Effect of dilution gas composition on the evolution of graphite electrode characteristics in the spark gap switch

Hongyu DAI(戴宏宇),Lee LI(李黎),Shuai REN(任帥),Jingrun GUO(郭景潤(rùn)),Xin GONG(宮鑫) and Anthony Bruce MURPHY

1 State Key Laboratory of Advanced Electromagnetic Engineering and Technology,Key Laboratory of Pulsed Power Technology(Ministry of Education),School of Electrical and Electronic Engineering,Huazhong University of Science &Technology,Wuhan 430074,People’s Republic of China

2 CSIRO Manufacturing,Lindfield NSW 2070,Australia

Abstract As the widely implemented electrode material,graphite has the characteristic of sublimation by the thermal shock of the switching arc,and the produced carbon vapor is easy to condense into carbon powders and deposit in the switch.The impact of the type of dilution gas in a mixture of 20% oxygen and 80% dilution gas on the sublimation and oxidation characteristics of the graphite electrode is investigated.It is found that when nitrogen dilution gas was replaced by argon,the heat flux to the electrodes decreased,which led to a 63% reduction of graphite sublimation.At the same time,the cooling rate of the arc was slower in argon,which promotes oxidation of the carbon vapor.The residual solid carbon can be reduced by 70%–85%by using argon as the dilution gas.Consequently,it is demonstrated that the stability and working life of the switch could be increased by appropriate selection of the dilution gas.

Keywords:pulsed discharge,graphite electrode,thermal arc,dilution gas,electrode erosion

1.Introduction

The graphite-electrode spark gap switch is a type of gap switch that uses a non-metallic conductor as the electrode material.Its peak power is up to several gigawatts and its current-carrying capacity is several hundreds of kiloamperes.The spark gap switch is the optimal choice for use in the laser power supplies because of its extremely high current-carry capacity[1,2].At the same time,it has been broadly applied in the underwater pulsed discharge[3],controlled nuclear fusion[4],and other devices that require high pulsed current as the input condition.The arc,which transfers high energy fluxes across the gas gap,is a kind of thermal plasma,which has a temperature in the order of 104K.The root of the arc is in direct contact with the electrode,and the heat flux is extremely high at the contact area.As a result,electrode erosion is an ongoing problem.

The heat flux from the arc leads to sublimation of the graphite electrodes[5].The erosion processes of metal and non-metal materials are quite different.After heating by the arc,the metal material first melts into liquid state.Then,the liquid metal film on the electrode surface is splashed under the action of the Lorentz force,the shock wave force[6],and the thermal explosion force of the arc[7],and continues to vaporize in the high-temperature arc column[8],resulting in a severe mass loss from the electrode.However,the phase transition temperature of graphite is different from that of metal electrodes[9],and its melting point and boiling point are approximately the same.When the temperature exceeds about 4000 K,the graphite begins to sublimate[10].Because graphite has no liquid phase at atmospheric pressure,the surface of the graphite electrode is relatively flat after a discharge[11].In addition,the thermal conductivity of graphite is low at high temperatures.So the ablation range is effectively controlled because there is an approximately adiabatic process[12],which reduces the mass loss of the electrode.Donaldson and Kristiansen have confirmed that the graphite electrode has a lower mass-loss rate than a tungsten–copper electrode when the amount of transferred charge is greater than 25 C[13].Although the selection of graphite electrodes has significantly decreased the rate of electrode loss,the maintenance cycle of gap switches is still determined by the lifetime of the electrodes.The mass loss of electrodes still restricts the development of long-lifetime spark gap switches.

The mechanism of thermal erosion of graphite has been studied for a long time.Graphite has a layered structure,and van der Waals bonds connect each layer.The carbon atoms in each layer are bonded covalently to form a hexagonal network[7].On the surface of graphite electrode,the bond structure is weak at the locations with geometry defects,and carbon atoms can be easily removed under the effect of the arc.Then,a local ablation pit is formed[13].Early studies show the amount of mass loss of graphite electrodes is proportional to the transferred charges[14].The insulating gas composition is also an important factor in determining the mass loss of the electrode.

Affinito et al[15]studied the phenomena associated with the gas composition in the switch,demonstrating that pure N2is more likely than air to lead to failure of the switch.The same result was obtained by Donaldson et al[16],who found a large amount of amorphous carbon ejected from the graphite surface and accumulated on surrounding insulator for repetitive pulse discharges in pure N2.Vinaricky et al[17]noted that Ar will not react with graphite in the way that air and N2do.Therefore,it has a less destructive effect on the surface morphology of the electrode.For other gases,the damaging effects of SF6are stronger than N2[18].The ablation intensity depends on the ionization state and collision frequency of the discharge gas molecule.

The high-current arc is a form of local thermodynamic equilibrium(LTE)plasma[19].The numerical analysis of thermal plasmas,taking into gas properties is well established[20].Nowadays,the ‘a(chǎn)tmosphere control method’ is being used as an efficiency optimization strategy in the fields of plasma gas decomposition[21],material modification[22],disinfection and sterilization[23].It has also been widely used in arc welding[24],nano material preparation[25,26]and other fields.In this way,the intensity of the heat source of the arc can be changed.Previous research has shown that the temperature of Ar arcs is lower than those of many other gases,the inert nature of Ar also prevents chemical reactions[27,28].

