Design and test of double-row walking garlic combine harvester

Hou Jialin, Li Chao, Zhang Zhilong, Li Tianhua, Li Yuhua, Wu Yanqiang

(1. College of Mechanical and Electronic Engineering, Shandong Agricultural University, Tai’an, 271018, China; 2. Shandong Agricultural Equipment Intelligent Engineering Laboratory, Tai’an, 271018, China)

Abstract: The planting area of garlic in China accounts for more than 90% of the whole area in the world. The major producer of garlic also needs mechanized harvesting in modern agriculture in recent years. Two kinds of harvesting technologies are divided mainly into: the widely-used segmented harvesting for the separation of garlic and soil individually, whereas, the new combined harvesting to concurrently separate the garlic, stem, root, and soil. However, the current garlic combine-harvester in the world can only collect the garlic under the upright position and wide rows, but cannot achieve the harvesting and cutting roots of lodging garlic plants. In this study, a novel garlic combined-harvester was designed to improve the harvesting efficiency, while reducing the labor intensity, according to the current state of garlic planting. Some specific conditions were also considered,including the working process of digging, the posture correction of garlic seedling, clamping, cutting, and low-damage collecting.The parameters of key components were determined using a theoretical and dynamic simulation of the operation process. A Box–Behnken orthogonal test was performed, where the forward speed, digging depth, and clamping distance were taken as the test factors, whereas, the damage rate and loss rate were the evaluation indices. A three-factor three-level Box-Behnken simulation was also carried out. A field test was conducted at a planting cooperative in Mindong, Shandong Province of China in May 2019. The test object was set as a variety of "Jinxiang Red Garlic". The shaft of shovel and gearbox gears were adjusted to change the distance between the clamping chains, thereby obtaining the different forward speeds, digging depths, and chain spacing during the test. The damage and loss rates were recorded for the harvested garlic in the field. Variance and response surface were utilized to determine the effects of forward speed, digging depth, and clamping distance on the evaluation index. A Design-Export software was used to optimize the model. An optimal combination of parameters was achieved as followed: the forward speed of 0.51 m/s, digging depth of 97.2 mm, and clamping distance of 7.6 mm, corresponding to the damage and loss rates of 0.63% and 1.25%, respectively. The parameters were tested in the field to verify the accuracy of the optimized model.The relative errors of all indices in the predicted and experimental data were less than 5%, indicating that the model was reliable and suitable for prediction and further optimization. The main factors affecting the damage and loss rates of garlic were determined for the forward speed, digging depth, and clamping distance. The finding can provide a sound theoretical reference for the design and optimization of garlic combine-harvester in mechanized production of intelligent agriculture.

Keywords: agricultural machinery; design; experiments; garlic harvesting; dynamic simulation; parameter optimization

0 Introduction

Garlic, a seasonal product, grows rapidly in a short harvesting period, and it can easily deteriorate if harvesting is delayed[1]. China is a major producer of garlic in the world, with a planting area accounting for more than 90% of the global planting area[2]. The need to harvest a large area of garlic in a short time and labor shortage have increased the demand for garlic harvesters. Currently, garlic harvesting is characterized by a low degree of mechanization, high labor intensity, and high cost[3]. Therefore, it is necessary to develop a combined garlic harvester with a high operation degree and reliability.

