Effect of Different Processing Methods on Storage Quality of Strawberries

Jun WANG, Feng MIAO, Rui ZHOU

College of Life Science, Cangzhou Normal University, Cangzhou 061001, China; 2. Cangzhou Academy of Agriculture and Forestry Sciences, Cangzhou 061001, China

Abstract [Objectives] This study aimed to explore the effect of different processing methods on the storage quality of strawberries. [Methods] Strawberries purchased from Xintongtian Supermarket in Cangzhou City were used as the experimental material, and they were subjected to different processing methods: 45 ℃ hot air for 30 min, 45 ℃ hot water for 10 min and 3% calcium chloride for 1 min. [Results] The processing effect of 45 ℃ hot water for 10 min was better than that of 45 ℃ hot air for 30 min. The processing effect of 3% calcium chloride for 1 min was good. Hot water processing could prolong the time to begin to rot, obviously alleviate the increase in weight loss rate, and obviously alleviate the decrease of soluble solids and Vc contents of strawberry fruit. However, the ability of hot water to delay the decrease of strawberry fruit hardness was not as good as that of calcium chloride. [Conclusions] The strawberries processed with 45 ℃ hot water for 10 min showed the best storage quality.

Key words Strawberry, Hot water, Hot air, Calcium chloride, Preservation

1 Introduction

Strawberry (FragariaananassaDuch.), also known as Yangmei, is a plant in the Rosaceae. It is a perennial evergreen plant. The fruit is sweet and delicious, rich in nutrition. Strawberry fruit contains fructose, sucrose and a variety of vitamins[1]. The ripening period of strawberry is relatively early. Strawberries are a good nourishing product, which is deeply loved by consumers. They can also be processed into sauce, wine, fruit tea drinks, quick-frozen food,etc., with very broad market[2]. Strawberry fruit has very high water content, and the fruit skin is thin, without hard skin protection. As a result, it is very easy to be damaged. After strawberry fruit is stored at room temperature (25 ℃) for 1-2 d, the color will change, the taste will change, some rot will appear, and the commodity will decrease, severely restricting the sale and storage of strawberries[3].

At present, the preservation of fruits and vegetables mainly starts from the three stages of pre-production, middle and late stages. In order to improve the storage durability and then extend the storage time, among the three stages, preservation after harvest has always been a key issue in the preservation of fruits and vegetables. In recent years, varieties represented by strawberry have developed rapidly. People have a new understanding of the nutritional value of strawberries. As a result, the demand for strawberries in domestic and foreign markets has increased. There are many researches on the fresh-keeping technology of strawberry fruit. At present, the commonly used domestic strawberry preservation methods include low temperature storage, radiation storage, film packaging and chemical preservation[4]. The costs of low temperature storage and film packaging are relatively high, and radiation storage may have an impact on human health.

Because of the increasing demand for green food, heat processing, as a pollution-free fruit preservation technology, is attracting widespread attention. Heat processing before storage has bactericidal effect on fruits, and it can extend the storage period and maintain the quality of the fruit after harvest[5]. The advantage of chemical method is that it is convenient to operate and does not require specific equipment. As an efficient and non-toxic bactericide, calcium chloride can effectively kill bacterial propagules, and the processed strawberries are not harmful to human health. At present, there are many studies on the effect of heat processing and calcium chloride processing on the storage quality of strawberry fruit. However, which treatment has a better effect on the postharvest storage quality of strawberry fruit has been rarely reported so far[6]. For this reason, taking strawberry fruit as the experimental material, this experiment explored the effect of hot water processing (45 ℃, 10 min), hot air processing (45 ℃, 30 min) and calcium chloride processing (3%, 1 min) on the storage quality and screened out the most suitable method to keep strawberries fresh after harvest, in order to achieve the purpose of improving the economic benefits of strawberries.

2 Material and methods

2.1MaterialIn this experiment, strawberry fruit purchased at Xintongtian Supermarket was used as the experimental material.

2.2Methods

2.2.1Material processing. Hot air processing: After removing impurities from strawberry fruits with basically the same size and maturity, no diseases and insect pests, and no mechanical damage, 6 groups of strawberries, 200 g for each group, were weighed. The strawberries were placed in white porcelain dishes, wrapped with plastic film, placed in a digital display blast drying oven, processed with hot air at 45 ℃ for 30 min, and observed at room temperature successively. The physiological and biochemical indices of the strawberries after hot air processing were measured.