Unoxidized graphite vapor will condense as solid carbon powder,which can lead to damage to the insulation of the switch.A volume fraction of 20% O2has been shown to reduce the production of solid carbon by promoting gas-phase oxidation reactions[29].In this work,the erosion characteristics for the traditional dilution gas of 80%N2and the novel dilution gas of 80% Ar,both combined 20% O2,are compared in pulsed discharges.The morphological changes to the graphite electrode are examined on microscopic level by surface morphological analysis and on macroscopic level by mass analysis,revealing the differences in the erosion reactions in the different dilution gases.

2.Experimental methods

2.1.Experimental setup

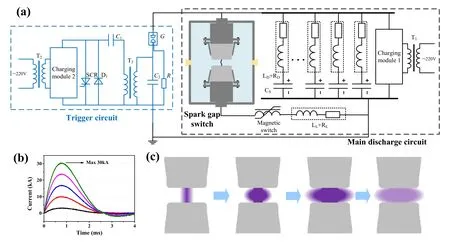

A high-current discharge platform was built to study electrode ablation.As shown in figure 1,there was a trigger circuit and a main discharge circuit.The main discharge circuit was mainly composed of energy storage capacitors Cs,and damping inductors LD(in which the resistance is RD).The spark gap switch included an insulating shell with epoxy material,inlet and outlet nozzles and a pair of graphite electrodes.A magnetic switch was used to maintain the cathode potential of the spark gap switch when the trigger voltage is generated[30].The working principle of the discharge platform was explained in detail in a previous paper[31].

Figure 1.Schematic diagram of the experimental apparatus.(a)Electrical circuit,including trigger circuit and main discharge circuit;(b)five different current waveforms under discharge voltages of 1 kV,3 kV,5 kV,7 kV,9 kV;(c)schematic diagram of the shape change of the arc with the pulsed current.

The energy storage capacitor Csand damping inductor LDconstitute an energy storage module.There were 48 groups of energy storage modules.The capacitance of each module was 110 μF,and the inductance and resistance were 73 μH and 112 mΩ respectively.An inductor LL=73 μH with resistance RL=112 mΩ was chosen as the load.The amplitude of the pulsed current and the amount of transferred charges can be adjusted by changing the voltage across Cs.

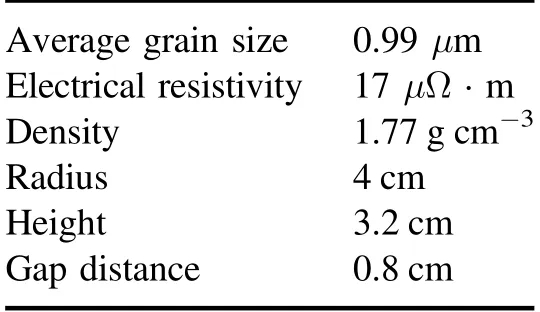

The electrodes of the spark gap switch were made from EDM-AF5 graphite supplied by the POCO company.The surface was polished by ultrafine sandpaper.The properties and geometric parameters of the electrodes are shown in table 1.

Table 1.Parameters of graphite electrodes.

Two gas nozzles were connected to the pneumatic circuit,which was a control apparatus of the outer gas cylinders and can be used to control the gas pressure of the switch chamber.The working pressure was set to 230 kPa.

2.2.Experimental procedure

The experimental steps used in this paper were as follows:

(1)The pneumatic circuit was connected to the switch to ensure the chamber is completely sealed.A Pearson Rogowski coil(0.02 mV A?1)was connected between the switch and the load to monitor the discharge current.A Tektronix P6015A was connected to the anode of the switch to monitor the voltage.

(2)The pre-mixed gas with 80% N2+20% O2was introduced into the pneumatic circuit and circulated for 1 min at a rate of 2 l s?1.Then,the pneumatic circuit was set to ‘internal recycle’,and the pressure was increased to 230 kPa.

(3)The storage capacitor was charged to the predetermined voltage.The voltage range was 1–9 kV with a step size of 2 kV.The current waveform,shown in figure 1(b),was recorded by a Tektronix DPO4104B oscilloscope.

(4)After the discharge,the gas in the switch cavity was collected,and measured by a Temet GASMET DX4000 Fourier infrared flue gas analyzer.

(5)The switch was then disassembled and the electrodes removed.A Carl Zeiss GeminiSEM300 scanning electron microscope(SEM)was used to view the surface morphology.A Keyence VK-X200K laser confocal scanning microscope(LCSM)was used to detect surface roughness.

(6)The platform was set to ‘a(chǎn)uto run’ mode.Under the rigid condition,repeated discharge was carried out 100 times,and the electrode mass before and after discharge was recorded by an Ohaus AR224CN electronic balance with the accuracy of 0.1 mg.

(7)The gas was replaced with the 80% Ar+20% O2mixture.The above steps were repeated.