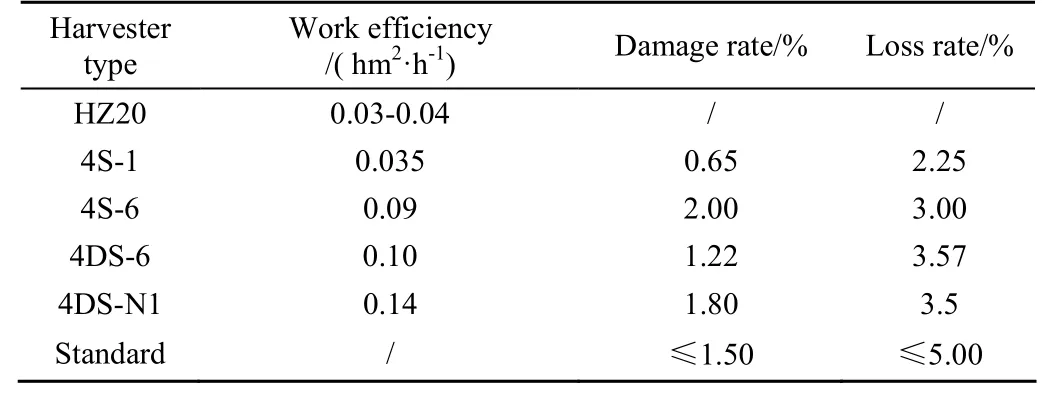

With several years of research and development, the technology of combined garlic harvest in developed countries is relatively mature. The representatives types in European are the CZ1-5 series garlic harvester (Maquinaria Zocapi S. L,Spain), ARAT/AO series garlic harvester (JJ Broch S. L,Spain) and RE1/2/S/P/CL series garlic harvester (ERME,France) and these machines are characterized by high work efficiency, large row spacing requirements for harvesting and lacking of seedling correcting and roots cutting[3]. The representatives type in Asia is HZ1/20 series garlic harvester(YANMAR, Japan). Although this series can complete roots cutting through the reciprocating cutting principle, its working efficiency is low, only 0.03-0.04 hm2/h[4]. At present,combined garlic harvesters with 1-6 rows spacing has been developed in China, such as the 4S-1 garlic harvester(Shandong Academy of Agricultural Machinery Science)However, due to the serious leakage of garlic, the loss rate reaches 2.25% and the working efficiency is low, only 0.035 hm2/h[5]. 4S-6 garlic harvester (Qingdao Agricultural University) has improved the working efficiency to 0.09 hm2/h,but the damage rate and loss rate are relatively high[6]. 4DS-6 garlic harvester(Shandong Agricultural University)[7]and 4DS-N1 modularized garlic harvester(Jinan University)[8]could adjust the row spacing and hang harvesting units, but the problem of serious damage and loss has not been solved.

In order to solve the problems of high loss rate caused by lodging of garlic seedlings and high damage rate caused by collision in the collection process, and to break through the restriction of garlic mechanization, this paper proposes a combined garlic harvester that can simultaneously realize digging, correcting posture of lodging seedlings, cutting and low-damage collecting for garlic planted with a row spacing of 180-220 mm, and provide to reference for optimizing the structure and improving the working performance of garlic harvesting machinery.

1 Main structure and working principle

Based on the garlic planting agronomic requirements in China, a combined garlic harvester was designed,comprising frame, driving device, depth limiting device,digging device, seedling correcting device, clamping device, cutting device, collecting device and other accessory parts, as shown in Fig.1.

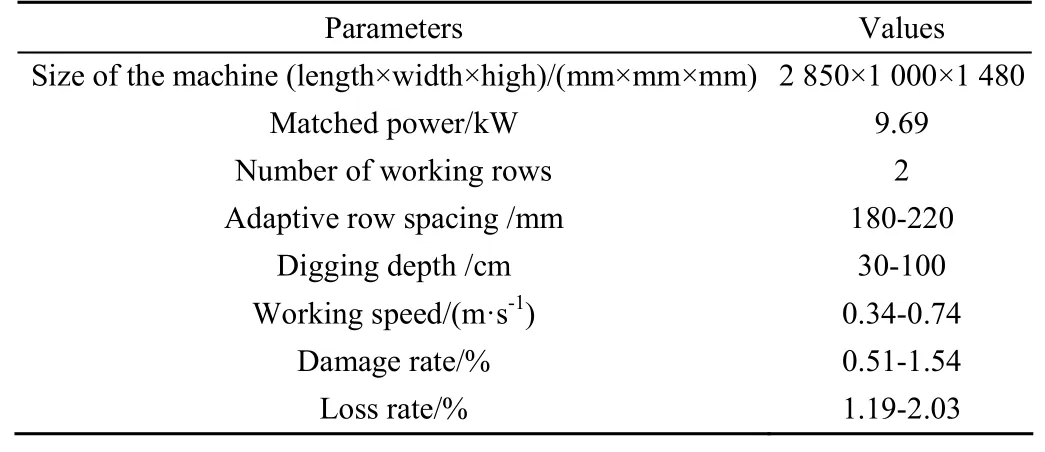

During operation, seedling correcting device calibrates garlic seedling posture. Digging device realizes separation of the garlic and soil[9]. Clamping device carries garlic for transportation. Cutting device realizes separation of garlic,straw and other impurities. Collection device realizes low loss collection and laying of garlic. Main parameters of combined garlic harvester are shown in Table 1.

Table 1 Main parameters of combined garlic harvester

2 Key components design

2.1 Design of the digging shovel

The digging shovel is driven by forward force of machine, which can harvest two rows of garlic simultaneously. In the process of digging, a part of the digging shovel point and shovel shank enters the soil. The furrow is broken during the oblique upward movement along the shovel surface and is thrown out at the end of the shovel[10]. Subsequently, the garlic straw enters the clamping device under the action of the garlic seedling correction device. The main parameters of the shovel are the angle between the shovel and the groundαs, the length of the shovelLand the width of the shovelB, as shown in Fig.2.

To ensure the digging of the two rows of garlic,considering the deviation of driving[11]and planting[5-8], the width of the shovelBshould meet:

Research results show that garlic plant width[5]σis 42-64 mm; row spacing[7]Dis 180-220 mm; line spacing deviation[8]μis 2-10 mm; machine travel offset[11]λ'is 40-70 mm. According to Formula (1), the width of shovelBshould be greater than 364 mm. To reduce power consumption and meet the needs of harvesting, the width of shovelBis designed as 370 mm.

