Advances in Electrospun Nanofiber Yarns

ALI Muhammad

National Engineering Laboratory for Modern Silk, College of Textile and Engineering, Soochow University, Suzhou 215000, China

Abstract: In order to increase the application area of nanofibers, electrospun nanofiber yarns have drawn attention of many researchers around the globe. Once the production method of nanofiber yarn is mature enough to be universally accepted, many new gates of applications will open to the world. In this review, different electrospinning techniques of electrospun nanofiber yarns are divided into needle electrospinning and needleless electrospinning. Considering yarn twist as an important mechanism, needle electrospinning technique is further categorized into mechanical, electrical and field flow twisting methods. Moreover, parameters influencing the mechanical properties of electrospun nanofiber yarns are investigated. Methods of improving mechanical properties of nanofiber yarns are addressed, including hot-water-bath treatment, addition of carbon nanotubes (CNTs) and introducing regulators. Finally, applications of electrospun nanofiber yarns in different fields of smart textile and bioengineering are summed-up. In summary, challenges encountered in the industrialization of nanofiber yarns and future prospects are anticipated.

Key words: nanofiber yarn; electrospun nanofiber yarn; smart textile; bioengineering

Introduction

With the advancement of science and technology, nanotechnology has developed rapidly and many derivative products have been produced including fibers at nanoscale. Nanofibers refer to a linear material with a diameter in nanometers and a certain aspect ratio[1-2]. Nanofibers are characterized by their high specific surface area, high porosity and excellent physical and chemical properties[3-4]. They have a wide range of applications in high-efficiency filtration[5-6], miniature sensors[7], biomedicine[8]and other fields. Nanofibers have become an important material for any country’s future strategic development with broad market prospects[9].

Electrospinning is widely used to prepare nanofibers[10]. Nanofibers produced from electrospinning are also termed as superfine or ultrathin fibers in some literatures. Most of the fibers prepared by electrospinning are collected in the form of non-woven webs, and their mechanical properties are poor, which limit the applications of nanofibers[11]. Bolandetal.[12]found that the mechanical properties of nanofibers could be improved by oriented nanofiber bundles. Others found that twisting nanofibers in the form of yarns could make the fibers arrange in order and improve the mechanical properties of the fibers[13-20]. Gaoetal.[21]fabricated composite nanofiber yarns with carbon nanotubes (CNTs) and polyurethane (PU) for super-elastic conductive wires. Jietal.[22]produced core-shell piezoelectric nanofiber yarns by twirling the yarns around a conductive thread. They found that output voltages were directly dependent on applied pressure. However, the energy harvested through piezoelectric materials was still too little to count on it. Moreover, the durability and the production rate were other bottle neck problems for such yarns to be used in practical life. Most of the researches on the electrospun nanofiber yarns were still in the laboratory. In order to realize mass production and wide application, it is necessary to review the research results of the electrospun nanofiber yarns and look forward to the future research direction.

In this paper, different techniques of electrospinning nanofiber yarns are discussed and divided into needle electrospinning and needleless electrospinning. Several typical fiber twisting methods are summarized, and advantages and disadvantages of these methods are compared. The influence of electrospinning process parameters on the mechanical properties of yarns is discussed and several methods of improving the mechanical properties of yarns are introduced. The application fields of nanofiber yarns are summarized. At last, the problems in the preparation of nanofiber yarns by electrospinning are pointed out and the development direction of nanofiber yarns in the future is prospected.