Hot water processing: After removing impurities from strawberry fruits with basically the same size and maturity, no diseases and insect pests and no mechanical damage, 6 groups of strawberries, 200 g for each group, were weighed. The strawberries were processed with hot water at 45 ℃ for 10 min. After processing with hot water, the strawberries were placed in a ventilated place for 3-4 h until the moisture on the surface of the strawberries was air-dried, cooled to room temperature, wrapped with plastic film, and observed at room temperature. The physiological and biochemical indices of the strawberries processed with hot water were measured[7].

Calcium chloride processing: After removing impurities from strawberry fruits with basically the same size and maturity, no pests and no mechanical damage, 6 groups of strawberries, 200 g for each group, were weighed, and processed with 3% calcium chloride for 1 min, respectively. After processed, the strawberries were placed in a ventilated place for 3-4 h until the moisture on the surface of the strawberries was air-dried, cooled to room temperature, wrapped with plastic film, and observed at room temperature. The physiological and biochemical indices of the strawberries were measured.

2.2.2Evaluation of sensory flavor. The sensory flavor of strawberry was graded from the four aspects of color, flavor, appearance and texture[8-10].

The grading criteria were as follows. 5 points: The strawberry fruit is red or reddish yellow, and there is no mechanical damage on the surface. There is a strong strawberry aroma, a certain degree of hardness, and no rotten strawberry fruit. 4 points: The strawberry fruit is bright red, with a light aroma and a certain degree of hardness. There is no rotten strawberry fruit. 3 points: The strawberry fruit is red, the strawberry skin shrinks, and the hardness begins to decrease. 2 points: The strawberry fruit is darkened, with some water-soaked spots. The aroma is lost. Some fruits are moldy. 1 point: The strawberry fruit is soft and rotten, with a rotten smell. 0 point: The strawberry fruit is severely rotted and smells bad.

2.2.3Determination of weight loss rate. The weighting method was used. Strawberries in groups, 200 g for each group, were weighed. After different processing, the weight of the strawberries was measured every 24 h. The weight loss rate was calculated according to the following formula:

Weight loss rate (%)=[(Weight of fruit before storage-Weight of fruit after a certain period of storage)/Weight of fruit before storage]×100%[11-13].

(1)

2.2.4Determination of hardness. It is measured by a hardness tester (GY-4).

Three strawberries were randomly selected from the strawberries processed by different method, respectively for determination of hardness. Two points were selected on the shoulder of each strawberry, and the hardness tester was inserted into each of them, and the readings were recorded. Each replicate was measured three times[14].

2.2.5Calculation of decay index. According to the size of the decay area of the fruit, it can be divided into four levels[15]. Level 0: No decay. Level 1: The decay area of the fruit is less than 25% of the total area of the fruit. Level 2: The decay area of the fruit accounts for 26%-50% of the total area of the fruit. Level 3: The decay area of the fruit is greater than 50% of the total area of the fruit.

Decay index (%)=∑ (Number of decayed fruits×Value of decay level)/Total number of fruits×Value of highest decay level×100.

(2)

2.2.6Determination of soluble solids content. Soluble solids content was determined with digital Abbe refractometer (WAY-2S). Three strawberries were randomly selected from the strawberries processed by different method, respectively. The pulp was collected using a scalpel and placed in a mortar to grind. The ground pulp was filtered with two layers of gauze once to squeeze out the strawberry juice. One drop of the strawberry juice was loaded to the digital Abbe refractometer, and the refractive index was recorded and converted into soluble solids content[16].

2.2.7Determination of Vc content. Content of Vc was determined using ultraviolet absorption method. To determine the maximum absorption wavelength, an accurate volume of Vc standard solution was transferred into the cuvette and scanned multiple times in the wavelength range of 200-400 nm, using distilled water as the blank. The maximum absorption wavelength of Vc was determined to be 265 nm. Therefore, the absorbance of the Vc sample solution was measured at 265 nm.