The angle between the shovel and the ground[6-8]αsis controlled by the depth-limiting wheel for macro-reference,and the inclination angle adjustment shaft is used for fine-tuning within a certain range. The smaller the entry angle, the lower the soil resistance[12]. For the effective digging of garlics without damaging them, it should meets the following conditions[8]:

In order to meet the rigidity requirements of the shovel,the shovel is made of manganese steel with a thickness of 10 mm. According to garlic planting agronomy[5-6], garlic planting depth is 10-55 mm; Learn from relevant research experience[7-13], when blade angleβsis 8°, dip angleαsis 12°, shovel surface transition lengthSis 150 mm andh2is slightly larger thanh3, the digging resistance of garlic is small and it is easy to separate garlic from soil. According to Formulas (2)-(5), the length of the shovelLis calculated to be 220 mm and the digging depthHis 56-101 mm.

2.2 Design of seeding correcting device

The row spacing of garlic planting in Chinachanges a lot. Under separation of the divider, garlic plants are divided into 2 rows. The divider realizes the shunting of the garlic plants[14]. Then, the seedling correction device corrects the posture of garlic straw. The garlic plants enter into the seedling correcting device under the action of the rubber bars. The design method of vertically twirling the garlic straw effectively guarantees the upright state of the garlic plants. To adapt to different planting pattern in different locations, the installation distance between the rubber bars should meet the varying agronomy and machine operation requirements, as shown in Fig.3.

The installation distanceTbetween the left and right rubber bars should satisfy the following condition:

Through Formula (6), the installation distance between the left and right rubber barsTranges from 154 to 220 mm. If the spacing is too large, it will reduce the uprightness of the poaching[15]. After repeated poaching tests, the calibrating effect is ideal when the installation distance between the left and right rubber barsTis determined to be 180 mm. The seedling correcting device is mainly composed of divider and rubber bars and its working process diagram is shown in Fig.4.

The working trajectory of the seedling correcting device is the combined motion of its own rotating motion and the forward motion of the garlic harvester[16]:

When the rubber bar rotates once, the combined garlic harvester moves forward by:

The effective threshing distance for one revolution can be expressed as:

To achieve the ideal working effect of garlic seedling correction device and reduce the damage of garlic seedling before clamping, it is necessary to establish the speed ratioλbetween the machine forward speed and the bar edge velocity, and effect index of seedling correction deviceη:

where,λis the reel speed ratio, which represents the speed ratio between the machine forward speed and the bar edge velocity, and affects the tracks of the rubber bars;η isthe effect index of seedling correction device, which represents the level of garlic seedlings corrected by rubber rod. If its value is too big, the garlic seedlings will be damaged, and too small, the garlic seedlings correction effect will be poor.

Derivation of Formula (7) can get:

Shifting the term can get:

Sorting out Formulas (8)-(13) can get:

It can be obtained by Formula (14) that the effect index of seedling correction deviceηis affected by the speed ratioλand the function of garlic seedling correction can be realized preliminarily when its value is 0. To avoid the damage of garlic straw, the speed ratio value should not be too large.

In order to realize the function of correcting garlic seedlings and determine the appropriate speed ratio,ADAMS kinematic simulation model is needed. which is shown in Fig.5. The model of seedling correction device was established in SolidWorks software, then it was simplified and imported into ADAMS software and defined as a rigid body. Based on Ref. [17], the material parameters of rubber bar such as density, Young's modulus and Poisson's ratio were set: the density of rubber bar was 1 000 kg/m3, Young's modulus was 7.84×106Pa and Poisson's ratio was 0.47.Based on Refs [18-19], in ANSYS software took Solid186 to construct garlic plant model and mat orthogonal anisotropy was selected as material type.

According to the data recorded in the studies by Maria et al[17], hybrid garlic plants was used as experimental samples, the material parameters of garlic plant such as density, Young's modulus and Poisson's ratio were set: the density of hybrid garlic plants was 438 kg/m3, Young's modulus was 1.1×10-10Pa and Poisson's ratio was 0.33[20-22].In ANSYS software, the automatic mesh generation command divided garlic plant into 71 167 elements. In ADAMS software, the degree of freedom of the rubber rod was limited except for the rotation constraint around the localzaxis and the translation constraint in thexdirection.

Because of the water loss of garlic stem in the mature stage, the inclination of garlic seedling was varying[20]. A definition was given: when the angle between garlic seedling and ground was less than 60°, it was mild lodging;when the angle between garlic seedling and ground was less than 30°, it was severe lodging. According to the actual survey data, the simulated plant spacing was set to 150 mm[22]. The combined garlic harvester forward speed ranged from 0.34 to 0.74 m/s[8], the median value of 0.54 m/s was taken to simulate the forward movement in the simulation experiment. The simulation duration was set to 10 s and the number of steps was set to 10 000[18], as shown in Fig.6.

A definition about the final result in the simulation experiment was made: when the lodging seedlings could not be corrected to the vertical state, it was a correction failure;when the lodging seedlings were overlapped, it was a wrong order; when the lodging seedlings were rectified in turn, it regarded as successful correction, as shown in Fig.6.