1 Production of Nanofiber Yarns

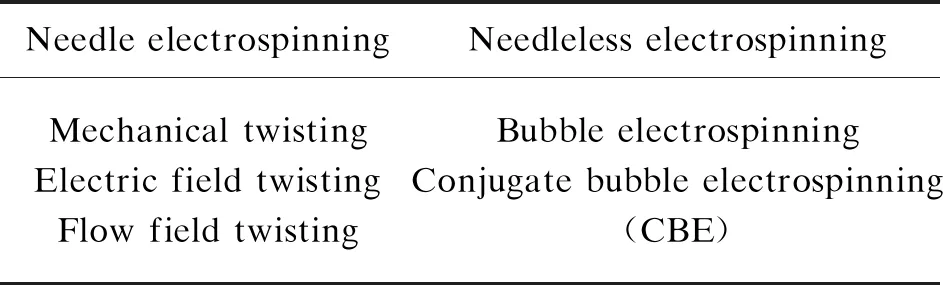

Electrospinning is a process in which high voltage overcomes the surface tension of polymer solution to form a jet and collects it in the form of fibers up to a diameter of some hundred nanometers[23]. Electrospun nanofibers are usually collected in the form of non-woven webs where fibers are randomly arranged. Many researchers suggested different ways to produce bundles of parallel aligned fibers. Though high degree of fiber alignment was achieved, it only enabled to produce a limited length of yarn. This problem is overcome by introducing a twisting unit in the electrospinning setup. A special collector in the twisting device collects the fibers from electrospinning and twists them into a continuous length of yarn. Methods of electrospinning nanofiber yarns can be divided into needle electrospinning and needleless electrospinning, as shown in Table 1[24]. We have discussed the nanofiber yarns production, principle, advantages and disadvantages of both methods.

Table 1 Classification of electrospun nanofiber yarns

1.1 Production of nanofiber yarns by needle electrospinning

In needle electrospinning, the polymer solution is drawn into fibers from the Taylor cone which is arranged in electrostatic field between the needle tip and the collector[25]. Nanofibers are mostly produced by single needle electrospinning (SNE) due to the fewer components and simpler operation. However, many researchers prefer conjugate needle electrospinning (CNE) for the production of continuous nanofiber yarns. CNE involves oppositely charged pair of spinning units which enhance the stability and the production. Electrospinning of nanofiber yarns involves two steps: the first step is to produce nanofibers continuously; the second step is to twist the nanofibers in a proper way. According to the different modes of twisting, it can be divided into mechanical twisting, electric field twisting and flow field twisting[26-27].

1.1.1Mechanicaltwistingofelectrospunnanofiberyarns

The use of mechanical rotation to wind and twist the fibers is a traditional twisting method. Some researchers considered twisting the nanofibers through the rotation of mechanical devices. Levittetal.[28]tried to use a copper funnel device to prepare nanofiber yarns. Two nozzles that applied positive and negative charges sprayed nanofibers onto the funnel. The copper funnel rotated at a speed of 150 r/min and used an insulating rod to start the collection of nanofiber yarns. The nanofibers are drawn into a cone and as the copper funnel rotates, and the fibers are rotated and twisted into the yarn. The diameter of the prepared yarn is 4 μm and the diameter of a single fiber is 400 nm. The device diagram is shown in Fig. 1(a).

Daltonetal.[29]proposed to use a pair of discs to collect the oriented nanofibers. Yanetal.[30]improved the device of double discs to collect the oriented nanofibers, as shown in Fig. 1(b). A winding rod was placed between the two discs, and the rotation of the rod was used to collect and twist the nanofibers into yarns.

Methods of mechanical twisting nanofibers have the advantage to control parameters, but it is easy to produce a whip by rotation in the process twisting. Electrospun nanofibers are ultrathin, and the wind field generated from the rotating mechanical device hinders the effective collection of nanofibers. In addition, the production efficiency of mechanical twisting nanofibers is low and the twisting degree is not high. So, it is only applicable to the laboratory scale.

1.1.2Electricfieldtwistingofelectrospunnanofiberyarns

In electrospinning process, the electric field stretches the fibers to a diameter of few hundred nanometers. The researchers found that the electric field formed by the opposite charged nozzle could induce the twist to fiber while drawing it. Dabirianetal.[31]used a pair of opposite charged spinnerets and a grounded receiving plate to prepare polyacrylonitrile (PAN) nanofiber yarns, and continuously collected the yarn through a winding drum. The diameter of the prepared yarn was 160.43 μm and the diameter of the single fiber was 411.77 nm. The device is shown in Fig. 2(a).

Hajianietal.[32]produced a continuous polyamide (nylon 66) nanofiber yarns by using the CNE system. Nanofibers were produced by a pair of oppositely charged needles and then twisted to form nanofiber yarns using a rotating disc twisting system. Yarns were collected on a winding roller connected to a rotating disc. The device is shown in Fig. 2(b), which mainly includes electrospinning needles, a high voltage power supply and a winding device.

(a)

The electrical field twisting nanofiber has the advantage of a simple device structure, but there is limited information regarding the stability of the spinning system or the control of yarn properties.

