米曲霉固體發(fā)酵降解豆粕植酸及其生長(zhǎng)條件的優(yōu)化

GAO Youling WANG Caisheng ZHU Qiuhua QIAN Guoying

(Laboratory of Aquatic Molecular Nutrition and Physiology,Collecge of Biological and Environmental Sciences,Zhejiang Wanli Univerisity,Ningbo 315100,China)

Soybean meal is increasingly acceptable as a protein source for animal feed due to its high content of protein(around 45%),relatively well-balanced amino acid profiles,constant composition and steady supply in relation to other traditional protein sources(e.g.cottonseed meal etc.),as well as the reasonable price[1].Antinutrients in soybean meal,however,affect the animal growth and health,and consequently limit the use of soybean meal[2].One of the major antinutrients in soybean meal is phytic acid.

The adverse influence of diets containing phytic acid on animal growth and health has been well documented[3-6].The positive effect of solid-state fermentation on the reduction of phytic acid has been proved[7-10],which was ascribed to the phytase generation during the fermentation[8,11].The ratio of substrate to water,inoculum size and duration was identified as the major factors that influence the phytase generation and phytic acid reduction.However,so far,limited research concerned on the optimization of those factors has been done.Hence,the first aim of the present study was to determine the optimal levels of the 3 factors for minimum phytic acid content through response surface methodology in laboratory-scale solid-state fermentation with Aspergillus oryzae.

The reduction of phytic acid may be related to the Aspergillus oryzae biomass growth.The present study therefore applied response surface methodology to predict the strain biomass growth.The second aim thus was to determine the optimal levels of the 3 factors for maximum Aspergillus oryzae biomass growth and to determine the correlation between Aspergillus oryzae biomass and phytic acid content.Ergosterol is the primary sterol that only existed in the cell membranes of filamentous fungi[12],and is a good marker of fungi biomass[12-14].Therefore,ergosterol would be used as a tool to estimate the Aspergillus oryzae biomass in the current study.

1 MATERIALS AND METHODS

1.1 Strain and soybean meal

Aspergillus oryzae(CICC 40214)was purchased from China Centre of Industrial Culture Collection.Soybean meal was purchased from Ningbo Jinguan Soy Feed Co.Ltd.,and was smashed by a FW100 grinder machine(Tianjin Taisite Instrument Co.Ltd.,Tianjin,China).The soybean meal then was screened through a 0.4 mm mesh before dried in an oven at the temperature of 60℃.The dried soybean meal was stored at a drier containing silica.

1.2 Solid-state fermentation with Aspergillus oryzae

Aspergillus oryzae,which was in slant preservation,was transferred to potato-dextrose agar(PDA)medium(Xinran Biological,Shanghai,China),and then was incubated at 28℃for 5 to 7 days until enough amounts of spores grown on the surface of PDA medium and distributed equally.The spores were scratched by an inoculation loop and washed carefully by sterile water.The washed spores were served as the seed(CFU=1×107)after enlargement.

Fifty grams of soybean meal was transferred to a 1 L-flask with sterilized cotton plug.The air exchanging was allowed through cotton plug.Ratio of substrate to water,inoculum size and duration were set in accordance with the Box-Benhnken design[15](Table 1 and Table 2),and the flask with substrate and water was pasteurized at 70℃for 30 min before incubation.The incubation was performed at 28℃in QYC-211 incubator(Shanghai Fuma Laboratory Instrument Co.LTD.,Shanghai,China).The fermented soybean meal was freezing dried after solidstate fermentation,subsequently smashed and kept at 4℃for further chemical analysis.

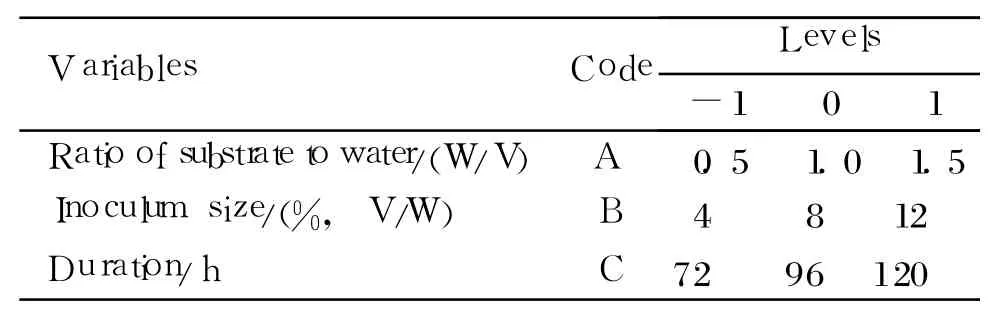

Table 1 Levels and code of independent variables chosen for Box-Behnken design in solid-state fermentation with Aspergillus oryzae

1.3 Optimization of solid-state fermentation with Aspergillus oryzae

A Box-Behnken design with the ratio of substrate to water,inoculum size and duration of solid-state fer-mentation as well as 3 levels,including 5 replicates at the center point,was used for fitting a second-order response surface.A total of 17 runs were used to optimize the3 independent variables(Table 2).Each run was conducted in duplicate.The levels and code of the independent variables in the Box-Behnken design were given in Table 1.The contents of phytic acid and ergosterol in soybean meal after each run was taken as the dependent variables,and themean values of duplicate data were used.

