Advanced PWR Technology—HPR1000 and Unit 5 of Fuqing Nuclear Power Plant

Ji Xing, Chunning Jing, Yemin Dong, Li Fan

China Nuclear Power Engineering Co.Ltd., Beijing 100840, China

1.Introduction

HPR1000 is an advanced mega-kilowatt-class third-generation pressurized water reactor (PWR) nuclear power technology developed by China,based on more than 30 years of experience in the scientific research,design,equipment manufacturing,construction,and operation of nuclear power.HPR1000 incorporates the innovative concept of a combined active and passive safety design and contains a number of major technological innovations,including an advanced reactor core design, double-shell containment, and a 60-year plant design lifetime.The core damage frequency (CDF) and large release frequency (LRF) are one order of magnitude better than the utility requirements for third-generation technologies in the United States and Europe.In addition, the technology has high seismic resistance and is capable of resisting the impact of a large commercial aircraft crash, and its unit safety and performance indicators have reached the same level as those of similar international third-generation nuclear power technologies.The first HPR1000 unit in the world—namely,Unit 5 of Fuqing Nuclear Power Plant—was officially put into commercial operation on January 30, 2021, after the shortest construction period(i.e.,68.7 months)and with the best economic indicator among the first units of global third-generation technologies.HPR1000 is known as the landmark project of the Made in China 2025 policy.At present,it is being implemented in a batch construction at home and abroad, including at the Karachi Nuclear Power Plant (Pakistan), Fujian Zhangzhou Nuclear Power Plant (China),and Hainan Changjiang Nuclear Power Plant (China).The successful research and development (R&D) and construction of HPR1000 has greatly enhanced China’s capabilities in the R&D of advanced nuclear power technologies and the manufacturing of nuclear power equipment, propelling a leap forward in the development of China’s nuclear power technology and placing China within the top level of nuclear development in the world.

2.Overview of HPR1000 and Unit 5 of Fuqing Nuclear Power Plant

2.1.R&D of HPR1000

China’s development of nuclear power started in the 1980s, with the design and construction of the country’s first nuclear power plant, Qinshan Phase I.In 1999, the conceptual design of a megakilowatt-class PWR nuclear power plant with partial third-generation characteristics (CP1000) was initiated, and 22 major technological improvements were gradually identified,such as a 177-fuel-assembly reactor core, a single unit layout, double-shell containment, and so forth.In response to the Fukushima nuclear accident in Japan, countries with nuclear power set more stringent safety requirements for newly built nuclear power plants.Based on the CP1000 technology,China’s R&D team learned from advanced nuclear power design concepts worldwide, as well as from feedback from the Fukushima nuclear accident, and successfully developed HPR1000, a thirdgeneration PWR nuclear power technology, to meet the latest international safety standards.

HPR1000 introduces the concept of a combined active and passive safety design, which reflects the idea of integrated safety and balanced design [1].Based on the safety design of traditional PWRs,HPR1000 also deploys a secondary-side passive residual heatremoval system, a passive part of a cavity injection and cooling system, a passive containment heat-removal system, and other safety features to deal with conditions beyond the design basis.This safety design not only retains the mature and efficient characteristics of active systems but also makes full use of the inherent safety characteristics of passive systems based on natural circulation and gravity,as well as their advantage of not requiring a power supply, thereby improving the advanced nature and reliability of the safety measures.Table 1 presents the main design parameters of HPR1000.To ensure the integrity of the fuel cladding, reactor pressure vessel(RPV), and reactor containment, diversified safety measures have been provided,and the defense in depth is strengthened at multiple levels;thus,an early radioactive release or a large radioactive release is practically eliminated by the design [2].