1.1.3Flowfieldtwistingofelectrospunnanofiberyarns

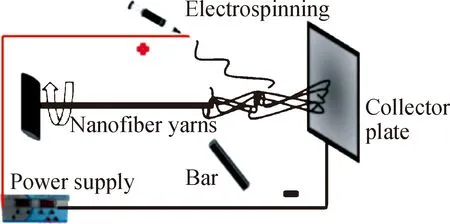

In order to increase the efficiency of twisting nanofibers into a yarn, some researchers considered using a flow field to twist the nanofibers. Flow field twisting methods include the water flow twisting and the air flow twisting. Teoetal.[33]invented a method for processing nanofiber yarns by using the vortex of water. The device is shown in Fig. 3(a). The spinning solution is a copolymer of vinylidene fluoride and hexafluoropropylene (PVDF-co-HFP) and acetone is used as the organic solvent. To generate a water whirlpool, a small hole is opened in the middle of the reservoir. When water flows down into the water tank below, a rotating vortex is formed at the small hole. The vortex of water is used to pull and twist the fibers down out of the small hole and collect them in the form of a yarn. Circulating water pumps can ensure the recycling of water while the rotating roller collects the nanofiber yarn. The diameter of the prepared yarn is 96 μm and the diameter of a single fiber is 1.7 μm. Yousefzadehetal.[34]tested the mechanical properties of the nanofiber yarn prepared by this method. The method has a simple structure and convenient operation, but the method requires that the polymer raw material is insoluble in water and the preparation efficiency is low.

The air flow twisting is another way of flow fluid twisting. Compared with solution electrospinning, melt electrospinning has the advantages of not using toxic solvents and high production efficiency. Some researchers have made efforts to prepare nanofiber yarns by melt electrospinning. Ma[35]successfully prepared nanofiber yarns by the air flow twisting method using melt blown electrospinning device shown in Fig. 3(b). The device mainly includes a high voltage power supply, a heating unit, a spinning device, and an air cyclone twister. The melted material is transported to the differential nozzle by the extruder to form a jet, and the uncontrolled jet is bundled and twisted by the cyclone generator. The airflow speed of the cyclone generator can control the fiber bundle and the twist angle. The rotational speed of the winding roller can control the orientation of the collected fibers. Through this device, polypropylene (PP) nanofiber yarns were successfully prepared, with a yarn diameter of 100 μm and a single fiber diameter of 1 μm. The preparation of the nanofiber yarn by melt electrospinning has the advantages of green production, high efficiency and suitability of preparing nanofiber yarn in batches. However, the structure of the device is relatively complex, requiring a heating device to melt the polymer.

(a)

1.2 Preparation of nanofiber yarns by needleless electrospinning

Needleless electrospinning is a method of producing nanofibers, in which needle is replaced with balls[36], rollers[37], discs[38], cylinders[39], moving yarns[40], bubbles[41], beaded wires[42]and so on. The fatal drawback of needle electrospinning is its low productivity. Using multi-needle electrospinning devices is a common approach to overcome this problem. For example, Heetal.[43]used multi-needle conjugate electrospinning to fabricate continuous polyacrylonitrile (PAN) nanofiber yarns. It was able to achieve a comparatively higher production rate of 2.0 m/min, but some problems associated with needle electrospinning still remained, such as needle clogging and interaction between the jets.

