalence ratios(Φ)

Fig.2 Current ignition delay time of decalin/air mixtures

For measured data at pressure of 5.05×105Pa,a reduction in the fuel concentration leads to a bit increase in ignition delay time at temperatures below1152 K,but leads to a bit decrease when temperature is higher than 1152 K.This intermediate pressure behavior of ignition delay time was seldom reported.

Overall,the effect of equivalence ratio on the ignition delay time of decalin/air is complex,and there is no definite law to describe it.At pressure of 2.02×105Pa with temperatures higher than 1200 K,the effect of equivalence ratio on ignition delay time is positive(τ∝Φ+n).At 15.15×105Pa,the equivalence ratio dependence is negative(τ∝Φ-n)over the current temperature range.This shift in decalin/air ignition delay time dependence on equivalence ratio at 2.02×105and 15.15×105Pa was observed for the first time.At pressure of 5.05×105Pa,it seems that ignition delay time influenced by equivalence ratio and temperature simultaneously.A discussion about the cause of the shift in the ignition delay dependence on equivalence ratio is provided in sensitivity analysis section later.

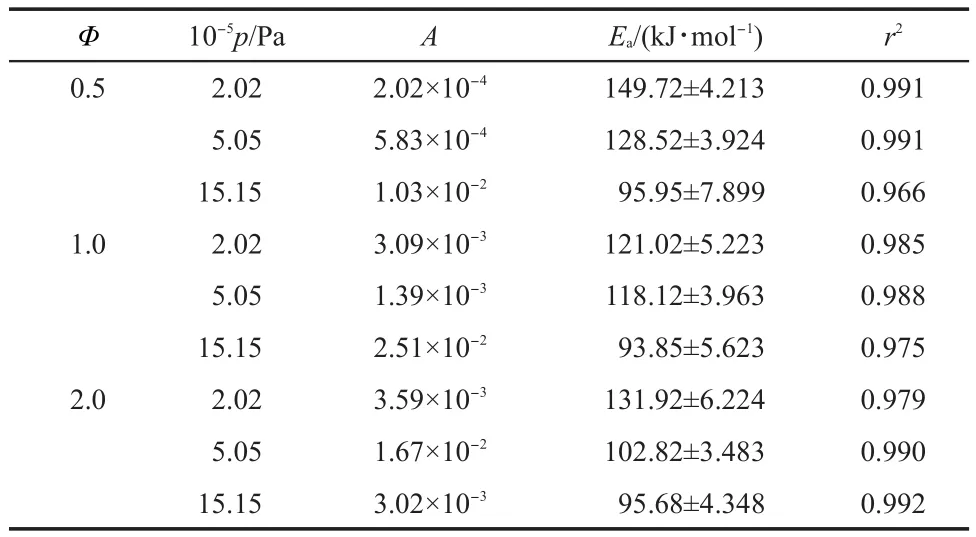

Fig.2 also shows that the sensitivity of ignition delay time on temperature varies with equivalence ratio or pressure.In order to compare the sensitivities of ignition delay time on temperature,an Arrhenius temperature dependence equationτ=A×exp(Ea/RT)was used to correlate measured data,whereAis the pre-exponential factor,Eais the global activation energy(kJ?mol-1)which indicates the sensitivity of ignition delay time on temperature,Tis the ignition temperature in K,andRis the universal gas constant(8.314 J?mol-1?K-1).The correlated results are shown in Table 2,wherer2is a correlation coefficient.Table 2 shows that global activation energy of decalin/air mixture decreases with the increase of pressure for same equivalence ratio.It indicates that the change of ignition delay time at low pressures is more sensitive to the variations of temperature.These trends have been observed for other hydrocarbon fuels in shock tube experiments,21,22and it may due to different chemistry controlling the ignition process at different pressures.

