Research and Commercial Application of CPP Technology for Producing Light Olefins from Heavy Oil

Zhu Genquan; Xie Chaogang

(Research Institute of Petroleum Processing, SINOPEC, Beijing 100083)

Research and Commercial Application of CPP Technology for Producing Light Olefins from Heavy Oil

Zhu Genquan; Xie Chaogang

(Research Institute of Petroleum Processing, SINOPEC, Beijing 100083)

Catalytic pyrolysis process (CPP) producing ethylene and propylene from paraffin base atmospheric residue was developed by RIPP and its first in the world unit was put into commercial operation successfully. The results of performance test showed that the yield of ethylene and propylene reached 14.84% and 22.21%, respectively, at a reaction temperature of 610 ℃ by using Daqing atmospheric residue as the feedstock under an operation mode of producing ethylene and propylene at the same time, and the aromatic content of cracked naphtha reached 82.46%. The successful operation of this unit has opened a novel route for producing light olefins and aromatics from heavy oil, which is also a good example symbolizing the integration of refining technology with petrochemical process.

atmospheric residue; catalytic pyrolysis; ethylene; propylene; aromatics

1 Introduction

The light olefins such as ethylene and ethylene are the basic organic chemical raw materials of synthetic fibre, synthetic resins and synthetic rubber. They are mainly manufactured via the steam cracking technology, which provides 95% of total ethylene supply and 70% of total propylene supply. The feedstocks for steam cracking include 29% of ethane, 8% of propane, 4% of butane, 53% of naphtha and 1% of other feedstocks in the world. In China, the distribution of steam cracking feedstocks comprises about 6.8% of light hydrocarbons, 58.2% of naphtha, 9.8% of hydrocracked naphtha, 22.5% of light diesel and 2.7% of other feedstocks, and the ratio of naphtha in the feedstock diet accounts for more than 50%[1]. Now the steam cracking feedstock is becoming lighter and its product slate is changed, and accordingly the propylene and aromatics yields will decrease significantly. In China, the steam cracking is faced with another challenge because of the shortage of light feedstocks. So the Catalytic Pyrolysis Process (CPP) was developed by RIPP of SINOPEC to provide an increased ethylene yield while keeping propylene production at a reasonable ratio. The commercial trial of CPP has been successfully accomplished in 2001[2], and a unit with a capacity of 500 kt/a has been put into commercial operation since June 2009[3].

2 Research and Development of CPP

By the end of the 1980s, RIPP developed the DCC process which could produce propylene from heavy oil using a proprietary catalyst. The first DCC unit has been put into commercial operation since 1990 and now there are already ten commercial units in operation. The Catalytic Pyrolysis Process (CPP), also developed by RIPP of SINOPEC, is an extension of the DCC technology to give an increased ethylene yield while keeping propylene production at a reasonable rate. The key features of this process are as follows:

1) A new catalytic material has been developed which can reduce the activation energy required, thus allowing the reaction to be carried out at a significantly lower temperature compared with that required for steam cracking, and can also favor the production of light olefins.

2) The catalyst possesses excellent hydrothermal stability and good attrition resistance.

3) The operating conditions for CPP are more severe than RFCC to an extent that helps operate the existing idle RFCC units without the risk of damage to the fabric of the plant.

4) The heat required for the cracking reaction can be provided by burning coke and HCO in the regenerator, making the reaction fully self-supporting.

5) A specially designed stripper located between the regenerator and reactor removes the flue gas that is carried over from the regenerator.

6) Since the reaction temperature is higher than that in the conventional RFCC unit, a post-riser quench has been introduced for heat recovery as well as for termination of secondary reactions in order to prevent further thermal degradation of the target products.

