Realizing high efficiency and large-area sterilization by a rotating plasma jet device

Hua LI (李華), Minglei LI (李明磊), Hongcheng ZHU (朱鴻成),Yuhan ZHANG(張雨晗),Xiaoxia DU(杜曉霞),Zhencheng CHEN(陳真誠(chéng)),Wenxiang XIAO (肖文香)and Kun LIU (劉坤)

1 School of Life and Environmental Sciences,Guilin University of Electronic Technology,Guilin 541004,People’s Republic of China

2The State Key Laboratory of Power Transmission Equipment & System Security and New Technology,Chongqing University, Chongqing 400044, People’s Republic of China

Abstract By tilting a plasma jet and rotating 360°, a large-area can be scanned and sterilized in a short time.Compared with the previous array device, this pipe has the significant advantages of high sterilization uniformity and low gas consumption.Firstly, a rotatable plasma jet device, which can control the swing and rotation of a jet pipe, is designed, and a corresponding theoretical model is established to guide the experiment.Secondly,with Staphylococcus aureus(S.aureus)and Escherichia coli(E.coli)as the target bacteria,the device achieves a short sterilization time of 158 s-the minimum sterilization flow of S.aureus and E.coli is 0.8 slm and 0.6 slm,respectively.The device is compared with an array plasma sterilization device in terms of sterilization speed and gas consumption.The results show that the device is not only better than an array plasma sterilization device with respect to scanning uniformity,but also far less than the array plasma sterilization device in gas consumption of 5 slm.Therefore, the device has great potential in applications involving efficient, large-area sterilization.

Keywords: low-temperature plasma sterilization, rotate, large area, applications

1.Introduction

An atmospheric-pressure and low-temperature plasma jet is a new type of discharge technology that has been developed in recent years.In contrast with other forms of plasma technology,it has the characteristics of low discharge temperature and flexible discharge, endowing it with great potential in applications such as material surface modification, sterilization, and biochemistry [1-6].

The treatment area of a cryogenic-plasma jet is only a few square millimeters, thereby limiting its prospects for use in industrial applications.In order to obtain a large-area plasma jet, researchers have carried out a large-scale expansion of the emission current.In general, several small-scale jets form a basic unit arranged in parallel to produce a largearea plasma,known as a jet array[7,8].Pei et al developed a battery-driven, hand-held and room-temperature air APPJ(Atmospheric Pressure Plasma Jet)device (known as a plasma flashlight, whose electrode structure consisted of 12 stainless steel needle arrays)and applied it in a biofilm inactivation experiment, achieving good results [9].Hubicka et al [10], using a ring-electrode, atmospheric-pressure and cold-plasma-jet source as a basic unit, ran multiple singlechannel jet sources in parallel, and obtained a small-scale,multi-channel, atmospheric-pressure and cold-plasma-jet array with relatively stable operation.Kim et al[11]designed a jet unit with a ring-electrode structure,using hollow optical fiber as the medium, wrapped with a layer of copper tape as the power supply ring-electrode.The unit had five jet units 2.5 mm apart to form a parallel-jet array,which was driven by a high-frequency and high-voltage AC power supply.When the He flow rate was 100 ml min?1, the applied voltage amplitude was 10 kV,and the frequency was 30 kHz,a stable jet array with a length of 10 mm was generated.Cao et al[12]carried out a two-dimensional jet array experiment,in which a number of parallel plasma jets were densely packed, and spatially extended atmospheric-plasma arrays were arranged in a honeycomb structure.

However, the array jet has several disadvantages.For example, the electric field between each jet pipe of a largearea plasma jet array varies, and there is mutual interference between tubes[13,14],leading to inconsistent discharge from each jet pipe.Therefore, the array jet often has the problems of uneven irradiation and unstable sterilization.In addition,the array jet uses helium gas and high-pressure ionization to produce a plasma jet, which is expensive as it consumes a large amount of helium.Obviously, this greatly reduces the potential for applications involving low-temperature plasma for large-area sterilization.

In this paper, a new type of low-temperature plasma device for sterilizing large-area is proposed,which is different from the traditional sterilization mode of fixed sterilization without moving, and can control the movement of a single plasma jet pipe and adjust the swing angle of the device,according to the size of the treatment area, allowing efficient and large-area sterilization.Escherichia coli and Staphylococcus aureus are selected as target cells to obtain the shortest sterilization time and minimum gas consumption based on this method.The experimental results show that the device is more practical than the traditional array device.Based on the realization of large-area irradiation, the device not only irradiates evenly without untreated areas, but also has a similar sterilization efficiency.Moreover, the device also greatly reduces the consumption of external helium gas, thus reducing the costs.

2.Experiment

2.1.Rotatable plasma sterilization device

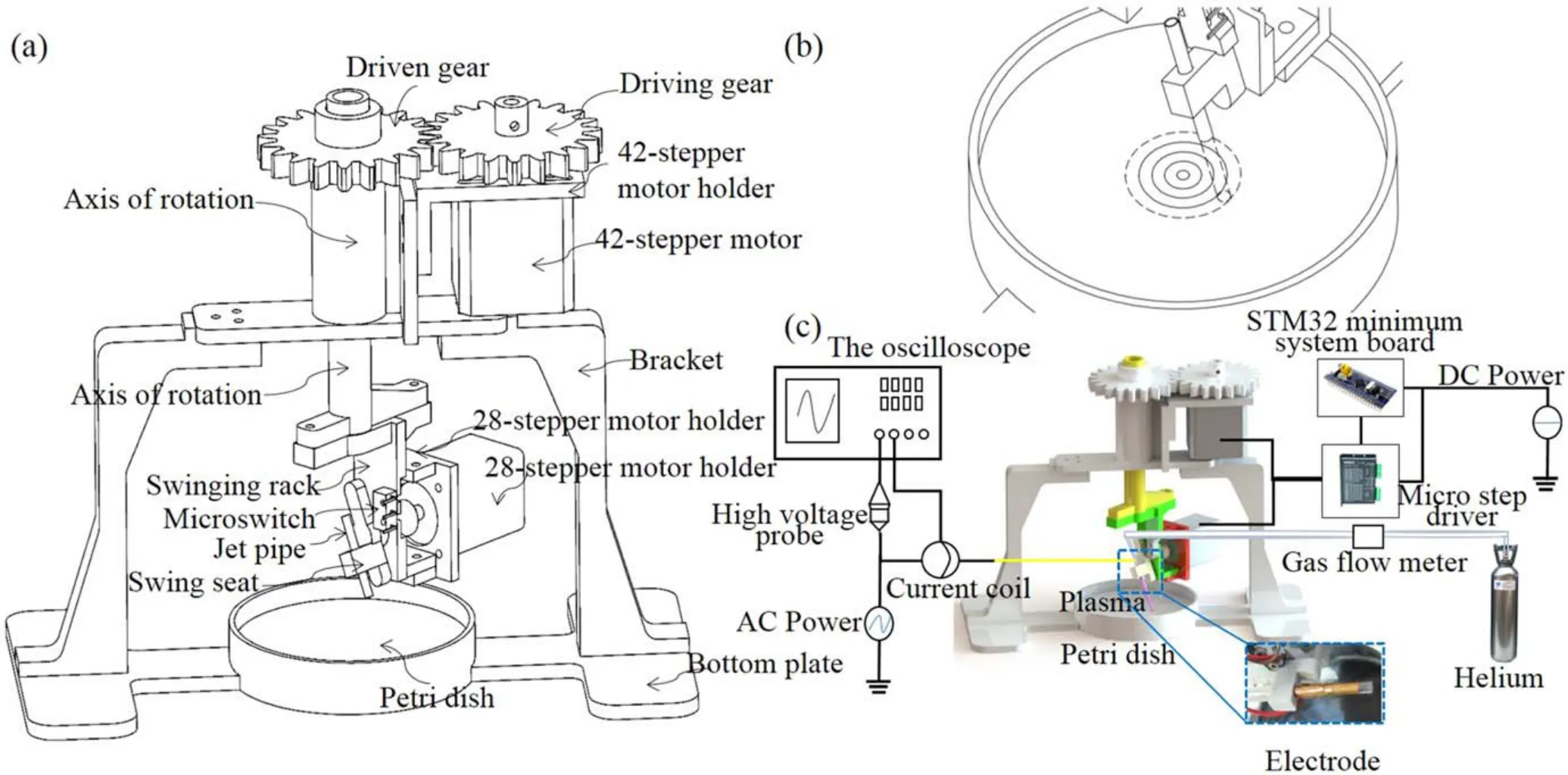

The overall size of the device was 280 × 120 × 240 mm3,as shown in figure 1(a).In general,a bottom plate and a bracket form the main support of the device.Two bottom plates possess arc-shaped interfaces for fixing the medium to the central axis of the device.A bearing seat bracket is connected to the bracket to support a 28-stepper motor holder.At the top of the device, a 42-stepper motor is fixed on a 42-stepper motor holder.The rotating shaft of the 42-stepper motor is connected to the driving gear through an interference fit.The driving gear meshes with the driven gear,and the interference fit between the driven gear and the rotating shaft transfers the power smoothly to the lower part of the device, thus making the lower part rotate 360°.At the bottom of the device,a 28-stepper motor is fixed on to the 28-stepper motor holder,which in turn is fixed on to a swing rack.The 28-stepper motor shaft is connected to a swing seat through the interference fit to make the jet pipe on the swing seat rotate.The jet pipe and the swing seat are also connected by an interference fit.A micro-switch is used to detect whether the jet pipe is in the vertical position, in order to reset the jet pipe easily.

