Machine Tool Fault Information Management System Software Development

LI Zi-chen (李子琛), LIU Yi-ping (劉以平), FU Guo-zhong (付國忠)

School of Mechanical Electronic and Industrial Engineering, University of Electronic Science and Technology of China, Chengdu 611731, China

Machine Tool Fault Information Management System Software Development

LI Zi-chen (李子琛)*, LIU Yi-ping (劉以平), FU Guo-zhong (付國忠)

SchoolofMechanicalElectronicandIndustrialEngineering,UniversityofElectronicScienceandTechnologyofChina,Chengdu611731,China

In order to collect failure data conveniently and reserve reliability research data, the data collection software, the machine tool fault information management system, was developed. The method to computer numerical control (CNC) machine tool reliability data collection was introduced. Through designing the form and applying SQL Server 2008 as the database and Visual Studio 2005 as the development platform, establish the database, develop the software based on the early stage work, and realize the comprehensive statistical information, laying the foundation for further data analysis.

datacollection;researchonreliability;softwaredevelopment;formdesign;databasedevelopment

Introduction

Computer numerical control (CNC) machine reliability analysis and fault analysis are based on sufficient reliability data. By developing machine fault information management system software more conveniently and efficiently, we can collect and arrange the CNC machine data, especially machine fault information and work condition information when the machine is at fault state, and the data can be more properly analyzed, processed, and preserved. CNC machine tool reliability data can reflect the reliability situation of the machine at different stages and affect the machine reliability by various relevant factors of the machine. Besides, this data are also the basis of reliability analysis of CNC machine tools and effective basis of reliability test and design[1]. Meanwhile, the failure data analysis can help us find the weak point of the CNC machine during operation process, and then suggest improvements to further enhance the reliability of CNC machine tools[2- 3].

In order to further improve the using reliability of machine tools, the machine tool failure and maintenance information need to be managed well. Based on the management and previous machine fault information, the working personnel can make maintenance strategy and maintenance plan quickly and accurately[4-5]. So we specially put forward software of machine tool fault information management system.

Solutions are as follows.

(1) Research various record files which are widely used in the workshop and literature records.

(2) Design forms which are able to collect comprehensive information and suitable for factory workers to fill in.

(3) Based on information contained in the created table, use SQL Server 2008 to design the database needed by fault information management system.

(4) Use C language and Visual Studio 2005 platform to design corresponding database application software according to the form and the record information.

(5) Debug software and work for its further improvement.

1 Form Design

Designing the data collection form is an important task of data collection. According to the demand, we can formulate unified and standardized form to facilitate exchange between different departments, as well as help reduce duplication of work and improve efficiency[6].

Before data collection, we must determine every piece of information, such as machine name, machine type, processing, fault location, fault mode,and invalid parts name. Then we use the information to design the form.

The design of forms is based on the actual operation requirements of factory. We arrange the content reasonably and design forms as shown in Table 1. Due to too many contents, only a small amount of data collection forms are shown.

Table 1 Data collection table

2 Database Design

Reliability analysis is based on a large number of field data. Only according to real and reliable data, we can perform failure analysis, reliability analysis and design, and then put forward reasonable suggestions to the improvement of design, use, and maintenance of the machine. Reliability of the data accumulation is a long and arduous process[7].

In the process, we must use a computer database technology. Database can be understood as a data collection that one or more units serve more users, run on a computer, and have a certain structure. Database is composed of three parts: history database, knowledge base, and CNC command libraries, and they are all used for storage device status. Implementation and management of the database is in relation to the degree of shared data in the system, therefore, the database system should have good safety, operability, and openness[8].

At present there are three popular database types: hierarchical, network, and relational. We use a relational database management system SQL Server 2008.