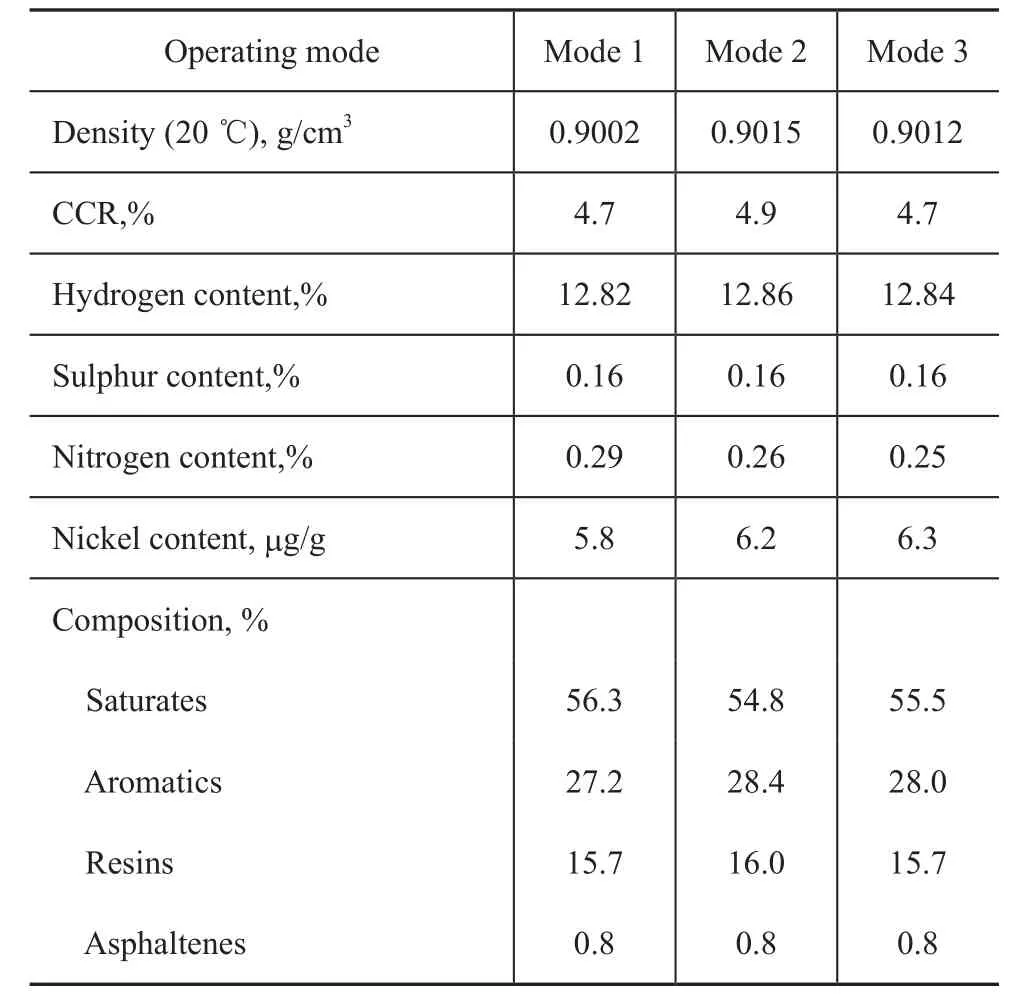

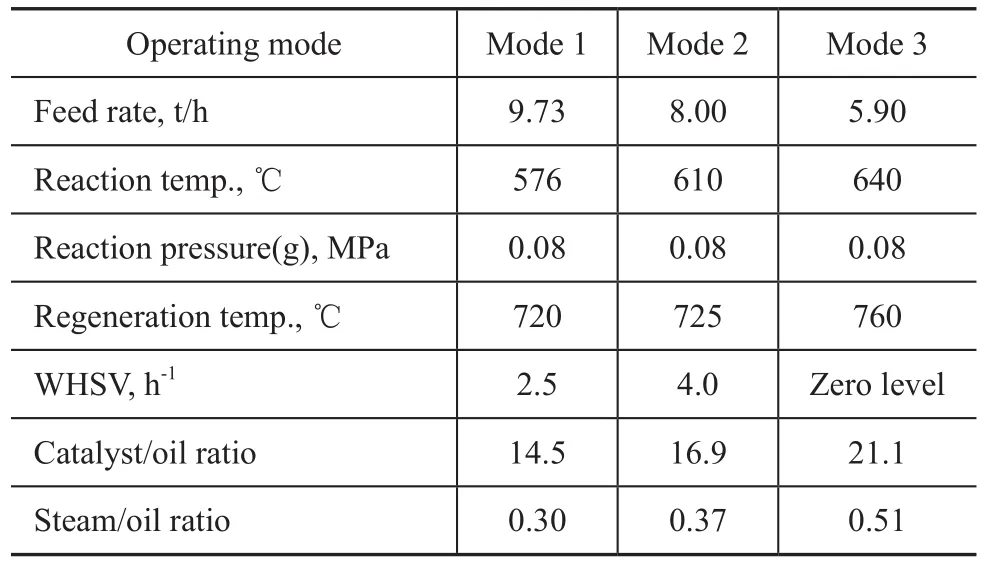

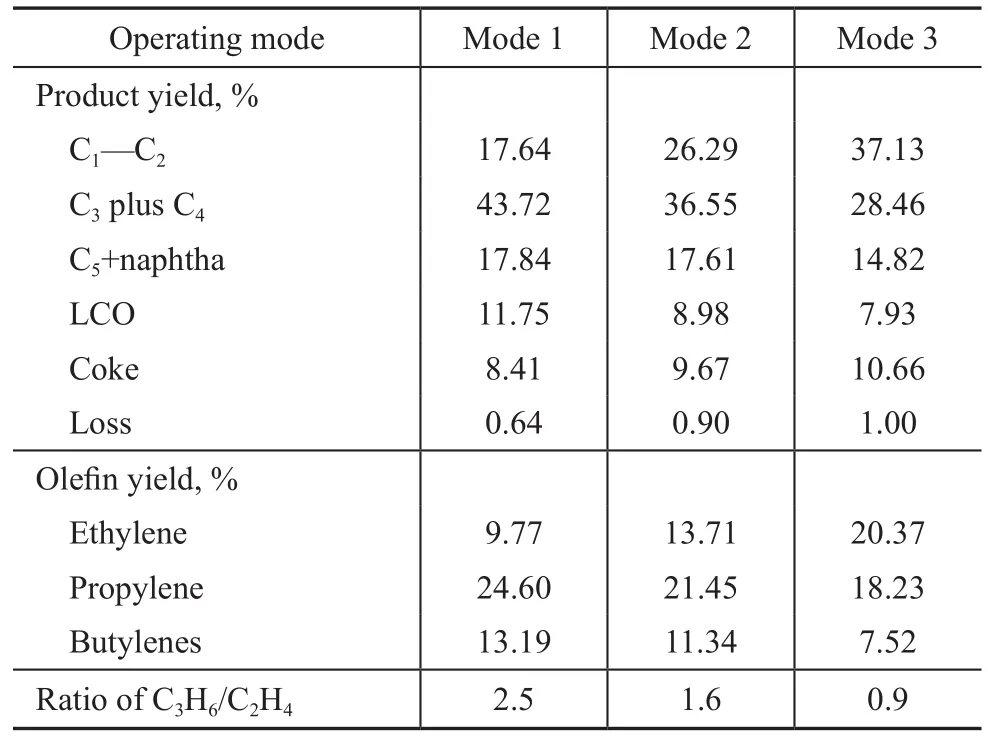

Commercial trial runs were successfully completed in early 2001 at the PetroChina Daqing Refining & Chemical Co. using a revamped DCC unit with a capacity of 80 kt/a[2]. Three sets of conditions were employed, viz.: Mode 1-aiming at maximum propylene yield; Mode 3-aiming at maximum ethylene yield; and Mode 2-aiming at an intermediate alternative between the two options. The feedstock properties, major operating parameters and product distribution are presented in Tables 1, 2, and 3, respectively. As regards the three modes, the combined yield of ethylene and propylene ranges