Research on Key Technology of Intelligent Numerical Control Machine Tool

Gu Wei,Xing Huanwu

(1.SHENJI(Shanghai)Intelligent system research and development design co.LTD,Shenyang,Liaoning 110142;2.Jiangmen YUNKEIntelligent equipment co.LTD,Jiangmen,Guangdong 529000)

Abstract:Based on the basic characteristics of intelligent machine tools,this paper discusses several key technologies of intelligent machine tools and the current technology development,such as thermal deformation error compensation,anti-interference system,tool monitoring and so on.It also briefly introduces theintelligent componentsof machinetoolssuch as CNCsystemand spindleset.

Keywords:intelligent machine tool;thermal deformation error compensation;anti-interference system;tool monitoring

CNC machine tool handles complex,precise,various and small batches of parts processing.It is a typical electromechanical integration product,and the key strategic equipment to realize the modernization of manufacturing technology and equipment,ensure the development of high-tech industry and the modernization of national defense and military industry.The intelligent numerical control machine tool is the one which makes the manufacturing process transparent.It has the ability to sense spindle operation,tool cutting,and guide rail abrasion will enable machine tool users to make better use of the machine tool and significantly improve efficiency to reduce costs.

I.Features of Intelligent Machine Tools

The intelligent machine tool can monitor,diagnose and correct all kinds of deviations in the production process of the machine tool through various sensors installed,and at the same time form the optimal solution of future production process through the precipitation of historical big data.At the same time,it can also record and warn the cutting tool life,spindle operation,bearing and guide rail abrasion during processing.The main difference between intelligent machine tools and ordinary CNC machine tools is that intelligent machine tools not only have CNC machining functions,but also have intelligent functions such as perception, reasoning, decision- making and learning[1].

II.Several Key Technologies of Intelligent Machine Tools

In the future,intelligent machine tools will be indispensable for the equipment manufacturing industry to realize comprehensive production automation.Major machine tool manufacturers in various countries have made a lot of achievements in the field of intelligent machine tool production.In the study and development of intelligent machine tools,intelligent monitoring of processing and remote fault diagnosis have always been the focus of people"s attention,mainly involving vibration,antiinterference,temperature,tools and other aspects of monitoring and corresponding compensation methods[2].

(i)Thermal Error Compensation Function ction

1.Thermal Deformation Error Mechanism

In the operation of machine tools,rising ambient temperature and heat generated by motors will transfer heat to mechanical parts,which may lead to changes in mechanical accuracy and thus affect the machining accuracy of workpieces.Therefore,in general,the use of high-precision machine tools,are required in the constant temperature workshop.Due to the change of temperature in the general environment,CNC machine feed system,spindle system will have thermal deformation,in this case,thermal error compensation is needed to improve the positioning accuracy and repeat positioning accuracy of the machine tool.In order to eliminate the influence of temperature rise caused by temperature change or its own friction,generally speaking,thermal error compensator should have the functions of temperature change data measurement,thermal error modeling and error compensation.

2.Realization Method of Thermal Error Compensation

Firstly,a temperature sensor is usually installed near the lead screw of a CNCmachine tool.The temperature sensor is used to measure the temperature of the lead screw,a key component of the feed system.The thermal error compensation model in the thermal error compensator calculates the displacement compensation value of each coordinate axis in real time and then sends it to the numerical control system to complete the real-time thermal error compensation.

(ii)Intelligent Anti-interference System ystem

1.Anti-interference System Function

If there is a collision of high-precision machine tool,it will have a very adverse impact on the accuracy and performance of the machine tool.The implementation of anti-interference system is before running the CNCprogram,the CNC machine tool judges the interference between the tool,workpiece,fixture and machine tool structural units through the way of self-inspection.If there is a possibility of collision,the machine will be automatically stopped before the collision to achieve collision prevention.The main benefit of the antiinterference system is that it can reduce the processing preparation time and processing time,improve the effective operation time of the machine tool,eliminate the potential downtime caused by collision and save maintenance costs.

2. Implementation Technology of Antiinterference System

The technology is realized through 3D animation simulation technology to simulate the actual machining work of CNC machine tools,the simulation of the process involved in cutting tool,workpiece,fixture,etc.3D model,in addition to the initial value modeling way,the modeling function can be used to input 3D model data of cutting tool,workpiece and fixture to realize machining process simulation.

The simulation process of virtual machine tool includes: numerical control system converts numerical control program or manual operation instruction into mechanical control signal;Then,the moving signal of the coordinate axis of the machine tool is firstly associated with the preset 3D animation simulation module,and the potential collision risk can be prevented through this process.In other words,if the interference is found through 3D animation simulation,the machine can be slowed down and stopped before the actual interference occurs to avoid collision.When it is judged that there will be no interference,the machine tool will maintain the original instruction to completetheprocessing action.