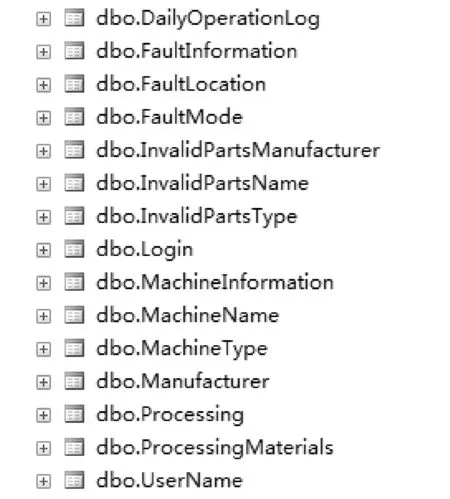

Apply SQL server 2008 to setting up data tables as shown in Fig.1.

Fig.1 Data tables of the database

3 Software Development

Machine fault information management system uses SQL Server 2008 as the basic database, and uses Visual Studio 2005 for program development. Both of the software are developed by Microsoft. Compared with other database software, SQL Server 2008 has great advantages: good protection of database queries; less time spending on server management operations; increased application stability; execution system performance optimization; and good forecasting capabilities. Visual Studio 2005 is based on NET 2.0 framework. It also can develop cross-platform applications, such as developing the phone’s procedures using the Microsoft’s operating system. Overall, it’s a kind of powerful software, even including code testing function.

Software development is the further optimization of the data collection applying the data table. Compared with the data table, the software is more convenient and conducive to the data collected and stored.

The information management system is a client/server (C/S) distributed three-tier architecture system structure of database application software. The basic information of the machine tool and fault information are stored (data access layer (DAL)) in the background database. User interface (the presentation layer (UIL)) is shown on the front desk. The specific logic functions (business logic layer (BLL)) realization is in the application server. Three-layer structure has great advantage for software development, so developers can focus on one layer of the whole structure; it can easily use a new realization to replace the realization of original level; it can reduce the dependence between layer and layer; it is conducive to reuse each layer logic; its structure is more clear; in the later maintenance, maintenance cost and maintenance time are greatly reduced.