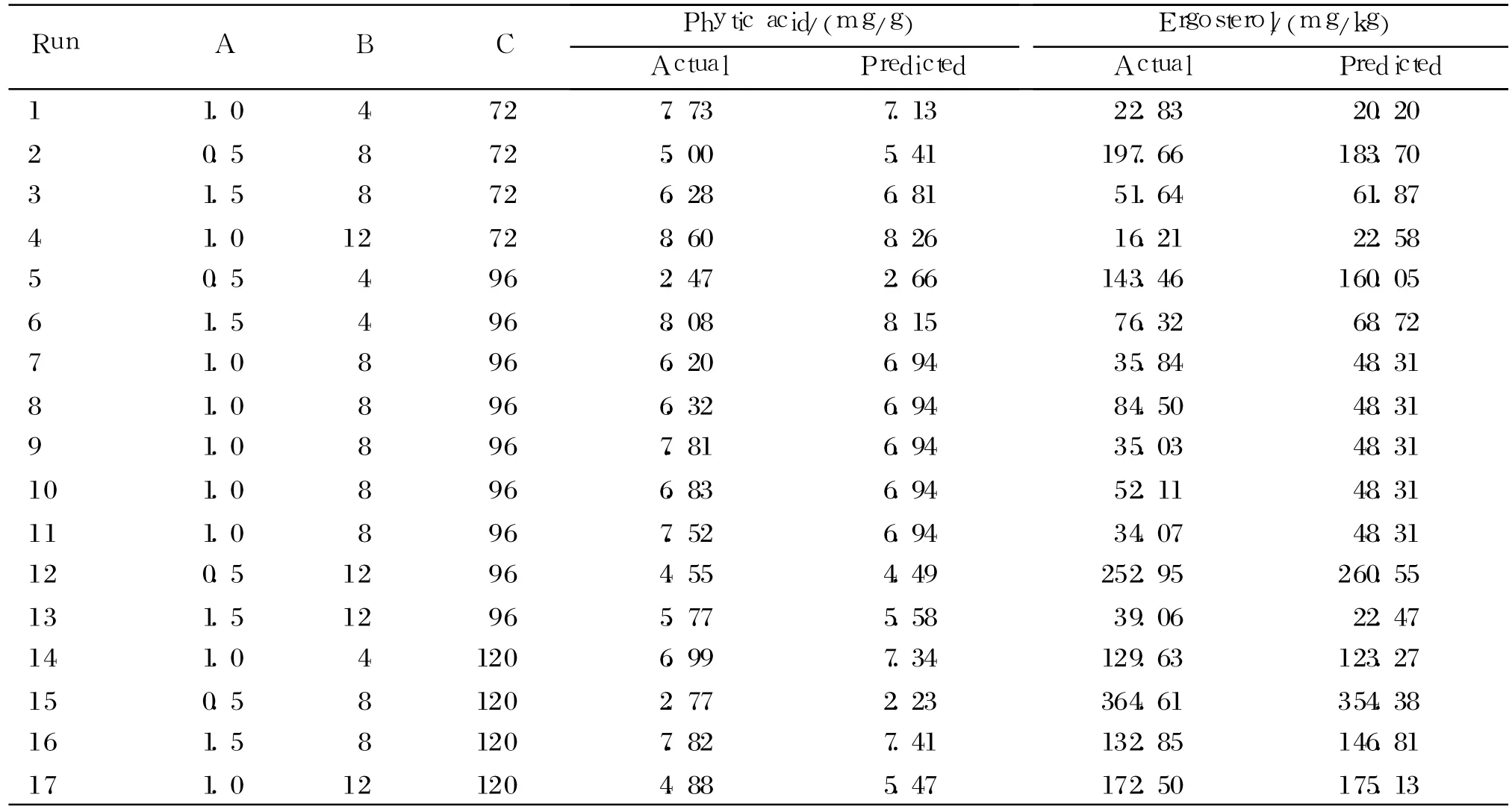

Table 2 Box-Behnken design matrix along with the experimental and predicted values of phytic acid and ergosterol contents in Aspergillus oryzae fermented soybean meal(DM basis)