3.2 Comparison with previous data and mechanism predictions

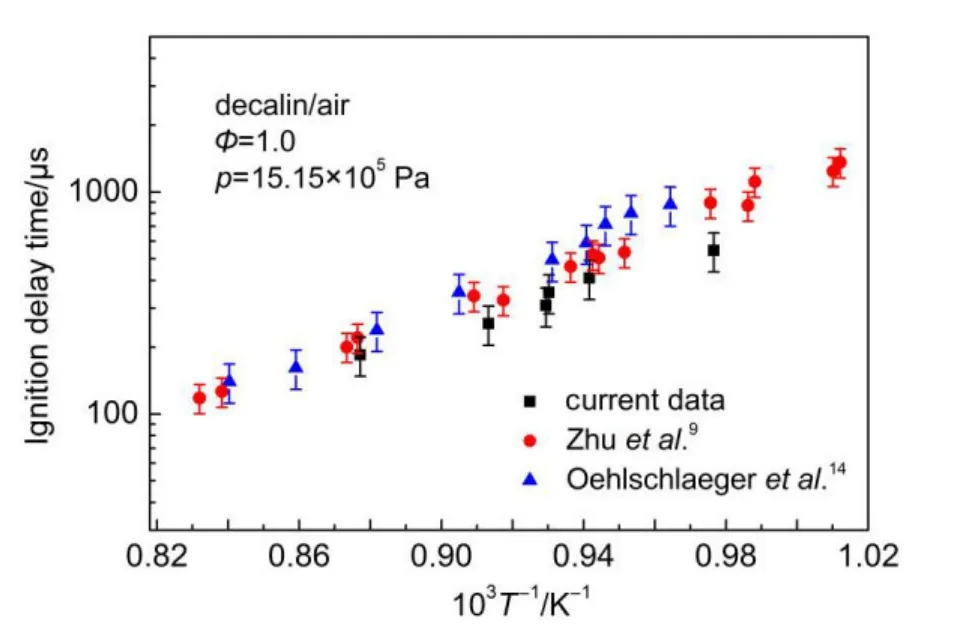

To our knowledge,there have been no previous decalin ignition delay time measurements at 2.02×105and 5.05×105Pa for comparison to the current study.The measured ignition time forΦ=1.0,0.5 at 15.15×105Pa is compared to the data of Zhu9and Oehlschlaeger14et al.in Fig.3 and Fig.4.Error bars(Zhu:±15%,Oehlschlaeger:±20%,and current work:±20%)have been added into these figures.In Fig.3,the data of Zhuet al.at 12.12×105and 20.20×105Pa and Oehlschlaegeret al.at 12.12 ×105Pa are scaled to 15.15×105Pa usingτ∝p-0.78given by those authors.In Fig.4,the data of Zhuet al.at 20.20×105Pa and Oehlschlaegeret al.at 12.12×105Pa are scaled to 15.15 ×105Pa using the same scaling factor.Results show that current data agree with previous data reasonably.ForΦ=1.0 with temperatures in excess of 1120 K,the three sources of data are in good agreement with each other,but for lower temperatures,Zhuet al.obtained slightly longer ignition delay time than measured data here,and Oehlschlaegeret al.given the longest data.Similarly,forΦ=0.5,data of Oehlschlaegeret al.are the longest and present data are the shortest.Presumably the discrepancy between three sources of data is mainly due to uncertainties of these experiments.

Table 2 Correlated results for decalin ignition data

Fig.3 Comparison of current ignition delay time for decalin/air at 15.15×105Pa and Φ=1.0 with previous experimental data

Fig.4 Comparison of current ignition delay time for decalin/air at 15.15×105Pa and Φ=0.5 with previous experimental data