3.Measurements and analysis of graphite electrode erosion

The effects of thermal erosion and oxidation on graphite electrodes are analyzed for the two dilution gases.The mass loss of the electrodes is analyzed with the influence of gas composition studied on microscopic and macroscopic levels.

3.1.Effect of dilution gas on graphite geometric properties

The micro-morphological characteristics of the ablated area on the graphite surface are measured for the two dilution gases.A charging voltage of 9 kV was used.As shown in figure 1(b),the peak current was 30 kA.The ablated regions after three discharges are shown in figure 2.The shape and location of these regions show that the center of the contact area between the anode and the arc is located at the edge of the electrode.The discharge channel is formed in the area where the electric field distortion is strongest.The center of the ablated region on the cathode is directly above the center of the ablated region on the anode.The ablated spots on the surface can be divided into two types.The region in the center in which erosion is uniform can be called the erosion center(EC).There is also a region with a sputtered texture around the ablation center,which can be attributed to heat flow damage(HFD)around the arc’s periphery.

Figure 2.Surface morphology of graphite electrode after three discharges at a peak current of 30 kA.

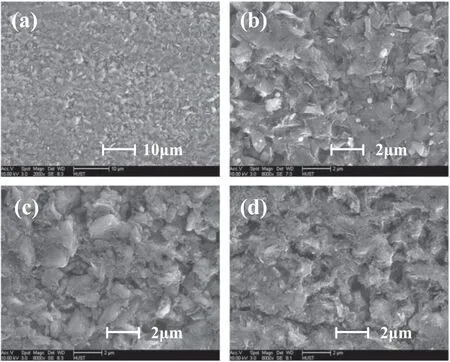

The morphology changes detected using the SEM are shown in figure 3.The clearly delineated grains visible on the original graphite surface disappear in the HFD and EC area.

Figure 3.Surface morphology of anode measured by SEM,(a)initial state in the scale of 10 μm,(b)initial state in the scale of 2 μm,(c)HFD area in the scale of 2 μm,(d)EC area in the scale of 2 μm.

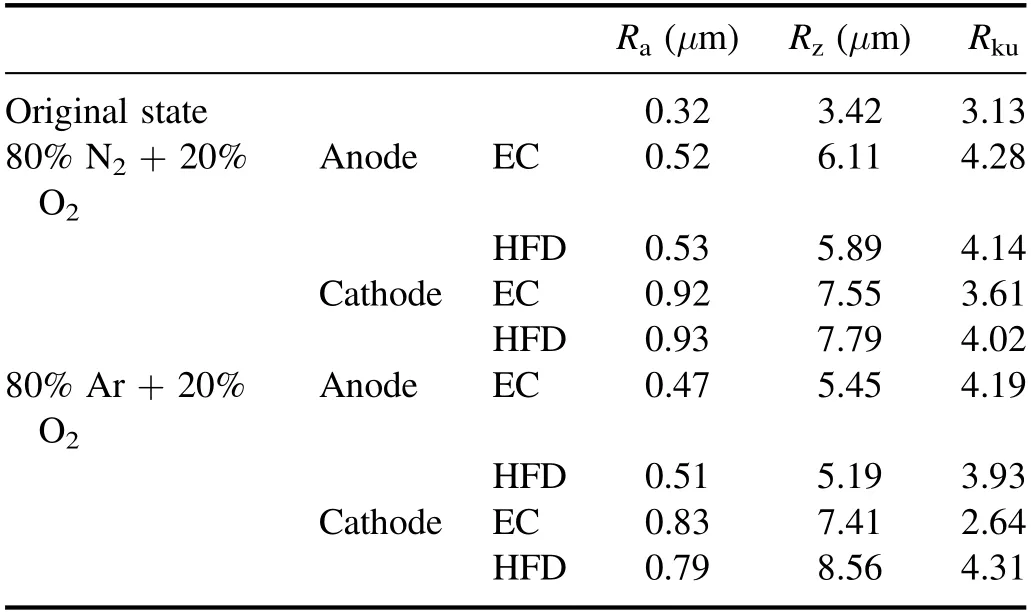

Table 2.Surface roughness of the center and edge of the ablated region in N2 and Ar dilution gases.

The EC area on the anode is smaller and more uniform than that on the cathode.This may attribute to the movement of the arc attachment location on the cathode.The arc tends to concentrate in the high electrical conductivity region,so the EC area carries more current.When using N2as the dilution gas,the radius of the EC is between 12.2 and 14.1 mm.For Ar dilution gas,the radius of the EC is smaller.However,the region with sputtered texture is larger,and the radius of the HFD area is larger,up to 25.3 mm.The radius of the HFD region when using N2as the dilution gas is between 13.8 and 16.3 mm,which is slightly larger than the EC radius.

Both the area and roughness of the damaged region can reflect the intensity of the ablation.The difference in the roughness between the anode and cathode is obvious from the LCSM measurements,as shown in table 2.In the table,roughness is expressed as Ra,Rz,and Rkuaccording to the the ISO 4287:1997 standard.Rais the arithmetical mean deviation of the assessed profile,Rzis the maximum peak to valley height of the profile,and Rkuis the kurtosis of the assessed profile.Under the thermal shock of the arc,the surface roughness of both electrodes increases significantly;the changes to the morphology of the cathode are more significant.This demonstrates that the heat flux is distributed unevenly in the sputtering area.The roughness changes on the surface of the anode and cathode are lower in the Ar dilution gas than in N2,which indicates that the heat flux at the contact area is smaller in the Ar case.