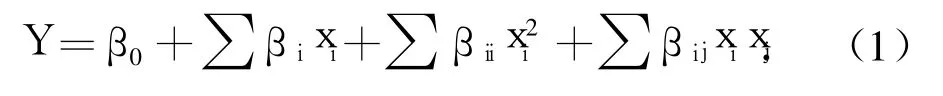

A quadratic polynomial regression model was assumed for predicted response.The model proposed for each response of Y was:

Where Y is the predicted response,β0is the intercept term, βiis the linear effect, βiiis the squared effect,andβijis the interaction effect.Design Expert 7.1.3(trial version,Stat Ease Inc.,Minneapolis,USA)was used for estimating the coefficients of Eq.(1)by regression analysis of the experimental data.

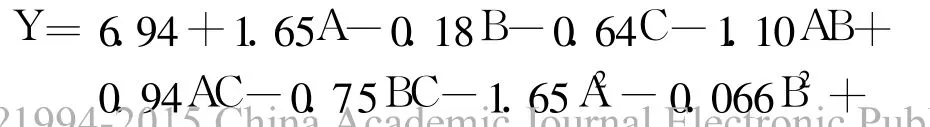

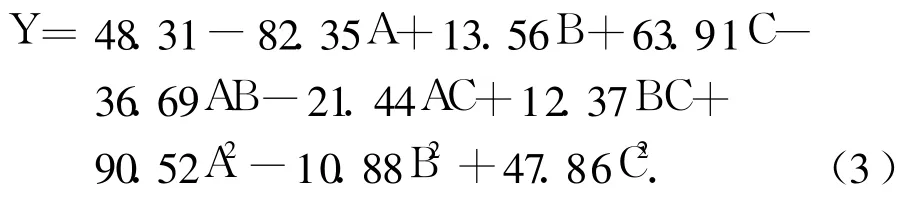

The quadratic model representing phytic acid content(Y)as a response of the ratio of substrate to water(A),inoculum size(B)and duration(C)was extrapolated by the Eq.(2).The statistical significance of Eq.(2)was determined by Fisher's F-test.