The device performs large-scale sterilization by making the jet pipe tilt by swinging continuously and rotate by 360°in the vertical direction.That is, for each swing, the jet pipe executes one complete rotation, and the number of swings is the same as the number of rotations.The scanning process is shown in figure 1(b).Firstly, the jet tube is sterilized vertically down to form a circular area.Then,the 28-stepper motor is used to make the jet pipe swing at a certain angle and to tilt.Then, the 42-stepper motor makes the jet pipe rotate 360°around the rotating shaft.In this way, the sweep range of the jet device is a small ring, which encircles the circular area covered by the vertical irradiation.The 28-stepper motor continues to make the jet pipe swing at a certain angle,so that it becomes increasingly tilted.The 42-stepper motor makes the lower jet pipe rotate 360°, so that the new ring-shaped area just covers the ring-shaped area that was scanned before.Finally,by continually repeating the process,a wide range of scanning sterilization can be achieved.Compared with the array jet device, the device not only achieves large-area sterilization, but also highly uniforms irradiation of the treatment area.

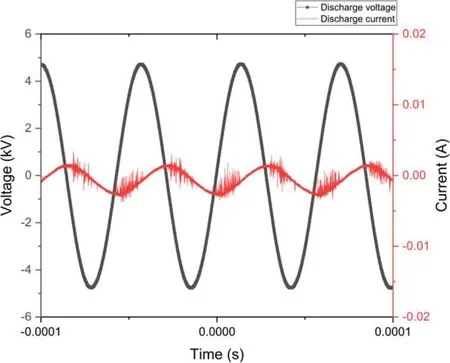

The working principle of the system is shown in figure 1(c), which includes a rotatable plasma jet device and some peripherals.First,high purity helium gas is injected into a copper-foil-wrapped quartz pipe (that is, the jet pipe)with an outer diameter of 3.5 mm and an inner diameter of 2.5 mm.The flow rate is controlled by a D08-1F flow indicator(Beijing Seven Star Huachuang Electronics Co., Ltd)and a CS200A digital gas-flow controller.The copper foil (20 mm in length)wrapped on the plasma jet pipe is used as a single electrode.The electrode is connected to a Nanjing Suman low-temperature-plasma experimental power supply, and changes in voltage and current are measured and displayed using a P6015A high-voltage probe (Tektronix), a PEARSONTM CURRENT MONITOR MODEL 2877(PEARSON ELECTRONICS.INC)and a DPO4034B oscilloscope (Tektronix).A voltage of 9.4 kV was applied to the device,and the waveforms of voltage and current were measured, as shown in figure 2.Accordingly, its discharge power can be calculated as 0.274 W.A UTP3704S DC power supply(Shenzhen Huaqing Instrument and Meter Co.,Ltd),provides a 12 V and 3.3 V power supply to a microstep driver and an STM32 minimum system board, respectively.The STM32 minimum system board sends pulsed signals to the microstep driver.The microstep driver receives a pulsed signal and sends it to the 42- or 28-stepper motors to achieve precise movement.

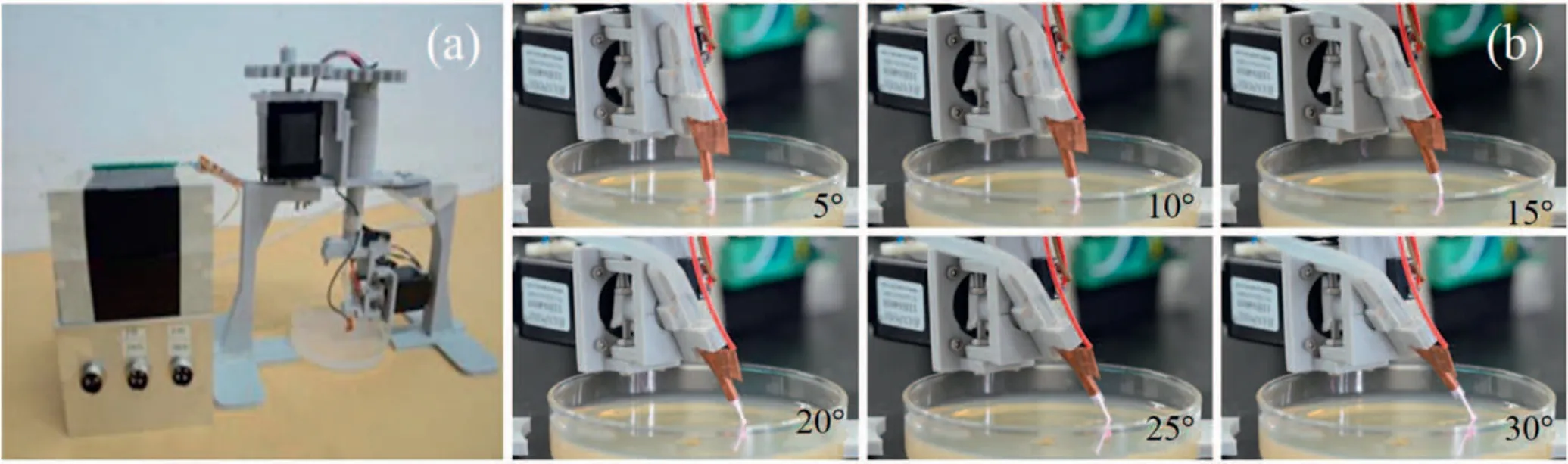

Figure 3 shows the rotatable plasma device, and figure 3(a)is a photograph of the device.From top left to bottom left are the stepper motor driver and the STM32 minimum system board, which is inside a metal shell; the right side shows the rotatable plasma sterilization device.The device when sterilizing S.aureus is shown in figure 3(b).Accurate sterilization of different areas via swinging at different angles is achieved.

Figure 1.Model drawing of rotatable plasma device:(a)three-dimensional model of the device,(b)schematic diagram of scanning mode and(c)schematic diagram.

Figure 2.Discharge current and voltage waveform of the device.

2.2.Theoretical model

This work constructs a theoretical model of the device,through the mathematical analysis, in order to guide the experiment.

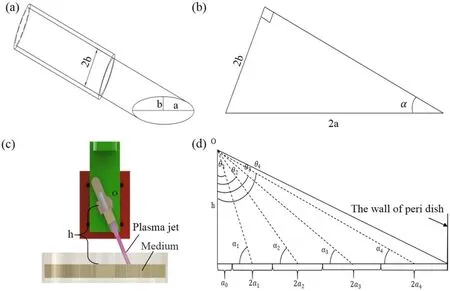

Firstly, we analyzed the instantaneous state of the sterilization process.In figures 4(a)and (b)on the left side is an elliptical region with a long axis a and a short axis b,which is irradiated by an inclined jet and projected on the horizontal plane.On the right is the elevation view of oblique irradiation.Compared with the fixed circular area formed when the jet pipe is perpendicular to the sterilized surface, the area acted on by the pipe when scanning the medium surface is elliptical,changing gradually with change in tilt angle.

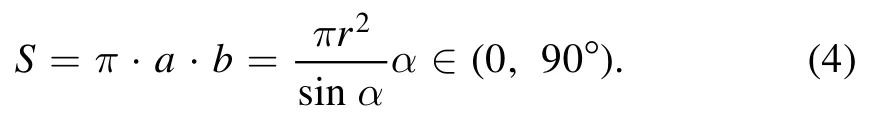

Figures 4(a)and (b)show the relationship between the circular area under vertical irradiation and the elliptical area formed by projection.Suppose the major axis of the ellipse is a and the short axis is b.The analysis is as follows:

Figure 3.Rotatable plasma sterilization device: (a)photograph of the device and (b)sterilization working diagram at different angles.

Figure 4.Schematic diagram of jet projection and theoretical analysis of device sterilization:(a)jet tilt,(b)positive section of an inclined jet,(c)front view of jet tube sterilization, (d)change diagram of central axis of jet pipe.

Long axis

Short axis

Circular area

Area of ellipse

Area relation between the two

Equations (1)-(5)show that the area S of the ellipse increases with decreasing rotation angle α; that is, the larger the inclination angle of the jet pipe, the larger the area of the projected ellipse.When the jet tube is tilted scanning, the sterilization area will increase, which helps to improve the sterilization efficiency.The swing angle of the jet pipe has a significant effect on the sterilization effect and efficiency.If each swing angle is too small, the jet pipe needs to swing more times to cover the required area,which will increase the sterilization time and reduce the sterilization efficiency.If each swing angle is too large,the ring swept each time is not completely consistent with the previously swept area, which means that the sterilization effect is poor.Therefore, it is necessary to analyze the mathematical laws existing in the sterilization process of the device.