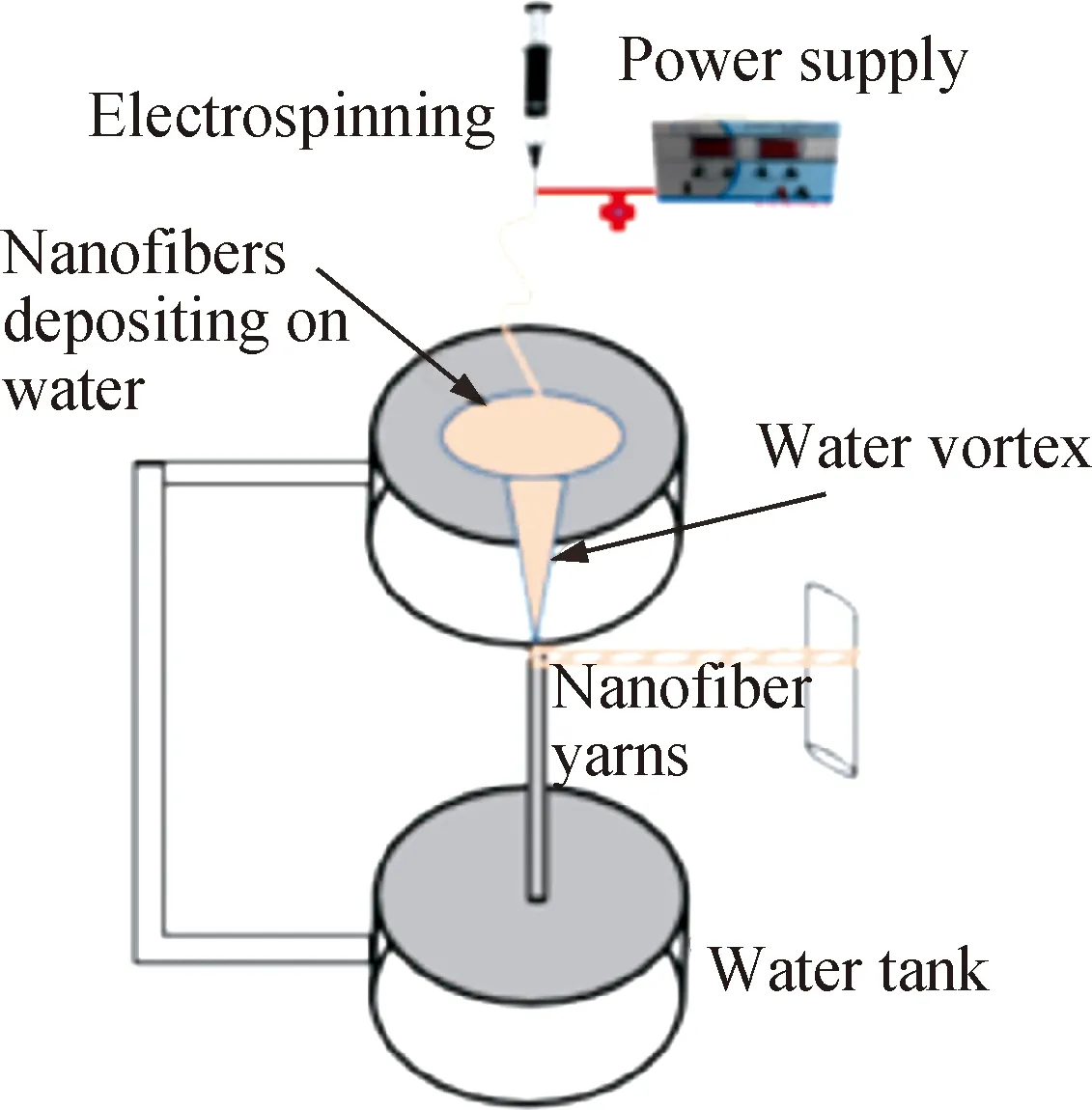

Bubble electrospinning is one of the most effective and the simplest approaches of needleless electrospinning techniques[44-47]. Heetal.[48]introduced a novel multi-nozzle CBE apparatus, which mainly included a spinning unit, a metering pump, positive and negative power supplies, a metal funnel and a yarn winder as shown in Fig. 4(a). The production rate achieved from 2.189 g/h to 3.227 g/h with yarn diameters ranging from 200 μm to 386 μm. This device firstly formed nanofiber bundles on a rotating disc, then the nanofiber yarn was wound by a take-up roller. The CNE eliminated the problems associated with needle electrospinning, but mechanically moving parts still constrained the production rate by generating air whip.

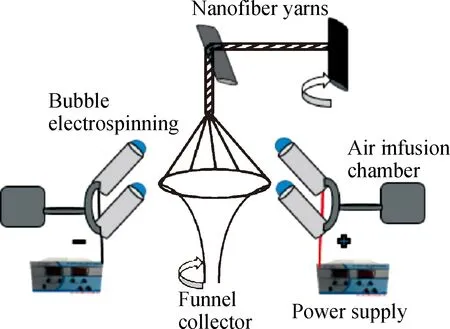

Blown bubble spinning (BBS) is a modification in bubble electrospinning, in which hot air in the form of two opposite “V” shaped streams, pulls the bubble rapidly and continuously to produce twisted fiber bundles[49-53]. The setup of BBS is shown in Fig. 4(b). Dou and Liu[54]introduced this direct method of production of nanofiber yarns and successfully produced nylon6/66 micro yarns with a diameter of 23 μm containing nanofibers of 376 μm. The angle of hot air courses plays a crucial role and is responsible for the entanglement of nanofibers. This method has the advantage of simple setups with few components. But it was not mature enough to fabricate yarns with continuous length[55].