between 34 % and 38% and the total yield ofolefins is around 45% in each case. The ethylene to propylene ratio can be adjusted by varying the operating conditions.

Table 1 Feedstock properties

Table 2 Main operating parameters

Table 3 Product distribution and olefin yields

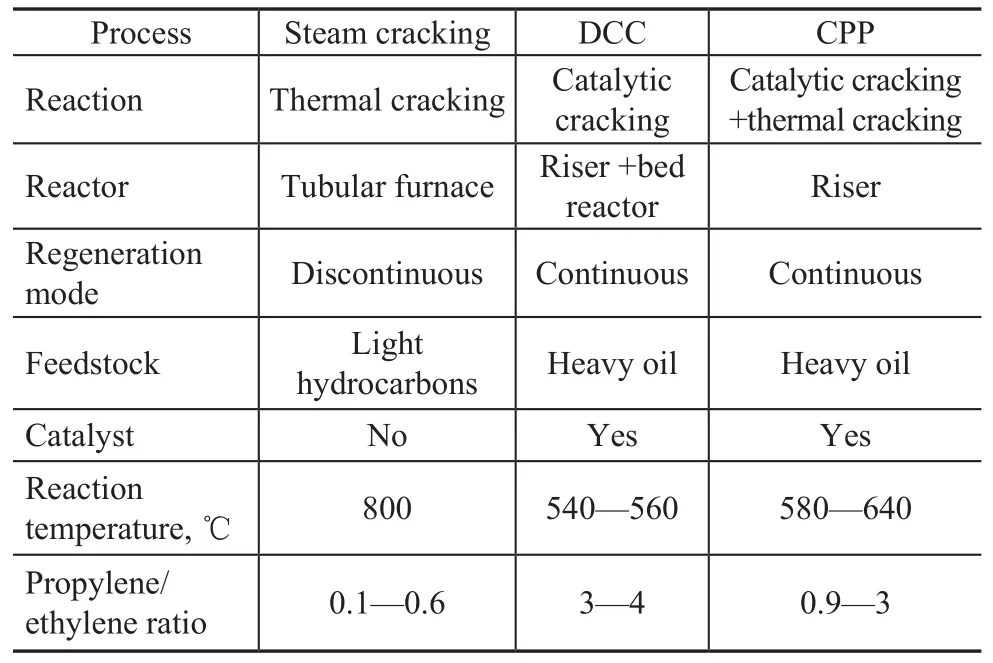

According to the specific features of CPP, DCC and steam cracking technology listed in Table 4, CPP shows a flexible operation mode, which has been attracting keen interests of many chemical companies. And the first in the world commercial CPP unit with a capacity of 500 kt/a was set up and put into operation in June 2009 at the Shenyang Chemical Group’s Shenyang Wax Chemical Company.