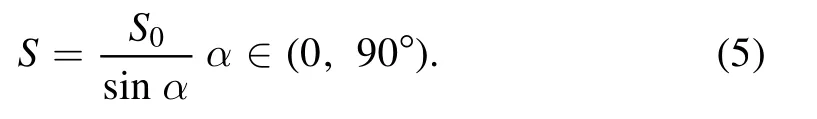

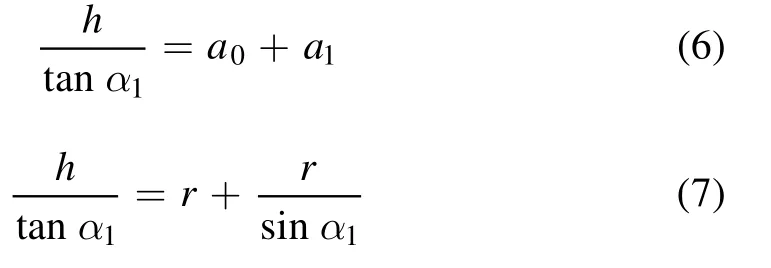

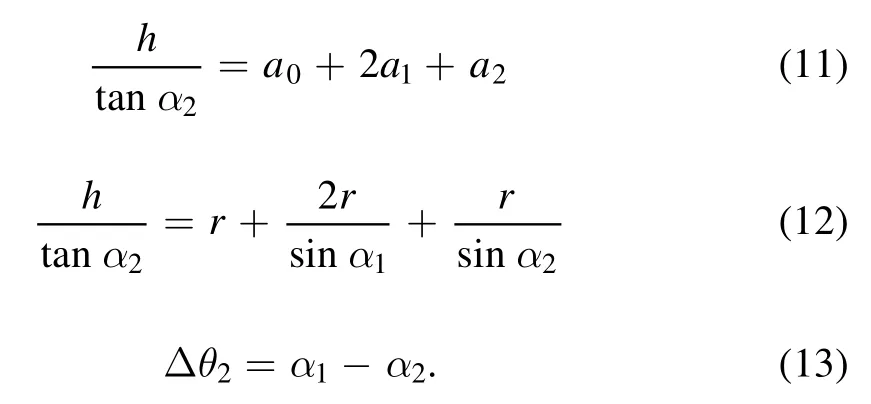

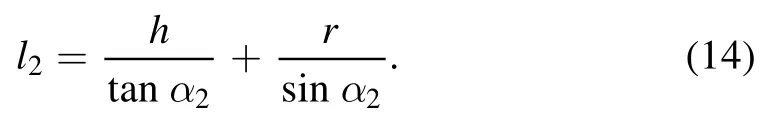

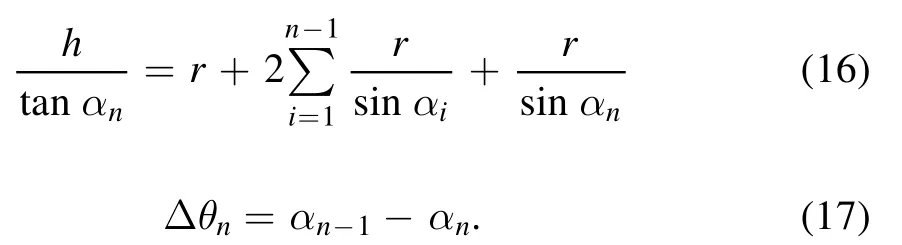

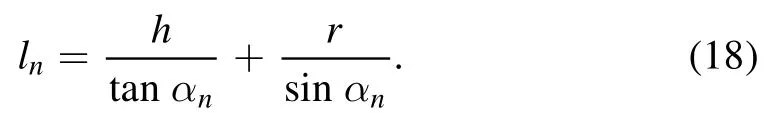

Figure 4(c)shows the frontal view of the sterilization device,wherein point O is the swinging center of the jet pipe,and h is the distance between the swinging center of the jet pipe and the surface of the medium.The purple part of the figure is the plasma jet, and the brown part is the medium.Point O in figure 4(d)is the swing center of the jet pipe,where the dotted line is the central axis of the jet pipe,aiis the length of the major axis of the ellipse projected by different anglesαi,h is the distance between the swinging center and the treatment surface, anda0= r,α0= 90°.In the nth swing, the change in jet pipe swing angleΔθn=θn-1-θn,the angle changes fromθn-1toθn.The geometric relationship Δθn=αn-1-αnshows that each swing angle varies in size.The main purpose of establishing the model is to determine the number of swings needed by the jet pipe to sweep the target area and to determine the appropriate variable quantity of swing angle in the sterilization process-the latter is used to realize the precise swing of the 28-stepper motor.The following is a step-by-step derivation.

Figure 5.Schematic diagram of rotatable plasma emission spectrometry: ①rotating plasma device, ②optical-fiber probe, ③optical fiber, ④spectrometer, ⑤computer.

For the first swing of the jet tube, the change in jet pipe swing angle isΔ:1θ

Total radius of the area swept for the first time:

The area swept for the first time:

For the second swing of the jet tube, the change in jet pipe swing angle isΔθ2:

Total radius of the area swept for the second time:

The area swept for the second time:

The nth variation in jet pipe swing angle isΔθn:

Total radius of the area swept for the nth time:

Sweeping the area for the nth time:

According to this theory,the angle and number of swings are related to h and r.Because the sterilization efficiency is highest when the number of swings corresponding to the angle of each swing is the least, the following part mainly analyzes how to find the least number of swings.Since the length of the jet pipe is only a few centimeters, in order to ensure that the sterilization effect is optimal, and to ensure that the vertical end of the jet pipe has an appropriate working distance of 3 mm from the surface of the medium,h needs to be a fixed value.Then, the number of swing times is only related to the radius of the jet.The larger r is,the smaller the number of swing times, the smaller the number of overall rotations of the jet pipe,and the shorter the sterilization time.In addition,according to equations(18)and(19),the larger r is,the larger the total area swept by the jet pipe after swinging at a certain angle will be.

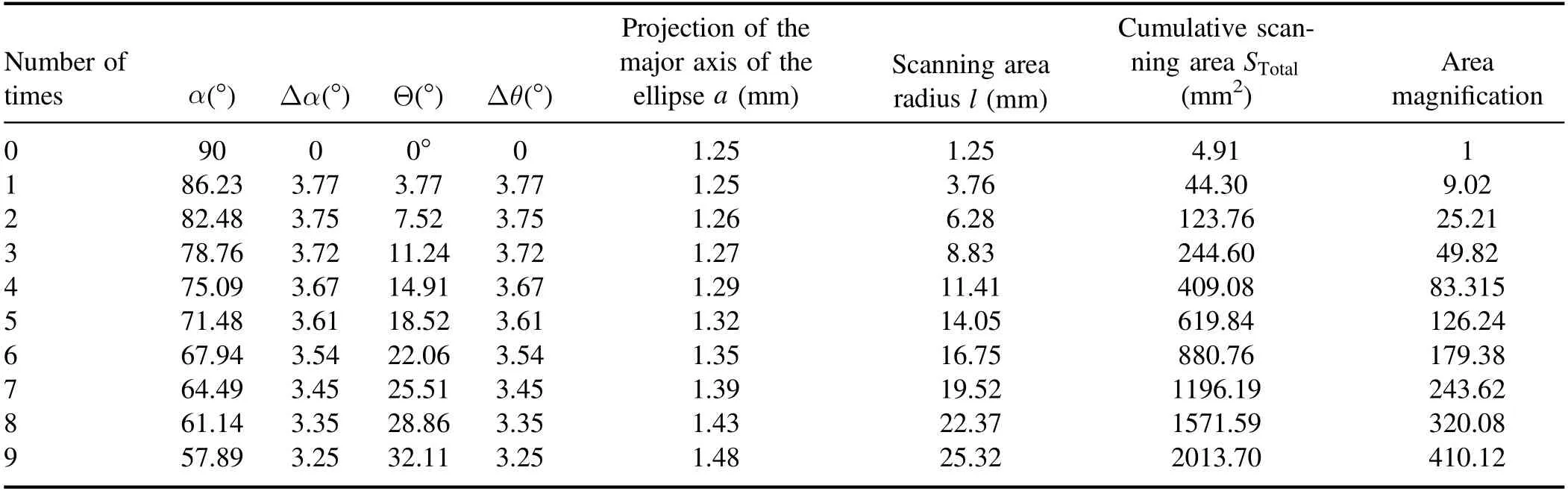

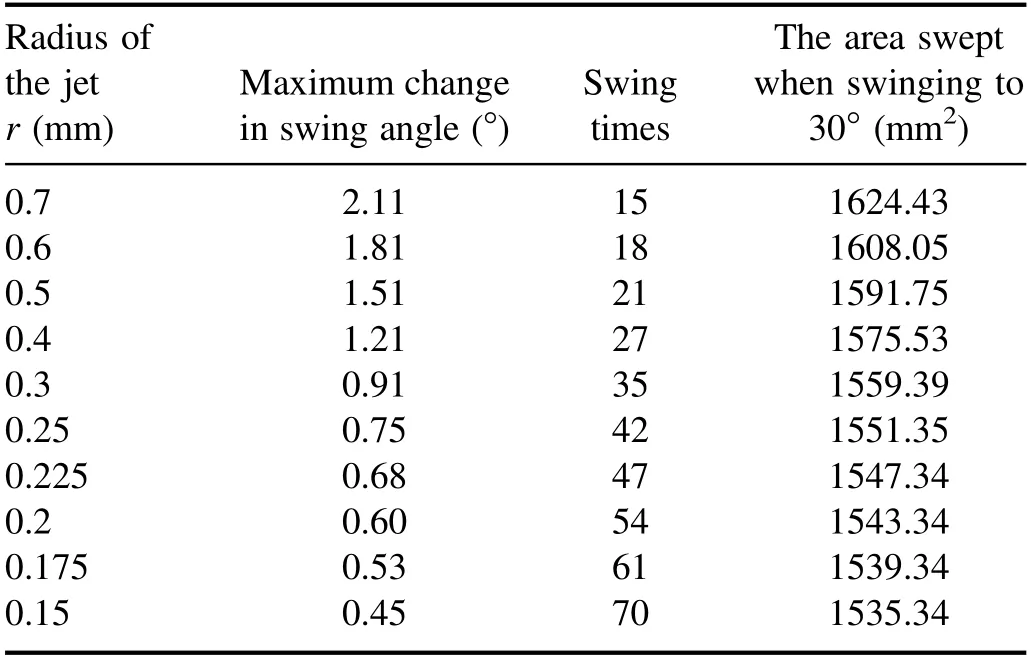

This mathematical model is then used to guide the experiment.Firstly, we need to determine the variablesθmax,h,and r.It is assumed that the maximum required swing angleθmax= 30° after the jet pipe sweeps the target area, and that this swing angle corresponds to a moderately sized sterilization area,which is convenient for the sterilization experiment and observation results.By adjusting the model size in the 3D modeling software SoildWorks, h is finally determined to be 38 mm.In real sterilization scenarios, the jet radius is often less than jet injection of jet pipe radius, but because the jet radius is difficult to measure, Here, the inner diameter of the jet was assumed to be 1.25 mm, and then the size of r was further determined according to the sterilization effect, to determine a relatively close to the real value of approximation, and then use the theory to guide experiments.Then,through MATLAB calculation, table 1 can be obtained.