Asemi-detailed kinetic mechanism proposed by Oehlschlaegeret al.14is the only one available for describing the oxidation of decalin.This mechanism was recently improved by them,which contains 200 species and 6826 reactions(online at www.chem.polimi.it/CRECKModeling/).Predictions of this mechanism for decalin ignition delay were carried out by using the program of CHEMKIN,23and the zero dimensional model and adiabatic constant volume constraint were applied.The criterion of maximum CH radical concentration as the ignition delay time was adopted in current work.The predictions and comparison with current experimental data are shown in Fig.5.At 2.02×105Pa,the mechanism well predicts global activation energies of experiments.The predictions show that ignition delay time have a crossover forΦ=1.0 andΦ=2.0,and the fuel-rich mixture is the slowest to ignite.At 5.05×105Pa,predictions indicate that the fuellean mixture gives longer ignition delay time at relatively low temperatures,but the fuel-lean mixture gives shorter ones at higher temperatures.At 15.15×105Pa,predictions show that the fuel-rich mixture is the fastest to ignite.In summary,the trends of experimental data were captured quite well by the mechanism under all conditions investigated,and the shift in the ignition delay dependence on equivalence ratio at 2.02×105and 15.15×105Pa was also obtained.However,the mechanism over-predicts the ignition delay time of decalin/air at all current experimental conditions.The discrepancy of model predictions and experimental data may partly due to rate parameters of some key reactions in the decalin oxidation system being not accurate enough in the mechanism,and partly due to the experimental data having±20%uncertainty.Since the mechanism captured all trends of experimental results,it was used to perform sensitive analysis whose results are given in the next section.

Fig.5 Comparison of current data with predictions from Oehlschlaeger mechanism for decalin/air ignition delay at different pressures

3.3 Sensitivity analysis

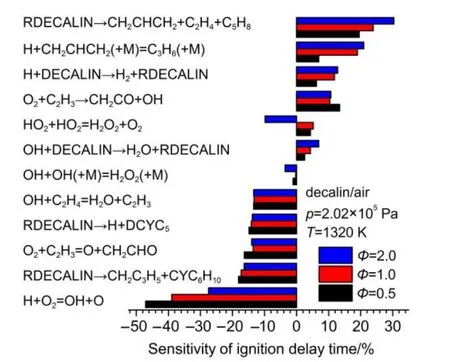

Sensitivity analysis was carried out by using the Oehlschlaeger mechanism to identify the important reactions on the ignition of decalin/air mixtures.The percent change in ignition delay time[τ(2ki)-τ(ki)]/τ(ki)×100%(kiis the reaction rate constant)is taken as the sensitivity of each reaction to the ignition delay time.24,25A positive coefficient indicates that the corresponding reaction has an inhibiting effect on the reactivity of the fuel and leads to an increase in ignition delay time,while a negative coefficient has a promoting effect.Fig.6 and Fig.7 demonstrate the results of the sensitivity analyses at typical conditions of 2.02×105Pa at 1320 K and 15.15×105Pa at 1100 K,respectively.

As shown in Fig.6,among the 12 high-sensitivity elementary reactions,the reaction H+O2=OH+O exhibits the strongest promoting effect on the ignition delay time.Reactions having negative coefficients are the decomposition of C10H17(RDECALIN)to form cyclohexane(CYC6H10)and C4H7radicals,molecular oxygen and vinyl radicals(C2H3)to form oxygen atoms and vinoxy radicals(CH2CHO),and the decomposition of C10H17to form hydrogen atoms and 3-cyclopentylcyclopentene(DCYC5).These reactions also have promoting influences on the ignition.The decomposition of C10H17to form allyl radicals(C3H5),ethylene(C2H4),and pentadiene(C5H8)has the strongest inhibiting effect on the ignition delay time.Since the ignition process is mainly controlled by the promoting reaction H+O2=OH+O at 1320 K and 2.02×105Pa,and theΦ=2.0 system has the less sensitivity thanΦ=0.5,1.0 systems to this reaction under the conditions,this may be the one of reasons for the fuel-rich mixture having the longest ignition delay time as shown in Fig.2.