Table 4 Specific features of CPP, DCC and steam cracking technology

3 Commercial CPP Unit

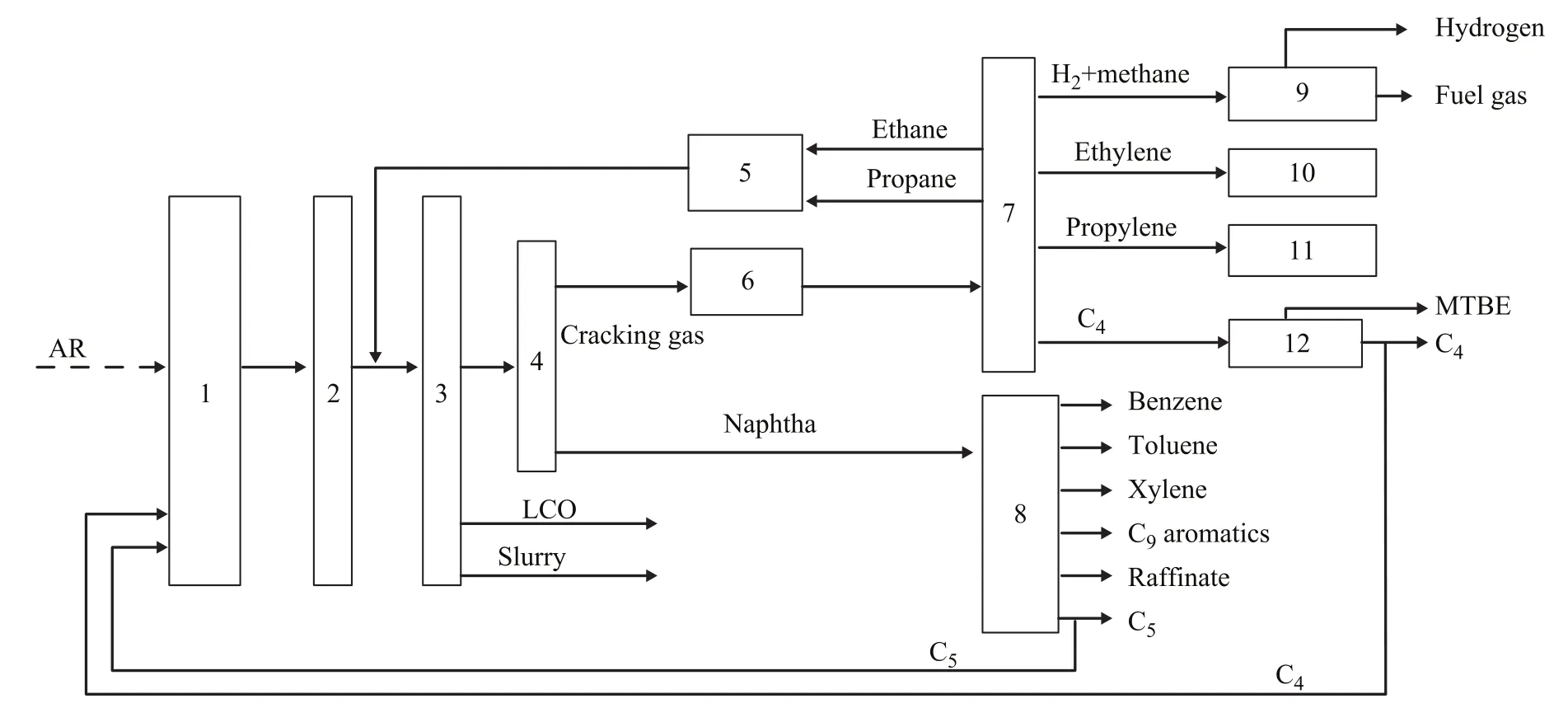

The plant producing ethylene and propylene from atmospheric residue at the Shenyang Chemical Group’s Shenyang Wax Chemical Company consisted of three parts: the CPP system, the ethane-propane tubular cracking furnace, and the pyrolysis gas purification and separation system, with the flow diagram shown in Figure 1. The catalytic and thermal cracking reactions of atmospheric residue take place in the reactor of the CPP system, and the reactor effluents are cooled down in the post-riser quench section prior to entering the fractionator and direct cooling tower to be separated into the cracked gas, naphtha and LCO. The cracked gas is compressed and pumped into the pyrolysis gas purification and separation system to yield the polymerization-grade ethylene and propylene products, while the separated ethane and propane are routed to the tubular cracking furnace to be cracked into ethylene and propylene. The C4fraction is etherified to produce MTBE, with the unconverted during etherification C4hydrocarbons being recycled back to the CPP reactor. The naphtha is hydrotreated and is then subjected to extraction to produce BTX.

Figure 1 The process scheme of plant producing petrochemicals from atmospheric residue

4 Start-Up of the CPP Unit

The plant producing ethylene and propylene from atmospheric residue was ready for test run in April 2009. Since June 20, 2009 the CPP reactor and regenerator linings were dried and then the temperature of reactor and regenerator began to rise. The AR was fed to the CPP system and the plant was put into operation on June 29, 2009. After adjusting the operating conditions, the qualified ethylene, propylene and other products were obtained on July 7. The ethane and propane streams were routed to the tubular furnace for participating in cracking reaction on August 15, and the cracked gas formed during cracking of ethane and propane then entered the fractionator. After that, all units and facilities of the CPP system, the tubular furnace for cracking ethane/propane, and the pyrolysis gas purification and separation system operated smoothly as a whole.

5 Performance Test Results

From March 22, 2010 through March 25, 2010 the performance of the CPP unit was calibrated jointly by the staffs of Shenyang Chemical Group’s Shenyang Wax Chemical Company, RIPP and SEI (SINOPEC Engineering Incorporation).

5.1 The capacity of CPP unit

The design capacity of CPP unit is rated at 500 kt/a of atmospheric residue, with its annual operating time equating to 8000 hours. During the performance calibration test, 4524.1 tons of atmospheric residue were processed, and the average feed rate reached 62.83 t/h, while theload rate of the CPP unit increased to 100.54% to achieve a full-load operating regime.