Table 1 shows that when r is 1.25 mm,the initial vertical irradiation area of the jet pipe is 4.91 mm2.As the number of swings increases, the variation in each swing angle gradually decreases.After nine swings, the swing angle of the jet pipe can exceed 30°,and the cumulative radius of the spray area is 25.32 mm.The total area is 2013.70 mm2, and the irradiated area is 410 times that of the original vertical irradiated single tube.This proves that the alternating-motion mode of swing and rotation of the jet pipe for sterilization is highly efficient in theory.The theoretical value of each swing can be calculated by the theory, which can be imported into a control program.The 28-stepping motor can then drive the jet pipe to swing according to the theoretical value.

Table 1.Theoretical data of swing angle.

Table 2.Influence of different jet radii on each parameter.

2.3.Spectroscopic measurement of plasma jet

In this work, an AVASSPE-ULS3648 fiber optic spectrometer was used to measure the emission spectrum of the plasma from the rotatable plasma jet device.Figure 5 shows the schematic diagram of spectral measurement.The optical signal in the plasma jet is detected by an optical-fiber probe and transmitted to the spectrometer through an optical fiber for analysis, before being sent to the computer display.

Figure 6.Temperature fitting curve.

Figure 7.Main spectral lines of the emission spectrum of a rotating plasma jet.

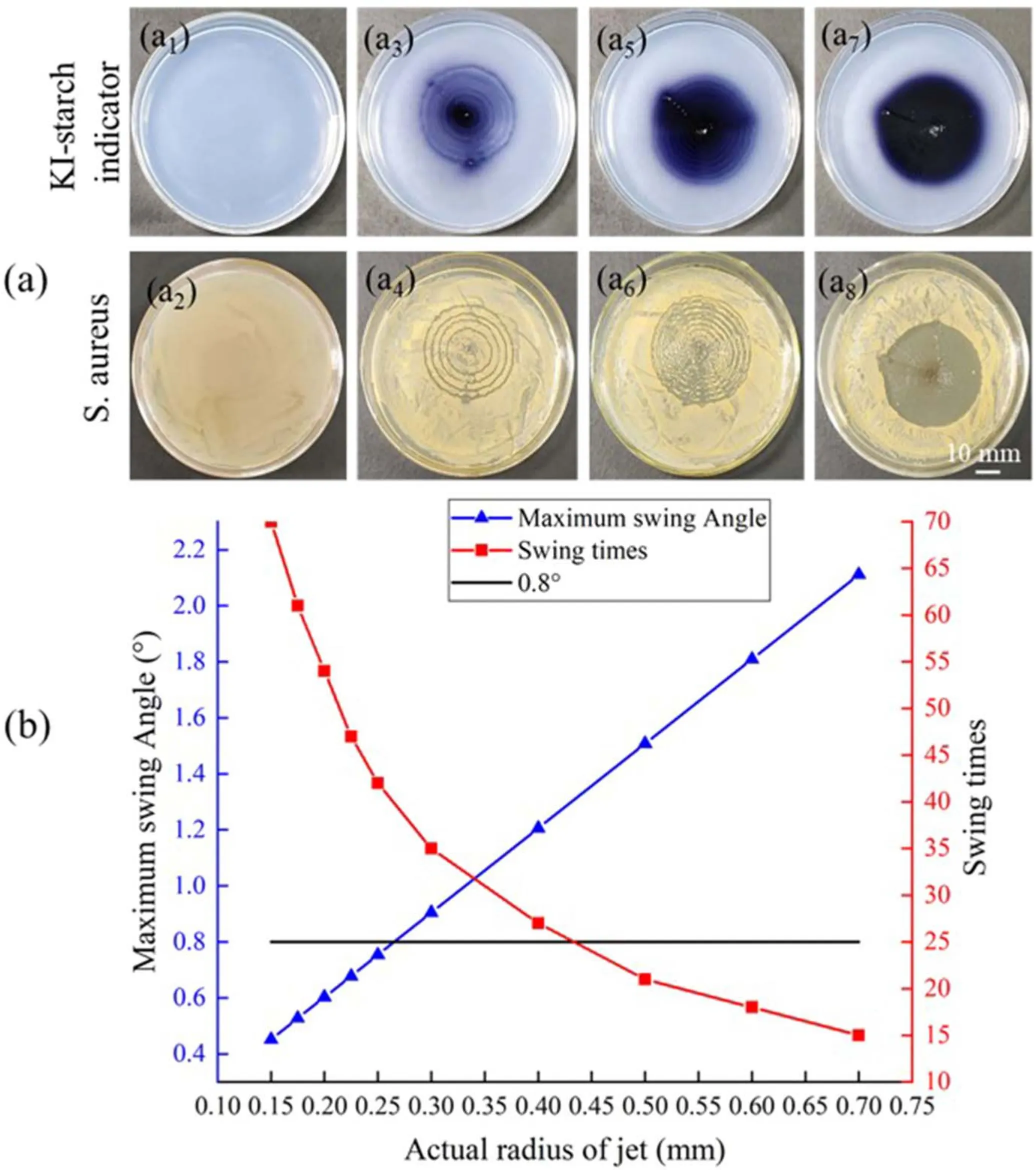

Figure 8.(a)Experimental results of inactivated S.aureus with different swing amplitude:(a1)and(a2)blank control group;(a3)and(a4)0°-20°,swing 5° each time; 20°-28°,each swing 4°;(a5)and (a6)0°-16°, swing 2° at a time; 16°-30°, each swing 1.5°;(a7)and(a8)0°-16°,each swing 0.8°;16°-30°,each swing 0.4°and(b)influence of the actual radius of the jet on the maximum variation in swing angle and the number of swings.

2.4.Microbiological tests

E.coli and S.aureus are ubiquitous in daily life, and were therefore used as experimental strains.E.coli and S.aureus strains were inoculated in sterile Luria-Bertani (LB)broth and placed separately in a shaking bed to activate at 37 °C for 16 h, while being shaken at 180 rpm.Then, 0.1 ml of the activated bacteria solution was transferred to 75 ml of fresh LB broth and cultured on a shaker at 37 °C for 6 h to obtain two bacterial suspensions containing 3 × 108colony-forming units per milliliter(cfu·ml?1).The concentration of the bacteria was indirectly obtained by measuring the optical density(OD600)using a spectrophotometer(Science Instruments Co., Ltd, Suzhou, China).

Two agar plates were used in the experiments.One was used for a bacterial culture,per 100 milliliter of distilled water containing the following components:1 g of tryptone,0.5 g of yeast extract,0.5 g of NaCl,and 1.8 g of agar.The other agar plate (containing KI-starch)was prepared by mixing the indicator and former agar plate at a volume ratio of 1:1.The KI-starch indicator was made by adding 10% (w/v)potassium iodide (Shanghai Sangon, China)and 10% starch(Shanghai Sangon, China)to distilled water to observe the distribution range of active substances generated by the plasma-jet array.According to the well-known iodine-starch reaction, generated active substances, including,,O3,O,OH,and H2O2,will oxidize I?in the KI-starch reagent into I2.I2reacts with excess I?to form I3?and then forms complexes with starch,which turns the color to blue-purple in an acidic environment because of the presence of active substances[15-18].In this study,0.1 ml bacterial suspensions containing about 3 × 108cfu ml?1of E.coli and S.aureus were diluted by a factor of 103.Then, 0.1 ml of these diluted suspensions were coated on agar plates for sterilization experiments.The agar plates coated with the bacterial samples were placed under the rotatable plasma device for processing.The treated bacteria were incubated at 37°C for 12 h to observe the sterilization effect with different processing times.Two control groups were used for each sample to prevent random errors.The agar plates containing KI-starch were treated using the same approach to investigate the relationship between the distribution of the active substances produced by the rotating plasma jet device and the sterilization range.