Fig.6 Sensitivity of different reactions to the ignition delay time for decalin/air at p=2.02×105Pa,T=1320 K,and Φ=0.5,1.0,2.0 using the Oehlschlaeger mechanism

At a pressure of 15.15×105Pa and a temperature of 1100 K,sensitivity analysis results shown in Fig.7 are not the same as above.The decomposition of C10H17to form C4H7radical and cyclohexane,abstraction by hydroperoxy radical from decalin molecule(HO2+decalin=H2O2+RDECALIN),HO2+CH2CHCH2=OH+CH2O+C2H3are the three most influential reactions.These reactions have promoting effects on the overall reactivity and reduce the ignition delay time.However,the chain branching reaction H+O2=O+OH is much less sensitive than that at 2.02×105Pa.ForΦ=2.0 system,negative coefficient reactions are the most sensitive ones and have the strongest promoting effects on the ignition.Referring to positive coefficient reactions,the decomposition of C10H17to form allyl radical,ethylene and pentadiene plays the greatest inhibiting role in the ignition delay time.Reactions also exhibiting positive coefficients are hydrogen atoms and allyl radicals to form propylene(C3H6),and hydroperoxy radicals to form hydrogen peroxide(H2O2)and molecular oxygen.These positive coefficient reactions have stronger inhibiting influence on the ignition delay time for fuel-lean mixture.Considering the effects of promoting and inhibiting reactions on ignition process at 15.15×105Pa and 1100 K comprehensively,that fuel-rich mixture has the shortest ignition delay time is reasonable as got in the experiments.

Fig.7 Sensitivity of different reactions to the ignition delay time for decalin/air at p=15.15×105Pa,T=1100 K,and Φ=0.5,1.0,2.0 using the Oehlschlaeger mechanism

4 Conclusions

Ignition delay time has been measured in a shock tube for decalin/air mixtures for temperatures of 950-1395 K,pressures of 1.82×105-16.56×105Pa,and equivalence ratios of 0.5,1.0,and 2.0.Results show that an increase in temperature or pressure leads to a decrease in the ignition delay time.A shift in ignition delay time dependence on equivalence ratio for decalin/air mixture at different pressures was observed for the first time.Under pressure of 2.02×105Pa,the fuel-rich mixture has the longest ignition delay time.However,at 15.15×105Pa,fuel-rich mixture presents the shortest ignition delay time,fuel-lean mixture has the longest one.Predictions of Oehlschlaeger mechanism can capture the trends of present experimental data quite well under all conditions investigated,however the predictions overestimated the ignition delay time.Several important reactions influencing the ignition delay time were identified by sensitivity analyses.The branching reaction H+O2=OH+O has the strongest promoting effect on the ignition at 2.02×105Pa,1320 K,and equivalence ratio of 0.5,this contributes most to fuel-rich mixture having the longest ignition delay time.However,reactions of RDECALIN=C4H7+CYC6H10and HO2+DECALIN=H2O2+RDECALIN play the most important promoting role to promote the ignition at 15.15×105Pa and 1100 K.Current results are valuable to understand the ignition characteristics of decalin,and provide new experimental data for the development and validation of decalin kinetic mechanisms at low to intermediate pressures.

(1) Ranzi,E.Energy Fuels2006,20,1024.doi:10.1021/ef060028h

(2) Simmie,J.M.Prog.Energy Combust.Sci.2003,29,599.doi:10.1016/S0360-1285(03)00060-1

(3) Westbrook,C.K.;Pitz,W.J.;Herbinet,O.;Curran H.J.;Silke,E.J.Combust.Flame2009,156,181.doi:10.1016/j.combustflame.2008.07.014

(4) Silke,E.J.;Pitz,W.J.;Westbrook,C.K.;Ribaucour,M.J.Phys.Chem.A2007,111,3761.doi:10.1021/jp067592d

(5) Vanderover,J.;Oehlschlaeger,M.A.Int.J.Chem.Kinet.2009,41,82.doi:10.1002/kin.v41:2