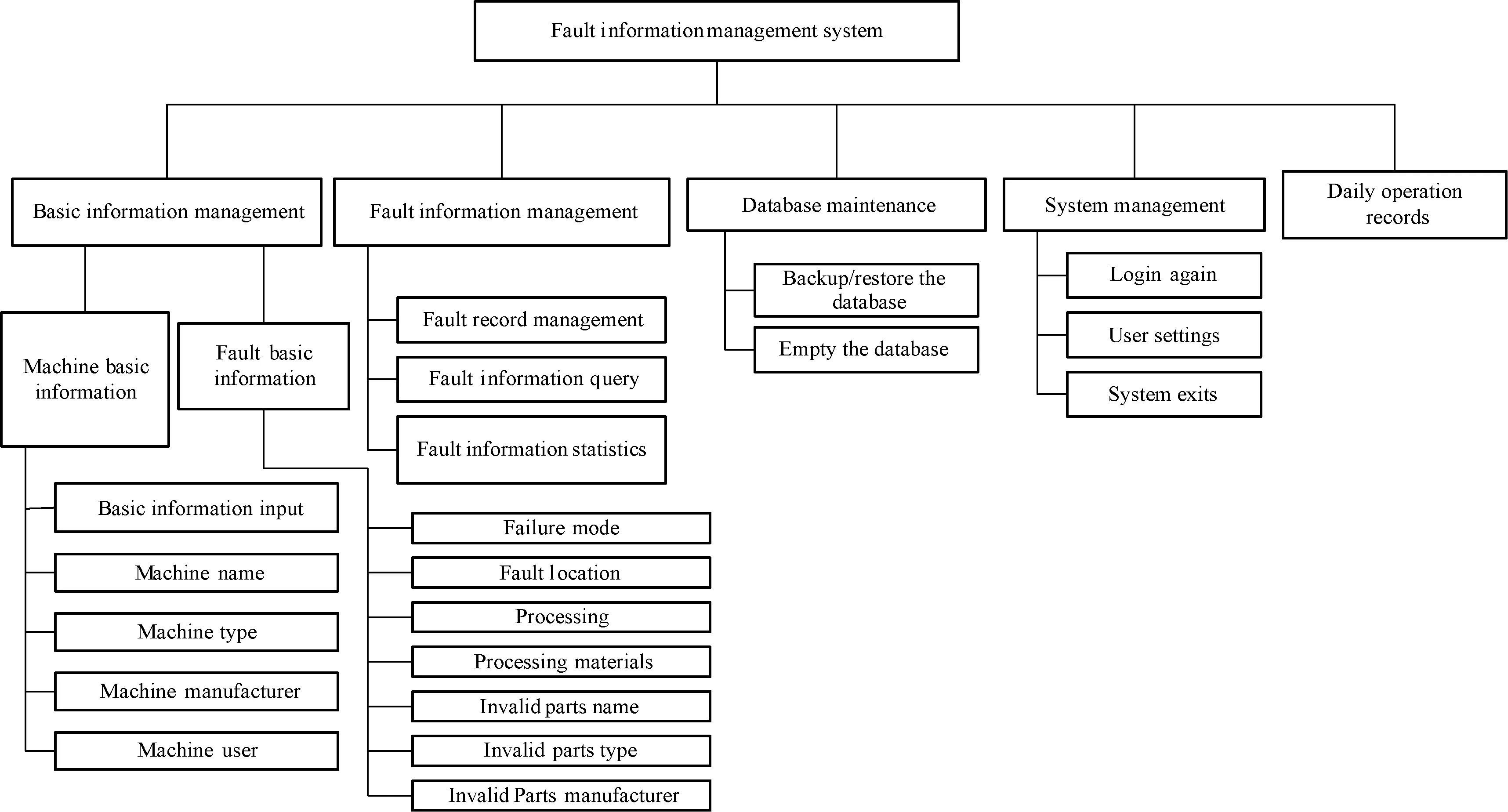

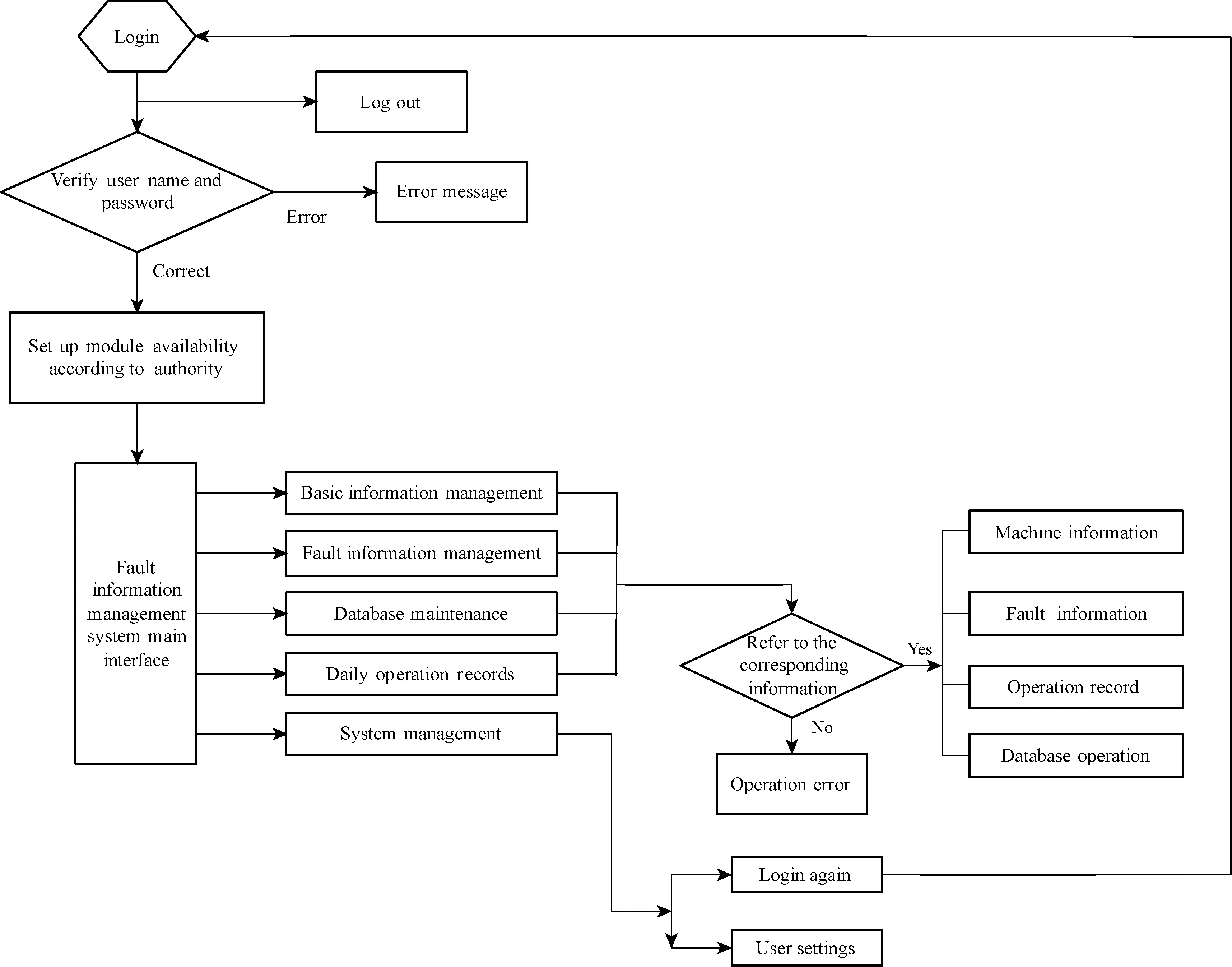

The structure figure of machine information management system is shown in Fig.2[4]. In the following diagram, each module includes a number of operations. For instance, fault records management module includes basic information input, modify, and delete. When the machine is at fault state, the software achieves comprehensive management of failure information. The operation flow chart of machine information management system is shown in Fig.3. The operation flow chart briefly summarizes the operation process of the information management system, and provides a brief instruction for the operation of the software.

Machine fault management system mainly includes ten modules programming: login module, the main interface module, basic information operation module, machine typical information entry module, basic fault information management module, database backup and restore module, user information operation module, the daily operation recording module, fault information statistics module, and fault information query module.

