A Brief Look at New Techniques and Technologies for Drilling and Completing in the United States with Suggestions and Recommendations

Susan Smith Nash

(Innovation and Emerging Science and Technology, AAPG, Norman, Oklahoma, 73071, U.S)

Abstract: Technological developments that specifically address automation,compliance with environmental regulations,and hazard avoidance have accelerated more quickly than other drilling and completion technologies in the United States.This brief article provides a review of areas experiencing some of the most dramatic advances,while describing the need and addressing the solutions as they are now,and how they can be developed in the future.One aspect that all the new technologies have in common is an enhanced use of data analytics and in many cases,cloudbased solutions.A challenge that all have is a need to be able to quickly accommodate rapidly evolving requirements for emissions detection,hazard monitoring,and a reduced carbon footprint.Many solutions to the challenges require the ability to repurpose existing databases and use them for new purposes.

Key words: oil and gas in the U.S.;drilling;well completion;data analytics;technology development recommendations

Accelerating at a remarkable pace,technological advancements in the United States have led to remarkable breakthroughs in automation,environmental compliance,and hazard avoidance within the drilling and completion domain.This work aims to explore and assess the most significant strides in these areas,while also shedding light on the current needs and proposed solutions,as well as their potential for future development.Notably,a common thread among these cutting-edge technologies lies in their reliance on data analytics and cloud-based solutions,revolutionizing their effectiveness.However,a key challenge faced by all these innovations is the necessity to adapt swiftly to evolving demands,including improving emissions detection,monitoring hazards,and achieving reduced carbon footprint.Many of the solutions to these challenges hinge on the ability to repurpose existing databases for new applications.

This brief overview shows dramatic advancement the following areas: automated geosteering,HSE-friendly drilling fluids,drilling problem predictive failure models,remote surveillance and automation for enhanced drilling operations,such as robotics cuttings gathering and analysis,and innovative solutions for water issues,such as the steps needed to be able to use brackish water instead of fresh water.

1 Novel Drilling Technologies in the U.S.

1.1 Automated Geosteering

Traditional geosteering is very labor-intensive and requires human oversight and a dependence on loggingwhile-drilling (LWD) data.Generally speaking,only two or three wells can be monitored at a time.However,an automated geosteering algorithm has been developed to make it possible to simultaneously monitor numerous wells.Such a move will significantly reduce the need for human geosteering experts.The process involves automated geo-correlations using machine learning.The most successful cases are in wells that have geology that does not have major faults or major dip angle changes.

The drilling contractor,Helmerich & Payne,working with the operator,Sabine Oil & Gas,tested the algorithm in wells in the Haynesville Shale in the U.S.,with positive results[1].As shown in Fig.1,the algorithm involves advanced LWD filtering,fault detection,correlation,tracking of multiple interpretations with associated probabilities and visualization using novel stratigraphic misfit heatmaps[2].

Fig.1 Algorithm tested in wells in the Haynesville Shale

In addition,automated geosteering has been developed by Factor Technologies using deep learning Bayesian models.Companies such as Rogii,with its StarSteer technology,and ZoneVu,a geosteering technology from Ubiterra.The primary challenges have to do with managing the multiple interpretive possibilities,and classifying,ranking,and assessing the goodness of fit[3–4].

Smart automation and robotics have evolved rapidly during pandemic and post-pandemic times as the need for efficiency,cost-cutting,and emissions detection and control are being require by legislation and shareholder action.Examples of companies involved in such include Diversified Well Logging (DWL),Baker Hughes,and Halliburton.

Technologies including mud/cuttings sample analysis,hazard avoidance,bit pressure monitoring and control,machine learning,torque avoidance,automated geosteering,wellbore trajectory control,etc.can be used in areas with a significant risk to personnel,such as deepwater platforms.They can be used in applications that help improve environmental safety,such as methane emissions monitoring,plugging leaks in subsea pipelines,etc.The focus must be given to ensure that customized solutions are developed for each use case so that the true gains these technologies can bring,either in cost reductions,revenue maximization,or enhanced safety,are realized.

The full promise of automation is yet to be realized.Data integration problems,poor sampling from sensors,data harmonization problems,and flawed algorithms must be overcome to avoid poor results.