3.2.Effect of dilution gas on the chemical reaction of graphite

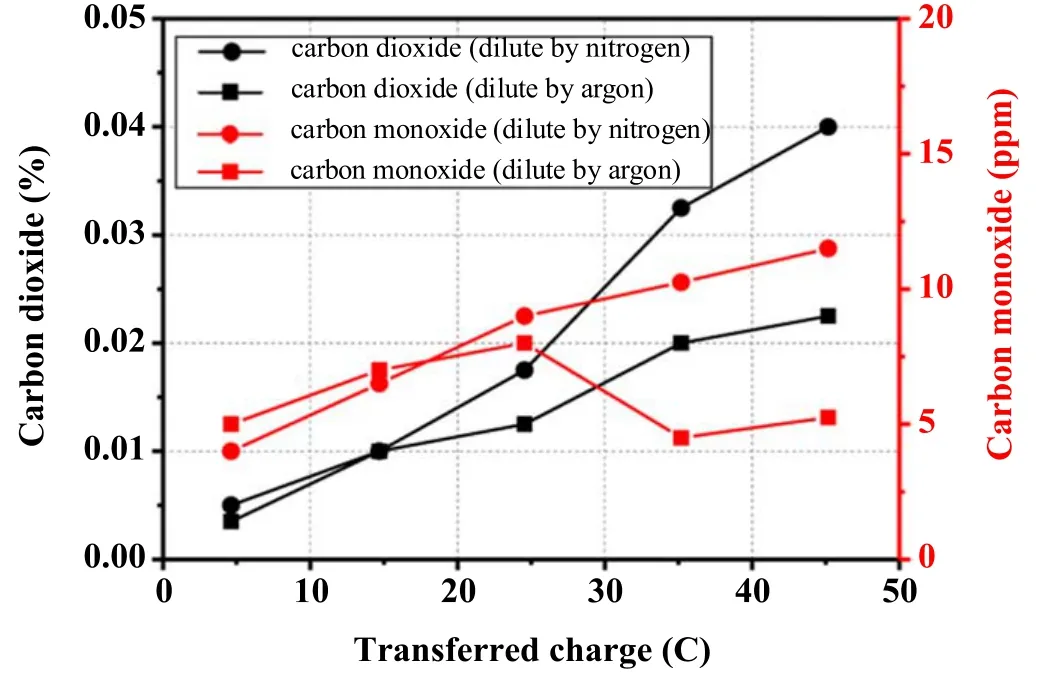

The solid graphite forms carbon vapor when it is heated to the sublimation point.The vapor enters the arc column,and reacts with the ionized gas to form gaseous carbon oxides.The concentration of the products CO and CO2is shown in figure 4.The trends of CO and CO2concentration are similar for low transferred charge in different dilution gases,but the CO2concentration increases rapidly in N2dilution gas when the transferred charge exceeds 30 C.

Figure 4.Variations in CO and CO2 concentrations with the transferred charge.

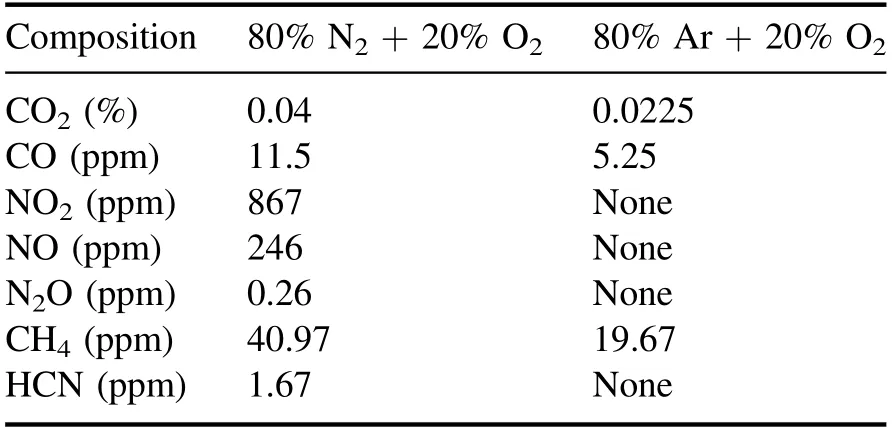

After one single discharge at a charging voltage of 9 kV,the composition and concentration of the gaseous products are measured by the Fourier infrared flue gas analyzer.The results are shown in table 3.

Table 3.Composition and concentration of insulating gas after one discharge with the peak current of 30 kA.

