Hygrothermal effect on high-velocity impact resistance of woven composites

Xio-chen Yng , Nn Ji b,c,d,*

aSchool of Urban Construction, Eastern Liaoning University, Wenhua 325, Dandong,118003, China

bCollege of Safety Science and Engineering, Liaoning Technical University, Fuxin,123000, China

c China Coal Technology & Engineering Group Shenyang Research Institute, Fushun,113122, China

dState Key Laboratory of Coal Mine Safety Technology, Fushun,113122, China

Keywords:Hygrothermal aging effect Woven glass/epoxy composite Impact resistance Dynamic failure Energy absorption

ABSTRACT The woven glass fiber reinforced composites (GFRP) subjected to high-speed impact is investigated to identify the hygrothermal aging effect on the impact resistance.Both the hygrothermal aged and unaged glass/epoxy laminates are subjected to different impact velocities, which is confirmed as a sensitive factor for the failure modes and mechanisms.The results show the hygrothermal aging effect decreases the ballistic limit by 14.9%, but the influence on ballistic performance is limited within the impact velocity closed to the ballistic limit.The failure modes and energy dissipation mechanisms are confirmed to be slightly influenced by the hygrothermal aging effect.The hygrothermal aging effect induced localization of structural deformation and degradation of mechanical properties are the main reasons for the composite undergoing the same failure modes at smaller impact velocities.Based on the energy absorption mechanisms, analytical expressions predict the ballistic limit and energy absorption to reasonable accuracy, the underestimated total energy absorption results in a relatively poor agreement between the measured and predicted energy absorption efficiency.

1.Introduction

The fiber-reinforced composite materials have been extensively employed in high-performance architecture,aerospace and marine applications owing to their high specific strength and stiffness compared with conventional metallic materials.Composite structures are exposed to the periodical heat and moisture environment during the long-term service.Additionally, some of the composite structures are potentially subjected to damage threats from the external objects, especially the impact phenomenon, such as the bird strike, the fan blade-out event, and the high-speed impact of fragments.As the composite are vulnerable to impact damage, a large amount of research has been performed on the impact resistance of the composite subjected to low and high speed impact, explosive impulses in the last decades [1-5].

Composites subjected to quasi-static and low-speed impact loadings have been studied to identify the failure modes and failure mechanisms by numerous researchers, with textiles, fibrereinforced laminates, and sandwich structures widely investigated.Surface buckling, fiber and matrix crushing, delamination,matrix crack, fiber breakage, and penetration are identified and quantified with the impact energy for the fiber-reinforced composites.Most of the fiber-reinforced composite is sensitive to the strain rates.Based on the experimental studies, Daniel et al.[6]evaluated the classical failure criteria of composite materials at the quasi-static and dynamic loadings under multi-axial states of stress.Liu et al.[7] presented the failure mechanism maps for the ultra-high molecular weight polyethylene fibre composite at different impact intensities.In order to investigate the impact resistance of the composite broadly,several impact parameters are undertaken, such as the shape and size of the projectile [8], the impact velocity, and angle [9-11].The thickness and lay-up sequence of the composite are studied to improve the impact resistance [12].The non-contact dynamic loadings focused on the dynamic failure behaviors,such as air blast and underwater blasts,on the fiber-reinforced composite have been studied previously as well[13,14].Besides the composite sandwich structures,ultra-high molecular weight polyethylene fibre composite [15], FML(fiber metal laminates), and 3D woven composite are performed to improve the impact or penetration resistance of the traditional composite.These studies involving the impact resistance focus on the normal environment, ignoring the temperature, moisture, and hygrothermal effect on the composites.

It is a well-known fact that exposure conditions affect the mechanical properties significantly, such as the strain to ultimate failure, the fracture toughness of adhesives, and resistance to plastic deformation [16].To meet up with the application of composite marine vessels, the effect of exposure conditions on the impact resistance of composites was investigated by many researchers.Compared with the fiber reinforcement, the epoxy matrix can absorb the tremendous quantity of moisture due to the larger moisture diffusivity of epoxy, which induces a considerable mismatch in the volumetric expansion and localized stress and strain field in the composite.Xin et al.[17]evaluated the moisture diffusion characteristic and hygrothermal aging properties in pultruded glass fiber reinforced polymer(PGFRP)composite laminates of bridge profiles exposed to the water and artificial seawater at varying temperatures.To enhance the moisture resistance,Ray[18]claimed the larger temperature effect increases the moisture absorption rate and degree of degradation of GFRP.Berketis et al.[19]reported the matrix and fibre/matrix interfacial degradation of glass/isophthalic polyester composites subjected to a hydrothermal environment(65C)for a very long duration.Mei et al.[20]studied the hygrothermal aging on the compressive properties of CFRP composite sandwich by employing different environment temperatures.Arhant et al.[21]found that both the in-plane compressive modulus and strength of CFRP decreases with hygrothermal age.Li et al.[3] proposed a novel dynamic degradation model by introducing the thermal and time fitting coefficients simultaneously to express dynamic elastic moduli of composite materials.The lowspeed impact and residual compressive strength tests showed that the duration of immersion time did not increase the damage size considerably but produced a greater density of throughthickness damage.Based on low velocity impact testing, Krystyna et al.[22] tested the influence of immersion aging on the residual strength of two different woven glass-aramid-fibre/epoxy laminates.According to the SEM results, they concluded that delamination threshold load and impact energy absorption were not significantly affected by the absorbed water, but the compression strength suffered significant reductions with water absorption.Pang et al.[23] evaluated the residual load carrying capacity of Eglass fiber reinforced epoxy composite after low-velocity impact by exploding into ultraviolet radiation for both air and water based immersion.The macro and micro analysis revealed the influences of the hygrothermal effect on load carrying capacity,but most of the impact loadings are limited to low velocity impact performed by drop weight [24,25].Liu et al.[26] reported the effect of the hygrothermal aging cycle on the impact resistance of CFRP laminate subjected to high-velocity impact, showing that the fiber/matrix interface is considerably affected by the duration of the hygrothermal aging.

In the present study, a typical hygrothermal aging spectrum is employed in the hygrothermal aging cycle to the saturation of the woven glass/epoxy composite.The high velocity impact experiments are performed on the hygrothermal aged and unaged woven glass/epoxy laminates to determine the effects of impact intensity and hygrothermal on the ballistic performance in terms of the dynamic response, ballistic limit, residual velocity, failure modes and energy absorption mechanisms.Based on the different failure modes and energy dissipation mechanisms revealed in the experimental study, a simplified energy absorption model is carried out to predict the ballistic limit parameters and absorbed energy.