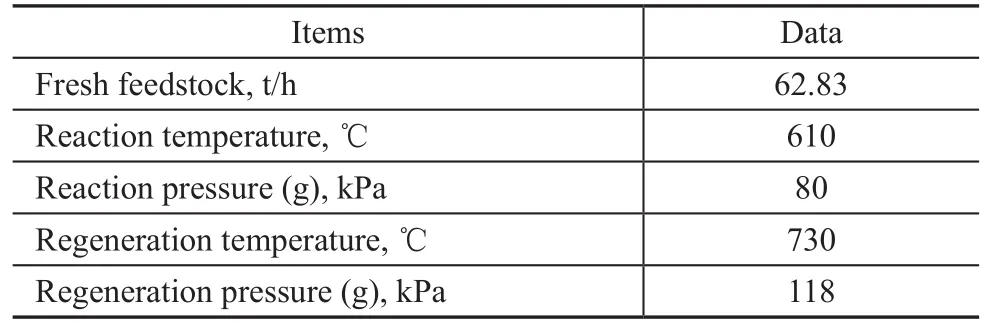

5.2 The performance of CPP reactor and regenerator

During the test run, the catalyst density in each part of CPP reactor and regenerator was stable, and the catalyst fluidization was smooth. The load in the equipment could be adjusted from 60% to 100% flexibly, and the operation could meet the elasticity requirements of the process unit. The content of catalyst fines (with grain size covering 0 to 40 microns) in the equilibrium catalyst ranged from 8 vol% to 10 vol%. The pressure accumulation before the slide valves in regenerated catalyst pipe, spent catalyst pipe and catalyst recycling pipe ranged between 259 kPa and 360 kPa, and the pressure difference of slide valve was between 17 kPa and 40 kPa which could be maintained stably within this range. The slide valve opening was about 36% to provide considerable room for adjustment. The driving force of the catalyst is enough to keep the catalyst in a normal fluidization condition.

During the test run, the gas phase temperature in the overhead quench section was 312 ℃, the liquid phase temperature at the bottom of quench section was 330 ℃, the temperature of slurry recycled back to the quench section was 239 ℃, with the pressure difference in the quench section equating to about 12 kPa. All the above operating parameters could meet the design requirements. The regeneration technique was a two-stage regeneration mode using coke burning tank plus a dense bed. The carbon content on the spent catalyst was less than 0.01%, denoting that the regeneration effect was very good. The main operating parameters of CPP system are listed in Table 5.

Table 5 The main operating parameters of CPP

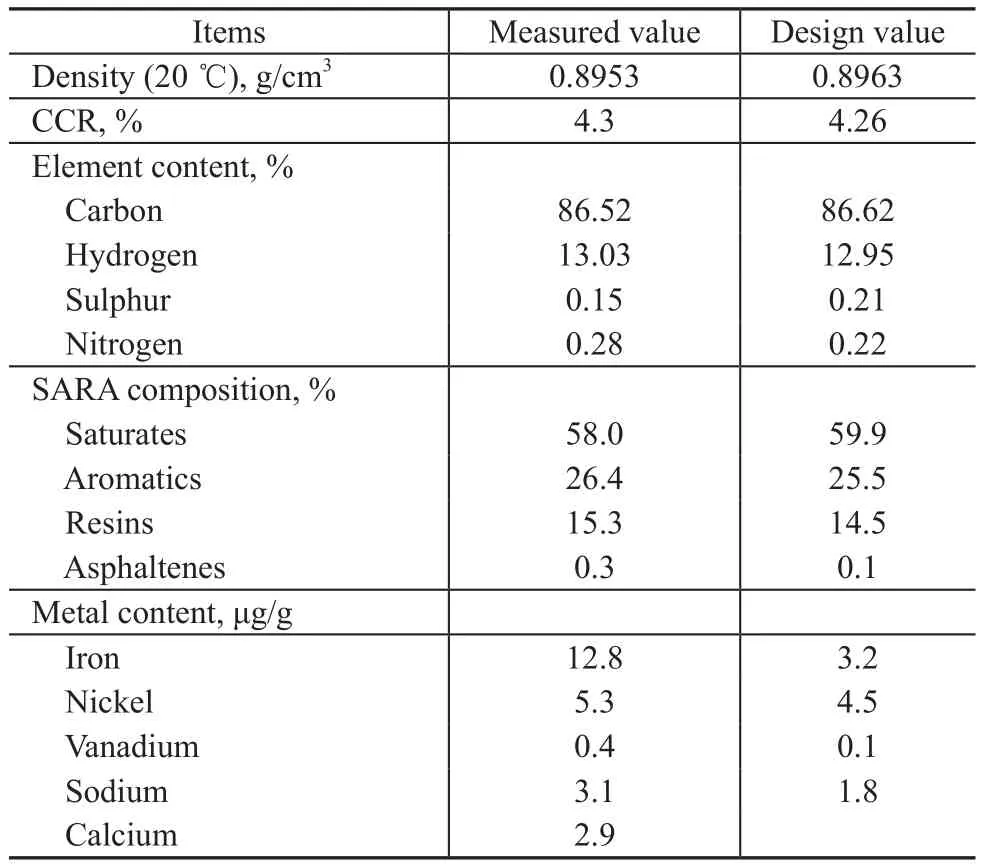

5.3 The feedstock properties

Table 6 lists the properties of CPP feedstock. It can be seen from the data that the metal content is higher than the design value with the other properties being similar to the design values.