(6) Eddings,E.G.;Yan,S.;Ciro,W.;Sarofim,A.F.Combust.Sci.Technol.2005,177,715.doi:10.1080/00102200590917248

(7) Agosta,A.;Cernansky,N.P.;Miller,D.L.;Faravelli,T.;Ranzi,E.Exp.Therm.Fluid Sci.2004,28,701.doi:10.1016/j.expthermflusci.2003.12.006

(8) Mueller,C.J.;Cannella,W.J.;Bruno,T.J.;Bunting,B.;Dettman,H.D.;Franz,J.A.;Huber,M.L.;Natarajan,M.;Pitz,W.J.;Ratcliff,M.A.;Wright,K.Energy Fuels2012,26,3284.doi:10.1021/ef300303e

(9) Zhu,Y.;Davidson,D.F.;Hanson,R.K.Combust.Flame2014,161,371.doi:10.1016/j.combustflame.2013.09.005

(10) Edwards,T.J.Propul.Power2003,19,1089.doi:10.2514/2.6946

(11) Dagaut,P.;Ristori,A.;Frassoldati,A.;Faravelli,T.;Dayma,G.;Ranzi,E.Proc.Combust.Inst.2013,34,289.doi:10.1016/j.proci.2012.05.099

(12) Stewart,J.;Brezinsky,K.;Glassman,I.Combust.Sci.Tech.1998,136,373.doi:10.1080/00102209808924178

(13)Yang,Y.;Boehman,A.L.Combust.Flame2010,157,495.doi:10.1016/j.combustflame.2009.08.011

(14) Oehlschlaeger,M.A.;Shen,H.P.S.;Frassoldati,A.;Pierucci,S.;Ranzi,E.Energy Fuels2009,23,1464.doi:10.1021/ef800892y

(15) Zhang,C.H.;Li,P.;Guo,J.J.;Li,X.Y.Energy Fuels2012,26,1107.doi:10.1021/ef201611a

(16)Tang,H.C.;Zhang,C.H.;Li,P.;Wang,L.D.;Ye,B.;Li,X.Y.Acta Phys.-Chim.Sin.2012,28,787.[唐洪昌,張昌華,李萍,王利東,葉 彬,李象遠.物理化學學報,2012,28,787.]doi:10.3866/PKU.WHXB201202161

(17)Vasu,S.S.;Davidson,D.F.;Hanson,R.K.Combust.Flame2008,152,125.doi:10.1016/j.combustflame.2007.06.019

(18)Li,S.;Campos,A.;Davidson,D.F.;Hanson,R.K.Fuel2014,118,398.doi:10.1016/j.fuel.2013.11.028

(19) Darcy,D.;Tobin,C.J.;Yasunaga,K.Combust.Flame2012,159,2219.doi:10.1016/j.combustflame.2012.02.009

(20) Shen,H.P.S.;Vanderover,J.;Oehlschlaeger,M.A.Proc.Combust.Inst.2009,32,165.doi:10.1016/j.proci.2008.05.004

(21)Daley,S.M.;Berkowitz,A.M.;Oehlschlaeger,M.A.Int.J.Chem.Kinet.2008,40,624.doi:10.1002/kin.v40:10

(22) Vasu,S.S.;Davidson,D.F.;Hong,Z.Energy Fuels2009,23,175.doi:10.1021/ef800694g

(23)Egolfopoulos,F.N.;Zhang,H.;Zhang,Z.Combust.Flame1997,109,237.doi:10.1016/S0010-2180(96)00152-6

(24) Zhang,C.H.;Tang,H.C.;Zhang,C.Z.;Zhao,Y.;Li,P.;Li,X.Y.Chem.Phys.Lett.2013,556,13.doi:10.1016/j.cplett.2012.11.023

(25)Kumar,K.;Mittal,G.;Sung,C.J.;Law,C.K.Combust.Flame2008,153,343.doi:10.1016/j.combustflame.2007.11.012