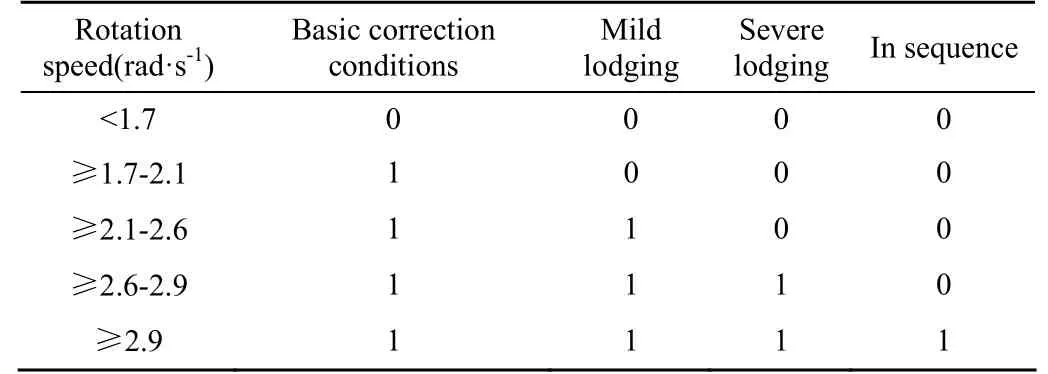

According to the different rotating speed of the paddle,several groups of simulation tests were done, and the results are shown in Table 2.

Table 2 Results of garlic seedling correction

Table 2 shown that when the rotation speed of the rubber bars was less than 1.7 rad/s, the effective correction distance was less than the inclined length of garlic seedlings,which could not achieve the purpose of garlic seedling correction. When the rotation speed of the rubber bars was between 1.7 and 2.6 rad/s, the effective correction distance was greater than the inclined length of garlic seedlings, but garlic seedlings were not completely corrected. When the rotation speed of the rubber bars was between 2.6 and 2.9 rad/s, although all garlic seedlings could be corrected, the garlic seedlings were not carried out in turn, which led to the error of clamping and cutting in the later stage. When the stripping speed was greater than or equal to 2.9 rad/s, all garlic seedlings could be corrected in turn. The greater the rotation speed of the rubber bars, the greater the damage degree of garlic seedlings. Therefore, the rotation speed of the rubber bars of 2.9 rad/s was selected, and the simulation time was 3-5 s. The movement track data was recorded with the top of severe lodging garlic seedling is showed in Fig.7.

As shown in Fig.7, within 2-3.66 s, the early process of posture correction, the harvesting machine drove seedling correction device forward, without touching garlic seedling and the curves of the garlic straw head in thex-axis andy-axis were relatively smooth. Within 3.66-4.03 s, the middle process of posture correction, the rubber bars corrected the attitude of the garlic seedling. The value of displacement in thex-axis direction gradually decreased andy-axis increased then decreases, when the value of velocity in thex-axis direction increased sharply then stabilizes andy-axis increased then decreases. Absolute value of speed and acceleration of garlic straw increased in the lodging state and decreased in the upright state. Within 4.03-5 s, the late process of posture correction, the garlic seedling moved into the clamping device, and the displacement, velocity and acceleration ofx-axis andy-axis tend to be stable. Through the dynamic simulation test to analyze the garlic seedling trajectory, it proved that seedling correction device under condition of the rubber bars of 2.9 rad/s (λ=2.7) can achieve the purpose of garlic seedling correction.

2.3 Design of clamping device

Designing an ideal chain speed, sprocket parameters,and the type of transmitter are vital to ensuring the efficiency of clamping transportation[23-24]. Fig.8 shows the schematic diagram of clamping and conveying.

The clamping interval is an important parameter for clamping and cutting[25]. Under the action of the chain-II, the garlic along with the chain-I undergo a small slip in the vertical direction, whereas there is no slip in the horizontal direction. Under the pulling action of the chain-I, the garlic along with the chain-II undergo a slip in the vertical and horizontal direction. Thus, the clamping distance should meet the following conditions:

where,e0is the clamping pitch of the garlic seedling with no slip under normal pulling force, mm;e2is the chain spacing of the cutting device, mm;ois the rate of garlic seedling diameter after clamping deformation to original diameter.

Through the actual garlic seedlings clamping tensile test, the following rules were found: when the radial deformation rate was between 40% and 60%, external interference caused vertical displacement, and when the radial deformation rate was up to 80%, external interference caused vertical and horizontal displacement. Therefore, the spacing of chain-I is designed as 7-9 mm and the spacing of chain-II is designed as 13 mm.

To ensure garlic clamping, the forceFNshould meet the following conditions[26]:

where,mis mass of garlic, g;pis pressure on garlic straw, MPa;γis safety factor of clamping;μfis the static friction coefficient between garlic stalk and chain; The industrial-grade quarter chain is used as the transmission chain, and its heightBchainis 15 mm. By consulting Zou’s related research, safety factorγis 2 and static friction coefficient is 1.9[27].

According to Formula (17), the clamping force[22]usually changes from 80 to 120 N as the tension changes.Under different clamping force, the pressure on garlic seedling changes with clamping angle, as shown in Fig.9.