Table 6 Atmospheric residue feedstock properties

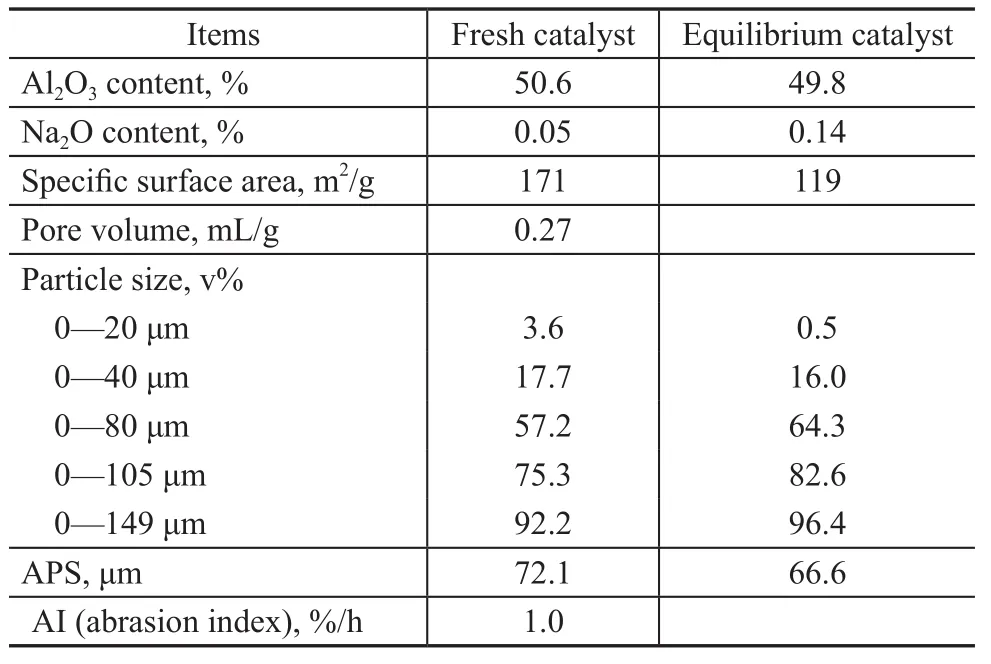

5.4 Properties of CPP proprietary catalyst

The CPP proprietary catalyst—CEP-1(SY)—was developed by RIPP and manufactured at the Qilu Division of SINOPEC Catalyst Company. The properties of fresh catalyst and equilibrium catalyst are listed in Table 7. It can be seen from Table 7 that the physical properties of catalyst CEP-1(SY) are similar to the general FCC catalyst, but the abrasion index of this catalyst is much better. Table 7 also shows that the catalyst CEP-1(SY) has good attrition resistance. Because the CPP operation is more severe than the DCC process and the conventional FCC process, the CPP catalyst must have better thermal stability and hydrothermal stability besides its good ethylene selectivity. Commercial run shows that the CPP catalyst has better thermal stability and hydrothermal stability andcan meet the CPP process requirements.