2.Experimental methodology

2.1.Materials

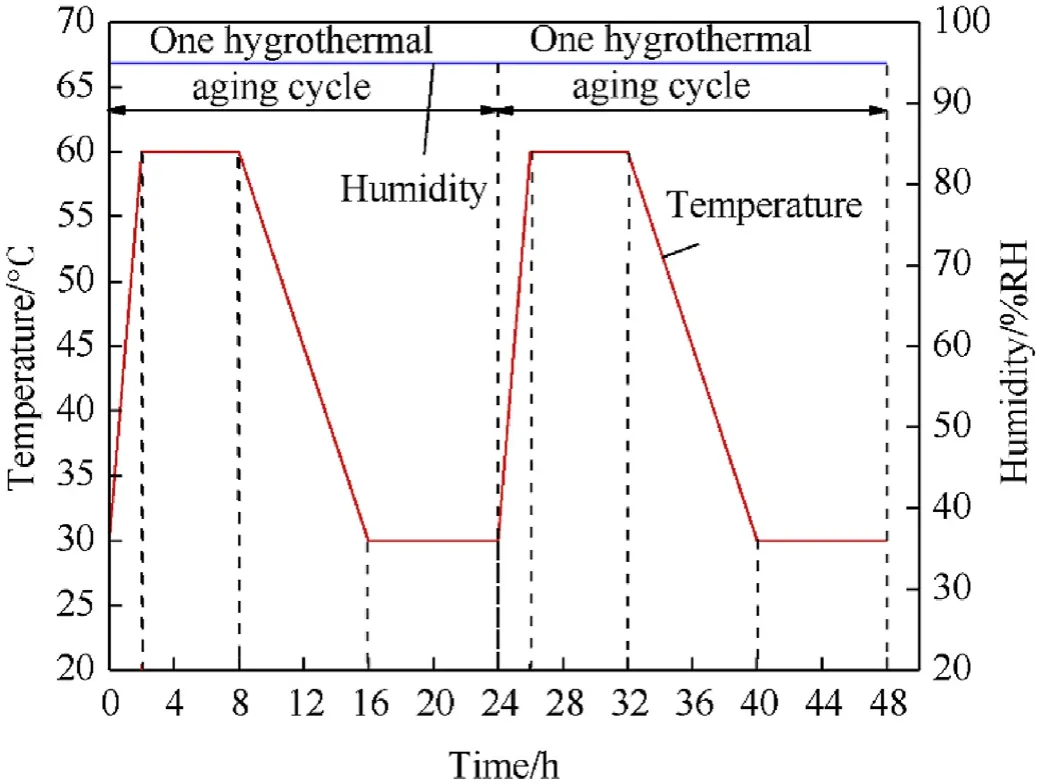

The woven glass/epoxy laminates are used to study the highspeed impact resistance, with a stacking sequence of [0/90].The plain-weave fabric in the laminate is obtained from prepreg layers made of E-glass.The identical thickness of the woven glass/epoxy laminate is 2.7 mm.The mechanical properties of the ply material drawn from the manufacturer’s technical data sheet are shown in Table 1.The average density of the specimen is 1600 kg/mand the fiber volume fraction of the laminated is 60%.

Table 1 Material properties of glass fiber reinforced polymer(GFRP).

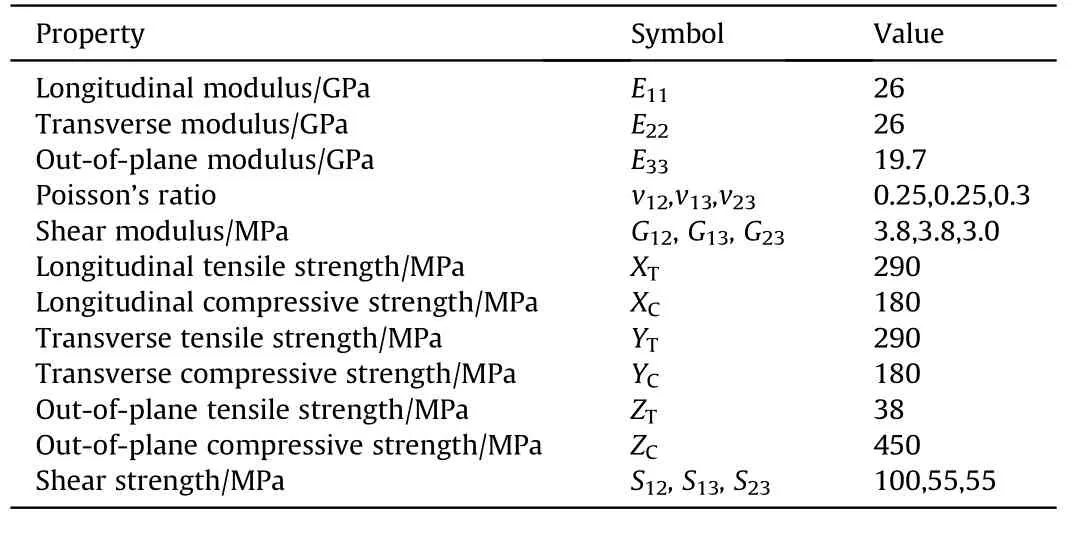

2.2.Cyclic hygrothermal aging methods

To model the hygrothermal aging effect in a natural ground environment, the hygrothermal aging spectrum shown in Fig.1 is adopted for the woven glass/epoxy laminate.A cycle of hygrothermal aging takes 24 h.During the cycle of hygrothermal aging,the temperature experiences significant changes,but the humidity remains 95%RH.In every hygrothermal aging cycle, the temperature initiates from 30C to 60C in 2 h and remains at 60C for another 6 h.The decrease of the temperature occurs after the first 8 h, dropping from 60C to 30C in 8 h.At the end of the hygrothermal aging cycle, the temperature keeps at 30C for 8 h.

Due to the dimension of the specimen acquired for the impact test, the laminate is cut into 100 mm × 100 mm for measuring moisture absorption.Before putting into the environmental chamber, the square laminate is exposed into the 30C to ensure the weight of the plate does not change (less than 0.02%).During the process of the hygrothermal aging cycle, the weight of each laminate is measured every 24 h, in which the increased weight represents the absorbed moisture content by the laminate.

2.3.Quasi-static mechanical property

To obtain more valuable information on the composite laminate,the quasi-static tension test is performed on the unaged woven glass/epoxy laminate.According to the ASTM D3039,the dimension of the tensile specimen is 200 mm×25 mm×2.7 mm.The gauge length is 100 mm, and both sides are 50 mm in length and reinforced by the 1.5 mm-thick aluminum tabs.The specimens are cut along or perpendicular to the wrap of fibre to measure the tensile property of the composite.The tension tests are conducted on a universal testing machine,MTS-809.The loading rate is 2 mm/min.An extensometer is employed to record the strain of the tension specimen.The tension tests are repeated four times.