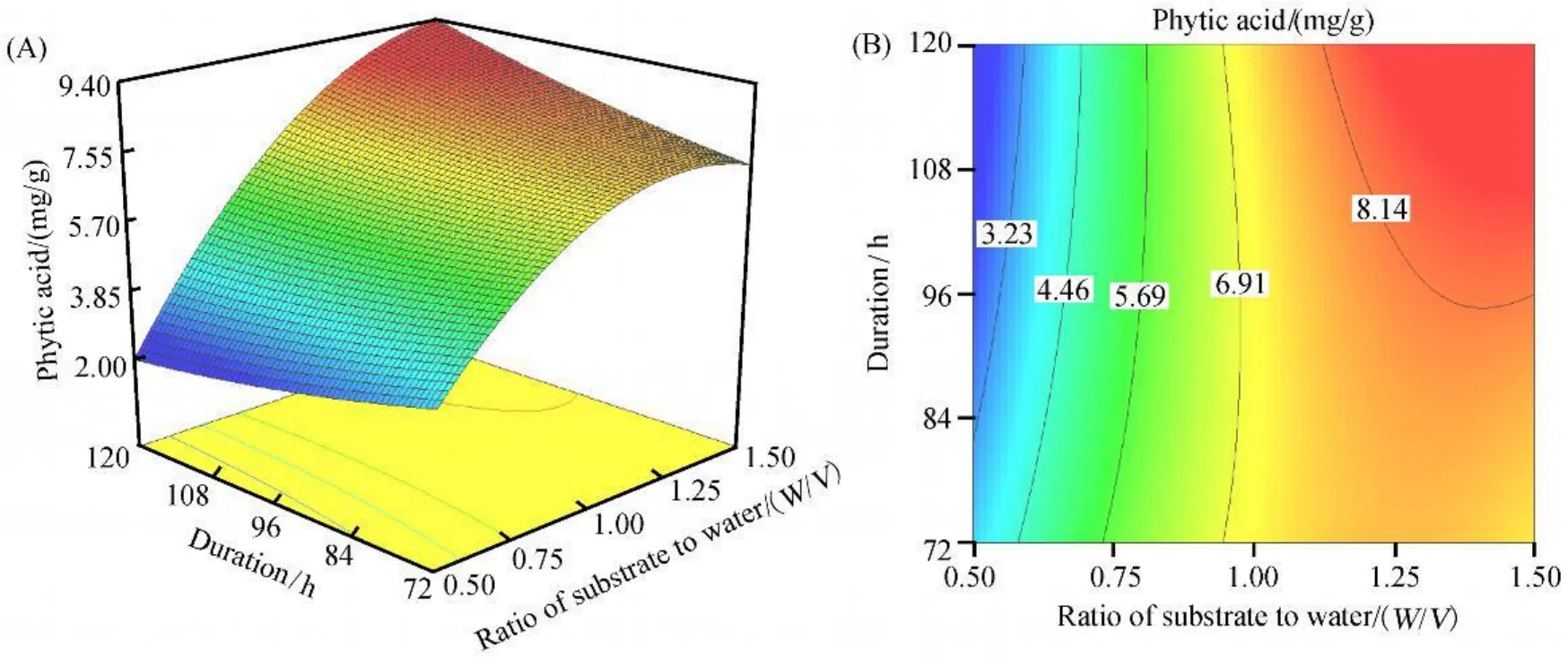

The quadratic model representing ergosterol content(Y)as a response of ratio of substrate to water(A),inoculum size(B)and duration(C)was extrapolated by the Eq.(3).The statistical significance of Eq.(3)was determined by Fisher's F-test.

1.4 Chemical analysis

Phytic acid analysis was performed in accordance with colorimetric method developed by Vaintraub et al.[16]using D201 ion exchange column(5 g D201 resin;Shanghai Huizhu Resin Co.Ltd.,Shanghai,China)and 723PC spectrophotometer.

Ergosterol was analyzed as followings.Four grams of sample was suspended in 20%KOH solution and redistilled for 2.5 h at 90℃,followed by adding 20 mL ether with shaking.The upper phase was collected,washed and dried at 70℃,followed by adding 5 mL ethanol to dissolve.Finally the ethanol solution was filtered through a microporous filtering film(0.45μm)and the filtrate was collected for high performance liquid chromatography(HPLC)analysis using the an Agilent 1100 system with an Agilent ODSC18(4.6 mm×150 mm,5μm)analytical column.The program was run for 10 min with 97%methanol and 3%H2O as mobile phase,an injection volume of 20μL,and a flow rate of 1.2 mL/min.The samples were detected for UV absorbance(282 nm).

2 RESULTS

2.1 Optimization of solid-state fermentation with Aspergillus oryzae for phytic acid degradation

The design matrix of the variables in coded units along with the predicted and experimental values of phytic acid content were presented in Table 2.The analysis of variance(ANOVA)of the quadratic regression model(Table 3)demonstrated that Eq.(2)was an extremely significant model at 99%confidence level based on the low F-value(9.28)and P-value(0.003 9)(Table 3).Terms A,C,AB,AC and A2in the current model were significant(P<0.05),which revealed that the ratio of substrate to water(at 99%confidence level),duration,the interaction between the ratio of substrate to water and inoculum size,as well as theinteraction between theratio of substrate to water and duration significantly affected the phytic acid content in soybean meal during solid-state fermentation.In contrast,the effects of inoculum size,as well as the interaction between inoculum size and duration on phytic acid content were not significant(P>0.05).In this study,the P-value of lack of fit was 0.401 4,implying the lack of fit was not significant.

Table 3 ANOVA of the regression for phytic acid

Results in the current study indicated that this model can be introduced to analyze the process of degradation of phytic acid in soybean meal during solidstate fermentation with Aspergillus oryzae,and to optimize the 3 conditional factors for maximum degradation of phytic acid within the given ranges.