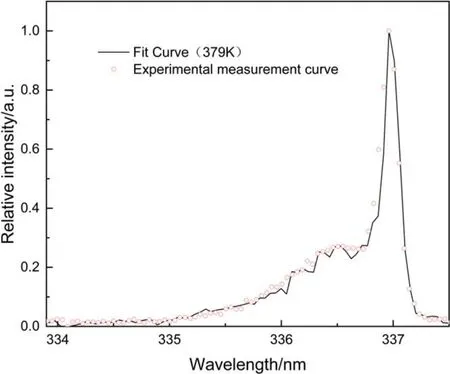

2.5.The temperature tests

Temperature is one of the most important factors for plasma medical applications.Therefore, the temperature of the plasma must be considered.In this work,spectral lines were fitted by Specair software, and the rotational temperature of the plasma source generated by the device is 379 K.The temperature fitting curve is shown in figure 6.

3.Result and analysis

The minimum achievable sterilization time and flow rate of using S.aureus and E.coli were explored.The sterilization time is determined by the rotational speed and the swing times of the device.The faster the rotational speed, the fewer the swing times, and the shorter the sterilization time.The minimum flow rate refers to the flow rate required for complete sterilization.

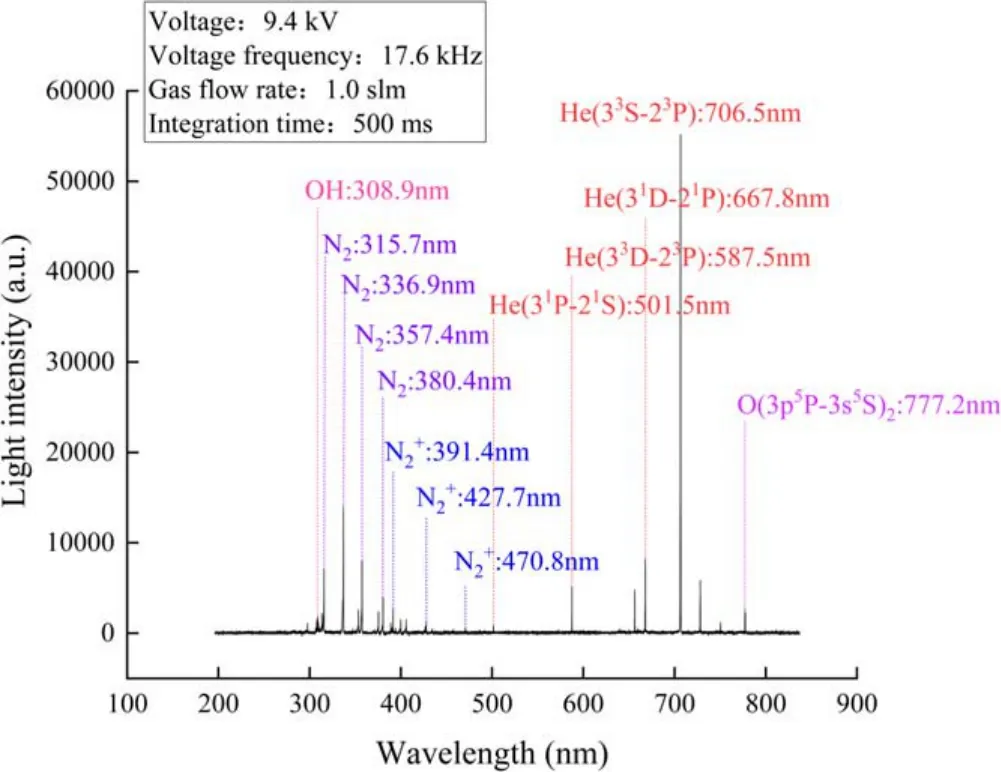

3.1.Spectral analysis

Emission spectroscopy is a method commonly used to ascertain plasma composition; it is simple to perform and does not interfere with the plasma.The principle of emission spectroscopy in the context of a plasma is to establish and comprehend the properties of the plasma using the plasma emission or absorption spectra [15].Although the plasma is composed of many components, the key factor affecting sterilization is the active particle.Therefore, it is of great significance to establish the composition of the plasma produced by the plasma-jet device in advance to evaluate its sterilization effect.In this work, a 9.4 kV peak-to-peak voltage and 17.62 kHz power frequency were applied.The gasflow rate was 1.0 slm and the integration time of the spectrometer was 3 s.

The main spectral lines of the emission spectrum of the rotating plasma jet device are shown in figure 7.The experiment was carried out in atmospheric environment.Although the working gas was helium,nitrogen,oxygen,and water vapor in the air mixed with it and ionized during the experiment.Figure 7 shows that nitrogen and helium have the most spectral lines-two spectral emission lines are very prominent: N2(336.9 nm)and He (706.5 nm).The plasma produced by a rotating plasma jet emitter consists of OH free radicals, N2,,He, and O, and contains many active particles,which is one condition for high efficiency sterilization.During sterilization, these active substances react with water on the surface of the medium to form H2O2,,and[19-22].

3.2.Exploration of the shortest sterilization time of the device

3.2.1.Preliminary determination of the variation in swing angle.Because the actual radius of the plasma jet cannot be measured,the change of the swing angle corresponding to each swing cannot be determined.In order to start the experiment, the variation of swing angle is preliminarily determined in this work.

Figure 8(a)shows the treatment of S.aureus broth and a starch potassium iodide agar plate by a rotating plasma jet device with an applied voltage of 9.0 kV, a gas-flow rate of 1.42 slm,and a rotation speed of 7 s/r(unit of rotation speed:time required for each rotation of the plasma jet).Figures 8(a1)and(a2)show the blank control groups.Figures 8(a3)and(a4)show that the rotatable plasma jet device rotates once after swinging 5° for each time, and cycles for four times,swinging to 20°.On this basis, after swing 4° each time, thedevice rotates once for two cycles to 28° for 36 s, forming a very sparse ring on the starch potassium iodide AGAR plate and on S.aureus treated area.Figures 8(a5)and(a6)show the rotating plasma jet device after each swing 2°rotating a circle,circle 8 times,swing to the 16°,on this basis,after each swing 1.5° rotating a circle, circle 10 times to 31°.After the 108 s,agar plate and S.aureus potassium iodide in starch processing area formed a thin ring.As shown in figures 8(a7)and (a8),the rotatable plasma jet device rotates once after each 0.8°swing and cycles for 20 times to 16°.On this basis,the device rotates once after each 0.4° swing and cycles for 35 times to 30°, over a total period of 330 s.In the starch potassium iodide agar plate and S.aureus treatment area,active particles produced from jet tube formed a very dense ring, and sterilization effect is remarkable.

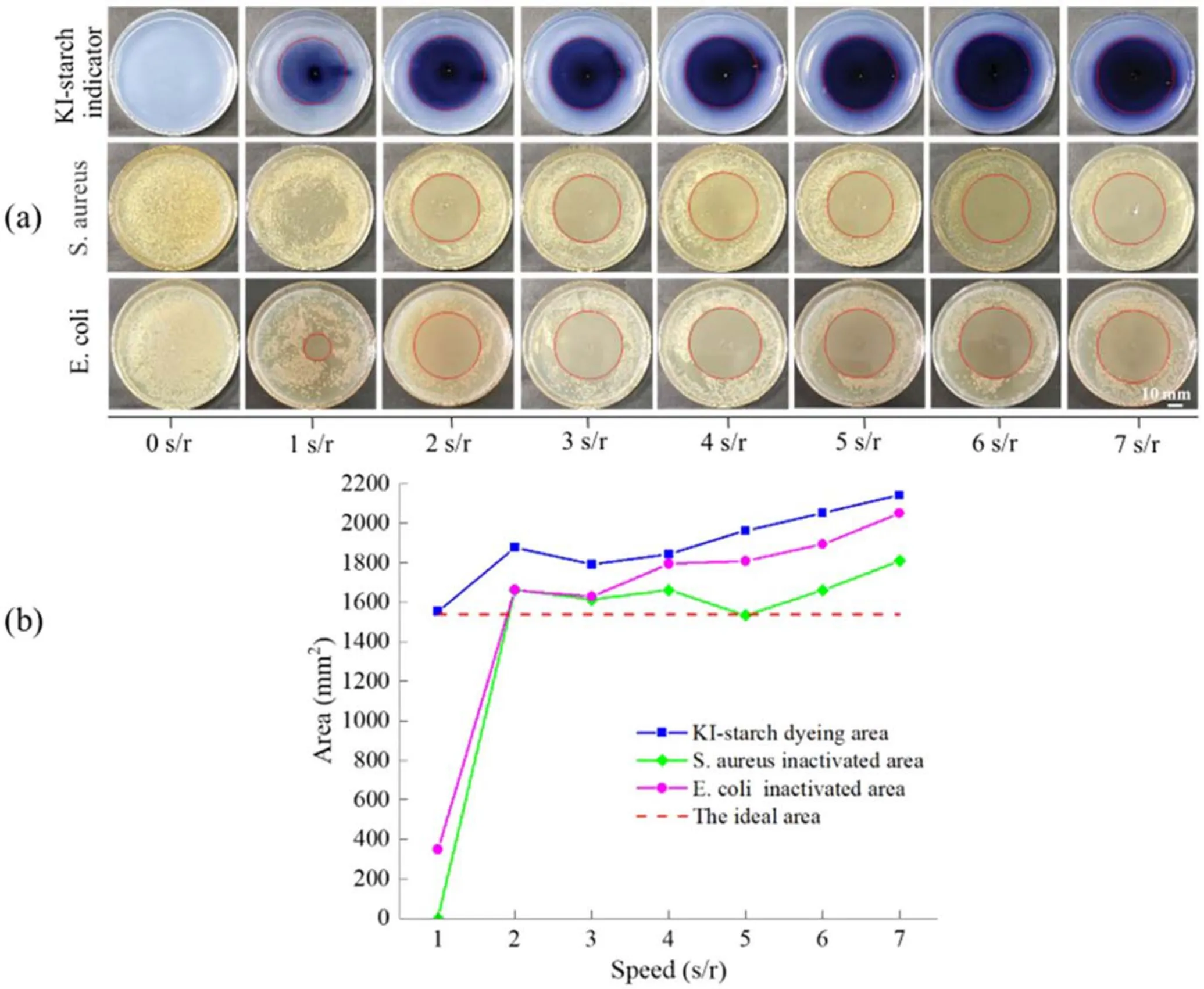

Figure 9.Experimental results of S.aureus, E.coli and starch potassium iodide agar plate: (a)treated with different rotation rates, and (b)results of the fastest speed were between 1 and 7 s/r.