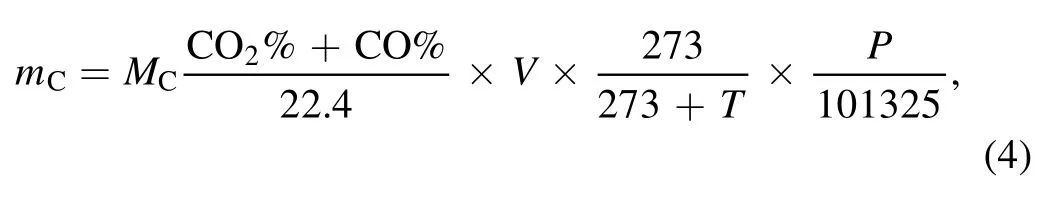

When Ar is used as the dilution gas,there are no nitrogen oxides formed,and the consumption of O2is lower.HCN is discovered in a high-current graphite-electrode spark gap switch.When the arc temperature rises to about 2773 K,free nitrogen atoms still exist[32],which easily combine with carbon atoms to generate cyanide radicals,including CN and C2N2.CN is not stable at room temperature[33],and as the temperature decreases,it reacts with O2,as shown in formulas(1)and(2).However,HCN is stable,and can be formed by reactions with water vapors,as shown in formula(3).The detection of HCN and CH4indicates that water vapor is present in the chamber.

In general,the oxidation of carbon vapor is incomplete,and it quickly reaches a ‘hypoxic’ state.Therefore,unoxidized carbon vapor condenses as solid carbon,which remains in the switch chamber in the form of powder or aerosol[29].

3.3.Effect of dilution gas on mass loss of graphite electrodes

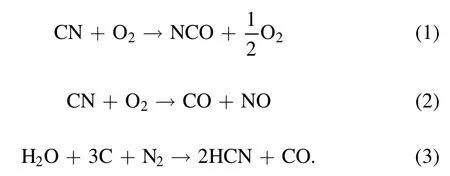

The carbon in the gaseous products is mainly in the form of CO2and CO.The mass of carbon in these gases can be expressed as

where MCis the relative molecular mass of carbon,V is the volume of the switch chamber,T is the temperature,and P is the pressure in Pa.

The thermal erosion effect of the arc on the graphite electrode is manifested by the removal of graphite particles.In the contact area between arc and electrode,graphite particles escape from the close-packed structure,leaving pits of micro-scale diameter.When the discharge time is increased,the steep edges of the pit become vulnerable to be shocked,which increases the area of the pit.The surface of the electrode subsides when the switch is discharged tens of thousands of times.The gap distance between the anode and cathode gradually increases until it is too long to be triggered.

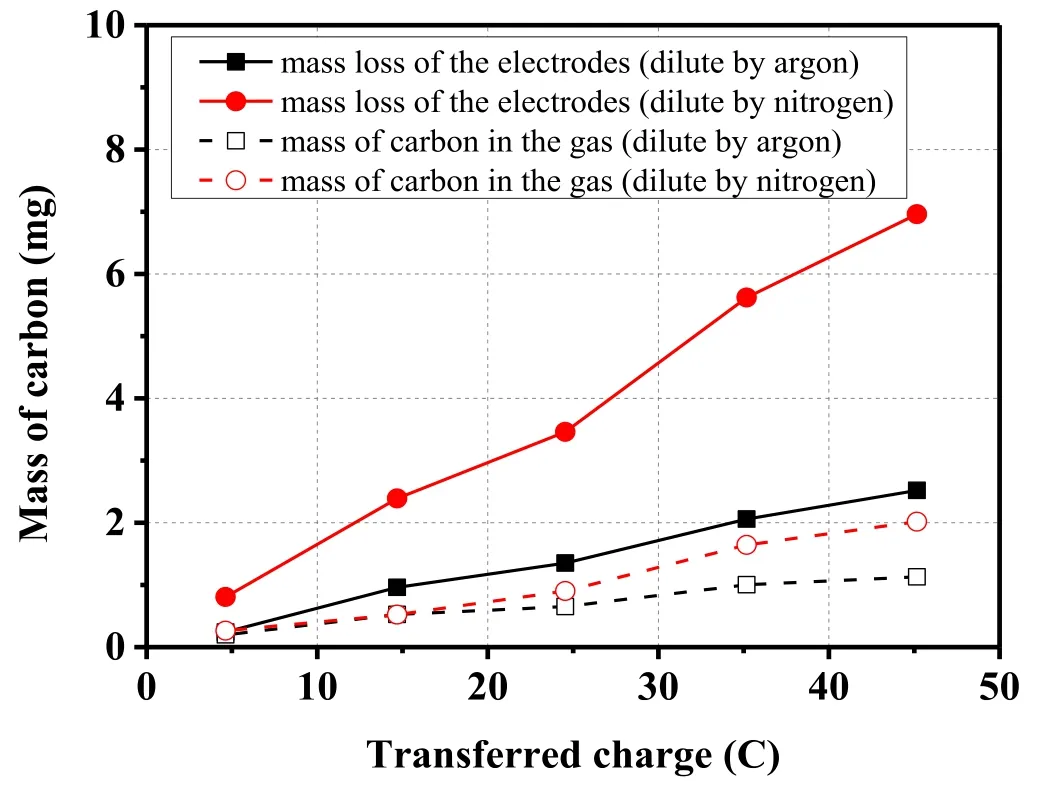

The dependence of electrode mass change on the transferred charge was studied[34,35].The switch discharge was repeated 100 times for the transferred charges of 4.6 C,14.6 C,24.5 C,35.1 C and 45.3 C to measure the mass loss of the electrode.The total mass of the cathode and anode before and after discharges was measured by an electronic balance,and the mass of carbon in the gas phase was calculated by equation(4).