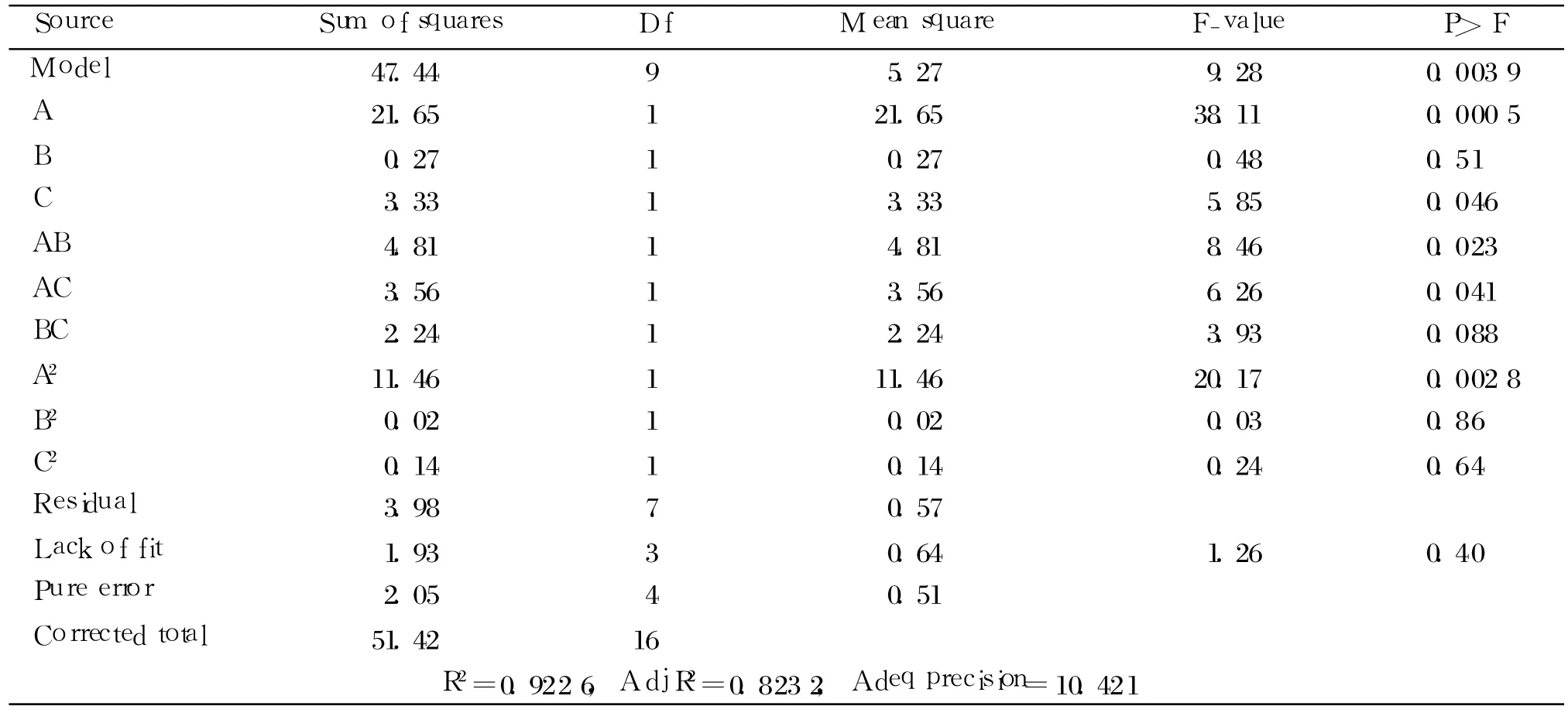

The graphical representations of the regression of Eq.(2)called the response surface and the contour plots of this experiment were obtained using the Design Expert and were displayed in Fig.1.The graphs were generated for the pair-wise combination of the 3 variables.

The factors of the ratio of substrate to water and duration significantly affected the phytic acid content in soybean meal during solid-state fermentation,which could be revealed from Fig.1.It shown that the phytic acid content reduced as the the ratio of substrate to water reduced.The content of phytic acid reduced from 3.68 to 2.00 mg/g DM as the duration increased from 72 to 120 h,when the ratio of substrate to water was kept at 0.5.However,it increased from 7.27 to 9.32 mg/g DM as the duration increased from 72 to 120 h,when the ratio of substrate to water was kept at 1.5.The optimal values of the 3 factors during fermentation for obtaining the predicted minimum content of phytic acid(2.00 mg/g DM)derived from response surface achieved when the ratio of substrate to water was 0.5,inoculum size was 4%and duration was 120 h.

Fig.1 Response surface of 3D plot(A)and contour plot(B)of phytic acid content in soybean meal(DM basis)during solid-state fermentation with Aspergillus oryzae(inoculum size at the optimal level)

2.2 Validation of the optimal conditions of solidstate fermentation with Aspergillus oryzae for phytic acid degradation

In order to confirm the optimized conditions,3 additional laboratory-scale solid-state fermentation runs were performed with the optimal conditions of the ratio of substrate to water,inoculum size and duration.The mean content of phytic acid in fermented soybean meal was 2.38 mg/g DM(9.50 mg/g DM in untreated soybean meal),which was closeto the predicted value(2.00 mg/g DM).The results confirmed the approriate response model.

2.3 Optimization of solid-state fermentation with Aspergillus oryzae for ergosterol

The design matrix of the variables in coded units along with the predicted and experimental values of ergosterol content in fermented soybean meal were presented in Table 2.The ANOVA of the quadratic regression model(Table 4)demonstrated that Eq.(3)was an extremely significant model at 99%confidence level based on the low F-value(34.43)and P-value(<0.000 1)(Table 4).Terms A,C,AB,A2and C2in the current model were significant(P<0.05),which revealed that the ratio of substrate to water(at 99%confidence level),duration(at 99%confidence level),and the interaction between the ratio of substrate to water and inoculum size significantly affected theergosterol content in solid-statefermentation.In contrast,the effects of inoculum size,interaction between the ratio of substrate to water and duration,as well as interaction between inoculum size and duration on ergosterol content were not significant(P>0.05).The interaction between theratio of substrate to water and duration,however,exhibited the tendency of significant effect(P=0.085 7).In the current study,the P-value of lack of fit was 0.487 5,implying the lack of fit was not significant.