(a)

2 Mechanical Properties of Nanofiber Yarns

Mechanical properties of nanofiber yarns are far better compared to those of the nonwovens due to the regular arrangement of nanofibers in the yarn structure. The twist angle and the twist of the yarn are important parameters to characterize the degree of fiber twisting[56].The larger the twist angle is, the greater the twist of the yarn is. At the same time, the greater the crystallinity of the yarn is, the better the mechanical properties of the yarn are. Mechanical properties determine the application field of yarns, and good mechanical properties are the key to the wide application of nanofiber yarns. Table 2 compiles the mechanical properties of nanofiber yarns produced by above mentioned spinning methods. Abbreviations are explained here, polyvinylidene fluoride-trifluoroethylene (PVDF-TrFe), Polycaprolactone (PCL), PVDF-hexafluoropropylene (PVDF-HFP), poly-L-lactide (PLLA).

Table 2 Different techniques of electrospinning nanofiber yarns and their mechanical properties

2.1 Effect of spinning parameters on mechanical properties of yarns

The parameters of electrospinning mainly include solution concentration, solution viscosity, spinning voltage, polymer flow, receiving distance, ambient temperature, ambient humidity,etc. The process parameters of electrospinning are important factors affecting the morphology of nanofibers, so it is of great significance to study the influence of spinning parameters on the yarn properties[63-64].

Douetal.[65]studied the influence of spinning parameters on the mechanical properties of nanofiber yarns with nylon 66 as the raw material, including solution concentration, spinning voltage, flow rate and spinning distance. It is observed that the concentration of the spinning solution has the most significant effect on the mechanical properties of the yarn. With the increase of the concentration of the spinning solution, the breaking strength of the yarn shows a declining trend. This is because when the concentration of the spinning solution is low, there is adhesion between nanofibers in the yarn and these adhesion points will increase the strength of the yarn. When the concentration of the solution is high, the diameters of the yarn and its internal nanofibers increase. According to the weak node theory, the probability of defects increases and the mechanical properties of the yarn become worse.

2.2 Method of improving mechanical properties of nanofiber yarns

In the process of electrospinning, due to the rapid solidification of polymer jets, nanofibers prepared by electrospinning generally have poor crystallinity and mechanical properties[66]. At present, the twist angle of the nanofiber yarn prepared by most methods is not easy to control and the twist is low[67]. Therefore, it is necessary to find new ways to improve the mechanical properties of the nanofiber yarns. The methods of improving the mechanical properties of nanofiber yarns include hot water-bath treatment, adding carbon nanotubes and introducing regulators.

2.2.1Hot-water-bathtreatment

Jalilietal.[68]improved the mechanical properties of nanofiber bundles by hot-water-bath treatment. The nanofiber bundles were prepared by solution electrospinning using PAN as raw material. After the preparation, the nanofiber bundles were tensioned in water at 94 ℃ for 10 min, and then dried at 110 ℃. The mechanical properties of the nanofiber bundle before and after hot-water-bath treatment were compared. The strength and the elongation of the untreated fiber bundle were 2 786 MPa and 43.34%, respectively. The strength and the elongation of the fiber bundle after hot-water-bath treatment were 4 575 MPa and 18.37%, respectively. The tensile strength increased by 64.21%. The essence of hot water bath treatment is to remove the residual stress between yarns and improve the mechanical properties. Hot-water-bath treatment has the advantages of simplicity and low cost, but the improvement of the mechanical properties of the yarn is limited. Therefore, it is difficult to meet the needs of practical applications of the yarn.

2.2.2AddingCNTs

CNTs have excellent mechanical properties. CNTs can be utilized as reinforcement by using other engineering materials as matrix in a composite material. Some researchers have improved the mechanical properties of nanofiber yarns by adding CNTs[69-70]. For example, Lietal.[70]used PAN as matrix to prepare nanofiber yarns by water twisting. In the process of preparation, water bath was replaced by the multi-walled nanotubes (MWNTs) water dispersion system. After the nanofiber yarn was extracted from the MWNTs water dispersing bath, the surface of the yarn was covered with a layer of MWNTs non covalent coating. The mechanical strength test results show that the tensile strength and the tensile modulus of the yarn with CNTs increase by 600% and 690%, respectively, compared with those of the untreated nanofiber yarn, and the yarn has considerably improved the electrical conductivity. The principle of adding CNTs is to coat the yarn with CNTs to enhance its mechanical properties. The mechanical properties of nanofiber yarns can be greatly improved by adding CNTs, but the cost of CNTs is relatively high. This method is suitable for aerospace, military science and technology and other fields.