According to the damage mode after the impacts, the out-ofplane compressive strength of the woven GFRP composite plays an important role in energy dissipation.The GFRP composite panel is cut into average dimensions of 10 mm × 10 mm × 2.7 mm and tested on the universal testing machine with a loading rate of 0.2 mm/min.To achieve the effect of hygrothermal aging on the compressive strength,five groups of specimens with hygrothermal aging for 0 cycle,10 cycles, 20 cycles, 30 cycles, and 33 cycles are compressed, respectively.

Fig.1.Hygrothermal aging spectrum for the GFRP laminates.

2.4.Impact resistance experiments

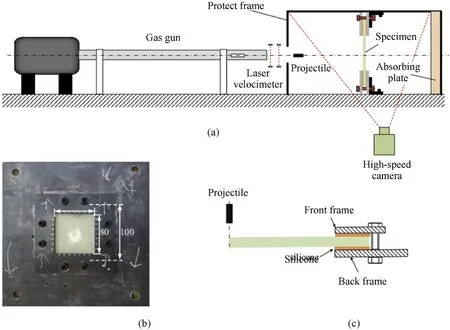

The impact experiments are conducted at a one-stage light gas gun system which can accelerate and control the velocity of the projectile, as shown in Fig.2a.The projectile is made of 45# steel with a dimension of φ 12.6 mm × 35 mm.All of the tested composite laminates have the dimensions of 100 mm×100 mm×2.7 mm.As shown in Fig.2b and c,the 1 mmthick silicone rubbers are bonded along the clamped area to avoid pullout of the specimens.The deformation area of the composite is 80 mm × 80 mm.To capture the process of impact, a high-speed camera, Photron Fastcam Sa-Z, is placed at the front of the view window.Rather than perpendicular to the ballistic trajectory, the camera lens has a slight incline angle to the ballistic trajectory to observe the dynamic response of the composite, as shown in Fig.2a.After the distance calibration,the back view of the camera is also used to measure the residual velocity of the projectile after penetration.The front view of the camera and laser velocimeter are employed to measure the initial velocity which is within the range of 20 m/s240 m/s.During the impact experiment,the camera is set to record the impact at 60,000 frames per second with a resolution of 896 × 368 pixels.

3.Experimental results and discussions

3.1.Quasi-static mechanical properties

Fig.3a shows the typical stress-strain relationships of the woven GFRP laminate with different hygrothermal aging cycles under quasi-static compression.After the initial serrations,all the stressstrain curves exhibit good linear responses up to the peak stresses followed by suddenly unloading due to the damage of the specimens.The compressive strength and modulus undergo significant decreases due to the degradation of matrix and matrix-fiber interfaces of the composite with the increasing hygrothermal aging cycle.The relationship between the compressive strength and square root of the hygrothermal aging hour is shown in Fig.3b, in which the compressive strengths are 432.6 MPa, 418.2 Mpa,400.4 MPa,375.8 Mpa,360.9 MPa according to the 0,10,20, 30, 33 cycles of hygrothermal aging, respectively.Similar to the residual strength model proposed for in-plane compressive strength in Ref.[27],a power function is adopted to fit the experimental data,which represents the variation of compressive strength of the woven composite as a function of the hygrothermal aging hour.Hence, the out-of-plane compressive strength of the composite withhours hygrothermal aging is σ() = 432.6- 0.029MPa,as shown in Fig.3b.

The results of the quasi-static tensile test show the average value for the tensile strength,tensile modulus,and failure strain are 327.5 MPa,14.1 GPa,and 7.2%, respectively, as shown in Fig.3c.

3.2.Moisture absorption behavior

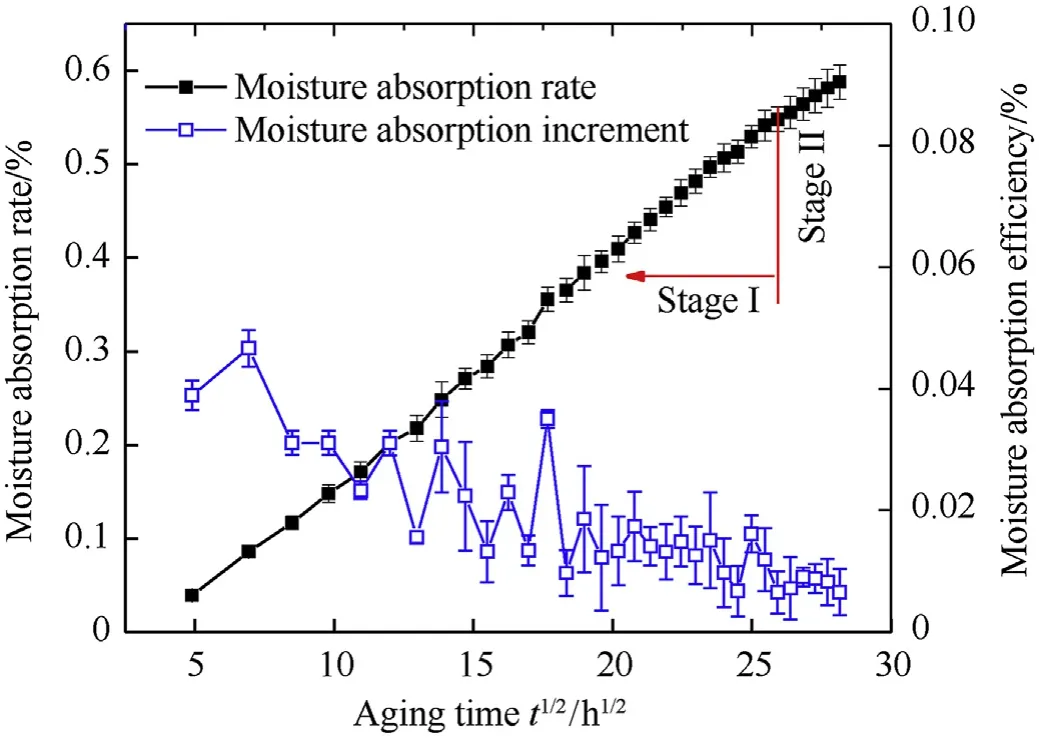

In this paper,33 hygrothermal aging cycles are performed on the composite laminates.There are five specimens are weighted at every cycle.Based on the weight measurement every 24 h, the moisture absorption ratecan be given by the following equation according to ASTM D5229 [28].

whereandare the masses of the wet laminate at timeand initial unaged GFRP laminate.Fig.4 presents the moisture absorption rate of the composite laminate with the increasing time.According to the ASTM D5229, the efficiency of the moisture absorption can be expressed as

where Wand Ware the measured weights of+1 cycle andcycle.The moisture absorption of the composite laminate can be divided into two stages.During stage I,the moisture absorption rate experiences a linear increase with the increasing time.The water content in the composite varied linearly with the absorbing time square root, which has a good agreement with Fick’s second law.The microdefects, including cracks and micro-gaps, and resin are the main reasons for the rapid moisture absorption rate at stage I.With the gradually decreasing moisture absorption rate, the composite is about to reach the saturation point where the moisture absorption increment rate is within 0.01% according to ASTM D5229.In stage II,the matrix crack expansion,resin hydrolysis,and resin-fibre interface debonding can be attributed as the mechanisms for the moisture absorption.Due to the less than 0.01%moisture absorption, the woven GFRP laminate is regarded as it reaches the equilibrium after the 33 cycles which is chosen as the set of the impact experiment.