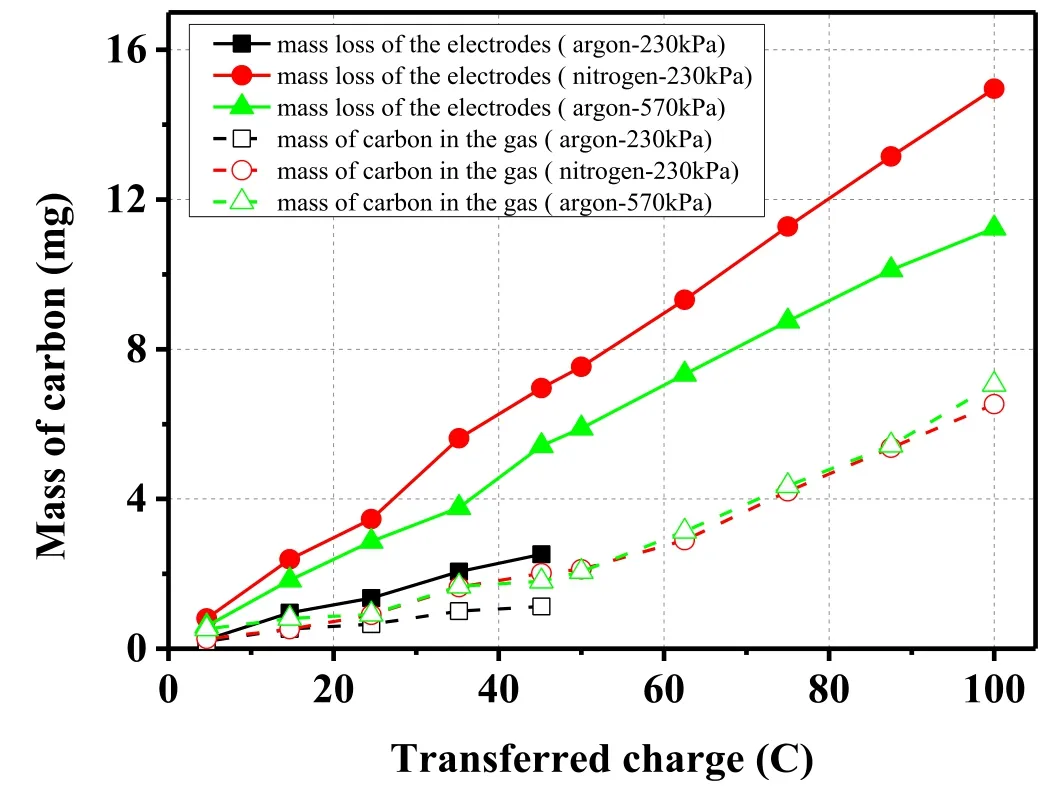

As shown in figure 5,in the same discharge atmosphere,the mass loss of the electrode is approximately linearly related to the amount of transferred charge.By linear fitting,it is found that the mass-loss rate of the electrode in the dilution gas of Ar is 0.0557 mg C?1,64% lower than that for N2.According to the conservation of mass,the mass of residual solid carbon is the difference between the sublimated mass of graphite and the mass of carbon in the gas phase.The residual solid carbon can be reduced by 70%–85%by replacing N2by Ar dilution gas.

Figure 5.The dependence of carbon mass lost from the electrodes and in the gas phase on the amount of transferred charge for N2 and Ar dilution gases.

4.Discussion

4.1.Sublimation of the graphite electrode

The pulsed discharge is a strongly transient process.As shown in figure 1,the overvoltage of the trigger system breaks down the insulating gas to form the initial arc channel.The arc current rises to peak value in 0.6 ms.As the gas surrounding the arc column was ionized,the radius of the discharge channel increases.New spots on the cathode emitted more electrons during the current rising phase.The new discharge channels that are formed converge to the main ionization channel by the influence of Lorentz force in the arc.The arc channel approximately conforms to the LTE state[36].

The erosion rate of the electrode depends mainly on the intensity of the heat flux to the electrode[37].For the graphite electrode,there is no liquid phase at the working pressure.The evaporation caused by the heat flux is the main factor affecting the mass loss of the electrode[18].