Different volume (0.00, 1.00, 2.00, 4.00, 6.00, 8.00, 10.00 and 12.00 mL) of Vc standard solution was diluted to 100 mL, respectively. The absorbances of the diluents at 265 nm were determined, with distilled water as a reference. With absorbance as the ordinate and concentration of Vc standard solution as the abscissa, the standard curve was drawn[17].

3 Results and analysis

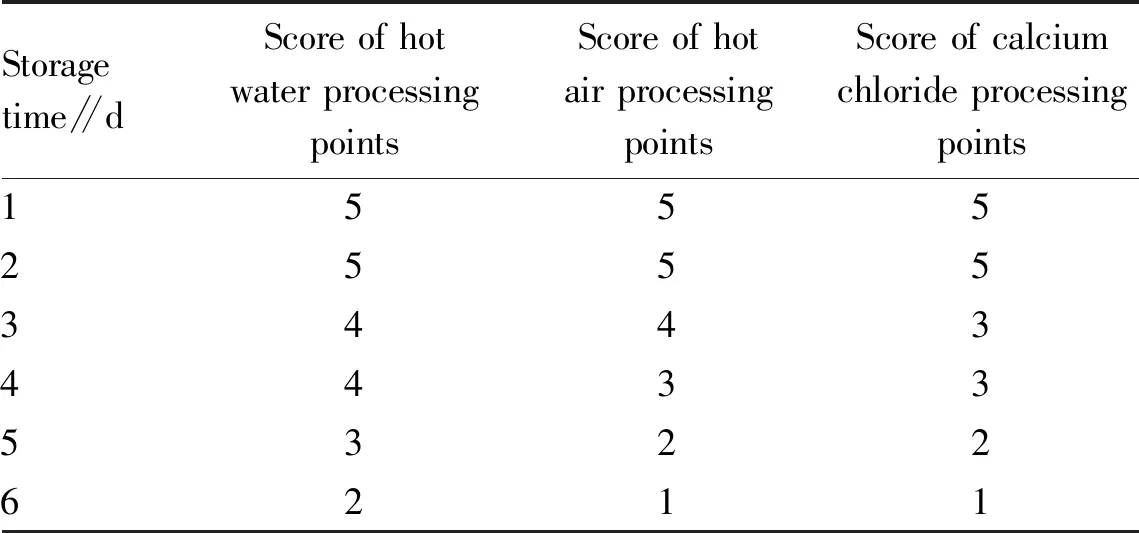

3.1SensoryflavorAs shown in Table 1, with the extension of storage time, after hot water, hot air and calcium chloride processing, the sensory flavor of strawberries decreased and showed differences. The sensory flavor of the strawberries processed by different methods did not decreased on days 1 and 2, all maintained at 5 points. The sensory flavor of the strawberries processed by different methods began to show a downward trend on day 3. The declining trends of sensory flavor of the strawberries processed with hot air and calcium chloride were basically the same. The sensory flavor of strawberries processed with hot water was obviously the best. It shows that hot water processing can better maintain the sensory flavor of strawberry fruit.

Table 1 Changes in sensory flavor of strawberry fruit processed by different methods

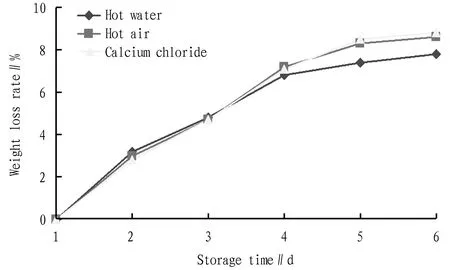

3.2WeightlossrateAs the storage time increased, the weight loss rate of the strawberries processed with hot water, hot air and calcium chloride increased and showed differences (Fig.1). From day 1 to day 3, the weight loss rate of the strawberries processed by different method all increased significantly, while no significant difference was observed. From day 4 on, the weight loss rates of the strawberries processed with hot air and calcium chloride were significantly higher than that processed with hot water, indicating that hot water processing can delay the weight loss of strawberries to a greater extent and keep strawberries fresh and tender.