3.3.Hygrothermal effect on ballistic performance

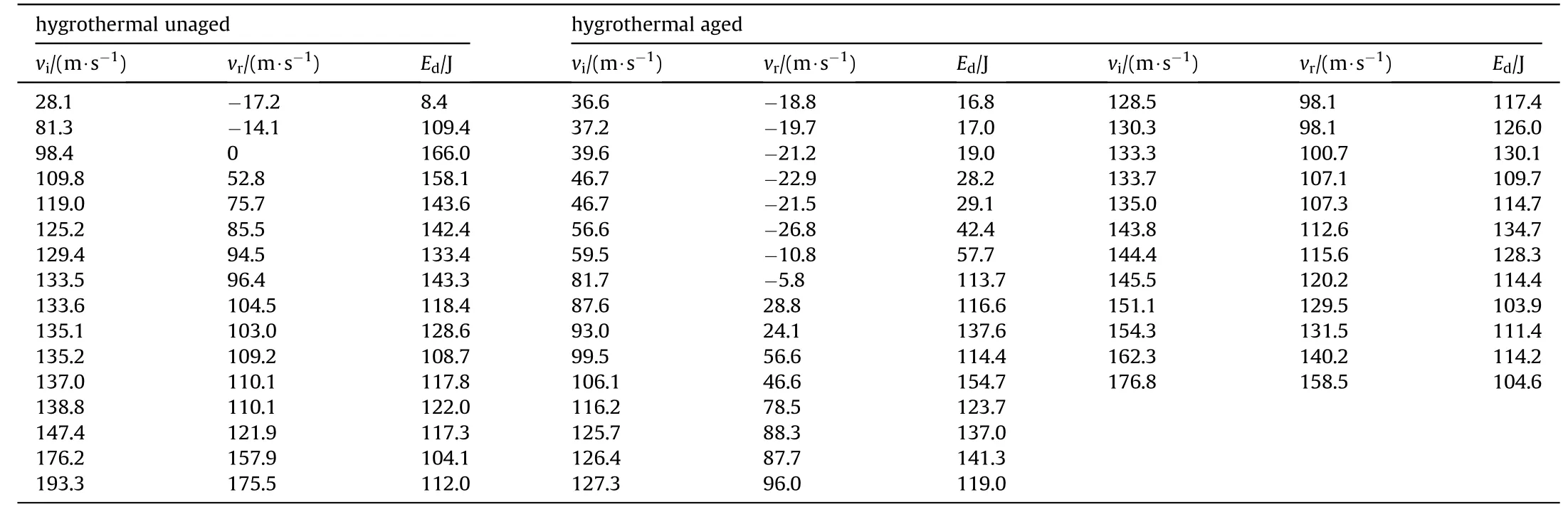

The experimental results of the hygrothermal unaged and aged woven composite laminates subjected to the impact are listed in Table 2.Theandare the initial impact velocity and residual velocity of the steel projectile.The negative residual velocity represents the rebound velocity of the projectile.Theis the experimental energy dissipation of the composite laminates.

Table 2 Experimental results of the aged and unaged woven GFRP laminates.

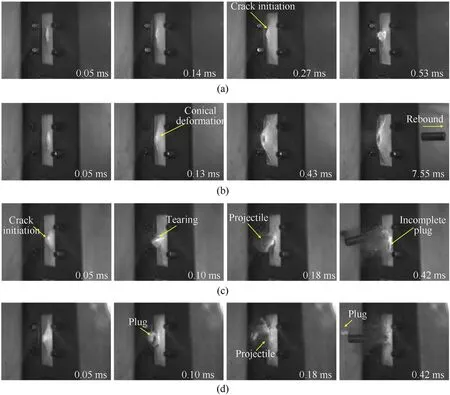

Fig.5 shows the dynamic failure processes of the hygrothermal aged and unaged woven GFRP laminates subjected to high-speed impacts with various intensities.With the increasing impact velocity, both kinds of composite laminates experience similar dynamic responses due to the longitudinal and the transverse waves in the fabric plane and out-of-plane directions respectively: local deformation at impact site,structural deformation,crack initiation,crack evolution, perforation.The noticeable difference of the dynamic failure between the hygrothermal aged and unaged composite is that the hygrothermal aged composite exhibits smaller critical impact velocity of the same failure mode due to the degradation of matrix and fiber-matrix interface.All the laminate undergoes elastic recover after the impact.At low impact velocity,the projectile hits the woven composite and compresses the impact region, initiating the conical-shaped deformation.Without fiber fracture, the tension wave induced by the reflection of the compressive wave causes the local delamination at impact region.Then the projectile is rebounded with residual kinetic energy.As the impact velocity is close to the ballistic limit, the composite laminate experiences larger structural deformation than that of the lower impact velocities and larger response time than that of the higher impact velocity, as shown in Fig.5b.The significant structural deformation indicates a change of the regime of the energy dissipation as the impact velocity increases from low to high speed,in which the structural deformation has a larger proportion of energy absorption as the impact velocity close to the ballistic limit.

Fig.2.Sketch of (a) the experimental setup, and (b, c) the clamped devices (unit: millimeter).

As is subjected to high-speed impact, the longitudinal and transverse stress waves move faster in the in-plane and out-plane laminate, resulting in a faster structural deformation.As shown in Fig.5c and d,the laminates experience significantly larger areas of transverse deformations than that is shown in Fig.5a and b at 0.05 ms.Besides the fiber fracture caused by the stretching, a shearing plug forms in front of the projectile and moves with the projectile as the dry laminate is subjected to impact velocity of 176.2 m/s, leaving the composite laminate recovering from the transverse deformation, as shown in Fig.5d.Subjected to similar impact velocity,the hygrothermal effect shown in Fig.5c affects the penetration in terms of the speed of stress wave propagation and dynamic failure mode.At 0.05 ms, the wet composite undergoes more local transverse deformation and slightly cracking initiation.At 0.10 ms, an obvious shear tearing and more slightly structural deformation are identified at the wet composite, instead of the shearing plug at the dry composite.An incomplete shearing plug with smaller thickness is formed during the penetration as well.It is worth noting that the slight incline of the ballistic trajectory of the projectile should be also considered as a factor inducing the differences.