2.2.3Addingregulator

In order to meet the performance requirements of mass application, some researchers began to find low-cost regulators to improve the mechanical properties of yarns. The principle of adding regulators is to alter the chemistry of spinning raw materials, improve the crystallinity of the solute, and then improve the mechanical properties of the yarn. Suietal.[71]found that in the process of the electrospinning poly(methyl methacrylate) (PMMA) nanofiber yarn, adding a small amount of sodium chloride (NaCl) could enhance the molecular arrangement of the nanofiber yarn in the formation process, and thus significantly improve the mechanical properties of the yarn. The tensile strength of untreated PMMA nanofiber yarn is 35.0 MPa, and that of treated NaCl-PMMA nanofiber yarn is 79.9 MPa, which increases by 128.9%. Compared with that of CNTs, the cost of NaCl regulator is greatly reduced and the mechanical properties of yarns are improved significantly. Therefore, the method of adding regulator is helpful to the realization of batch preparation.

3 Applications of Nanofiber Yarns

3.1 Application of nanofiber yarns in field of intelligent fabrics

The characteristic of intelligent fabrics is the combination of fabrics and electronic devices, which shows the flexibility that the electronic device does not have. Flexible conductive materials can help intelligent fabrics to achieve sensing function, feedback function, and response function[72]. At present, flexible conductive materials based on fibers include conductive polymers[73], metal oxides[74], carbon materials[75],etc. Electrospun nanofiber yarns has broad prospects in the manufacturing of intelligent fabrics.

3.1.1Electronicskin

Nanofiber yarns that can transmit signals conductance can be used in the field of electronic skin. Zhongetal.[76]prepared a stretchable nanofiber yarn using polyolefin elastomer (POE) and three-dimensional silver nanowires (AgNWs). The POE nanofiber yarn was dispersed in uniformly suspended solvent system of AgNWs by ultrasonic vibrations. The continuous AgNWs enabled the nanofiber yarn to conduct electrical signals. The researchers applied it to the electronic skin, which could perform the diagnosis of human vocal cord vocalization, expressions monitoring and detection of human pulse, shown in Figs. 5(a)-(c). Chengetal.[77]produced an electronic skin based on the multi-purpose sensor using composite nanofiber yarns. PU fibers helically wounded by a layer of polyester (PE) yarns were dip-coated in AgNW dispersion in ethylene followed by quick drying and stretching to generate evenly distributed cracks on the surface of the AgNW film. The conductivity of the yarn was tuned by dip-coating cycles. The sensor was tested on hand to monitor proximity, pressure and multidirectional strain on local muscles occurring by palm and thumb movements, as shown in Fig. 5(d). Qietal.[78]developed a pressure sensor based on core-sheath nanofiber yarns with high sensitivity and spatial tactile acuity. Ni coated cotton yarn was used as an electrode in core and electrospun CNT-embedded PU nanofiber wrapping was served as sheath. The developed sensor is able to monitor the subtle psychological signals to vigorous body movements. The sensor is applied on the human wrist to monitor the pulse in real time, as shown in Fig. 5(e). Furthermore, an interlaced structure is developed with point-to-point overlapping of the core-sheath nanofiber yarn for large contact area and high sensitivity, as shown in Fig. 5(f).

(a)

3.1.2Flexiblesensor

The nanofiber yarn endowed with conductivity can be used for the preparation of flexible sensors, which can show the suppleness that traditional sensors do not have. Jangetal.[79]reported intelligent braided composite materials using three-dimensional braiding technology, and embedded CNT yarn sensors into the composite materials. As a built-in sensor of three-dimensional braided composite material, CNT yarns can be used to monitor the internal damage of the test specimen. Wangetal.[80]recently developed a yarn supercapacitor (YSC) as a flexible energy storage device based on directly twisted CNT@bacterial cellulose membrane followed by electrochemical deposition of polypyrrole (PPy). The developed capacitor showed a high areal capacitance of 458 mF/cm2at less than 1 mA/cm2. More significantly, the YSC also exhibited specific capacitance stability, even after 2 000 cycles of charging and discharging.

Jangetal.[79]attempted to produce entangled CNT yarns to be used as an elastic strain sensor over a large range (up to 500%). The entangled arrangement was created by over-twisting the nanofiber yarn in order to generate a snarled and knotted structure that changed electrical resistance reversibly and linearly when unencumbered by pulling the yarn ends (tensile strain). Such type of CNT yarns can be used in smart electronics which require diverse physical movement while sensing the strain deformation.