Table 7 The properties of CEP-1(SY) catalyst

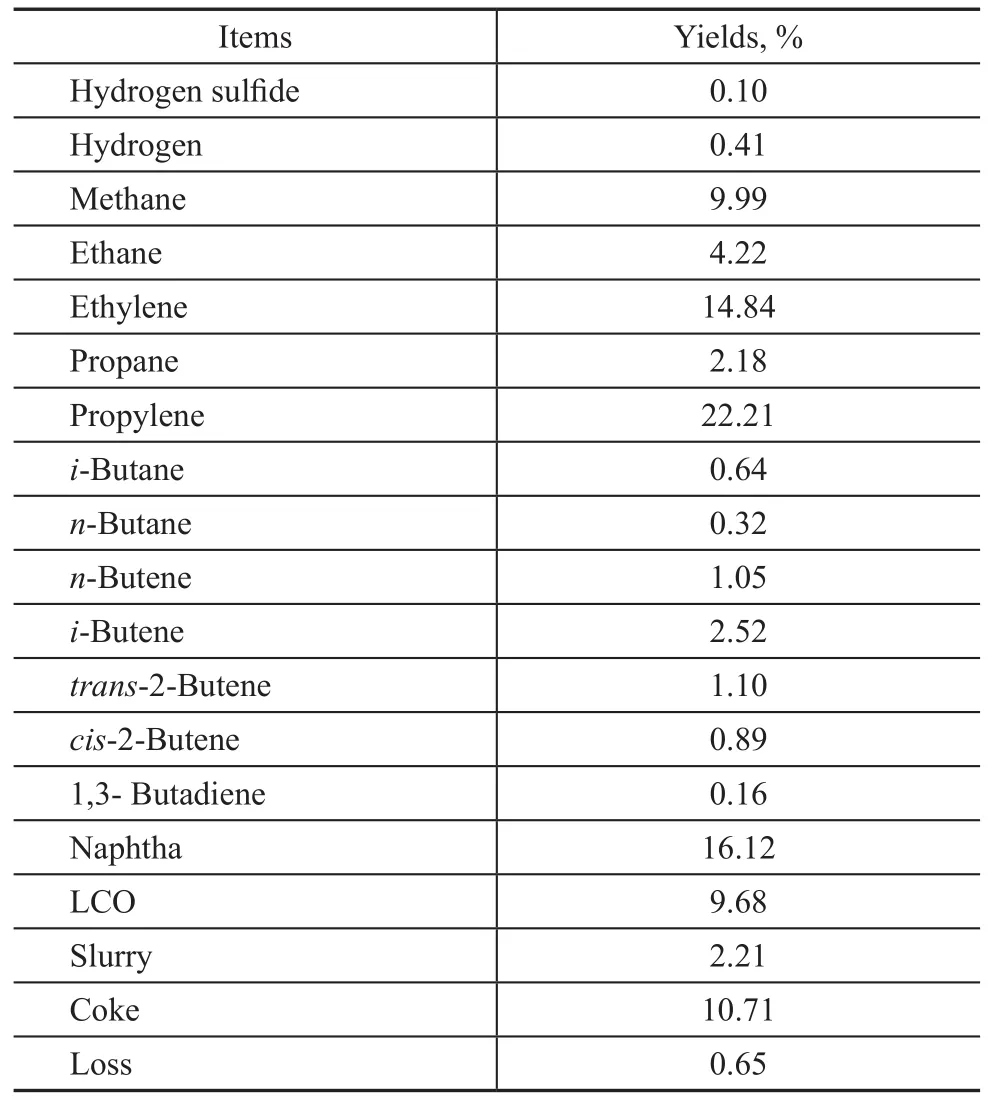

5.5 Product distribution of CPP system

The product distribution obtained during the performance test of the CPP system is listed in Table 8, the ethylene yield is 14.84%, and the propylene yield is 22.21%.

Table 8 The product distribution of CPP system

5.6 Pyrolysis gas purification and separation system

Pyrolysis gas compressor, propylene refrigeration compressor and ethylene refrigeration compressor were all put into regular service through adjustment and optimization of operating conditions. The temperature of feed to the alkaline tower was 50 ℃, and the circulation rate of alkali liquor was 12 t/h. According to the design requirements, both H2S and CO2content in the effluent from alkaline tower was less than 5μg/g. Moreover, the operation of the dryer, the reactor for removal of thiols and carbonyl sulfide, the acetylene hydrotreating reactor and other reactors all met the design requirements.

5.7 Properties of CPP product

The results on analysis of ethylene product are listed in Table 9, which indicates that the ethylene purity can reach 99.99%. The ethylene quality can meet the premiumgrade product specifications defined in “Ethylene for Industrial Use” (GB/T 7715—2003).

Table 9 The ethylene product specifications and analysis results

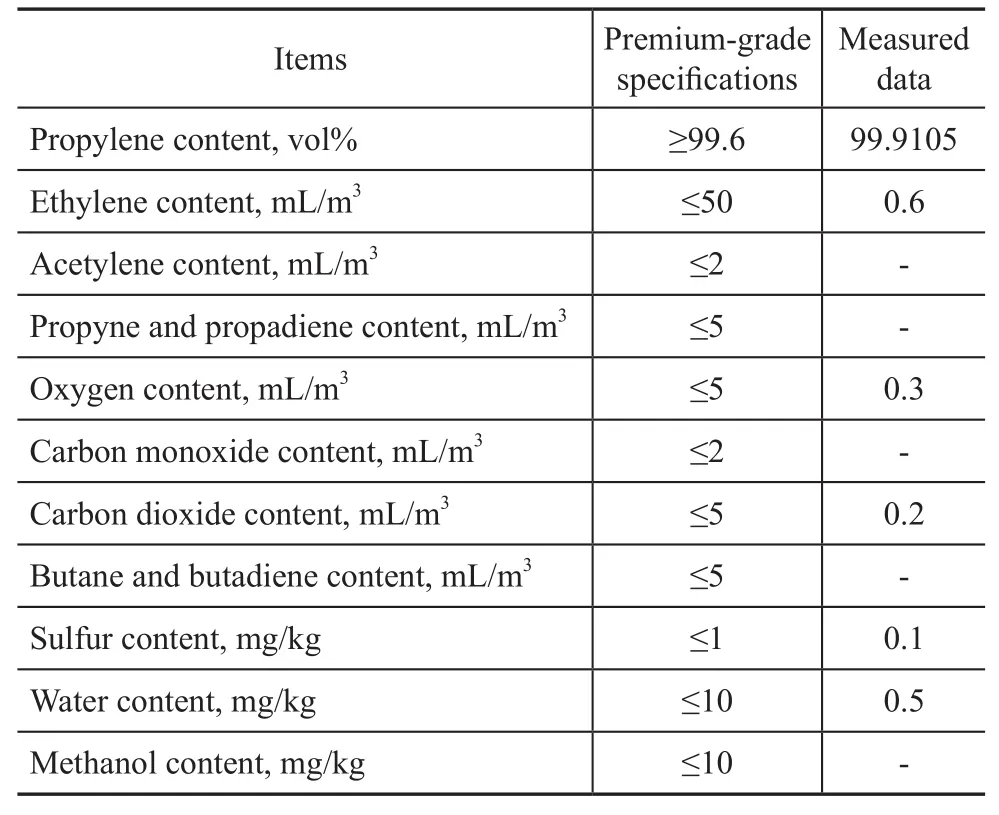

The results on analysis of propylene product are listed in Table 10, which shows that the purity of propylene can reach 99.99 v%. The propylene quality can meet the premium-grade product specifications defined in “Propylene for Industrial Use” (GB/T 7716—2002).