1.2 Machine Learning for Drilling Hazards Identification

The need to measure and monitor geopressure and the geomechanical stress regimes in drilling and completion is of great importance in ultra-deep drilling,where pressures,stresses,and temperatures can be high,leading to potential failures in borehole stability and the inability to design an effective hydraulic fracturing program.Different types of sensors have been developed for those purposes.For example,fiber optics sensors,while expensive,have become very important in borehole stability and in monitoring of wells during drilling,completion,and in stimulation.Specifically,distributed acoustic sensors (DAS) can be implemented.As shown in Fig.2,Optasense has developed a novel data streaming solution for wellbore digitalization.It allows remote operations as well as early hazard detection,such as vibration detection.Machine learning is used to implement algorithms that detect patterns,and then subsequently identify them.

Fig.2 Novel data streaming solution for wellbore digitalization

Distributed temperature (DTS) and distributed acoustic (DAS) fiber optic sensing are also now commonly used as key reservoir surveillance tools.This work shows the benefit of continuous downhole monitoring during the lifetime of a well.In one study,fiber optic cables were permanently installed in a doublet injector/monitor well system as part of a CO2controlled released experiment at the In-Situ Laboratory in Western Australia.During the completion and injection operations various planned and unplanned events (mud circulation,cementing,drilling,wireline logging,gas and water flows) occurred.The events were monitored from surface to reservoir with DTS and DAS fiber optic cables.The DTS was recorded continuously data starting during well completion throughout the lifetime of the wells while DAS was recorded at specific points in time,mostly associated with borehole time-lapse seismic acquisitions[5].

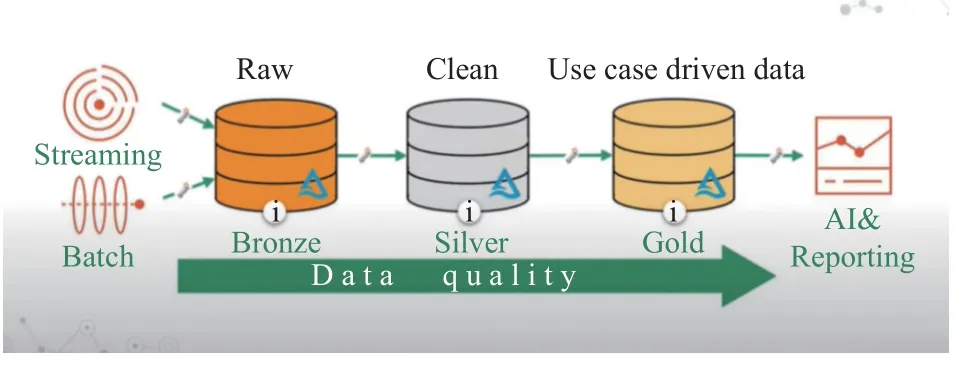

Fig.3 demonstrates how three different approaches to data analytic are currently being used for specific uses in drilling and completions.The data warehouse is something that Microsoft Azure and Snowflake specialize in.The Data Lake approach is one that has been used by both Amazon Web Services and Google.The Data Lakehouse is a hybrid approach that has been developed by Databricks.

Fig.3 Three different approaches to data analytic

In terms of safety,being able to detect and quantify gas kicks during drilling and completions is vital.It is one way to prevent blowouts.Again,distributed sensing techniques,acoustic (DAS) and temperature (DTS),can make it possible to have real-time communication of these multiphase flow events.Gathering the data is not enough,however.It is important to be able to manage it in a way that yields reqults quickly.The first step is to put all the data in a data warehouse,where it is kept in the cloud and accessible,although not classified.

The data lake is where the analytics can take place.For example,identifying and validating event signatures(fingerprinting) in these sensing technologies can help operators decide how to interpret these data streams.It is possible because this type of analytics involves working with structured,semi-structured,and unstructured data.

The data lakehouse can work quickly across all kinds of data and can not only identify patterns and classify events,but can also predict when other events will happen,such as equipment failure,drillbit sticking,seismicity,and more.Further,a full-scale analysis can let the team accurately interpret the event,given the complexities in the fluid mechanics and gas dynamics.