Results in the experiment indicated that this model therefore could analyze the process of ergosterol generation in soybean meal during solid-state fermentation with Aspergillus oryzae,and optimizethe 3 conditional factors for maximum generation of ergosterol within the given ranges.

Table 4 ANOVA of the regression for ergosterol

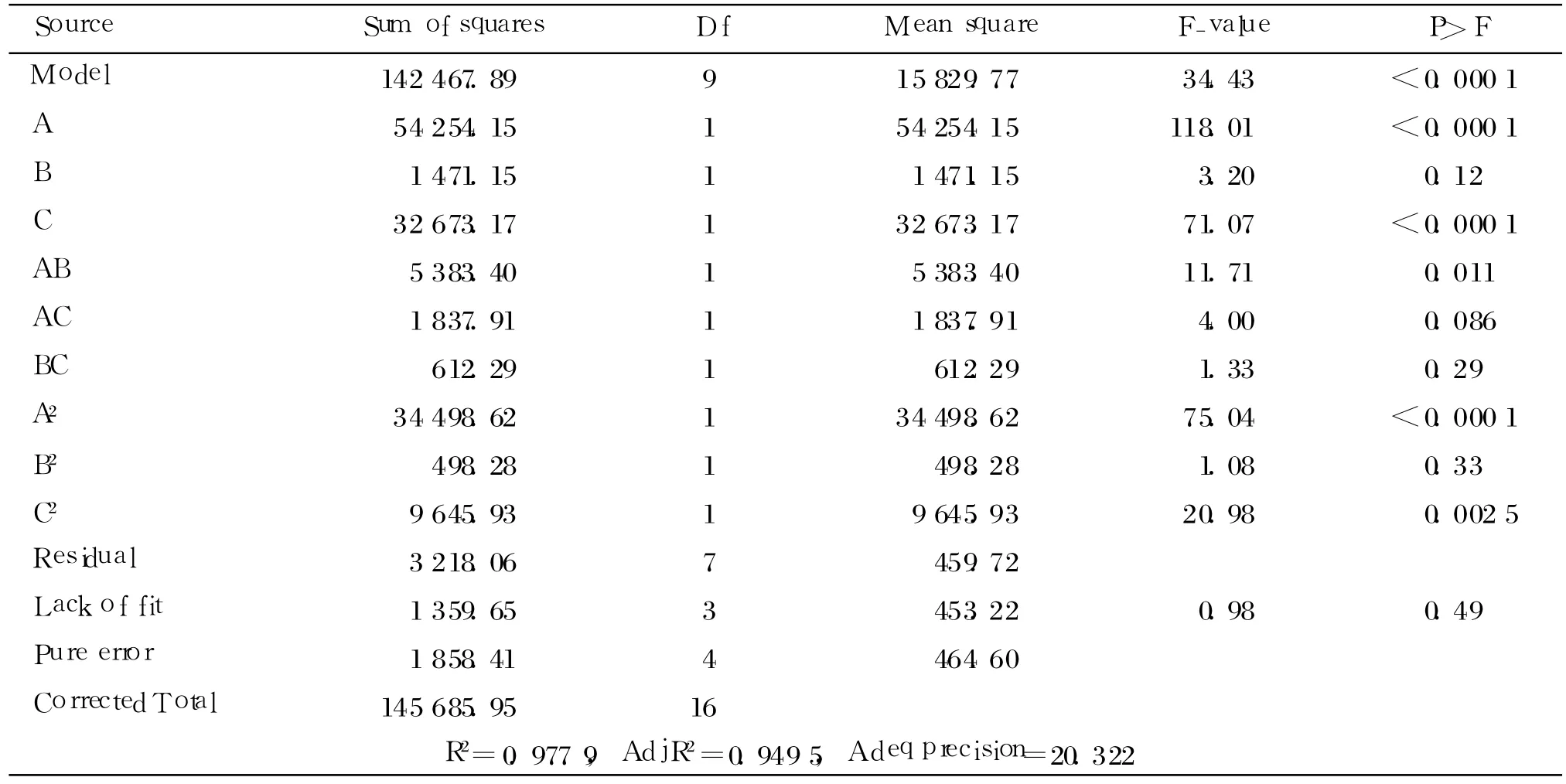

The graphical representations of the regression of Eq.(3)called the response surface and the contour plots of this experiment were obtained using the Design Expert(Fig.2).The graphs were generated for the pair-wise combination of the 3 variables.The factors of the ratio of substrate to water and duration significantly affected the ergosterol generation during solid-state fermentation,which could be revealed from Fig.2.It showed that the ergosterol content was increased as the ratio of substrate to water reduced from 1.5 to 0.5,and as duration increased from 72 to 120 h.The optimal values of the 3 factors during fermentation for obtaining the predicted maximum content of ergosterol(406.12 mg/kg DM)derived from response surface achieved when the ratio of substrate to water was 0.5,inoculum size was 12%,and duration was 120 h.