The pressure applied on the garlic seedling should not exceed 0.72 MPa[28-29], so the clamping angle should be between 10° and 20°. Combined with the actual operation,median value of 15° is designed as the clamping angle.

2.4 Design of cutting device

The cutting device can cut through the fixed point[30]to separate the impurities from the garlic, as shown in Fig.10a and force analysis of cutting device is shown in Fig.10b. The garlic plants move in a fixed trajectory via the movement of the clamping chain, and the positioning mechanism accurately positions the garlic head. Combined with the physical characteristics of the garlic, the cutting blades must be placed precisely to ensure that remaining length of the garlic seedlings are same and garlic roots are completely cut[31-32].

A total of eight cutters on the cutting table are connected to the gears on the cutting device through a spline shaft for transmission. The cutting line speed can be expressed as follows:

In order to cut off the garlic seedlings and roots effectively, combined with the characteristics of the garlic[33-34], the shear force provided by the cutter should be greater than the maximum seedlings and roots breaking force. Thus, cutting force provided by the cutter should meet the following conditions:

where,Fis the shear force required for garlic seedling, N;iis the number of cutting units;Kfis the safety factor of the cutting force for cutting seedling;Peis the engine power;Z*is the power conversion efficiency from the engine to the cutting unit; By consulting Han’s research, the maximum shear force required for garlic seedling with a height of 40 mm from the bottom is 22.8 N[35]. By consulting Barman’s and Xin’s studies, when the safety factor of the cutting force for cutting seedlingKfis 1.5, actual cutting effect is ideal[36-37]. It can be seen from mechanism transmission: the total power comes from the 188F gasoline engine with a power of 9.69 kW, and power transferred to the cutting device only 10% considering the power consumption. The cutting device needs to complete the cutting of 2 rows of garlic seedlings and roots, so the number of cutting units is 8.Because the breaking force of garlic root is smaller than that of garlic seedling, the maximum cutting force provided by cutting device is designed according to the maximum cutting force of garlic seedling. It can be calculated by Formula (20)that the cutting force provided by the cutter to be 52.56 N,which is far from the value required for the breaking force of the seedling and root. Therefore, the design of the cutting unit meets the actual requirements.

As the garlic falls, garlic falling speed is calculated to reduce the impact in the vertical direction to achieve a low-damage collection[38-40]. Schematic diagram of garlic falling speed analysis is shown in Fig.11.

The mathematical model of kinematics is established as follows:

Due to the limitation of installation space, the distance between the brush and cutterhc1is 0.1 m, the distance from the center of the brush to the bottom of the garlic boxhc2is 0.2 m. By Formulas (25)-(26), the velocity in the vertical direction when the garlic slows down as it approaches the bottom of the garlic box through the brush is 1.41 m/s. The velocity in the vertical direction when the garlic reaches the bottom of the garlic box without deceleration is 2.45 m/s.Under the brush effect, the vertical velocity to the bottom of garlic box is reduced to 58.3% compared with the drop without deceleration, which reduces the garlic damage rate.

3 Field test

3.1 Test conditions and method

The field test was conducted in a professional planting cooperative in Mindong, Shandong Province during May 2019. Test equipment included the garlic harvester, soil moisture tester, soil hardness tester, speedometer, electronic scale, stopwatch, tape measure, steel ruler, Vernier caliper,and other tools[41]. The main planting variety “Jinxiang Red Garlic” in the main producing area was selected for the experiment. The average seedling diameter of garlic is 28.43 mm, the average bulb height is 39.46 mm, the average bulb diameter is 54.37 mm, and the average garlic plant height is 76.93 mm. The local weather was sunny, the temperature was 30.5℃, the soil moisture was 25.32%, and the soil firmness was 13.28 kg/cm2. For the garlic harvester,the indicators used for the assessment were the garlic damage rate and loss rate.