1.3 Drill Pipe Failure and Sticking Prediction Models

Being able to predict the failure for drill pipe can increase productivity and reduce costs,particularly in deepwater offshore operations.Brazilian drilling contractor,Ocyan,worked with the artificial intelligence technology company,RIO Analytics to develop a predictive failure model.It was then implemented to manage and control the use of drill pipe in offshore drilling platforms.To develop the algorithm,the first step involved identifying the factors that cause drill pipe fatigue,including stress during drilling,corrosion pitting,thinning of the pipe,abrasive wear,mechanical damage from bad handling.Although the pipe is inspected,and sensors are sometimes used,the problem is sparse data and the timing of detection of conditions of likely failure.The predictive algorithm can improve the historical practices of collecting excel spreadsheets that include operational and historical maintenance data,rotating hours,drilled meters,and aggregating data,which tend to be full of gaps[6–8].

Further,wellbore instability is often caused by cavings and increased volume of cuttings and other rock fragments.Cavings occur as the rocks undergo spalling and breakage,which can be explained through geomechanical models.The failed rock prediction model includes data from offset wells data,hollow cylinder tests conducted on cores from the formation of interest,which reflect the quantity and size of cavings,both from mechanical disturbance from the bit,plus spalling[9–10].The result was a 3D poro-elasto-plastic finite element model (FEM) which allowed for derisking operations by predicting wellbore instability,spalling,cavings,and thus reducing the likelihood of stuck pipe.AlBahrani etal’s model is a three-dimensional numerical model and uses a unique cavings volume determination methods to determine the downhole pressure necessary to avoid the production of cavings and thus wellbore instability and potential sticking[9].

Initial mudweight or bottom hole pressure is insufficient for borehole stability,resulting in cavings that dramatically increase the mud volume in the annulus.The effect of the additional volume is a wellbore enlargement and increased diameter.The result is an increase in mud weight,pressure with the cuttings and cavings loading.Here is where predictions come in and different changes in mud weight,rheological properties,rig hydraulics can be made to prevent further cavings.The interventions can stabilize the wellbore.

1.4 HSE-Friendly Drilling Fluids

Drilling fluids have been developed to be green and more effective in developing a healthy and safe working environment for the workers and for the ecosystem.Further,environmental laws and regulations are increasingly strict,making environmentally hostile additives and chemicals impossible to use[11].The industry is accelerating is progress toward eco-friendly,biodegradable,non-toxic,and HSE-friendly additives and chemicals.To find an effective substitute,researchers developed drilling fluids from waste vegetable oil from the food and catering industry,and then tested them on wells drilled by Saudi Aramco.The products were effective in practice[12].Fig.4 shows the drilling fluids developed from waste vegetable oil.To assure an ongoing supply,partnerships were established with sources of waste vegetable oil.

Fig.4 Drilling fluids developed from waste vegetable oil

Oil-based muds are used,particularly when drilling through salt zones or anywhere that water-based muds would result in washout zones and cavings.To find the raw materials for oil-based muds can be complicated,particularly where there are supply chain issues.To that end,studies have been performed to determine a process for converting waste vegetable oil to fatty acids by base hydrolysis reaction.Application of synthesized fatty acids for water-based and oil-based mud formulation as lubricants,emulsifiers and rheology modifiers is also used.Halliburton,AES Drilling Fluids,and Baker Hughes are just a few of the companies that have been making strides in developing environmentally friendly drilling fluids for a low carbon footprint.The coefficient of friction reducing potential of waste vegetable oil-based lubricants was demonstrated in a series of experiments while also providing a solution for the disposal of waste cooking oil.

1.5 Bits and Cutting Elements Failure Predictive Model

Drill bit damage detection and failure prediction are vital for prolonging the life of the bit and improving drilling efficiency.The methodology requires identifying drillbit cutters,quantifying the damage to each cutter through cutter image analysis,location of the cutters,and the root cause of the damage.Finding the cutters,grading the cutters,and then categorizing cutter locations are done,and then a classification for root cause.The critical factor for success is based on the quality of bit images and the standardization[13].