An International Atomic Energy Agency (IAEA) Generic Reactor Safety Review was conducted for HPR1000 by an expert group from the IAEA,and the detailed review confirmed the safety of the design,stating ‘‘The design generally follows the IAEA Safety Requirements for safety assessment and for design.The design appears to be robust as it is an evolutionary design and relies on proven engineering practices and an extensive experimental program for validation of the design safety.” Compared with similar third-generation advanced PWRs, such as AP1000, EPR, and VVER-1200, HPR1000 adopts an innovative core design with 177 fuel assemblies and is the first PWR to apply a combined active and passive safety design within all three radioactive confinement safety barriers.The lowest value of CDF has been achieved in HPR1000,while the PWR’s seismic capability and capability to resist a large commercial aircraft crash are the most robust among all third-generation PWRs in the world.

Table 1Main design parameters of HPR1000.

2.2.Unit 5 of Fuqing Nuclear Power Plant

The first global unit of the HPR1000 Demonstration Project, Unit 5 of Fuqing Nuclear Power Plant (Fig.1), is located at the foot of Mountain Qiwei, Fuqing City, in Fujian Province (China).Construction on Unit 5 began on May 7, 2015, and the unit was officially put into operation on January 30, 2021, setting a record for both the shortest construction period and the lowest project costs among the first reactors of third-generation nuclear power technologies in the world.China Nuclear Power Engineering Co., Ltd.undertook the role of engineering procurement construction for Unit 5 and was comprehensively responsible for the design, procurement, construction, and commissioning; moreover, more than 5300 construction and manufacturing companies participated in the project.

Major challenges were encountered with Unit 5 regarding the technology R&D, equipment management complexity, and high demand on construction period control, among others.Therefore, a 3D digital design platform was developed for this project in order to realize simultaneous 3D design by multiple parties in different places.In terms of project organization, based on an Engineering Procurement Construction Startup (EPCS) integrated management mode with a strong focus on design, the organic and in-depth integration of design, procurement, construction, and commissioning was realized, fully utilizing the advantages of the general-contracting construction mode and ensuring the quality, progress, and cost control of the project.

Unit 5 of Fuqing Nuclear Power Plant has completed the operation of two fuel cycles while maintaining a stable operation status without unplanned outages,and its safety indicators meet the design requirements.At the same time, another three HPR1000 units,including Unit 6 of Fuqing Nuclear Power Plant in China and Units K2 and K3 of Karachi Nuclear Power Plant in Pakistan, have been put into commercial operation and have shown good operational performance.The smooth construction and stable operation of the first four units, both at home and abroad, have fully demonstrated the safety, advancement, and maturity of HPR1000 [3].

Fig.1.Aerial view of the first unit of the HPR1000 Demonstration Project in the world: Unit 5 of Fuqing Nuclear Power Plant.

3.The ten technological innovations of HPR1000 and Unit 5 of Fuqing Nuclear Power Plant

3.1.Advanced reactor core design

HPR1000 adopts an innovative 177-fuel-assembly core (Fig.2)design with advanced technical indicators, including a 60-year lifetime, 18-month refueling cycle, and a high thermal margin of 15%[4].With its innovative core design, HPR1000 adopts a doubleenrichment low-leakage loading scheme, which not only significantly improves the thermal power and neutron economy but also reduces the average linear power density and improves the safety margin.With the innovative design of reactor vessel internals, a full set of analyses including seismic analysis, dynamic response to a loss-of-coolant accident, flow-induced vibration, and an overall hydraulic model test have been carried out, demonstrating the HPR1000 advanced functions, which include a high seismic-resistance level of 0.3g (where g is gravitation constant), the quick replacement of detector components, and the efficient dismantling and installation of in-core instrumentation.

In addition,with the development of a new type of flow-distribution structure, the number of parts has been reduced by 55.3%, and the maximum non-uniform coefficient of flow distribution between neighboring fuel assemblies has reached an internationally advanced level of only 0.0688.In terms of the R&D of the core measurement system, HPR1000 realizes the high-accuracy and quick (at the millisecond level) online monitoring of safety parameters, such as the linear power density of the fuel assembly,departure from the nucleate boiling ratio,3D power distribution of the reactor core,burnup of fuel assemblies, and key-point water level of the RPV, significantly enhancing the reactor’s capability for core safety monitoring and demonstrating that the system performance is at the international advanced level.