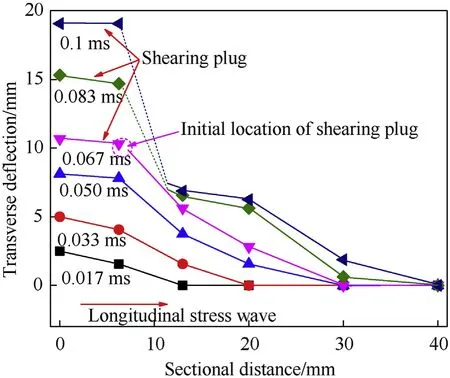

Fig.6 shows the transverse deformation history of the sectional profile,where four measuring points are selected along the half of the sectional profile of the hygrothermal unaged composite panel subjected to impact velocity of 176.2 m/s.The transverse deflection of the points presents the propagation of the longitudinal wave initiating from the impact site to the boundary.It can be seen that the deformation shows two different profiles up to the elastic recovery,the conical shape before the initiation of the shearing plug and the structural deformation with a 10 mm-long plateau near the plug, as shown in Fig.5d.This significant structural deformation does not occur on the hygrothermal aged composite according to the dynamic failure,primarily due to the fact that the degradation of the composite inhibits the propagation of the longitudinal stress wave.The dynamic response and deformation indicate the hygrothermal aged composite is more likely to undergo the local deformation than the unaged counterpart.

Fig.3.Relationship between the compressive strength and the hygrothermal aging time, and stress-strain relationships under quasi-static tensile.

Fig.4.Moisture absorption increment and efficiency of the woven GFRP laminates.

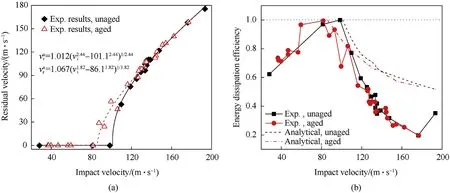

To analyze the hygrothermal aging effect on the ballistic performance of the woven GFRP laminate, the relationship of the impact and residual velocities is fitted by Recht-Ipson Eq.[29].as below.

where,andare the fitting parameters.The ballistic limit of the composite laminate is defined as the critical velocity of the projectile when it perforates the laminate with a residual velocity of zero.From Fig.7a it can be seen that the ballistic limit of the woven composite with the hygrothermal aging is 86.1 m/s,decreasing by 14.9% in comparison with the ballistic limit of 101.1 m/s of the unaged woven GFRP laminate.The locally structural deformation discussed above and the degradation of matrix and fibre/matrix interface caused by the hygrothermal effect are the predicted reasons for the decreased ballistic resistance.The difference of the residual velocity between the two kinds of composites narrows with the increasing impact velocity.It can be observed from the results that the residual velocity of the two composites exhibits striking agreement as the impact velocity exceeds 138 m/s.Correspondingly, the hygrothermal effect has a slight influence on the energy absorption of the woven composite when the impact velocity exceeds 138 m/s,as shown in Fig.7b.The capacity of energy absorption of the composites is defined as

whereis the mass of the projectile which has no mass loss during the impact.The energy absorption efficiency η is defined as follow

The curve of the energy absorption efficiency can be divided into three stages.The impact velocity lower than the ballistic limit is stage I, where the efficiency increases with the increasing impact velocity due to the fact that the failure modes of the composites transfer from the elastic deformation to local fiber fracture and delamination.Besides the energy absorbed by the structural deformation, the additional fiber fracture and fiber-matrix delamination dissipate more energy.In stage II,the impact velocity is larger than the ballistic limit and the projectile perforates the laminate.The fiber and matrix fracture, delamination, stretching tearing are induced by the increasing impact velocity.As the impact increases,the fiber fracture caused by the stretching is replaced by the complete shear plug at the impact site in stage III.The energy absorbed by the composite in this stage experiences an increase due to the shearing and friction erosion.

Fig.5.High-speed images of impact and penetration of the GFRP laminates,(a)aged,vi=59.5 m/s,vr=-10.8 m/s,(b)aged,vi=81.7 m/s,vr=-5.8 m/s,(c)aged,vi=176.8 m/s,vr = 158.5 m/s, (d) unaged, vi = 176.2 m/s, vr = 157.9 m/s.

Fig.6.Sectional profile of the hygrothermal unaged composite subjected to impact velocity of 176.2 m/s.

Fig.7.(a) Residual velocity vs.impact velocity, and (b) the energy dissipation ratio of the composite laminates to various impact velocities.

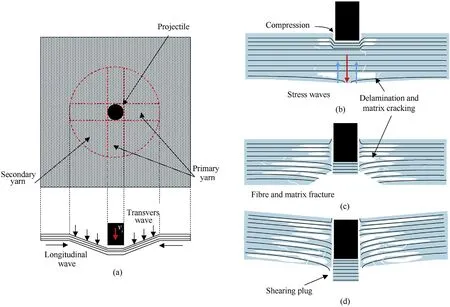

When the impact loading impinges on the composite laminate,a number of deformation and failure modes are observed with the varying intensities of the impact.The dynamic failure of the woven GFRP laminate has already been discussed based on Fig.5.The structural bending and stretching caused by the longitudinal and transverse waves are depicted in Fig.8a.Subjected to the low impact velocity, the woven GFRP composite panel experiences extremely local compression at the impact site.Due to the propagation of the transverse shear wave in the in-plane direction, the surrounding region of the impact region undergoes slight compression as well.The delamination occurs as the strength of the reflected tension wave exceeds the bonding strength of the fibermatrix interface or tensile strength of the epoxy matrix, as shown in Fig.8b.The delamination initiates from the back to top plies due to the propagation of the tension wave.With the velocity increases,the primary yarn is pulled out from the matrix and tends to fail when the induced tensile strain of the yarns exceeds the ultimate strain, which provides the resistance of perforation and dissipates the kinetic energy.Then,the tension of the secondary yarns follows.Meanwhile, the finite shear plug and significant delamination and matrix cracking can be observed in the panel.Similar to the failure observed in ceramic,a troncoconic volume is created by the impact of the flat projectile due to the fracture of the fiber and matrix, as shown in Fig.8c.As the strength of the impact exceeds the allowable shear plugging strength of the composite laminate, the highspeed projectile induces a through-thickness shear plugging, with significant delamination, as shown in Fig.8d.