Fig.1 Dynamics in weight loss rate of strawberry fruit processed with different methods

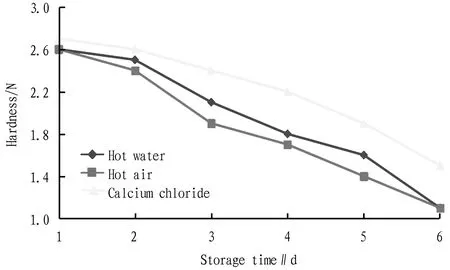

3.3HardnessAs the storage time increased, the hardness of the strawberries processed with hot water, hot air and calcium chloride all decreased to varying degrees, leading to fruit softening and storage performance decline (Fig.2). From day 1 to day 6, the hardness of the strawberries processed with hot water and hot air decreased significantly, and the degree of decrease was roughly similar. The hardness of the strawberries processed with calcium chloride also decreased to a certain extent, but the decrease was smaller than the decreases of strawberry hardness after hot water and hot air processing. It shows that calcium chloride processing can delay the decrease of strawberry hardness to a greater extent, inhibit the softening of strawberries and improve the storage performance of strawberries.

Fig.2 Dynamics in hardness of strawberry fruit processed with different methods

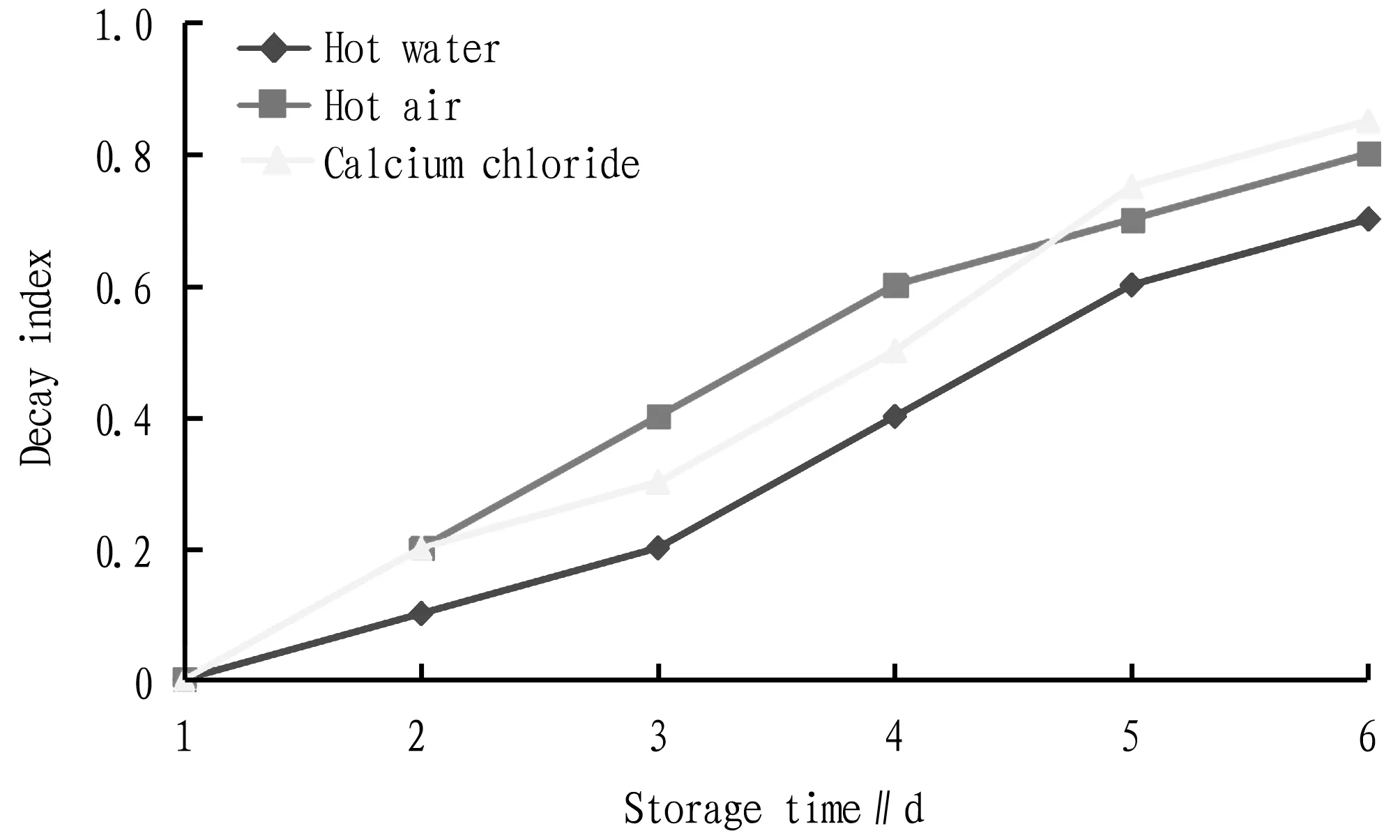