3.2.Active and passive safety design

Fig.2.Initial fuel loading for the 177-fuel-assembly core of HPR1000.

As mentioned earlier,HPR1000 adopts the concept of a combined active and passive safety design,supplementing mature and efficient active safety systems with passive safety features that can effectively cope with loss-of-power-source accidents.The design deploys diverse safety measures to avoid common mode failure, such that the defense in depth of the nuclear power plant has been substantially strengthened and the plant safety has been improved.Based on complete test verification and simulation, the R&D team has realized advanced technologies such as the simulation of two-phase natural circulation and the numerical simulation of coupling between the natural circulation system and the containment thermal-hydraulic functions.Moreover,they have pioneered technical schemes such as directly injecting super-cooled water into the thermal insulation of the RPV in the early stage of a severe accident and establishing a low-pressure open-cycle containment natural circulation system.Based on these technical schemes, three major passive systems—including a secondary-side passive residual heatremoval system, the passive part of the cavity injection and cooling system, and a passive containment heat-removal system—were developed and deployed in HPR1000.Thus, both active and passive technologies have been applied to ensure the integrity of each of the three safety barriers (Fig.3).

In addition,by studying the phenomena and mechanisms of severe accidents and solving a series of challenges such as simulating the 3D non-uniform distribution of hydrogen in a large space, dedicated countermeasures have been deployed in HPR1000 to prevent phenomena such as hydrogen explosions, high-pressure corium ejections, and long-term overpressure from jeopardized containment integrity.In combination with non-permanent equipment such as mobile pumps and mobile diesel generators, these countermeasures equip the power plant with the comprehensive ability to deal with severe accidents,achieving the goal of the practical elimination of early or large radioactive release by means of the HPR1000’s design.

3.3.Innovative design of the nuclear island and containment

The nuclear island of HPR1000 adopts a seismic design of 0.3g,which is equivalent to being able to withstand an earthquake with a seismic intensity of 9.0.To achieve this design, difficulties in the seismic analysis of structures and equipment qualification have been solved, and the seismic input spectrum can cover a variety of foundational geotechnical conditions.The utilization of a single-unit layout is beneficial for reducing mutual influence between units and enhancing the siting flexibility.

The reactor building adopts a double-shell containment design(Fig.4).The inner containment is a pre-stressed reinforced concrete structure with a leak-tight steel liner, which can independently withstand the high temperature and high pressure resulting from a loss-of-coolant accident.The outer containment, which is made of reinforced concrete with a thickness of 1.8 m, not only provides additional confinement for radioactive substances but also sufficiently protects the inner containment and the internal structures of the reactor building by strengthening the capability to resist extreme external hazards.In addition to the outer containment,thickened external walls have been built for the fuel building and electrical building, and the different trains of the redundant safety systems have been geographically isolated.As a result, the unit has the ability to resist the impact of a large commercial aircraft crash,ensuring the safety of the reactor in the event of a hypothetical malicious strike.

Fig.3.The combined active and passive safety design of HPR1000.

3.4.Development and manufacturing of core equipment

The design of HPR1000 well addresses the technical challenges associated with the requirements of high reliability, high seismic resistance, a long lifetime, and tolerance to harsh accident conditions, successfully realizing the development and manufacturing of key equipment.As the main equipment, a large-volume RPV(Fig.5(a))matching the 177-fuel-assembly core has been developed and manufactured, overcoming the technical bottleneck of solid forging, avoiding circumferential welding of the cylindrical section outside the active core, and tackling technical difficulties such as the control of elements for the irradiation embrittlement of materials, thereby increasing the design life to 80 years.A ZH-65 steam generator(Fig.5(b))has been developed and manufactured,in which key technologies such as flow-induced vibration on the tube bundles and transient control have been established and key materials such as Inconel 690.T have been developed and manufactured, enlarging the heat transfer surface by 20%.An ML-B control-rod drive mechanism (Fig.5(c)) was independently designed for the first time, passing the 1500-step hot state length-of-life test and the 0.3g seismic test and controlling the step-length precision within 75 μm.