The system consists of ten modules, and we select several modules which have representative significance to introduce.

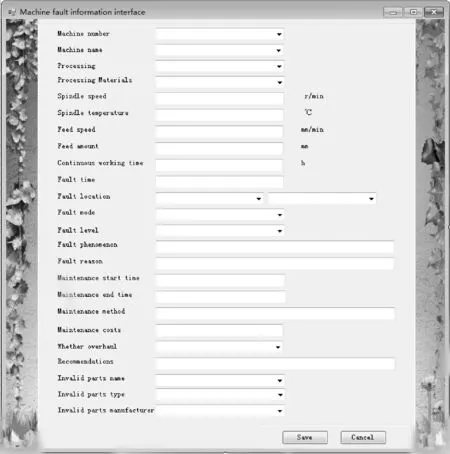

The interface of the machine basic information operation module is shown in Fig.4.

Machine tool will be displayed in the “dataGridView”form. The “comboBox” corresponding to “Query category” is used to fill in the category that needs to query. The “textBox” corresponding with “Basic information” is used to fill in the specific information that needs to query. After clicking the button “Query”, the corresponding record will be shown in the “dataGridView” form. Click on the button “Add”, “Modify”, page will turn to Fig.5. If the button “Add” is clicked, Fig.5 will show up with an empty form. If the button “Modify” is clicked, Fig.5 will show up with selected record information.