Further,successful predictive modeling requires a clear flowchart for quantifying cutter damage.Fig.5 provides a flow for the processes used to develop algorithms that predict the most likely outcome and the appearance.Perhaps the most critical step has to do with characterizing the cutter contour as transmitted by the sensors.The next steps require algorithms that eliminate noise and then binarize the resulting data.The difference between the ideal (original) shape and the damaged shape provides a way to quantify cutter damage.The following diagram illustrates the process:

Fig.5 Prediction process

A research initiative was launched to investigate new types of cutting elements.The project was successful and yielded an innovative conical-shaped polycrystalline diamond element (CDE).This element has twice the diamond thickness of conventional PDC cutters,resulting in higher impact strength and more resistance toward abrasive wear by approximately 25%.A new bit type was designed with the CDEs strategically placed across the bit face from gauge to the bit center utilizing FEA-based modeling system.NOV,EXIM,and others are companies that have developed drilling systems that include flexible pipe.

1.6 Drilling for Brackish Water Zones

Fresh water is increasingly scarce and there are multiple competing demands for the same reservoir of water,whether it be from an aquifer or a surface impoundment[14–18].Water for drilling and completing must compete with water for agricultural,industrial,and community use.Consequently,there is much more appetite for implementing purification processes,even if they were deemed too expensive in the past.Because of the additional demand and a willingness to utilize purification processes,a great deal of effort has been expended to improve the efficiency and effectiveness of microfiltration,distillation,and reverse osmosis processes.

One brackish water treatment system consists of ceramic microfiltration (CMF) and reverse osmosis (RO).The CMF stage is a robust filtration system and can remove metals,silica and other suspended solids from a waste stream as well as some hardness.The RO stage removes any dissolved ions from the water.This system is designed to achieve 95% plus water recovery,leaving only 5% of the feed water as RO brine requiring disposal or evaporation.This is a significant improvement over normal brackish water treatment.In most cases,the RO system will have a recovery of 50% to 60%.It is important to evaluate the corrosivity of brackish water[14].In this area,Veolia has consistently led the industry and continues to provide innovative ways to purify brackish water.In areas of high total dissolved solids (TDS),U.S.Strategic Minerals is developing effective ways to identify zones that could be prospective for brine mining.

The classification of brackish groundwater includes a wide range of water quality parameters and only some of the brackish groundwater falls within the technical specifications needed the hydraulic fracturing operation[18–19].Using brackish water for drilling and completion operations can have significant impact on corrosivity.It is important to track water chemistry.The assessment of water corrosivity is important for water management to predict corrosion-related failures.

2 Recommendations and Suggestions

What all the new technologies that are covered in this paper have in common is that they combine new analytics and computing capabilities to employ data storage architectures and artificial intelligence to increase the speed,accuracy,and safety of the operations,particularly in drilling and completions.However,there is still a great deal to be done to bring to bear the actual geological conditions of the reservoir,and also lithological characterizations of the formations adjacent to the borehole.

For that reason,it is imperative to take more cores and to analyze them well to determine the strength of the rocks,the porosity,permeability,fracture networks,and the rock properties based on the mineralogical composition of the formations.Then,models can be developed that bring together petrophysics,geomechanics,and fluid transport within the formation to classify performance of the new techniques against the actual formations and the wells.Thus,it is a geologically well-grounded approach for high-quality data-driven approaches.

Supporting this methodology are recently published reports from Devon Energy Company,based in Oklahoma City,which conducted extensive studies on the Eagle Ford formation in southern Texas.The Eagle Ford is an unconventional play,mainly shale,which produces both oil and gas.The question was whether or not refracturing the formation was worthwhile from an economic and production perspective.The study was a success,largely because each well incorporated extensive core studies and the results were calibrated against the different rock properties determined form the core analyses.

In the case of desalination of brackish water,there are numerous examples of purification through condensation,and water stills.The problem is that they cannot desalinate quickly enough to keep up with the production of brackish water or even produced water.Thus,it is imperative to modify existing approaches by experimenting with mirrors,special angles of glass,and to create analytical models before constructing and testing prototypes.

3 Conclusions

While all the technological innovations described in this paper were motivated by a need to increase efficiency,enhance automation,and reduce emissions and contaminants,what all have in common is a breakthrough with analytics.First,the functionality enhancements possible because of the ability to be cloudbased is significant.Second,the incorporation of machine learning algorithms in data storage,whether in a data warehouse,data lake,or data lakehouse,makes it possible to collect and analyze petabytes rather than gigabytes of data,and to incorporate simulations and models that utilize real-time data from sensors.Finally,predictive modeling has proven itself to be effective in new processes such as using waste vegetable oil in the development of green drilling fluids,as well as more standard applications such as automated geosteering.