3.1.3Smartclothing

Kimetal.[81]prepared the yarn by using CNTs followed by soaking the yarn in the electrolyte after completion, so that the ions in the electrolyte adhered to the surface of CNTs. When the yarn is tightened or stretched, the distance between the CNTs becomes smaller, and the density of ions gathered together becomes larger, so the mechanical energy in the process of tightening and stretching can be converted into electrical energy. The experimental results show that the maximum power output per kilogram of yarn is 250 W. The researchers sewed the yarn onto shirts for breath tests.

Although researchers have achieved some success in the field of intelligent fabrics, but most of their work is still in the stage of concept proof in the laboratory. Prototypes should be tested for inevitable factors involved in commercial use like wear and tear, wash-ability, working temperature and humidity. Future work needs to put forward requirements on the performance of the material according to the actual needs of intelligent fabrics, and then improve the yarn preparation process according to the performance requirements.

3.2 Application of nanofiber yarns in field of bioengineering

Tissue scaffold materials with excellent performance are required to be able to imitate the growth environment of cells in the body and require certain mechanical properties. Currently, the nanofiber membranes collected in the form of non-woven fabrics have poor mechanical properties, which limits their application in the field of tissue engineering. The electrospun nanofiber yarn can significantly improve the mechanical properties of nanofibers and it is an ideal material for tissue engineering. Yangetal.[82]developed an electrospinning oriented nanofiber yarn scaffold for tendon tissue engineering. They used a silk fibroin and polycaprolactone blend as raw materials, and used a two-electrode system to prepare a scaffold based on nanofiber yarns by electrostatic spinning technology. The research results show that the tissue scaffold prepared from nanofiber yarns has a higher cell proliferation rate, a larger pore size and a higher porosity. Although yarns have obvious advantages as tissue scaffolds, there are still some challenges, such as the homogenization of the size and the structure of electrospun nanofiber yarns, the mechanical matching between yarns and cells, and the biocompatibility of yarns implantedinvivo. These challenges need to be overcome by engineering researchers and biological workers.