3.4DecayindexAs the storage time increased, the decay indices of the strawberries processed with hot water, hot air and calcium chloride increased continuously, and the upward trends were roughly the same. However, the decay index of the strawberries processed with hot water was smaller than those of the strawberries processed with hot air and calcium chloride (Fig.3), suggesting that hot water processing can more delay the decay and maintain the quality of strawberry fruit.

Fig.3 Dynamics in decay index of strawberry fruit processed with different methods

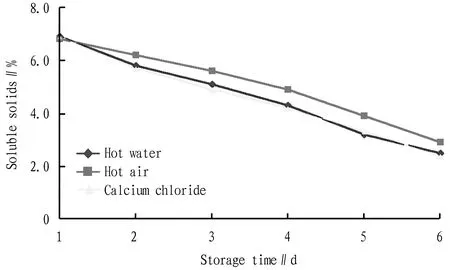

3.5SolublesolidscontentThe soluble solids contents of the strawberries processed with hot water, hot air and calcium chloride all decreased within the 6 d, and the decreases were approximately similar. The content of soluble solids in the strawberries processed with hot water was higher than those in the strawberries processed with hot air and calcium chloride (Fig.4), indicating that hot water processing can alleviate the decrease of the soluble solid content and maintain the quality of strawberry fruit.

Fig.4 Dynamics in soluble solids content of strawberry fruit processed with different methods