In terms of mechanical equipment for the nuclear island, a longthreaded,high-precision,fully digitally controlled refueling machine(Fig.5(d)) has been developed, with a comprehensive positioning precision of ±3 mm and a repeat positioning precision of ±1 mm,enabling the rapid loading and unloading of five to six fuel assemblies per hour.A fuel-transfer device (Fig.5(e)) was also developed and manufactured with a pioneering relay drive technology, and the technical challenges of the long-distance underwater transportation of fuel assemblies have been overcome.In terms of instrument and control equipment, a high-energy pipeline-leakage monitoring system has been developed and manufactured, integrating acoustic emission inspection,temperature and humidity leakage positioning,and quantification technologies.This makes it possible to predict leakage cracking and critical cracking, so that the rapid rupture of pipelines can be prevented before the occurrence of an accident.Critical parts of the turbine generator(Fig.5(f))unit have been innovatively developed, such as high-performance calandria technology for the condenser, a transverse independent landing mechanism for the inner cylinder of the low-pressure steam turbine, and a new type of finned heat-exchanging tube for the steam-water separation reheater, which improves the overall heat-exchange performance and the stability of the turbine generator unit.

Fig.4.The single-unit layout of the nuclear island and the double-shell containment design of HPR1000.

Fig.5.Key equipment in HPR1000.(a) The RPV, (b) steam generator, (c) ML-B control-rod drive mechanism,(d)refueling machine,(e)fuel transfer device,(f)steam

Fig.6.Outline drawing and photo of the CF3 fuel assembly.

Overall,HPR1000 realizes the development and manufacturing of 411 sets of key equipment.The first unit of HPR1000 in the world has achieved a localization rate of 88%, effectively driving the R&D and manufacturing of domestic nuclear power equipment and promoting the transformation and application of technological achievements and the transformation and upgrading of industry clusters.

3.5.Development and manufacturing of high-performance fuel assemblies

The core of HPR1000 is loaded with CF3 fuel assemblies (Fig.6),adopting a new type of grid design with a high thermal performance.The design has a 17×17 square pattern,including one skeleton and 264 fuel rods.It incorporates a novel nozzle design,meeting the seismic requirement of 0.3g.The designed burnup is as high as 55 000 MWd·t-1·U-1,which can meet the long refueling cycle of 18 months,and the average annual availability has been improved from about 82% to more than 90%.Due to the design of the guide thimble grid and lattice, the CF3 fuel assembly has greater seismic strength.The design team has fully considered the requirements of the thermal performance,hydraulic buffering,structural safety,and so forth,systematically completed the development and manufacturing of zirconium alloy from zirconium sponge, finished the tube and bar products, and completed an irradiation test by means of a commercial reactor and industrial application.

3.6.Innovative engineering project-management system

The construction of a nuclear power project is known for its high complexity, long period, and high safety and quality requirements.As the first unit of the HPR1000 Demonstration Project in the world,Unit 5 of Fuqing Nuclear Power Plant presented tremendous management challenges because it involved many constructionparticipation parties with complicated cooperative relationships,more than 5300 supply-participation manufacturers, more than 60 000 sets of equipment, and more than 100 000 construction participants.Therefore, China Nuclear Power Engineering Co., Ltd.introduced the concept of whole life-cycle management, which centered on the ProMIS project management platform (Fig.7), supported by the four management platforms of design, procurement,construction,and commissioning,in order to realize the cross-sector synchronized management of EPCS business, planning, interfaces,changes,quality,safety,and cost.The design sector took on the overall leading role, integrated planning management was applied, and multi-layer, multi-dimensional centralized control measures and coordination mechanisms were established.To effectively manage risks, risk prediction was carried out through sand table deduction,with a focus on solving key problems, and high-level control of the top risks was implemented, so as to promote integrated linkage throughout the entire project cycle and scope and to bridge the entire process data chain.In this way, a construction period of just 68.7 months was achieved for HPR1000—the shortest construction period for the first unit among the world’s third-generation nuclear power technologies.