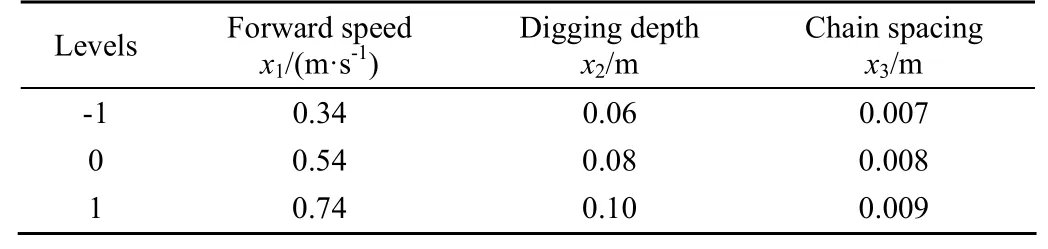

In the field operation, the operation effect was mainly determined by the damage rate and loss rate. The results showed that the forward speed, digging depth and chain spacing are the main factors affecting the effect of combined harvesting. In order to ensure the harvesting efficiency and the requirements of digging the garlic and breaking the soil,the forward speed should not be too small. The forward speed has a very strong positive impact on the grain loss, the higher the field speed of the combine, the higher the loss rate[42]. Based on the harvesting performance of the machine in the actual production operation[43], the throttle size and gear position are adjusted step by step by observing the speed meter value, and the forward speeds are selected as 0.34, 0.54 and 0.74 m/s respectively. In order to ensure effective digging and not damage garlic, the value of digging depth should not be too small. The amount of soil increased with the increase of excavation depth, which was not conducive to the extraction, transportation and cutting of garlic[43]. According to the theoretical calculation, the excavation depth is in the range of 0.056-0.101 m. By adjusting the digging shovel crank, the excavation depths of 0.06, 0.08 and 0.10 m were selected for the test. Through the analysis of stem deformation, the clamping spacing is 0.007-0.009 m. Therefore, the clamping spacing of 0.007,0.008 and 0.009 m were selected for the experiment. The indicators, regression equations, and optimization schemes were established, so as to obtain the regression equations and optimization schemes of the test index influencing factors, as shown in Table 3.

Table 3 Actual value and code of the variable

The forward distance of the combined garlic harvester is 20 m and each test was repeated 3 times. The damage rate and loss rate of garlic harvested in the test are defined:

(1) Measurement of the damage rate

The rate of garlic damage is a measure of garlic damage in the process of harvesting, fruit with small dents,pitting damage, blackspot bruise, and so on. The damage rate is calculated as Formula (27):

where,Y1is the damage rate of garlic, %;W1is the damaged garlic mass measured in the test, kg;Wis the total mass of the garlic measured in the test, kg.(2) Measurement of the loss rate The rate of garlic loss is a measure of garlic damage in the process of harvesting, digging loss, correction loss,clamping loss, and so on. The loss rate is calculated as Formula (28):

where,Y2is the loss rate of garlic, %;W2is the mass of the loss garlic measured in the test, kg;Wis the total mass of the garlic measured in the test, kg.

3.2 Test results and analysis

3.2.1 Test results

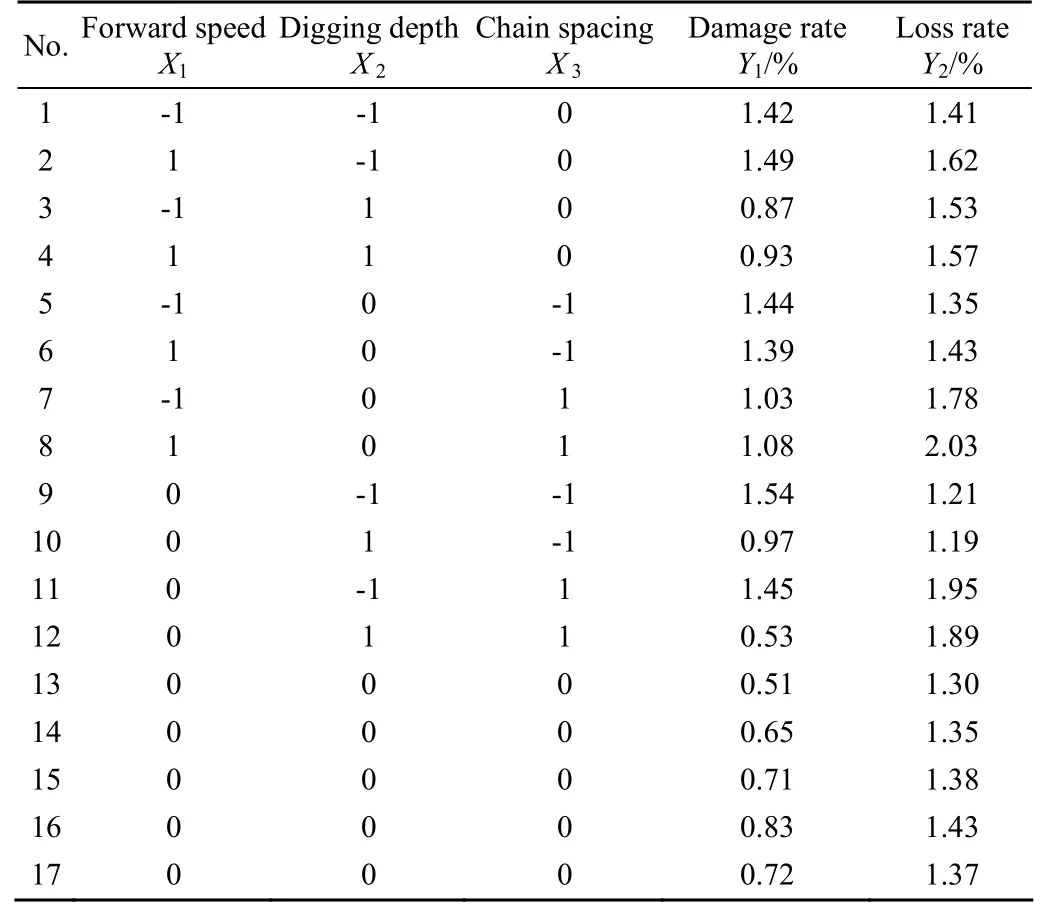

The test was based on the Box-Behnken orthogonal table, with the forward speed, digging depth, and chain spacing as the experimental factors, and the damage and loss rates of the garlic after harvest as evaluation indicators.Table 4 lists test scheme and results.