3.3 Application of nanofiber yarns in the field of electronic devices

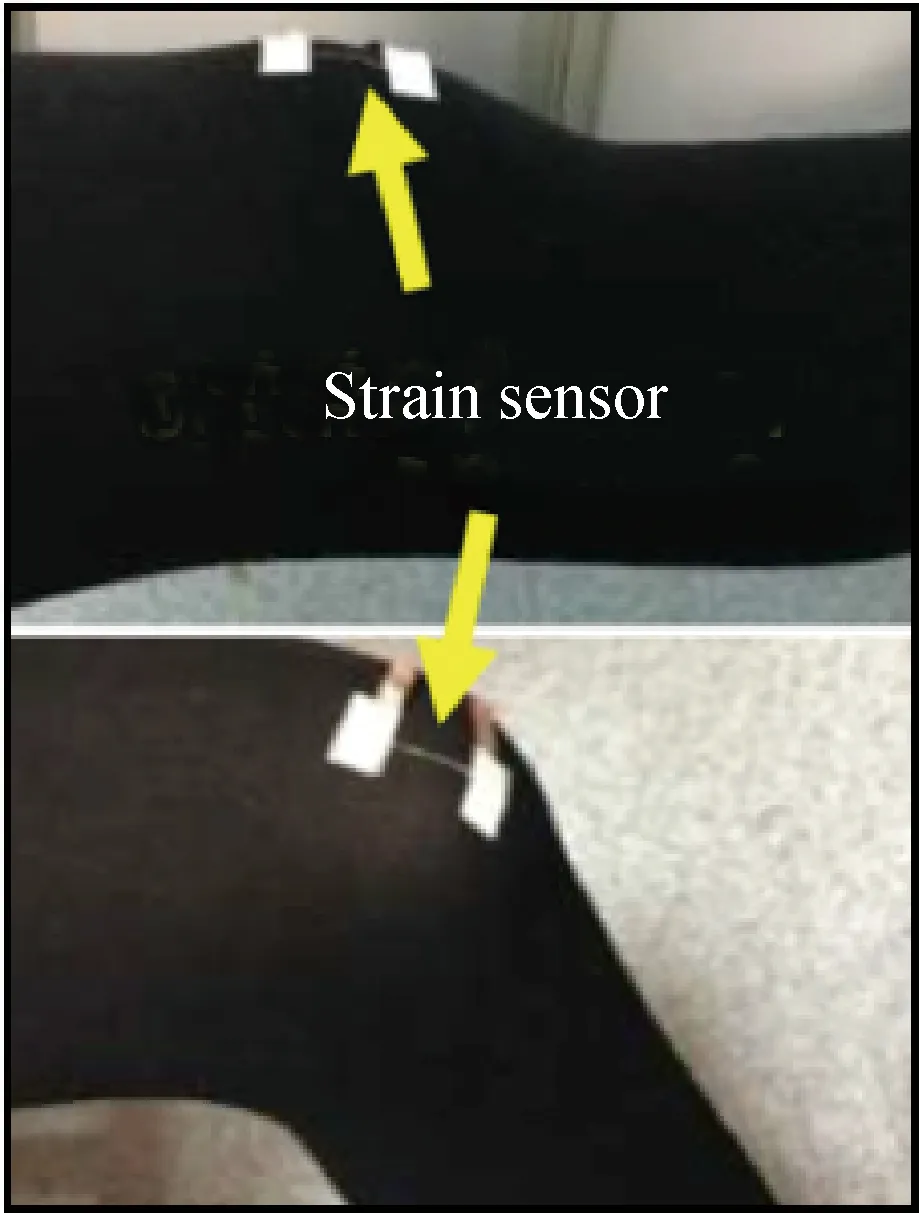

Nanofiber yarns have broad application prospects in the field of electronic devices. Leeetal.[83]prepared a SnO2nanotube micro-yarn and characterized its gas-sensing properties. The results show that the SnO2nanotube yarn at 400 ℃ has stable hydrogen sensing performance and can be used in the field of hydrogen sensors. Nanetal.[84]developed a multimodal mechanical sensor based on electrospun conductive nanofiber yarns using graphene oxide (GO)-doped PAN nanofiber yarns produced by the CNE method. Then electrospun yarn was coated with conductive PPy viainsitupolymerization. The resulting conductive yarn was wound on the elastic yarn to enhance the stretch ability. The developed sensor has the ability to detect the mechanical stress induced by static and dynamic pressure, strain, and bending. Due to the ease of weave ability into textiles, it has great potential in weavability devices, human health monitoring, sports monitoring, and robotics. Nano-scale sensors have high sensitivity, but at the same time, they also put forward higher requirements for repeatability, stability and mechanical properties.

4 Summary

In summary, many researchers have demonstrated efficient ways to produce nanofiber yarns or its composites with great potential to be used in wearable electronics. Their applications cover sensing, monitoring, detection and actuation of subtle movements. Uses of nanofiber yarns in piezoelectric, energy storage, implantable, flexible, stretchable and smart devices are also notable. However, it is not fully understood that what impact these devices will leave on human body. Substances used in the preparation, and electromagnetic waves generated from the sensor could adversely affect local cells and human behavior. In light of this point, nanofiber yarns based sensors require rigorous testing for animals and human safety. In future, researchers can develop self-powered sensing devices to remotely monitor the mood, behavior and movements of different species.

5 Conclusions

Well known for the higher surface to volume ratio and far better electrical and mechanical properties, electrospun nanofibers are taking us to a new digital era. High sensitivity and super conductivity of nanofiber yarns can be perfectly utilized in intelligent fabrics, energy harvesting devices, bioengineering and flexible electronic units. Researchers have developed several ways to produce nanofiber yarns, and their properties like tensile strength, elasticity, conductivity, and elastic recovery have been considerably enhanced. However, there are still some problems to be solved for successful industrialization. For example, system stability and production efficiency of available spinning methods are not good enough to use at the industrial scale. Moreover, mechanical properties of nanofiber yarns still cannot meet the requirements of many applications. There is a need to explore the cost effective methods to enhance the mechanical properties of yarns. Development of a mathematical model could be helpful for better understanding and making strategy for improving mechanical properties. Wearer comfort is another issue to be considered for ease of use in long term.

Journal of Donghua University(English Edition)2021年2期

Journal of Donghua University(English Edition)2021年2期

- Journal of Donghua University(English Edition)的其它文章

- Rational Design of a High-Performance KMnO4-Fe(Ⅱ)-Si Coagulant for Dye Removal

- Thermal Insulation Properties of Microfibrillated Cellulose Aerogel

- Mechanical and Thermal Properties of Apocynum and Ramie Fiber Mat Reinforced Polylactic Acid Composites

- Symmetry Classification of Partial Differential Equations Based on Wu’s Method

- Numerical Simulation of Space Fractional Order Schnakenberg Model

- Meta-Analysis on the associations between Prenatal Perfluoroalkyl Substances Exposure and Adverse Birth Outcomes