Fig.7.A nuclear power project management system realizing ECPS synchronized management.TC:team center;SAP:systems applications and products in data processing;IFS:industrial and financial systems.

3.7.Digital R&D of HPR1000

A digital R&D design platform was developed for HPR1000, supported by structured engineering data and high-precision 3D models.With more than 20 interconnected units and more than 500 terminals, the platform overcomes the problems of multi-discipline,multi-user,remote-collaboration,and complex 3D modeling(Fig.8);it also realizes intelligent data submission between upstream and downstream disciplines, 2D and 3D verification, visualization of the plant’s general plane, and the integration of design for various disciplines.The platform realizes the effectiveness and consistency of multi-source heterogeneous data, ensuring efficient statistics and the batch extraction of various items,and providing strong support for refined procurement, construction management, and nuclear power operation and maintenance.The application of digital concepts extends to other areas, such as digital reactors, digital design verification platforms,and digital main-control-room design.Moreover,the first digital power plant delivery standard in the field of nuclear power has been formulated, achieving the structured characterization of power plant design process data and delivery data for the first time,and essentially promoting the transformation of digital nuclear power.A design information system that links all disciplines has been created to realize the whole-process and total-factor integrated management of design planning, input, analysis, confirmation, verification, and output.

3.8.Innovative construction and installation technologies

Fig.8.A digital 3D model of the nuclear island of HPR1000.

During the construction of Fuqing Unit 5, new technologies,materials, processes, tools, and working methods were adopted for civil work and installation.A new type of anti-collision system for tower-crane group operation has been developed, promoting the operational safety and efficiency of the densely arranged towercrane group at the nuclear power construction site.Issues related to the double assurance of the construction period for the stainless steel cladded pool and 100%non-destructive testing have been overcome,and a pre-cladding method was adopted to implement factory prefabrication and onsite modularized installation,thereby enabling construction progress in two ways.Automatic welding and advanced detection technologies were explored and applied in order to improve the construction quality and efficiency and reduce the labor cost.Modular construction was adopted for the steel lining for the containment of HPR1000 (Fig.9); 13 sections of steel lining shells were assembled and welded on the ground in a modular way, and then the whole module was hoisted to the installation position.Compared with a traditional single-block construction process, this modular construction improved the installation efficiency, reduced the safety risk, and greatly accelerated the construction speed.All innovative construction and installation technologies were oriented to align with the engineering requirements, thereby improving the safety and convenience of the construction and installation process,supporting the project construction period, and ensuring timely delivery of the project.