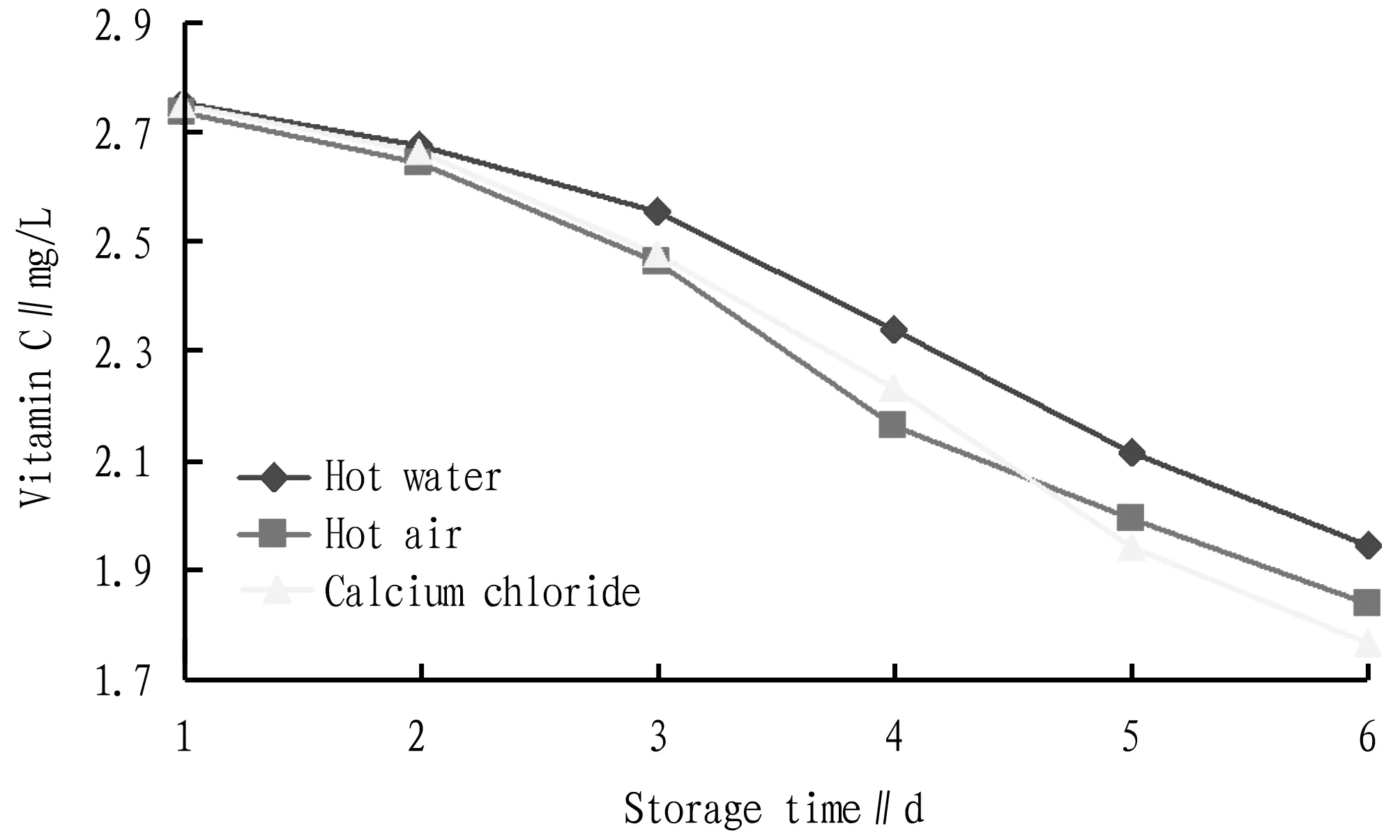

3.6VccontentFig.5 shows that the Vc contents of the strawberries processed with different methods all decreased within the 6 d, and the decreases were roughly similar. However, the content of Vc in the strawberries processed with hot water was higher than those of the strawberries processed with hot air and calcium chloride, indicating that hot water processing can alleviate the decrease in Vc content and maintain the edible value of commerciality of strawberries.

Fig.5 Dynamics in Vc content of strawberry fruit processed with different methods

4 Conclusions

Generally speaking, different processing methods of 45 ℃ hot water for 10 min, 45 ℃ hot air for 30 min and 3% calcium chloride for 1 min all can delay the decrease of hardness, Vc content and soluble solid content, inhibit weight loss rate and increase decay index of strawberry fruit, conducive to the storage and preservation of strawberries, maintaining the quality and ensuring the edibility and commerciality of strawberry fruit.

The results of this study show that the processing effect of 45 ℃ hot water for 10 min was better than that of 45 ℃ hot air for 30 min and 3% calcium chloride for 1 min. Hot water processing could prolong the time for strawberry fruit to begin to decay, obviously alleviate the increase in weight loss rate of strawberry fruit, and significantly alleviate the decrease of soluble solids and Vc contents of strawberry fruit. Although its ability to delay the decrease of strawberry fruit hardness was not as good as calcium chloride processing, considering comprehensively, the storage quality of strawberries proceed with 45 ℃ hot water for 10 min was the best. The overall effect of hot water processing was significantly better than that of hot air processing and calcium chloride processing. This may be because hot air and calcium chloride were not as effective as hot water in sterilizing and activating related resistant enzymes.

Acknowledgements

I would like to thank my tutor Wang Jun and classmates Zhang Jing, Jia Yuanyuan, Chen Yaping, Zhai Xin, Pan Linlin,etc. for their help for this study.

Asian Agricultural Research2020年12期

Asian Agricultural Research2020年12期

- Asian Agricultural Research的其它文章

- Practice of Mind Mapping Technology in "Re-flipped Classroom" Teaching Mode: A Case Study of the Course Principles of Residential District Planning

- A New Record of Orchidaceae from Guangxi: Galeola nudifolia Lour.

- Quality Evaluation of Threshing and Redrying Process Based on Analytic Hierarchy Process

- Development Strategy of Soundscape in Rural Tourism Based on Tourist Perception: A Case Study of Some Villages in Jiangxi Province

- Sustainable Utilization of Agricultural Land in Chengdu Metropolitan Area Based on Emergy Analysis

- Genome-wide Association Analysis of Maize Flowering Traits