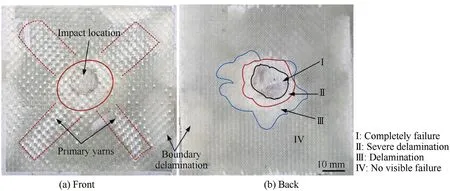

Fig.9 presents the typical failure modes of the hygrothermal unaged composite laminate subjected to impact velocity of 81.3 m/s which is 80%of ballistic limit velocity.The failure of the composite panel can be divided into three regions, the impact location, the region of primary yarns, and the boundary region.In the impact location, a slight transverse shearing and severe fiber and matrix fractures can be observed at the several front and back plies,respectively.Complete damage shown as the white area occurs in this region.The primary yarns are observed that are pulled out from the matrix outer the impact location,especially in the front surface.At the back side, there are four grades of damage shown in the composite plate.At the central region,the complete damage area of the composite is larger than the area of the projectile,showing the troncoconic volume in Fig.8c.This kind of failure mode appears only when the projectile has an impact velocity closed to the ballistic limit.At a higher impact velocity,the composite prevents the fiber failure of the non-penetrated plies during the impact process.The outer regions of impact location show different extents of matrix delamination, as shown in Fig.9b.Additionally, visible delamination failure happens at the periphery of the clamped boundary due to the bending.It can be seen from the figure that the fiber-matrix delamination is a predominant failure mode outer the impact location.

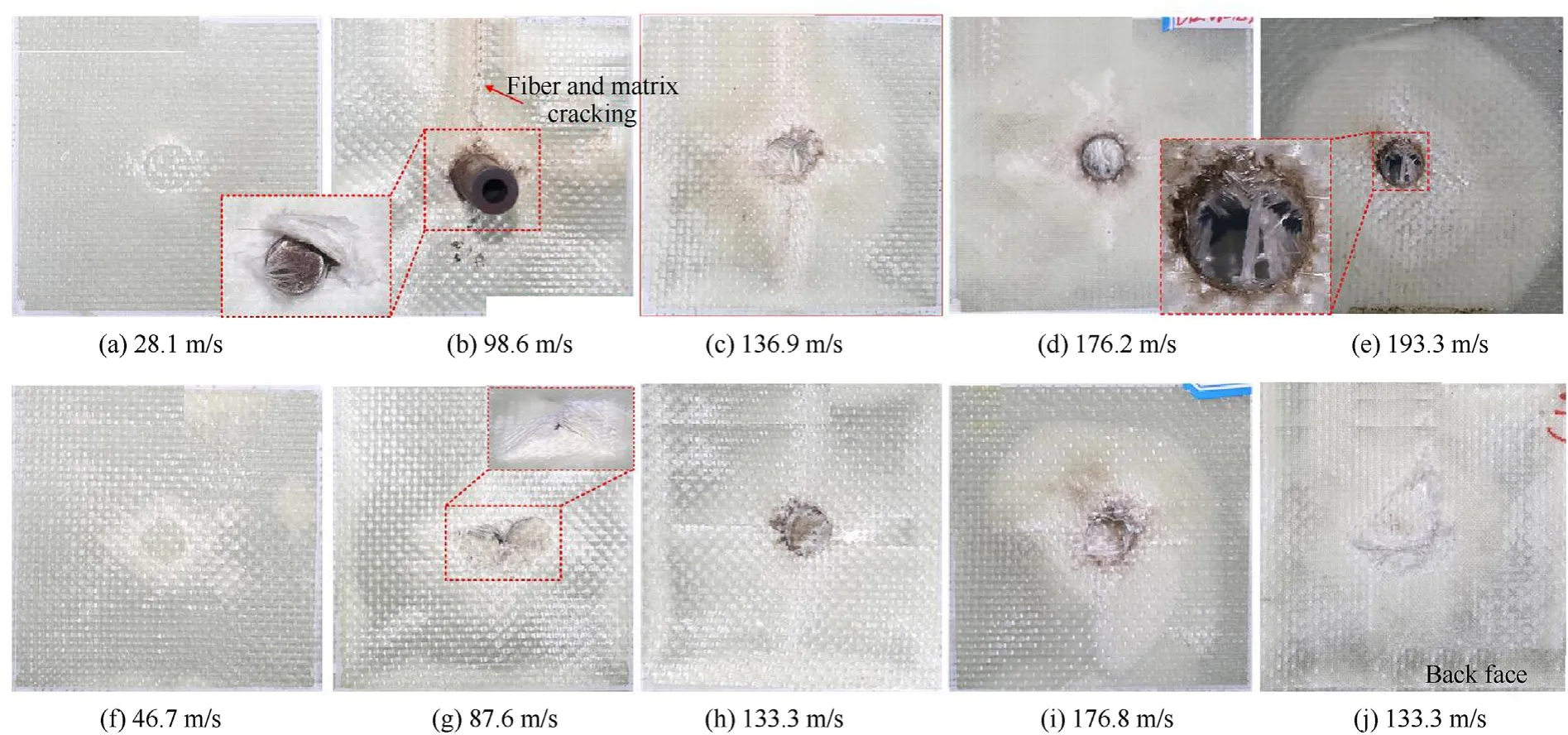

The woven GFRP laminates experience different failure modes and areas with the changing impact velocities,as shown in Fig.10.Fig.10a-e present front failure modes of the composite laminate without the hygrothermal aging as they are subjected to impact velocities from 28.1 m/s to 193.3 m/s.At 28.1 m/s, there is only a circle imprint caused by the transverse compression on the surface.When the impact velocity closes to the ballistic limit,the projectile is stuck on the plate.Besides the delamination, there is a visible fiber and matrix cracking which dissipates the residual kinetic energy of the panel and projectile system.With the increasing impact velocity, the compressed thickness in the impact site and area of the delamination both experience increases.When the impact velocity exceeds 176.2 m/s,an entire shearing plug forms.A through-thickness black band caused by the friction erosion between the projectile and the laminate can be observed as well.A complete delamination is observed in Fig.10d.However, as the impact velocity increase to 193.3 m/s,the area of the delamination undergoes a significant decrease,a more complete plug and severe friction erosion can be seen.The result indicates a transformation of the energy absorption mechanism, from structural deformation to the shearing plug and friction erosion.

Fig.8.Schematic of the failure modes and energy absorption mechanisms of the woven composite laminate.

Fig.9.Typical failure modes of the woven GFRP laminate subjected to impact velocity of 81.3 m/s.

The postmortem images of the hygrothermal aged woven GFRP laminate are shown in Fig.10f-j, which exhibit similar failure modes with the increasing impact velocity as the unaged counterpart.The difference is that the hygrothermal aged composite has a lower critical impact velocity to achieve the same failure mode as the unaged composite.As shown in Fig.10c and h, both of them show the same failure modes, incomplete shearing plug, cross pullout of primary yarns,delamination in center and periphery,and stretching tearing at the back side.Although the failure area shown as white region in the image presents different values and symmetries and become more obvious as the impact velocity is 176 m/s,this trend can not represent the difference caused by the hygrothermal effect between two kinds of composites according to the experimental results.

Fig.10.Failure modes of the hygrothermal aged and unaged woven GFRP laminate.