Fig.2 Response surface of 3D plot(A)and contour plot(B)of ergosterol content in soybean meal(DM basis)during solid-state fermentation with Aspergillus oryzae(inoculum size at the optimal level)

2.4 Validation of the optimal conditions of solidstate fermentation with Aspergillus oryzaefor ergosterol

In order to confirm the optimized conditions,3 additional laboratory-scale solid-state fermentation runs were performed with the optimal conditions of the ratio of substrate to water,inoculum size and duration.The mean content of ergosterol in fermented soybean meal was 396.74 mg/kg DM,which was close to the estimated value(406.12 mg/g DM).The result demonstrated the approriate response model.The model thus can be used to describe ergosterol or fungal growth pattern during solid-state fermentation in the current study.The Aspergillus oryzae dry biomass after solid-state fermentaion with optimized conditions was estimated to be 90.30 mg/kg DM.The estimation was in basis of the finding that the fungal ergosterol content was 5.50 mg/kg DM[13,17].

2.5 Corelation of phytic acid and ergosterol content

A significant negative correlation between phytic acid and ergosterol content of soybean meal in solidstate fermentation was detected,as the correlation coefficients(r)was 0.740 5 and P-value was 0.000 7.

3 DISCUSSION

A reduction of 75%of phytic acid content in the present study was higher than that in some previous studies[7,10,18].It might indicate that Aspergillus oryzae is of high efficiency in thedegradation of phytic acid during laboratory-scale solid-state fermentation with those optimized conditions.However,in the study with Penicillium canescens,the reduction of phytic acid reached to 90%[19],which might partly be ascribed to the longer fermentation duration(144 h)since the degradation of phytic acid was significantly affected by the duration as proved in the present study.The results in the present study also proved that the ratio of substrate to water of 0.5(equal to 66.66%moisture)was the optimum.The range of optimal moisture for filamentous fungi culture was from 20%to 70%[20],and the optimal moisture in the present study was reasonable since it was within the range.

In the present study,the model based on ergosterol content was significant.It indicated that ergosterol was changed stablely with the fermentation conditions changed.Thus ergosterol was proved to be relible for estimating the fungi biomass during fermentation.The significant negative correlation between phytic acid content and ergosterol content in soybean meal implied that the phytase generation of this strain was positively correlated with the strain biomass growth.It was in agreement with a previous study conducted by Spier et al.[21].The author observed a great correlation between Aspergillus oryzae biomass growth and phytase generation in solid-state fermentation.Thus,ergosterol can be an indicator of phytase generation or phytic acid degradation in solid-state fermentation of soyban meal.

Inoculum size did not significantly affect the degradation of phytic acid and the generation of ergosterol in the present study.This was inconsistent with a previous study conducted by Fu et al.[22].In that study,the degradation of phytic acid was significantly affected by the inoculum size in soybean meal.The variance between the two studies could be due to the different strains used.The optimal inoculum size for the degradation of phytic acid was 4%.It revealed that when the inoculum size was 4%,Aspergillus oryzae was metabolically active,and thus produced more phytase.The reason could be due to the aboundant supply of nutrients since the competition for nutrients was relatively low.

4 CONCLUSIONS

①The optimal conditions for phytic acid degration are:the ratio of substrate to water of 0.5,inoculum size of 4%,and duration of 120 h;the optimal conditions for ergsoterol generation are:the ratio of substrate to water of 0.5,inoculum size of 12%,and duration of 120 h.

②With optimized conditions,Aspergillus oryzaeis of high efficiency for phytic acid degradation(from 9.50 to 2.38 mg/g of DM),while the ergosterol content of Aspergillus oryzae is increased to 396.74 mg/kg DM.This suggests the potential use of Aspergillus oryzae in industry-scale solid-state fermentation.

③There is a negative correlation between phytic acid and ergosterol content,and ergosterol can be a good indicator for phytase generation or phytic acid degradation in solid-state fermentation of soyban meal.

[1] STOREBAKKEN T,REFSTIE S,RUYTER B.Soy products as fat and protein sources in fish feeds for intensive aquaculture[M]//DRACKLEY J K.Soy in animal nutrition.Savoy:Federation of Animal Science Societies,2000:127-170.