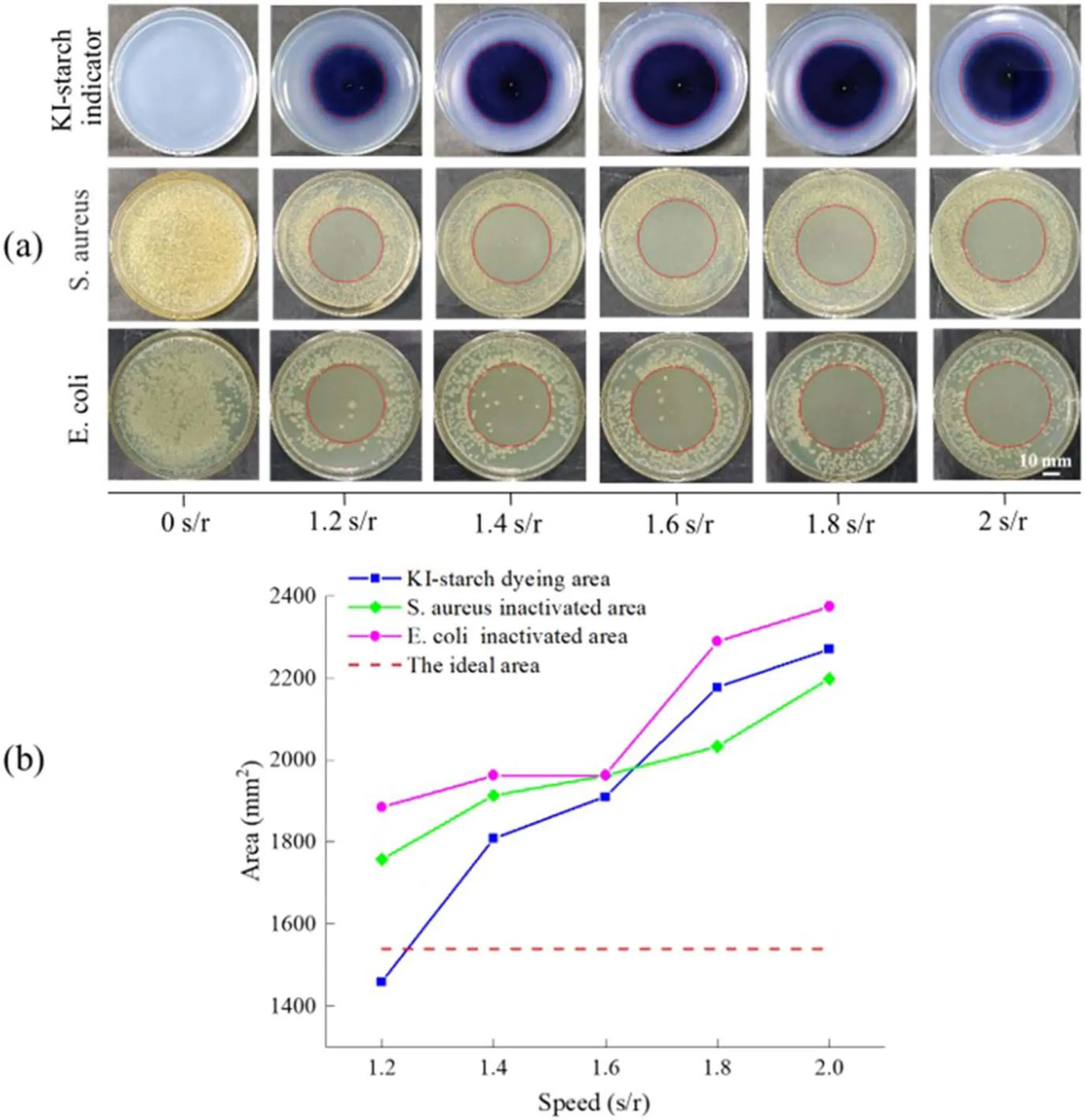

Figure 10.Experimental results of S.aureus,E.coli and starch potassium iodide agar plate:(a)the rotational speed change from 1 to 2 s/r,and (b)the relationship between rotation speed and sterilized area.

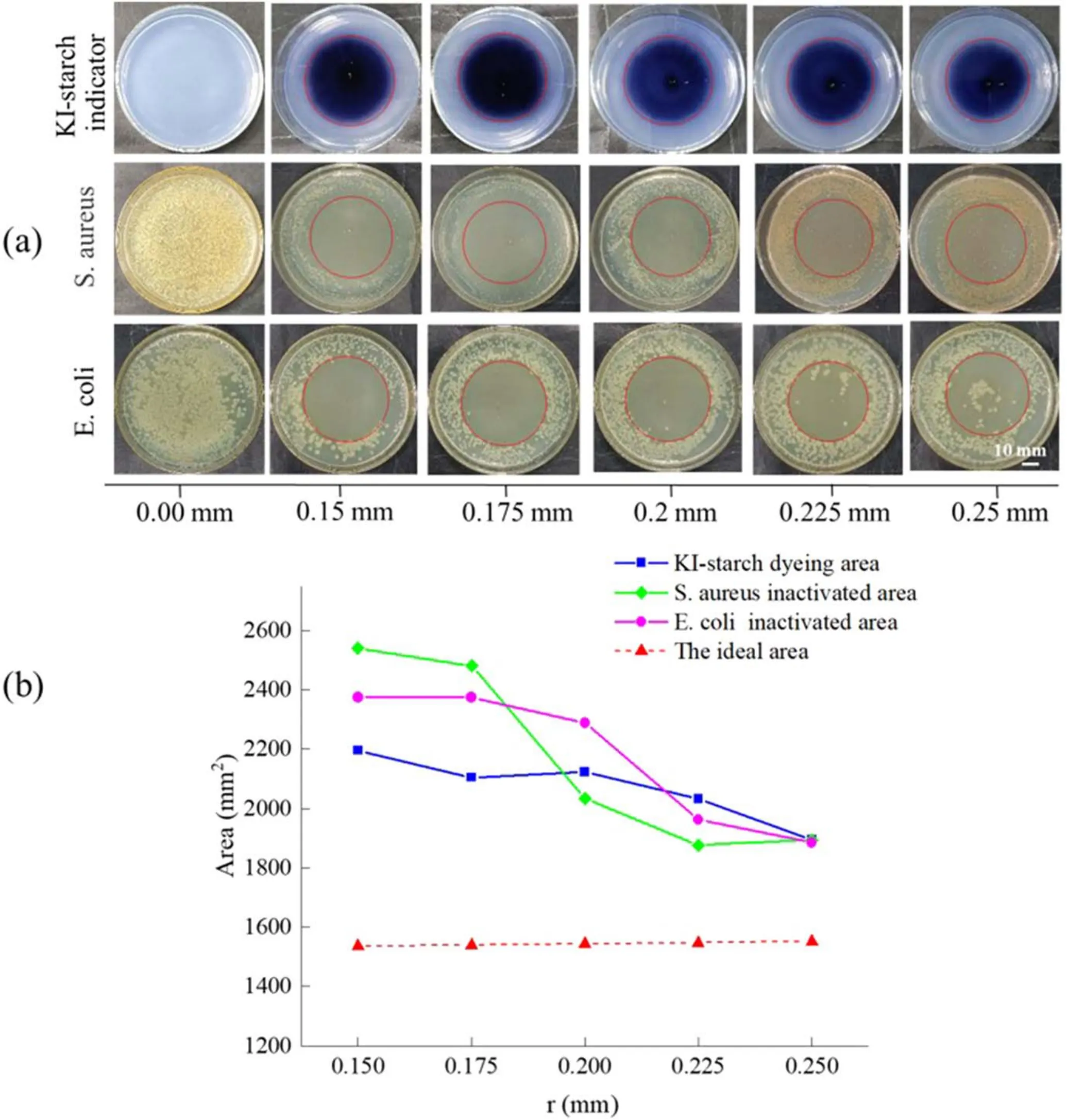

Figure 11.Experimental results of S.aureus,E.coli and starch potassium iodide agar plate:(a)treated with jets of different radii,and(b)the relationship between assumed jet radius and sterilization area.

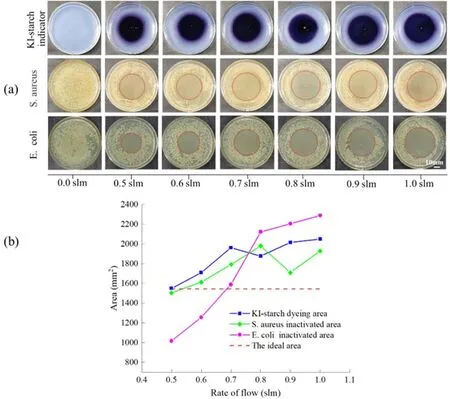

Figure 12.Experimental results of S.aureus,E.coli and starch potassium iodide agar plate:(a)at different gas flows,and(b)the relationship between flow rate and sterilized area.