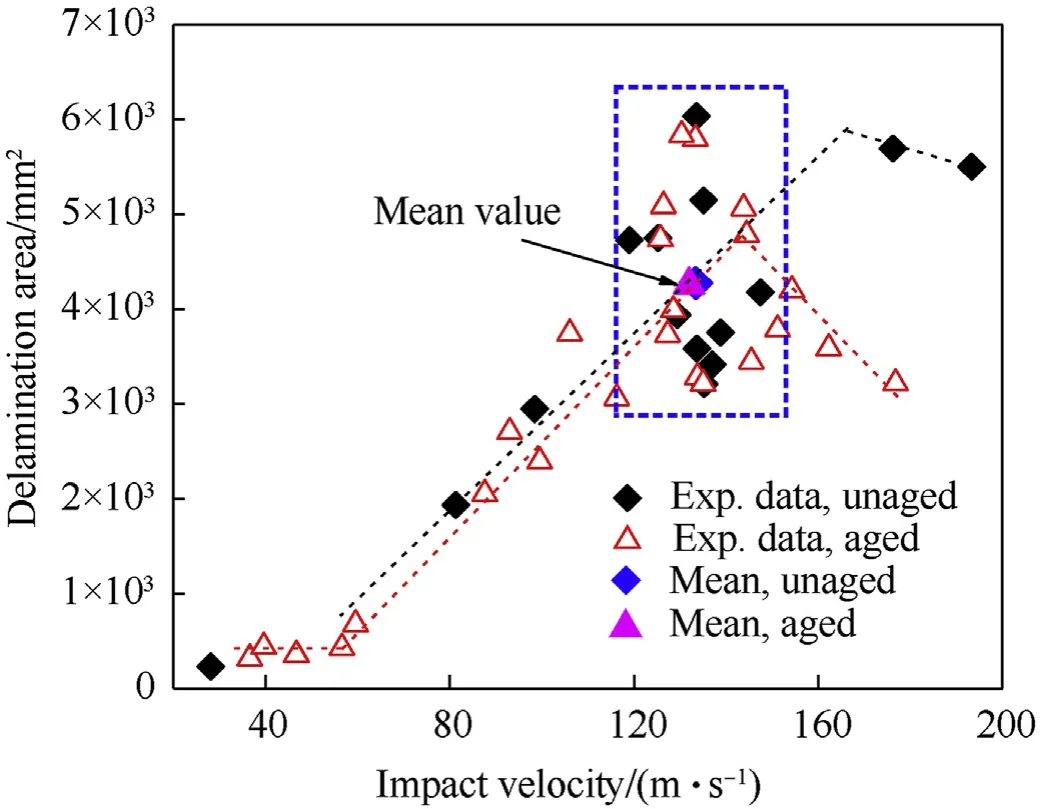

The impact intensity is the predominant reason for the variation of failure area, as shown in Fig.11.In order to identify the hygrothermal effect on the failure,Fig.11 presents the damage area of the hygrothermal aged and unaged GFRP laminate subjected to different impact velocities.The damage area measured on the front or back side of the same composite plate is confirmed to be similar to each other.Hence,the damage area on the front side is presented in Fig.11.Except for the invariable damage area within the low impact velocity stage,the relationship between the failed area and impact velocity undergoes three different stages, increasing stage,unstable stage, and decreasing stage with the increasing impact velocity.Within the increasing stage, the central and the surrounding delamination is the predominant mode for the composites.The central perforation and boundary delamination become more and more significant as the impact velocity increases, which increases the failed area significantly.As shown in Fig.11, the results in the blue box belong to the unstable stage,where the failed area shows a relatively big difference within a relatively small range of impact velocity, 116 m/s~153 m/s.The invisible distribution of damage on the middle-thick plies is likely the main reason influencing the failure area on the front or back side, which can be measured by non-destructive investigation methods for accurate results, such as C-scan.As for the failed composite subjected to relatively low velocity,the delamination with large failed area may occur at the fiber-matrix interface near the back face, but the number of the failed plies is less than the plate with a smaller failed area subjected to higher impact velocity,showing a lighter color of the failed area (Fig.9b).Within the decrease stage, it can be seen that the damage area of the two kinds of composites undergoes a noticeable decrease as the impact velocity exceeds a critical value due to the increasing portion of friction erosion and the number of the failed plies.Take the mean values in the unstable stage for the two kinds of plates,the clearer linear trends can be observed up to the decreasing stage.The results show that the hygrothermal unaged woven GFRP laminate shows the largest failed area of about 5843 mmat about 165 m/s.The composite with hygrothermal aging exhibits 20% smaller failed area than the dry counterpart at the impact velocity of 144 m/s, indicating a significant decrease of the impact-resistance performance.

Fig.11.Damage areas of the woven GFRP laminates subjected to varying impact velocities.

3.4.Energy dissipation analysis

As discussed above, the woven GFRP laminates with/without hygrothermal aging absorb the kinetic energy of the projectile by several failure modes, impact crushing, structural deformation,delamination, fiber and matrix cracking, and shearing plug.Highspeed images for the impact experiment suggest that the plastic deformation of the steel projectile can be neglected,indicating the sum of all the energy absorption mechanisms mentioned above must be equal to the kinetic energy lost by the projectile.The main energy absorption mechanisms are discussed as follow.

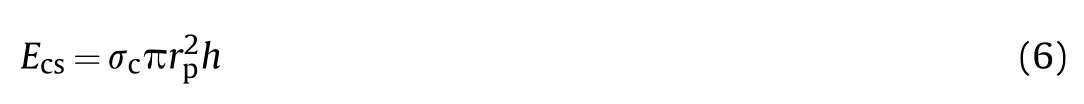

With obvious friction erosion,the shearing plug and the impact crushing happen at the impact location of the projectile.The two different damage mechanisms can be summarized as the well-known plugin failure mode.When the projectile impacts on the laminate, it breaks the fiber and matrix in front of it by compression and shearing.The energy absorbed by shearing is neglected due to the relatively small transverse shear strength.The corresponding term is written as follows:

where σis the compressive and interlaminar shear strength of the composite respectively.andare the radius and penetration distance of the projectile, respectively.

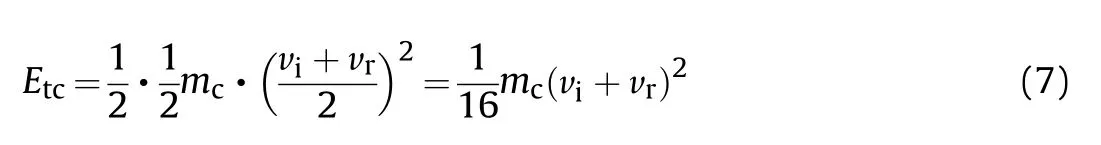

The conical deformation caused by the projectile absorbs a significant amount of kinetic energy.As shown in Fig.8a,the velocity profile of the cone is triangular.To simplify the analysis, the propagation of the longitudinal wave experiences a very short time and hence the energy dissipated during the period is neglected.The corresponding term is written as follows:

whereis the mass of the transverse cone.