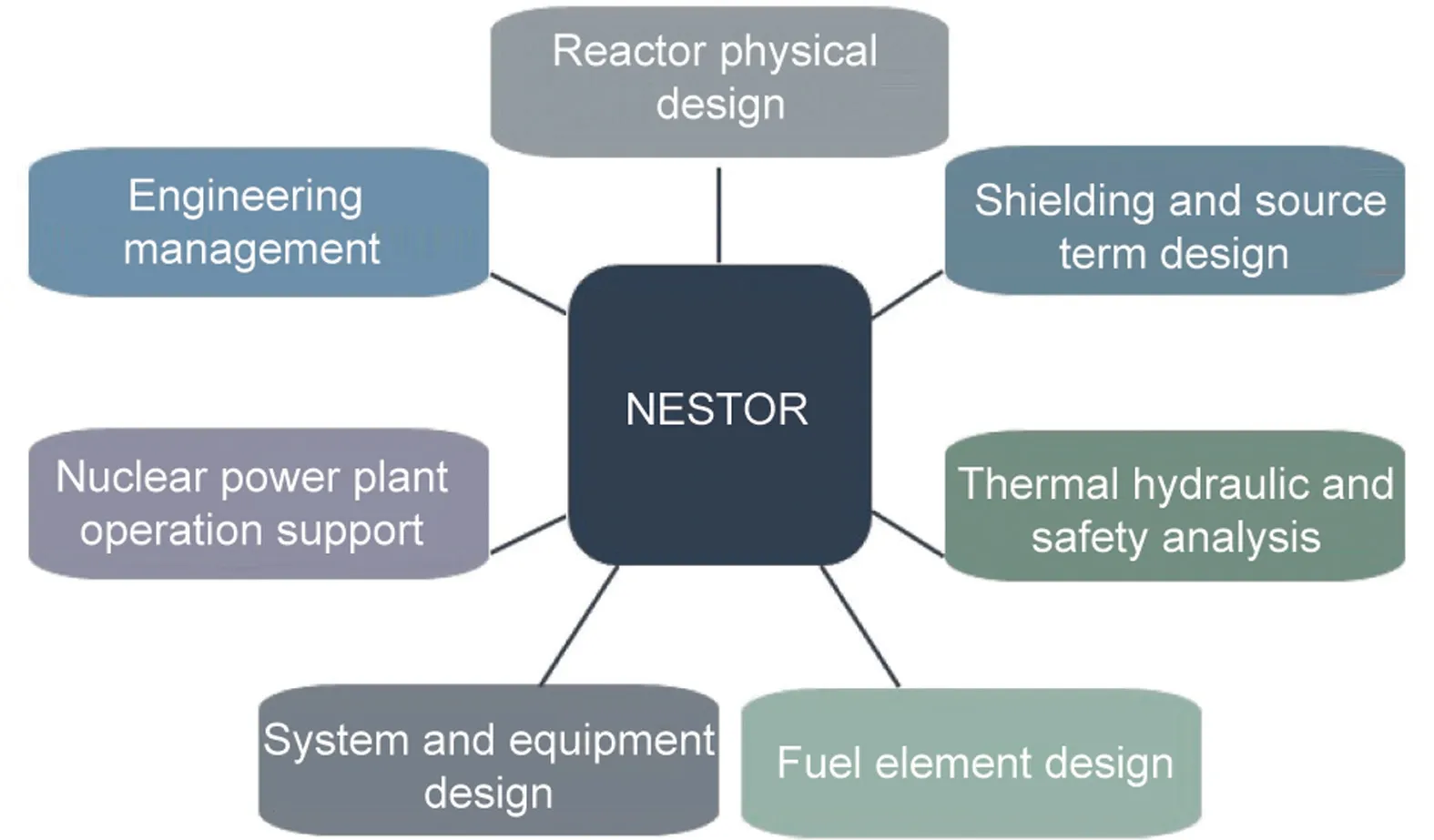

3.9.NESTOR: The first nuclear power software package

China’s first nuclear power software package and integrated software integration platform, NESTOR (Fig.10), has been developed based on 60 years of experience with China’s nuclear industry,close to 100 test platforms, thousands of experimental datasets, and the commissioning and operation data from nearly 30 nuclear power projects.NESTOR has been customized for the third-generation nuclear power characteristics of HPR1000, covering the following seven major disciplinary fields: core design; shielding and source term design; thermal, hydraulic, and safety analysis; fuel elements;system and equipment design; the operational support of nuclear power plants; and engineering management.It comprises 131 software programs, for which 112 software copyrights have been obtained.NESTOR not only overcomes technical problems such as the complexity,rigor,and safety of nuclear power software development but has also been fully verified via a great deal of operating laboratory data and through engineering and research experience.NESTOR can run on an integrated platform,which realizes multi-disciplinary parallel computing and improves the efficiency of R&D and design.NESTOR was officially released in Beijing in December 2015,indicating China’s capability to independently export complete sets of nuclear power technologies.