This experiment shows that for an optimal sterilization effect, the change in swing angle should be less than 0.8°.This is far less than the maximum variation in the swing angle in table 1, of 3.77°.Therefore, the actual radius r of the plasma jet generated by the jet pipe is far less than 1.25 mm.According to the previous theoretical analysis, the size of r not only determines the maximum change in swing angle(which is related to the sterilization effect), but also the number of swings, and therefore, the total area swept after a certain angle of swing.Since the previously given r value is not the true value,it is necessary to determine the actual value of the jet radius.

In order to determine radius of the jet, this work adopts the assumption of the actual value of jet radius into the theoretical model to obtain the swing angle parameters, and then carries out experimental verification to determine.If the experimental sterilization effect is good, it indicates that the assumed r is the true radius of the jet; otherwise it is not.Firstly,several values of r were set,and the theoretical model was substituted to calculate the maximum value of swing angle change and the number of swings when the final swing angle was greater than 30°(table 2).According to table 2 and figure 8(a), when the jet radius r is less than or equal to 0.25 mm,the maximum value of swing angle variation is less than 0.8°, meaning the uniform sweep of the jet can be obtained.

Table 2 is expressed as a line graph in figure 8(b).The actual radius of the jet flow r is roughly inversely proportional to the number of swing times.We can see that if r is 0.15-0.25 mm, then the number of swings of 70 will change to 40.A slight change in the value of r can cause a drastic change in the number of swing times.Since the maximum speed is unknown,further exploration of the optimal value of r is not only inefficient, but also unnecessarily wasteful of helium.Therefore,a compromised idea is that the value of r is tentatively set at 0.175 mm.On this basis, the fastest rotational speed is first explored, and then the actual radius of the plasma jet.

3.2.2.The fastest speed.The experiment parameters were set thus: r = 0.175 mm, flow = 1.0 slm, voltage = 9.4 kV,and speed = 0-7 s/r.A control group was constructed for each speed to explore the fastest speed for sterilization of S.aureus.The experimental results are shown in figure 9(a).Within the range of 2-7 s/r, the sterilization effect of S.aureus and E.coli on the whole is relatively good, until the rotation speed is 1 s/r, and it begins to significantly deteriorate.Thus, the optimal speed of sterilization of the device is between 1 and 2 s/r.For S.aureus, in the sterilization area, with a rotation speed of 3, 4, and 5 s/r,the bacteria did not disappear at the edge of the strafing zone.This is because when the jet was sprayed to the outside, the distance between the end of the jet tube and the surface of the medium was extended, leading to a decline in sterilization ability.The sterilized area of the graph was quantified and expressed in the form of a broken line graph, as shown in figure 9(b).Within the range of 2-7 s/r,the sterilized areas of S.aureus and E.coli were both larger than the theoretical values.

In addition, sterilization area decreased slowly as speed increased because of the decrease in sterilization ability due to the long processing distance when the jet pipe was swept to the outside of area where needs to be sterilized.In response to this problem,the jet pipe was moved from 0°to 30°,and then from 30° to 10°, making it sweep the outside 20° area twice.The sterilization ability of the jet pipe was reduced when it swept the outside area.Of course, although the number of swing times increased,the sterilization effect was guaranteed,allowing the further exploration of the effects of faster rotational speeds and to achieve higher sterilization efficiency.Next,the program was set to make the jet pipe swing from 0° to 30°, and then from 30° to 10°, according to the change in the theoretical swing angle, which was equivalent to sweep the edge of sterilization zone twice.

The parameters were set thus: the assumed value of the jet radius r = 0.175 mm, flow rate = 1.0 slm, and applied voltage = 9.4 kV.Based on the theoretical swing angle calculated by the theoretical model, first swing from 0° to 30°, then swing back from 30° to 10°.From multiple experiments, the results are shown in figure 10(a).As the speed increases, the sterilization area decreases, and the sterilization effect becomes worse.When the rotation speed was as fast as 1.6 s/r,S.aureus and E.coli are not completely destroyed.The sterilized area was quantified and expressed in the form of a broken line graph,as shown in figure 10(b).The sterilized areas of S.aureus and E.coli were larger than the theoretical area; each speed achieved the theoretical area.In general, 1.8 s/r is the fastest speed that can be achieved effective sterilization.In addition, the sterilization area of E.coli is larger than that of S.aureus,on the whole,which is in accordance with E.coli being a gram-negative bacterium with thinner cell walls than S.aureus and is in accordance with E.coli being easier to activate.

3.2.3.Exploration of the actual jet radius.After determining the fastest speed, the minimum number of swinging times of the jet pipe during the whole movement should be determined in order to explore the shortest sterilization time.According to the previous theoretical model and table 2,the jet pipe rotates as a whole once every time it swings.The number of swings determines the number of turns of the jet pipe, which determines the overall sterilization time-the actual radius of the jet pipe r determines the number of swings.Therefore,it is necessary to find an accurate r value and calculate the optimal swing angle change in the program for the experiment.This means sterilization by the jet pipe can be completed with the least number of swings and the shortest sterilization time.

The parameters were set thus:applied voltage = 9.4 kV,gasflow rate = 1.0 slm, and rotational speed = 1.8 s/r; the swing stroke: the jet pipe first moves from 0° to 30°, then from 30° to 10°.These conditions remained unchanged.Multiple sets of jet radius values, ranging from 0.15 to 0.25 mm, were substituted into the theoretical model.The corresponding theoretical swing angle data were calculated and imported into the program.Then,a starch potassium iodide agar plate, S.aureus and E.coli were treated respectively.The experimental results are shown in figure 11(a).When the assumed value of the jet radius is within the range of 0.15-0.2 mm, the sterilization effect is very good.When the assumed value is greater than 0.225 mm, bacteria are not completely wiped out in the sterilization area, and the sterilization effect worsens.Figure 11(b)shows that the sterilized area is larger than the theoretical area when the assumed value of the jet radius is within the range of 0.15-0.25 mm.Therefore,from a comprehensive perspective, the assumed value of the jet radius r = 0.2 mm is the closest to the real jet radius;that is,when the jet radius r = 0.2 mm,the number of oscillations is least,and the overall sterilization time is shortest.Table 2 shows that when r = 0.2 mm, the corresponding swing times is 88; that is, the preset region can be scanned for 88 alternate cycles of oscillations plus 360° rotation, and the shortest time is 1.8 × 88 ≈ 158 s.

Table 3.Comparison of rotary and array sterilization performance.

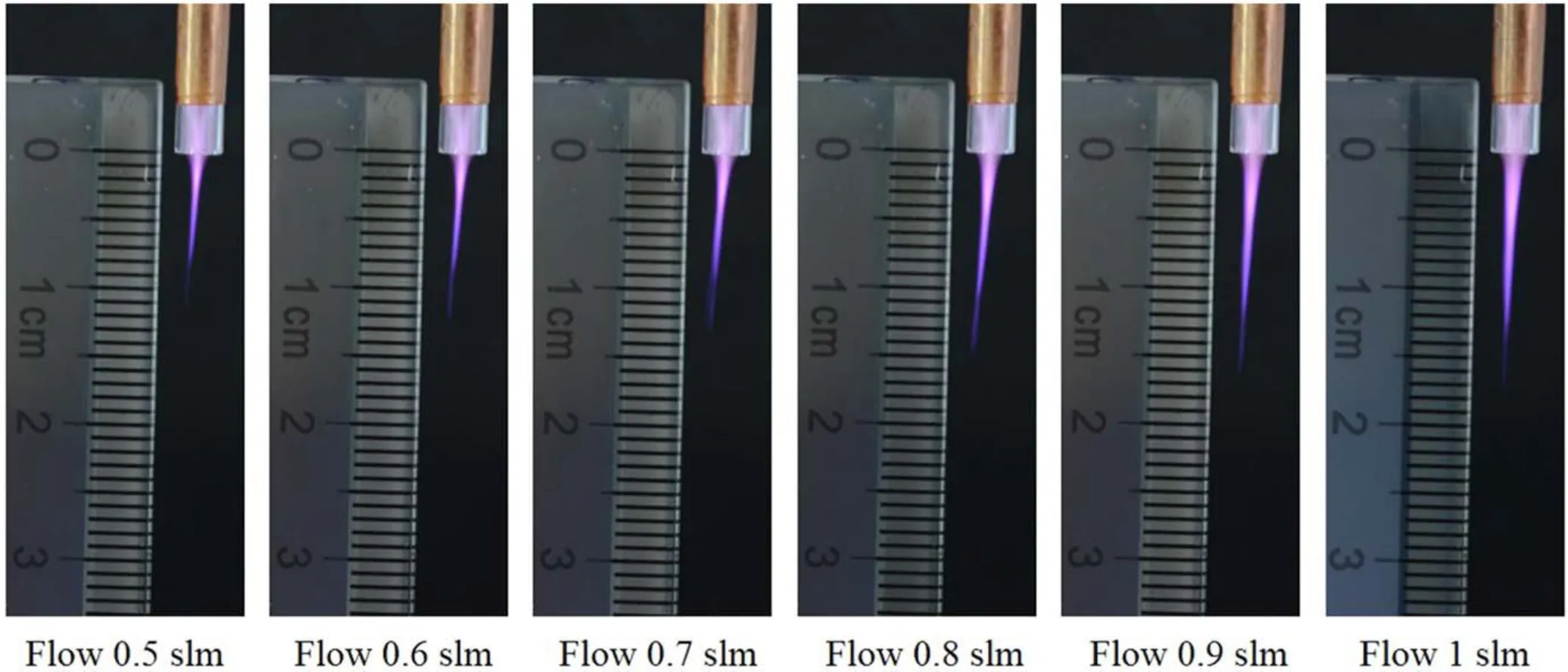

Figure 13.Diagram of variation of jet length with flow rate.