Table 4 Test scheme and results

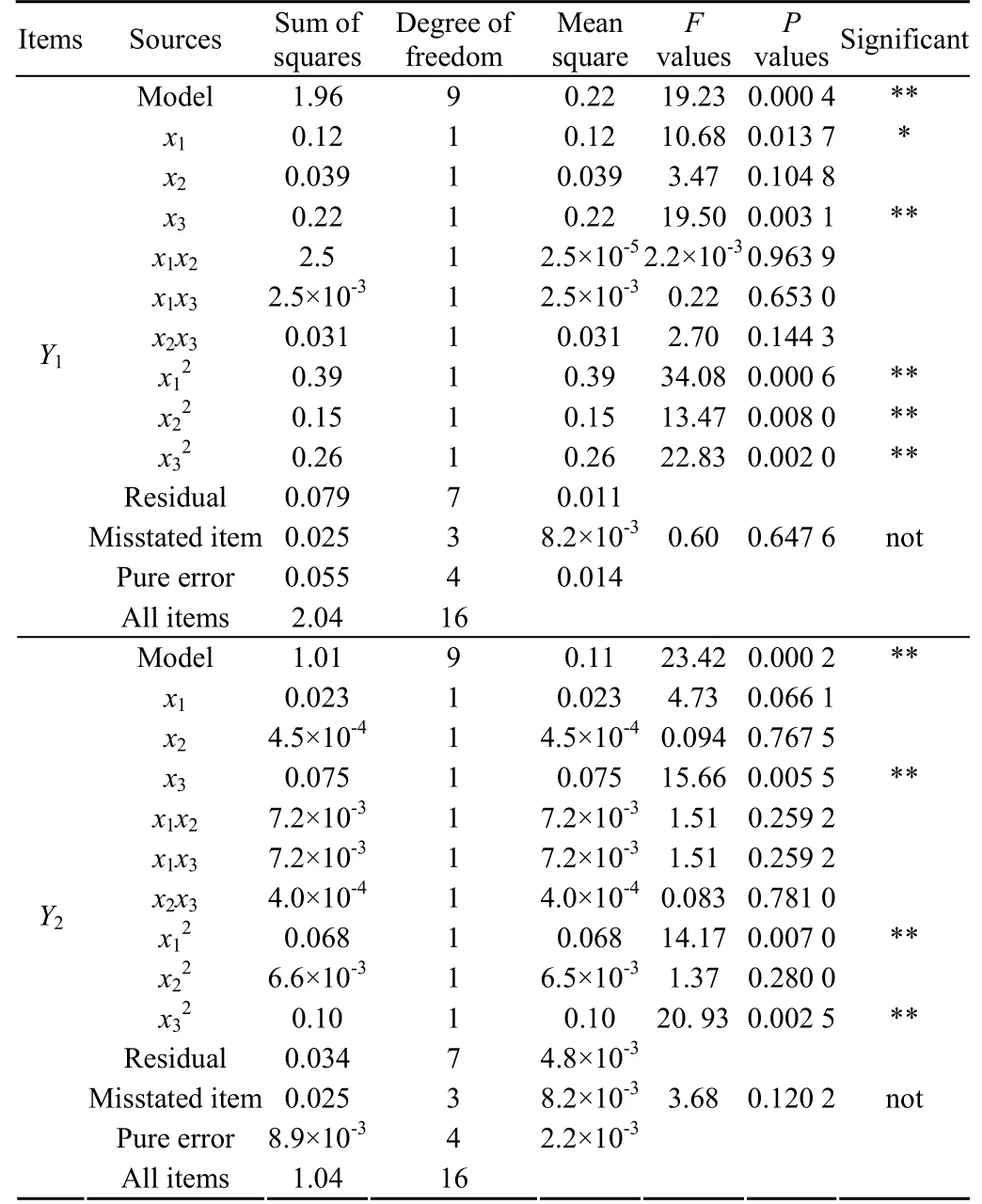

3.2.2 Establishment of regression model and significance analysis

Based on the experimental data in Table 4, Design Expert software was used to perform a multivariate regression fitting analysis and establish a response surface regression model with three independent variables: the forward speedx1, digging depthx2and chain spacingx3. The analysis of variance were performed on each regression coefficient in the regression model, as shown in Table 5. The model misfits of damage rateY1and loss rateY2were 0.647 6 and 0.120 2, respectively, which were greater than 0.05, proving that there was no misfit factor. Therefore, the results obtained using the regression equations could be used to replace the actual results of the test.