3.10.Establishing a complete nuclear power standards system

Fig.9.Modular construction process of the steel lining for the containment of HPR1000.

Fig.10.The NESTOR nuclear power software package.

Fig.11.A compilation of the reference books of the HPR1000 standards system.

Under the joint promotion of the National Energy Administration,the Standardization Administration of the People’s Republic of China,and the Ministry of Ecology Environment of the People’s Republic of China (National Nuclear Safety Administration), based on the HPR1000 Demonstration Project, the HPR1000 National Major Project Standardization Demonstration Project has been implemented and a complete standards system for HPR1000 has been established,which covers the whole life cycle of a nuclear power plant (Fig.11).The current PWR nuclear power standards system,which follows the tenet of ‘‘general purposes first, special purposes second” has been optimized and completed.The HPR1000 standards system covers a total of 2360 standards, of which 615 have been formulated or revised.It provides comprehensive support for the design,manufacturing, construction, and operation of the HPR1000 demonstration project, laying the foundation for the standardized batch construction of HPR1000.

4.Conclusions

Based on its advanced design concept, the systematic R&D of its technology, and its reliable manufacturing process, HPR1000 meets the latest international requirements for third-generation light water reactors in terms of safety, operation performance, and economy.The technology of HPR1000 has been fully recognized by the IAEA, third-party advisory bodies representing international users,and the China Nuclear Energy Association.The successful completion of the first reactor of the HPR1000 Demonstration Project—namely,Unit 5 of Fuqing Nuclear Power Plant—establishes China as a nation that has fully mastered third-generation nuclear power technology,following the United States, France, Russia, and other countries.The construction of the first unit of HPR1000 in the world has established an advanced nuclear energy R&D system, including testing technology, a simulation and verification platform, a digital R&D platform,and a project-management platform,thereby laying a solid foundation for the continuous innovation and research of advanced nuclear energy technology in China.

Since Unit 5 of Fuqing Nuclear Power Plant was first put into operation, it has fully undergone the test of the first two fuel cycles and demonstrated excellent operation performance, showing the maturity and reliability of the technology.On May 20,2021,the first overseas unit of HPR1000—namely, Unit K2 of Karachi Nuclear Power Plant—was officially put into commercial operation, in what is known as the best practice of international energy cooperation.

At present, several subsequent units of HPR1000 are under construction.A good start in batched construction has been accomplished with Units 1 and 2 of the Zhangzhou Nuclear Power Plant in Fujian and Units 3 and 4 of the Changjiang Nuclear Power Plant in Hainan, which are under construction.Moreover, pre-project work is being carried out on a total of more than ten units at Phase II of Zhangzhou Nuclear Power Plant(Fujian),Sanmen Nuclear Power Plant (Zhejiang), Huaneng Xiapu Nuclear Power Plant (Fujian), and Phase I of Jiangsu Lianyungang Heat Supply Plant(Shandong Yantai)with the adoption of HPR1000.

- Engineering的其它文章

- Corrigendum to ‘‘Emerging Organic Contaminants in Chinese Surface Water: Identification of Priority Pollutants” [Engineering 11 (2022)111-125]

- Incentive-Aware Blockchain-Assisted Intelligent Edge Caching and Computation Offloading for IoT

- Tailoring Photonic-Engineered Textiles with Butterfly-Mimetic Tertiary Micro/Nano Architectures for Superior Passive Radiative Cooling

- Methods on COVID-19 Epidemic Curve Estimation During Emergency Based on Baidu Search Engine and ILI Traditional Surveillance in Beijing,China

- Alterations in the Gut Microbiome in Liver Recipients with Post-transplant Diabetes Mellitus

- Profiling the Antimalarial Mechanism of Artemisinin by Identifying Crucial Target Proteins