The fiber in the primary region is subjected to a significant tension as the projectile exceeds the low impact velocity.These fibers are known as primary fibers.According to the results shown in Fig.10, the area and thickness of the failed primary fibers change with the increasing impact velocity.Since the primary fibers are under tension and strains in these yarns are plastic,the expression for the total energy absorbed by these primary fibers is given by

whereandare the length and width of the primary fibers,and εis the plastic failure strain of the fiber.

The secondary fibers do not exhibit obvious tensile failure during the impact process and hence the energy dissipated by this failure mode is neglected.

Compared with the large area of delamination observed in the plates, the energy dissipated by the matrix cracking is neglected here.According to the area of delamination () shown in Fig.11,this term is given by

whereis the interlaminar fracture toughness in mode II[30].is the number of layers andis the number of interfaces in which delamination takes place.is the area of delamination atth ply.As the impact velocity exceeds the ballistic limit of the composite plate,the number of delamination is taken as n-1 in this paper.

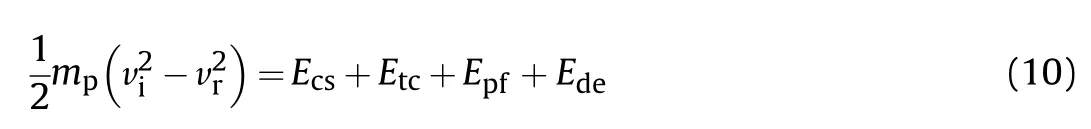

According to the energy conservation during the impacts, the total energy absorbed by the plate can be given by

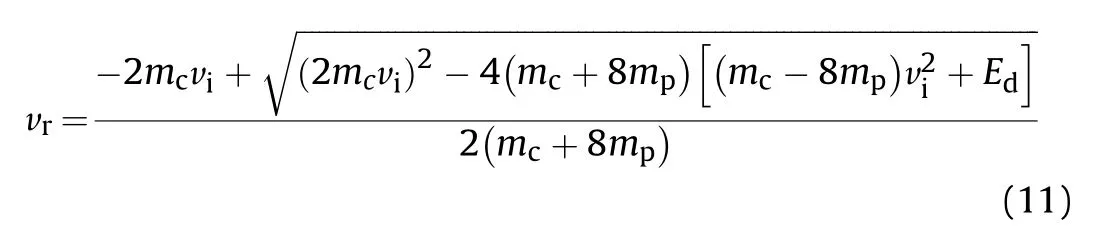

By using Eqs.(6)-(10), the residual velocity of projectile is obtained and is given by the expression:

In order to obtain the analytical ballistic limit, residual velocity in Eq.(10)is zero.The expression for the ballistic limit is given by:

According to Eqs.(7), (10) and (12), the ballistic limit and efficiency of energy absorption are sensitive to the compressive strength,Young’s modulus,failure strain of fibers,and interlaminar fracture toughness.The according energy absorption can be expressed as

As discussed by L′opez-Puente et al.[30],the crushing in front of the projectile can be regarded as the key mechanism of energy dissipation for the composite subjected to the impact velocity close to the ballistic limit.Subjected to the hygrothermal aging cycles,the mechanical parameters mentioned above undergo different degradations.Therefore,Eq.(13) can be simplified as

where σ(α) is the out-of-plane compressive strength of the composite as a function of hygrothermal aging time.According to the experimental results shown in Fig.3b, the ballistic limit, residual velocity and energy absorption capacity can be expressed as a function of hygrothermal aging time.

Based on Eqs.(11)-(14),the ballistic limit for the hygrothermal aged and unaged woven GFRP laminate are 89.0 m/s and 99.6 m/s,respectively.The analytical ballistic limit of the woven glass/epoxy composite with different hygrothermal aging time shows a great agreement with the experimental result, indicating the validation of the simplified model for ballistic limit.

According to Eq.(12), the residual velocity exhibits an approximately linear relationship with the impact velocity.To fit the trend of the residual velocity more accurately, the fitting parameters obtained in Fig.7a are adopted to revise the residual velocity.The revised residual velocity is given by

whereis the analytical residual velocity according to the ballistic limit of the woven composite.andare the ballistic limit fitting parameters of the given composite as introduced in Eq.(3).Hence,the analytical residual velocity and associated energy dissipation can be obtained,as shown in Fig.7b.Although the formula predicts the trend,the energy absorption efficiency is overestimated due to the underestimated revised residual velocity.

4.Conclusion

The periodic hygrothermal aged woven glass/epoxy laminates subjected to high velocity impact loading is investigated experimentally and analytically.After the hygrothermal equilibrium, the hygrothermal aging effect on the ballistic performance in terms of the dynamic response, ballistic limit, residual velocity, failure modes and energy absorption mechanisms of the composite is discussed.Some conclusions can be drawn:

The hygrothermal aged composite more likely undergo the local deformation than the unaged counterpart under the impact load.The hygrothermal effect decreases the ballistic limit of the woven GFRP laminate by 14.9%due to the degradation of matrix and fibre/matrix interface and localization of the transverse deformation.

Compared with the noticeable difference in the residual velocity close to the ballistic limit,the failure modes and energy absorption mechanisms are confirmed insensitive to the hygrothermal effect which can only induce the same failure mode at a smaller impact velocity than the dry composite.

The dynamic deformation,failure modes and energy dissipation mechanisms are sensitive to the impact velocity.With the increasing impact velocity, the failure undergoes different modes with the transformation of different energy absorption mechanisms.Based on the primary failure modes, a modified formula is proposed to predict the ballistic limit of the composites with different hygrothermal aging time and it can provide an accurate ballistic limit in comparison with the experiment.Due to the neglect of failure modes other than central crushing, although the semiempirical formulas provide good trends,the prediction of the energy absorption efficiency is significantly overestimated with the increasing impact velocity.

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

This work was supported by the Ph.D.Research Startup Funding of Eastern Liaoning University (Grant no.2019BS009).

- Defence Technology的其它文章

- Defence Technology

- Roll angular rate extraction based on modified spline-kernelled chirplet transform

- Buckling of composite cylindrical shells with ovality and thickness variation subjected to hydrostatic pressure

- Preparation of the core-shell HMX@CS microparticles by biological excitation:Excellent hydrophobic-oleophilic properties and decreased impact sensitivity effectively

- Quantitative prediction and ranking of the shock sensitivity of explosives via reactive molecular dynamics simulations

- An efficient light-to-heat conversion coupling photothermal effect and exothermic chemical reaction in Au NRs/V2C MXene membranes for high-performance laser ignition