Table 5 Variance analysis of target rate

The model of damage rateY1and loss rateY2were less than 0.001, proving that the regression equation was significant and the experimental design was reliable. With the insignificant factors eliminated, the second-order multiple regression equations for the coding factors, such as the forward rateX1, digging depthX2, and transport chain spacingX3, and damage rateY1and loss rateY2are as follows:

3.2.3 Analysis of interaction results

In the regression Equations (29) and (30), the level of any factor is 0, and the other two factors are studied in terms of the forward speed, digging depth, and chain spacing.Figures 13 shows the response surface of the interactive factors that affect the test indicator.

In Fig.13a, at the same digging depth, the damage rate decreases first and then increases slightly as the forward speed increases; at the same forward speed, the damage rate decreases with the digging depth; at the same chain spacing,the damage rate first and then increases slightly with the increase in the forward speed; at the same forward speed, the damage rate first and then increases slightly with the increase in the chain spacing; at the same digging depth, the damage rate decreases with the increase sharply in the chain spacing; for the same transport chain distance, the damage rate decreases with the increase in the digging depth. In Fig.13b, at the same digging depth, the loss rate decreases first and then increases slightly with the increase in the forward speed; at the same forward speed, the loss rate does not change significantly with the digging depth; at the same chain spacing, the loss rate increases slightly with the increase in the forward speed; at the same forward speed,the loss rate increases significantly with the increase in the chain spacing; at the same digging depth, the loss rate increases with the chain spacing; at the same chain spacing,the loss rate does not change significantly with the digging depth.

3.2.4 Parameter optimization and test verification

Through a Box-Behnken simulation test, the optimal combination of the parameters influencing the harvest was determined, thereby reducing the damage and loss rates of the garlic harvest and improving the working efficiency of the entire machine. Because of the influence of the various factors on the target value, a global multi-objective optimization was necessary. The optimal constraints are as follows:

Through the solution of the Design-Expert software,the best combination was found. When the forward speed,digging depth, clamping distance were 0.51 m/s, 97.2 mm and 7.6 mm, damage rate and loss rate were 0.65% and 1.28%.

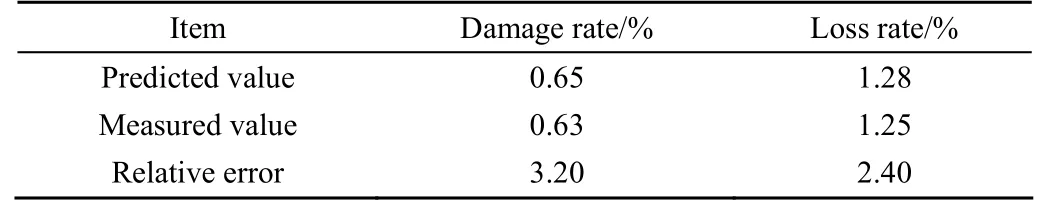

To verify the accuracy of the optimized model, the parameters of the optimized factors were tested in the field.The test was conducted in a professional planting cooperative in Qixian Jinjufang garlic planting professional cooperative (Latitude 34°, Longitude 114°), Henan Province during April 2020, and the test object was early ripening garlic. The average seedling diameter of garlic was 17.35 mm, the average bulb height was 32.83 mm, the average bulb diameter was 43.29 mm, and the average garlic plant height was 65.81 mm. Considering the practical application of the machine, the above parameters were taken as follows: the forward speed was 0.51 m/s, the digging depth was 97.2 mm and the clamping distance was 7.6 mm.The experiment was repeated 10 times with the optimized parameters, and the results were showed in the Table 6.

Table 6 Verification test results

In the comparison of the predicted result and experimental result, the relative errors of all property indices were less than 5%, which the established model was reliable and could be used for prediction and optimization.

When the forward speed, digging depth and clamping distance were 0.51 m/s, 97.2 mm, and 7.6 mm,the damage rate and loss rate were 0.63% and 1.25%, and the working efficiency was 0.10 hm2/h. From the data in Table 7, it can be found that the efficiency of the harvester is greatly improved compared with others,which the damage rate is reduced by 0.02% and the loss rate is reduced by 1% compared with the best working data. Moreover, the harvester is suitable for wide-ranging row spacing and low loss harvesting of lodging garlic plant, and meet the requirements of Shandong local standard DB37/T 2878.4-2016.

Table 7 Comparison of operation indexes

4 Conclusions

1) A double-row walking garlic combine harvester was designed to realize digging, correcting, clamping, cutting and collecting, which helped to reduce the damage and loss rates, improve the harvest efficiency, and decrease labor intensity. Through theoretical analysis and dynamic simulation, parameters of key devices were determined.

2) Using the Box-Behnken design, the response surface regression model of the damage and loss rates of garlic was established. Through variance and response surface analysis,the effects of the forward speed, digging depth, and clamping distance on the evaluation index were studied.

3) The Design-Export 8.0.6.1 data analysis software was used to optimize the model and the reliability of the calculation results were verified by conducting a field test.When the forward speed, digging depth and clamping distance were 0.51 m/s, 97.2 mm and 7.6 mm, work efficiency, damage rate and loss rate were 0.10 hm2/h,0.63% and 1.25%, which meeting the garlic harvest standards.