[2] FRANCISG,MAKKAR H PS,BECKER K.Antinutritional factors present in plant-derived alternate fish feed ingredients and their effects in fish[J].Aquaculture,2001,199:197-227.

[3] FU Q G.Anti-nutritive role of phytic acid in monogasric animals diets[J].Chinese Journal of Animal Nutrition,1998,10(4):1-10.(in Chinese)

[4] SAJJADI M,CARTERC G.Effect of phytic acid and phytase on feed intake,growth,digestibility and trypsin activity in Atlantic salmon(Salmo salar L.)[J].Aquaculture Nutrition,2004,10:135-142.

[5] DENSTADLI V,SKREDE A,KROGDAHL A,et al.Feed intake,growth,feed conversion,digestibility,enzyme activities and intestinal structure in Atlantic salmon(Salmo salar L.)fed graded levels of phytic acid[J].Aquaculture,2006,256:365-376.

[6] HELLAND S,DENSTADLI V,WITTEN P E,et al.Hyper dense vertebrae and mineral content in Atlantic salmon(Salmo salar L.)fed diets with graded levels of phytic acid[J].Aquaculture,2006,261:603-614.

[7] NAIR V C,DUVNJAK Z.Phytic acid content reduction in canola-meal by various microorganisms in asolid-state fermentation process[J].Acta Biotechnologica,1991,11:211-218.

[8] EL-BATAL A I,KAREM H A.Phytase production and phytic acid reduction in rapeseed meal by Aspergillus niger during solid state fermentation[J].Food Research International,2001,34:715-720.

[9] VIG A P,WALIA A.Beneficial effects of Rhizopus oligosporus fermentation on reduction of glucosinolates,fibre and phytic acid in rapeseed(Brassica napus)meal[J].Bioresource Technology,2001,78:309-312.

[10] EGOUNLETY M,AWORH O C.Effect of soaking,dehulling,cooking and fermentation with Rhizopus oligosporus on the oligosaccharides,trypsin inhibitor,phytic acid and tannins of soybean(Glycine max Merr.),cowpea(Vigna unguiculata L.Walp)and groundbean(Macrotyloma geocarpa Harms)[J].Journal of Food Engineering,2003,56:249-254.

[11] PAPAGIANNI M,NOKESS E,FILERK.Production of phytaseby Aspergillus niger in submerged and solidstate fermentation[J].Process Biochemistry,1999,35:397-402.

[12] NEWELL SY.Total and free ergosterol in mycelia of salt-marsh ascomycetes with access to whole leaves of aqueous extracts of leaves[J].Applied and Environmental Microbiology,1994,60:3479-3482.

[13] GESSNER M O,CHAUVET E.Ergosterol-to-biomass conversion factors for aquatic hyphomycetes[J].Applied and Environmental Microbiology,1993,59:502-507.

[14] MARíN S,RAMOS A J,SANCHIS V.Comparison of methods for the assessment of growth of food spoilage moulds in solid substrates[J].International Journal of Food Microbiology,2005,99:329-341.

[15] BOX G E P,BEHNKEN D W.Some new three level designs for the study of quantitative variables[J].Technometrics,1960,2:455-475.

[16] VAINTRAUB I A,LAPTEVA N A.Colorimetric determination of phytate in unpurified extracts of seeds and the products of their processing[J].Analytical Biochemistry,2005,175(1):227-230.

[17] CHARCOSSET J Y,CHAUVET E.Effect of culture conditions on ergosterol as an indicator of biomass in the aquatic hyphomycetes[J].Applied and Environmental Microbiology,2001,67:2051-2055.

[18] XIANG W Q,ZHONG Y C.Degradation of phytic acid in rapeseed meal by two strains of molds[J].Acta Microbiologica Sinica,1998,1:44-51.(in Chinese)

[19] CHU X N,WANG C J,YUAN J M.A preliminary study of phytatedegraded by solid statefermentation of Penicillium canescens[J].Microbiology,1996,23:217-220.(in Chinese)

[20] KRISHNA C.Solid-state fermentation systems—an overview[J].Critical Reviews in Biotechnology,2005,25:1-30.

[21] SPIER M R,LETTI L A J,WOICIECHOWSKI A L,et al.A simplified model for A-Niger FS3growth during phytase formation in solid state fermentation[J].Brazilian Archives of Biology and Technology,2009,52:151-158.

[22] FU H Y,LI L M,CAI H Y.Effect of strain and fermentation condition on antinutrients in soybean meal[J].Animal Husbandry and Veterinary Medicine,2009,41:32-35.(in Chinese)