Table 10 The propylene product specifications and analysis result

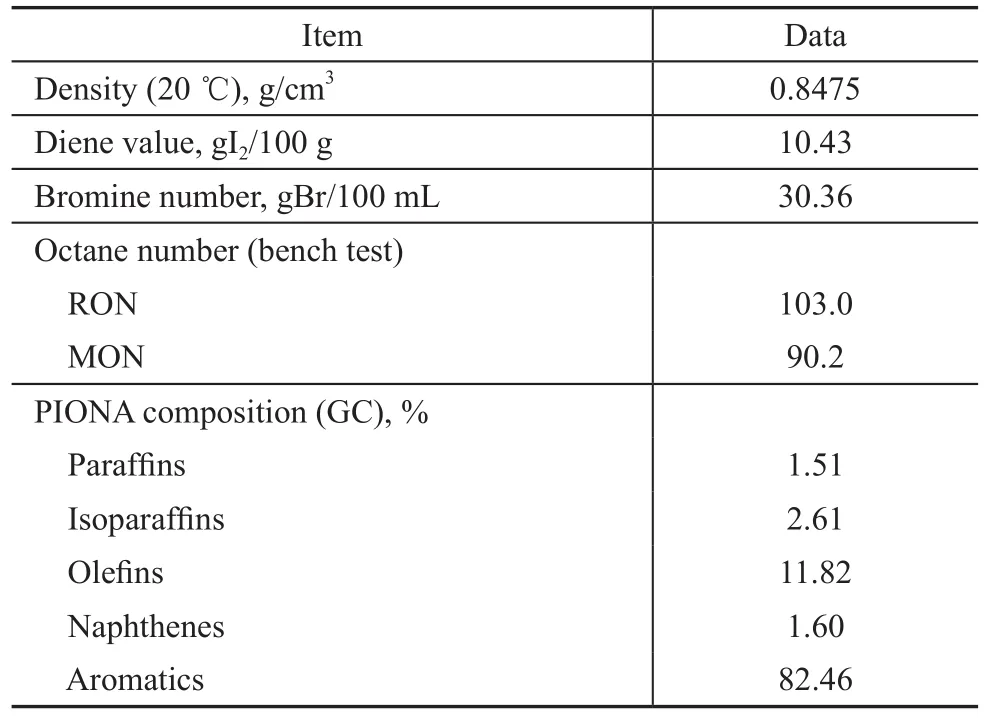

The analysis results of cracked naphtha are listed in Table 11. It can be seen from Table 11 that the naphtha has very high octane number and high aromatic content. The naphtha contains 82.46% aromatics and can be used to produce benzene, toluene and xylene through hydrotreating and extraction processes or can be used as a high-octanegasoline blending component.

Table 11 The properties of naphtha

5 Conclusions

1) CPP process is a reliable and flexible technology according to its performance measured at the first in the world commercial unit which has been put into commercial operation successfully at the Shenyang Chemical Group’s Shenyang Wax Chemical Company since 2009. 2) CPP’s commercial performance test showed that ethylene and propylene yield was 14.84% and 22.21 %, respectively, using Daqing atmospheric residue as the feed under an operation mode for manufacturing ethylene and propylene at the same time.

3) The CPP’s proprietary catalyst CEP-1(SY) developed by RIPP has good cracking ability, high light olefins selectivity, good attrition resistance, good hydrothermal stability and good fluid transportation performance.

4) The CPP technology is a new route for producing ethylene and propylene from paraffin-base atmospheric residue, which is an important alternative to the technology of producing light olefins via steam cracking.

[1] Cao X H. The Chinese Chemical Society Petroleum Chemical Industry 2001 Annual Symposium[C]. Beijing, 2001 (in Chinese)

[2] Xie C G, Wang X Q, Guo Z X, et al. CPP technology for olefin production and its commercial trial[J]. Petroleum Processing and Petrochemicals, 2001, 32(12): 5-9 (in Chinese)

[3] Wang Dazhuang, Wang Hezhou, Xie Chaogang.Commercial trial of CPP complete technology for producing light olefins from heavy feedstock[J]. Petroleum Processing and Petrochemicals, 2013, 44(1): 56-59 (in Chinese)

Recieved date: 2013-05-10; Accepted date: 2013-06-27.

Dr. Zhu Genquan, Telephone: +86-10-82369223; E-mail: zhugq.ripp@sinopec.com.

- 中國煉油與石油化工的其它文章

- Experimental and Molecular Dynamics Simulations for Investigating the Effect of Fatty Acid and Its Derivatives on Low Sulfur Diesel Lubricity

- Synthesis of MgO-Al2O3/ZSM-5 by Solid State Reaction for Propane Dehydrogenation

- Synthesis of TS-1 Films on Porous Supports for Epoxidation of Allyl Chloride by Hydrogen Peroxide

- Effects of Moisture on Rheological Properties of PAV Aged Asphalt Binders

- Spectroscopic Analysis of Structural Transformation in Biodiesel Oxidation

- Microwave-Assisted Decarboxylation of Sodium Oleate and Renewable Hydrocarbon Fuel Production