After the button “Add” or “modify” is clicked, Fig.5 will show up. The “Save” button is used to save a new record or a modified record, and the “Cancel” button is used to end the operation and change nothing.

4 Conclusions

By writing machine fault information management system software, we can collect and arrange the CNC machine data, especially machine fault information and work condition information when the machine is at fault state more conveniently and efficiently, and the data can be more properly analyzed, processed, and preserved. The software can be used in fault analysis system and help find the weakness and potential disadvantages of the machine, and reflect the fault analysis results to manufacturers and users, so that manufacturers take the measures of reliability improvement of machine tool. The software can provide a strong basis for maintenance plan of the user, so that enterprises can take effective measures at the aspects of manufacturing, using, and maintaining to improve the efficiency of machine tool, reduce repair costs, and increase the economic efficiency of enterprises.

However, the software defects in the function, structure, appearance, and other aspect, need to be further improved. In the following work, we will further review the related literature, fix bugs in the process, and improve the function of the system. At the same time, based on the various functions to achieve, we must beautify the interface and give the users a better experience.

Fig.2 The structure figure of machine Information management system

Fig.3 The operation flow chart of machine information management system

Fig.4 The Interface of the machine basic information operation module

Fig.5 Machine fault information interface

[1] Ong C L, Owen J M. Prediction of Heat Transfer in a Rotating Cavity With a Radial Outflow [J].JournalofTurbomachinery, 1991, 113(1): 115-122.

[2] Wang Y Q, Jia Y Z, Jiang W W. Early Failure Analysis of Machining Centers: a Case Study [J].ReliabilityEngineering&SystemSafety, 2001, 72(1): 91-97.

[3] Jia Y Z, Cheng X M, Jia Z X. Failure Mode Analysis of Machining Centers [C]. Proceedings of the 3rd ISSAT International Conference Reliability and Quality in Design, California, USA, 1997: 74-76.

[4] Zhang G, Tan C M. Reliability Data Analysis Software Development [C]. Proceedings of SPIE, Singapore, 2000: 107-115.

[5] Zhang Q. The Architecture of Reliability Information System for CNC Machine Tool in Concurrent Engineering [C]. Proceedings of the 11th International Manufacturing Conference, Jinan, China, 2004: 603-607.

[6] Hao Q B. A Fuzzy Maintainability Allocation Method for NC Machine Tools Based on Interval Analysis [C]. Proceedings of the 9th International Conference on Reliability, Maintainability and Safety (ICRMS), Guiyang, China, 2011: 889-896.

[7] Jia Z X, Jia Y Z. Collecting of Reliability Data of NC Lathe and Establishing of Database [J].ManufacturingTechnology&MachineTool, 2000(1): 11-14. (in Chinese)

[8] Lei X S, Zhang L P, Li J S,etal. Realization of Remote Diagnosis Database of CNC Machine Tools Fault [J].MachineTool&Hydraulics, 2003(1): 87-90. (in Chinese)

Foundation item: National Science and Technology Major Project of China (No. 2013ZX04013- 011- 05)

1672-5220(2014)06-0760-03

Received date: 2014-08-08

* Correspondence should be addressed to LI Zi-chen, E-mail: lzchen3970@163.com

CLC number: TP31 Document code: A

Journal of Donghua University(English Edition)2014年6期

Journal of Donghua University(English Edition)2014年6期

- Journal of Donghua University(English Edition)的其它文章

- Stress-Strength Structural Reliability Model with a Stochastic Strength Aging Deterioration Process

- Settlement Prediction of Dredger Fill with the Optimal Combination Model

- Condition-Based Maintenance Decision-Making for Equipment

- Identification of the Credit Guarantee Network of Steel Trade Enterprises in China

- Methods for Reliability Assessment under Irregular Time-Varying-Stress Degradation Testing

- Efficient Method for Accelerated Reliability Qualification Testing