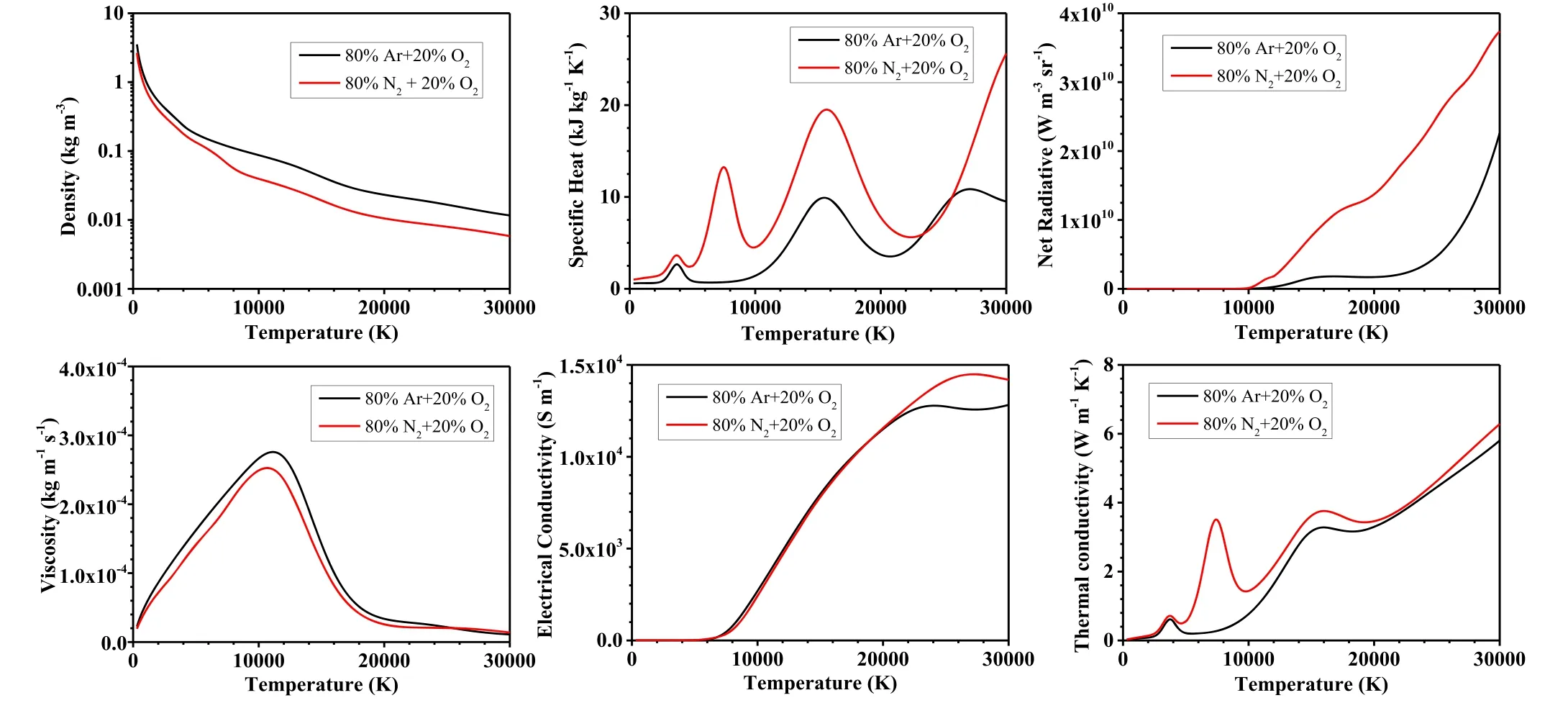

The plasma composition data are required in the calculation of the thermodynamic properties of the switching arc.The composition was calculated using the method of minimization of Gibbs free energy,which assumes the existence of local chemical equilibrium,and follows from the assumption of LTE.The required thermodynamic data were obtained from the tabulated by Moore[38]and JANAF Tables[39].

The oxygen species considered in the calculation were

Figure 6.Thermodynamic properties and transport coefficients for the N2 and Ar dilution gases at 230 kPa.

A magneto-hydrodynamic model was established to obtain the temperature distribution of arc plasma.The arc in the model was assumed to be in the LTE state.The mass conservation,momentum conservation,and energy conservation equations were coupled with current continuity to describe the fluid mechanics and current density of the arc.

The equation of mass conservation is

The equation of momentum conservation is

The equation of energy conservation is

wheretis the time,ρis the mass density,is the velocity,pis the pressure,is the viscous stress tensor,is the current density,is the Lorentz force produced by the selfinduced magnetic field,his the enthalpy,kis the thermal conductivity,cpis the specific heat,Uis the NEC,andkBis the Boltzmann constant.

The equation of current continuity is

The magnetic fieldis calculated from the vector potential.

whereσis the electrical conductivity,φis the electric potential,andμ0is the magnetic permeability in vacuum.

The maximum current waveform in figure 2 is selected as the input condition of the calculation model.The temperature distribution is shown in figure 7.At the time 0.1 ms,when the current is rising,the temperature of the N2arc is obviously higher than the that in the Ar arc.When the current reaches its peak value at 0.6 ms,the N2arc is more constricted.The hightemperature regions near the electrodes are concentrated in small spots.In contrast,the temperature is more uniform in Ar.At the time of 1.8 ms,the temperature in the Ar dilution gas is higher because of the lower thermal conductivity of the Ar.

Figure 7.Temperature distribution in the arc column.(a)Temperature in the dilution gas of 80% N2,(b)temperature in the dilution gas of 80% Ar.