3.3.Minimum flow rate of sterilization based on the device

For the rotating plasma jet device,the gas-flow rate is so high that the active particles will start to dissipate before they have time to treat the target material.The gas-flow rate is low and the jet length is not long enough.When the jet is sprayed to the outer ring, it easily becomes unstable, which reduces the sterilization range.Therefore, it is necessary to explore the effect of the gas-flow rate on sterilization.

The parameters were set thus: applied voltage = 9.4 kV,the jet radius r = 0.2 mm,and rotational speed = 1.8 s/r;the swing stroke: the jet pipe first moves from 0° to 30°, then from 30° to 10°.Different flow values were set to treat S.aureus and the starch potassium iodide agar plate.The experimental results are shown in figure 12(a).The distribution range of active substances and the range of sterilization are gradually reduced as the flow rate gradually decreases.This is because the distance between the end of the jet tube and the surface of the medium becomes longer when the jet tube scans the outer ring,and the lengths of the jet of 0.5 slm,0.6 slm and 0.7 slm are too short to be effectively sterilized.At the same time,when the flow rate gradually decreases,the number of not killed bacteria in the area of the spray gradually increases.The minimum flow rates for the complete sterilization of S.aureus and E.coli were 0.8 slm and 0.5 slm,respectively.In addition, figure 12(b)shows that the minimum flow rates for the complete sterilization of S.aureus and E.coli that meet the theoretical area requirements are 0.7 slm and 0.6 slm, respectively.Therefore, from the perspective of economy and sterilization effect, figures 12(a)and (b)show that the optimal flow rates of this device for inactivating S.aureus and E.coli are 0.8 slm and 0.6 slm, respectively.As the helium flow rate increases from 0.5 slm to 1 slm, the jet length increases from 10 to 17 mm, as shown in figure 13.

3.4.Comparative analysis of the rotating plasma jet device and the array plasma device

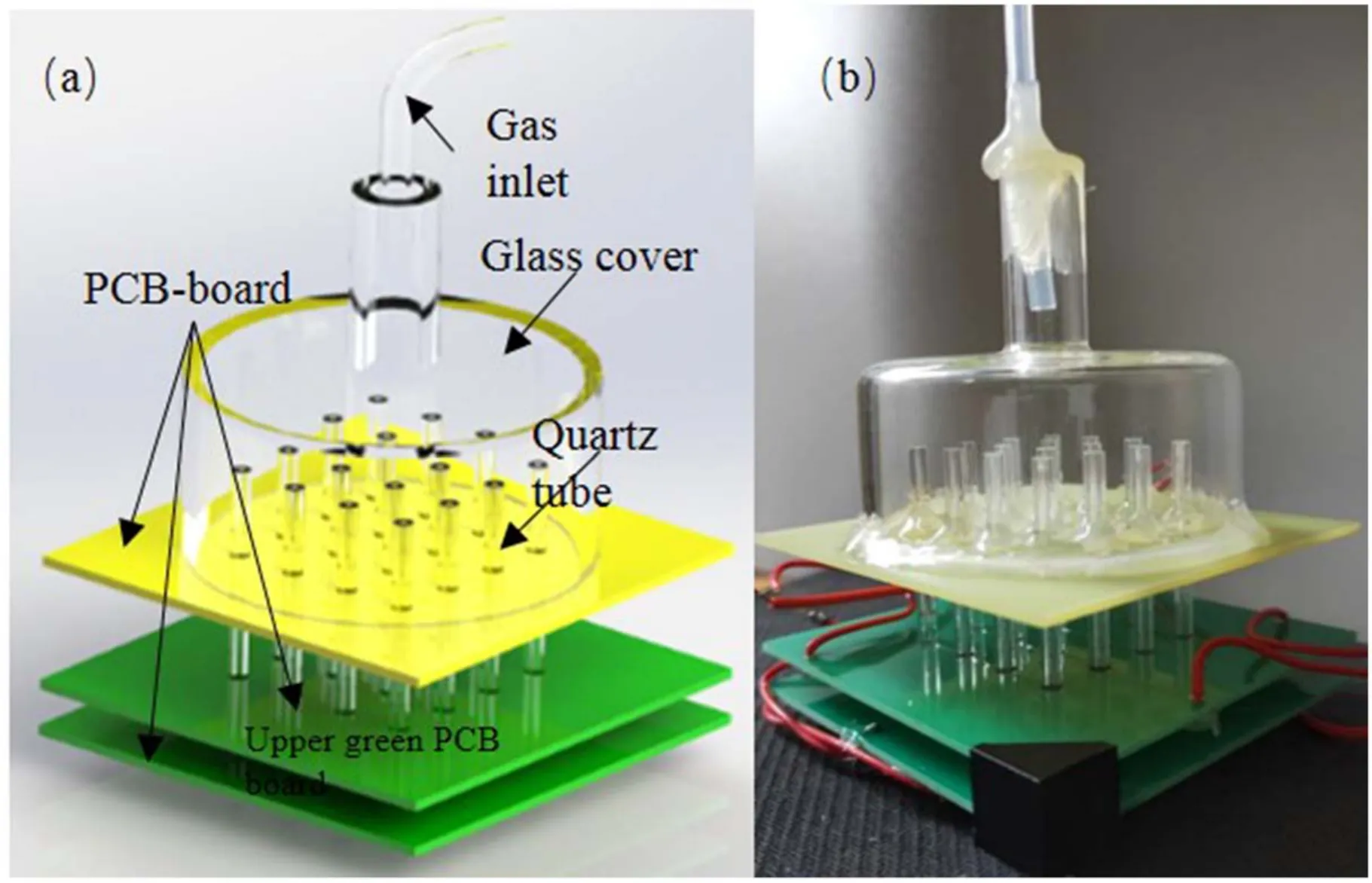

Compared with an array plasma sterilization device[23]in terms of the sterilization effect, sterilization time, and flow rate, it is generally superior to the latter in sterilization performance.Figure 14 is a picture of the array plasma sterilization device.A comparison between the two devices is listed in table 3.The sterilization uniformity of the rotating plasma sterilization device is much better than that of the array plasma sterilization device.In order for the latter to make up for its poorer uniformity,the array type has to increase the sterilization irradiation time, which is time-consuming and requires considerable quantities of gas,causing waste and increasing the cost burden.The gas consumption of the rotatable plasma sterilization device is much lower than that of the array plasma sterilization device, which effectively reduces the cost.Finally,the rotatable plasma sterilizer is equal to or faster than the array in terms of processing speed.

Figure 14.Array plasma sterilization device: (a)three-dimensional model, (b)photograph of PCB plasma array structure.

4.Conclusion

Existing array devices often suffer from uneven sterilization capabilities and considerable gas consumption.To solve this problem,a new sterilization method was innovatively proposed in this paper, and the corresponding rotating plasma injection device was designed.The theoretical model for the device is based on its sterilization mode to be used for guiding experiment,using S.aureus and E.coli bacteria;and the fastest effective sterilization rate of the device for S.aureus and E.coli diluted 103are 819 mm2min?1and 806 mm2min?1respectively.Under the premise of ensuring the shortest effective sterilization time, the helium gas-flow rate required by the device for inactivating S.aureus and E.coli is 0.8 slm and 0.6 slm, respectively.The device is compared with the excellent array plasma sterilization device in terms of sterilization uniformity, speed, and flow consumption, and the overall performance of the device is better than that of the array device.This indicates that the device has strong practicability and broad application prospect in the field of efficient sterilization.

Acknowledgments

This work was partially supported by National Natural Science Foundation of China (Nos.61864001 and 62163009),Key Projects of Guangxi Natural Science Foundation (No.2021JJD170019),the Foundation of Guangxi Key Laboratory of Automatic Detecting Technology and Instruments (Guilin University of Electronic Technology)(Nos.YQ21111 and YQ21204), and Innovation Project of Guang Xi Graduate Education (No.YCSW2021181).

Plasma Science and Technology2022年4期

Plasma Science and Technology2022年4期

- Plasma Science and Technology的其它文章

- Quantitative analysis and time-resolved characterization of simulated tokamak exhaust gas by laser-induced breakdown spectroscopy

- Influence of plasma-induced reflected wave variations on microwave transmission characterization of supersonic plasma excited in shock tube

- Quality enhancement and microbial reduction of mung bean (Vigna radiata)sprouts by non-thermal plasma pretreatment of seeds

- In situ quantification of NO synthesis in a warm air glow discharge by WMS-based Mid-IR QCL absorption spectroscopy

- Effects of the electric field at the edge of a substrate to deposit a ?100 mm uniform diamond film in a 2.45 GHz MPCVD system

- Study of post-arc residual plasma dissipation process of vacuum circuit breakers based on a 2D particle-in-cell model