The thermal conduction from the arc and the impact of electrons plays a major role in anode heating[44].The heat flux to the anodeSaand on the cathodeSccan be expressed as

wherejeis the electron current density,andjiis the ion current density.The current in the arc channel is mainly provided by the electrons emitted from the cathode.Here,is the work function of graphite,which is 4.7 eV[45],andis the energy required for the electron to escape from the electrode surface.Viis the cathode sheath voltage.The termdescribes the radiation heat loss of the electrode,whereTis the temperature of the arc surface,εais the surface radiation coefficient,andαis the Stefan–Boltzmann constant.

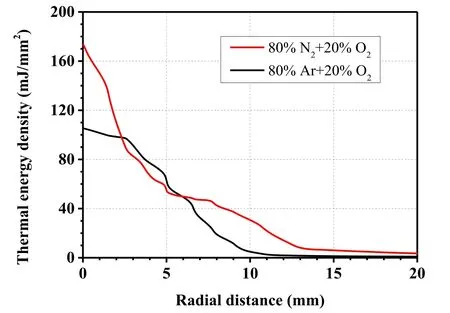

The total thermal energy density is the integral of the heat flux over time,and is shown in figure 8.The absorption rate of heat in the graphite sublimation area is higher than the cooling rate,so heat accumulates rapidly on the surface.When the absorbed energy exceeds the latent heat of the graphite,the graphite begins to sublimate from the surface.Figure 8 shows that density of the heat energy in Ar is lower than that in N2,so the damage to the electrodes is expected to be less.

Figure 8.Thermal energy heat density on the anode.

4.2.Oxidation of the graphite vapor

The diffused graphite vapor is oxidized to form a C–O chemical bond and exists as gaseous CO and CO2.The specific reactions include:

Carbon oxides are the main gaseous product in the spark gap switch,and their amount increases as the arc cools more slowly.In addition,when the dilution gas is N2,N2and O2are dissociated in the arc,and the atoms react during the cooling phase.Nitrogen oxides are found in the dilution gas of N2[46].The nitrogen oxidation reactions consume oxygen and energy.

However,changing the insulating gas affects the breakdown voltage of the switch.According to the experimental tests,at a pressure of 230 kPa,the breakdown voltage of the traditional dilution gas of N2is around 43 kV.In the dilution gas of Ar,the breakdown voltage is about 22 kV.If the switch should apply to the same insulation voltage of 43 kV using the dilution gas of Ar,the working pressure should be increased to 570 kPa.Figure 9 shows the mass loss of the electrodes and the amount of carbon in the gas under the different pressures of Ar dilution gas.When the pressure rises,the mass loss of the electrodes increases,but more carbon vapor is oxidized due to the higher oxygen atoms density.The residual solid carbon decreases about 42%compared with the traditional N2dilution gas.It appears that the Ar dilution gas still has advantages at high working pressure.

Figure 9.Comparison of mass loss of the electrodes and mass of carbon element in the discharge gas under different dilution gases and different working pressures.

In the different application scenarios,the dielectric strength of the switch is different.So it is hope that the different gas selection schemes can match different parameter conditions.The combined influence of working pressure and gas composition on the mass loss of graphite electrodes needs to be studied further.

5.Conclusions

The effect of insulating gas composition on the changes of the surface and the mass loss of the graphite electrodes is studied in mixture of the dilution gas of N2and Ar with 20%O2.The result shows that the gas composition is an important factor in the design of long-life,high-coulomb spark gap switches.The conclusions can be summarized as follows.

(1)Under the thermal shock of the pulsed arc,the sublimation of the graphite leads to the mass loss from the electrode.The composition of arcing gas has a significant effect on the extent and intensity of the erosion.The roughness of the erosion surface is smaller in the Ar dilution gas than that in the N2dilution gas.

(2)The mass-loss rate of graphite electrode in traditional N2–O2insulating gas is 0.1531 mg C?1.After replacing N2with Ar,under the same discharge conditions,the mass loss rate of the graphite electrode is reduced by 64%,which prolonged the working life of the electrode.

(3)The temperature and heat transfer characteristics of the arc are determined by the thermodynamic parameters and transport coefficients of the discharge gas.Argon has low thermal conductivity and low specific heat,which will help to weaken the thermal flux to the electrode.

There is no guarantee that the mixture of Ar with 20%O2is optimal,but it can prove that Ar has better performance than N2at the breakdown voltage below 9 kV.Further,the optimal insulating gas composition and the effect of pressure need to be further researched.

Acknowledgments

The study was supported by National Natural Science Foundation of China(Nos.51777082 and 52077091),and Chinese Scholarship Council(No.201906160101).The authors thank Huazhong University of Science and Technology Analytical and Testing Center for providing testing equipment.

Plasma Science and Technology2021年6期

Plasma Science and Technology2021年6期

- Plasma Science and Technology的其它文章

- Special issue on selected papers from HVDP 2020

- Microwave transmittance characteristics in different uniquely designed one-dimensional plasma photonic crystals

- Burst pulses for positive corona discharges in atmospheric air:the collective movement of charged species

- Effect of plasma step gradient modification on surface electrical properties of epoxy resin

- Reconstruction of energy spectrum of runaway electrons in nanosecond-pulse discharges in atmospheric air

- The enhanced aerosol deposition by bipolar corona discharge arrays