(iii)Intelligent Tool Monitoring Technology ology

1.Tool Abrasion Status Analysis

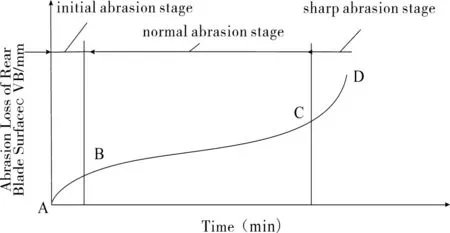

Tool abrasion mainly includes three stages:initial abrasion stage,normal abrasion stage and sharp abrasion stage,asshown in Figure1.

Figure 1 Tool Abrasion Curve

When the normal abrasion of the tool reaches the limit point D in the figure,with the continuous increase of cutting force and cutting temperature,the tool abrasion will increase,and the tool abrasion rate will also rise sharply into the stage of severe abrasion.At this time the cutting performance of the tool will be significantly reduced,prone to scrap workpiece,at the same time because of the increase in cutting force,there will be increased vibration of the machine tool,reduce the performance of the machine tool and even cause safety accidents.Therefore,the critical point entering the stage of rapid abrasion must be detected and the cutter must bereplaced in time[3].

2.Tool Condition Monitoring Process

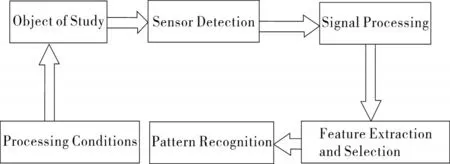

Tool abrasion monitoring process is simply a tool abrasion pattern recognition process,The monitored tool,sensor hardware,data acquisition and processing module,feature extraction and analysis module,diagnosis and decision basic modules constitute the main body of the tool monitoringsystem,asshown in Figure2.

Figure 2 Principle Diagram of On-line Tool Abrasion Detection

The workflow of the tool condition monitoring systemisasfollows:

First,the tool state monitoring system runs through the cutting process of the tool,so the monitoring object needs to be determined,including the tool,blank,and the sensor installed in the main monitoring position of the machine tool.

Second,the sensor detection process,the role of the sensor is to collect the cutting tool in the process of the acceleration,decibel,power,current and other signals.

Third,data acquisition and processing.In this link,the monitoring system will collect and analyze all kinds of signals detected by the sensor in the previous step.Before this,data preprocessing such as digital-to-analog conversion,filtering and noise reduction should be carried out,and then the collected data should be analyzed in the time domain,frequency domain and amplitude domain.

Fourth,through the expert database,the mathematical model between various signal characteristics and tool abrasion degree is established,through which the judgment of tool state and abrasion amount is realized,and the tool service life is predicted.

III. Machine Tool Component Intelligentization

(i)Intelligent Numerical Control System ystem

The process planning and programming of the intelligent numerical control system should take the structure of the machine tool,the shape and size of the specific workpiece,the physical characteristics of the process system and the working environment and other factors into account.By optimizing the machining parameters of the machine tool and the motion trajectory of each axis,the quality and efficiency of machining can be guaranteed.However,the existing programming system is mainly oriented to the geometric programming of parts,without comprehensive consideration of the characteristics of machine tools,tooling and parts materials,and unable to adapt to the uncertainty of processing conditions, stress distribution and temperature change.At the same time to realize intelligent process planning and intelligent programming also need to gradually accumulate expert experience and knowledge, establish correspondingdatabaseand knowledgebase.

The functions of the intelligent numerical control systemdeveloped areasfollows:

1.Graphics Guided Programming

Figure 3 3D Machining Simulation

Graphics bootstrap programming is a new kind of programming besides traditional programming.Based on the concept of working procedure,graphical guided programming can decompose the processing from rough to finished product into a series of continuous working procedure steps,and then use a working procedure language to express each working procedure.Process language can directly display the process parameters of the current process,so that the operator can easily edit the tool used,feed speed,feed quantity,spindle speed and so on,improving the programming efficiency and reducingtheprogrammingdifficulty.

2.3 DMachining Simulation

The numerical control system itself integrates 3D graphics simulation software,which can carry out online real-time simulation of the machining process.There are a variety of workpiece shapes to choose from,and the workpiece size is fully parameterized.Common tools and fixtures can be selected freely,and interference inspection between tools and workpieces can be carried out actively in the process of machining simulation.This function can visually observe the cutting effect of complex process features such as thread cutting,grooving and drilling,asshown in Figure3.

3.Graphical Diagnostic Tools

The main function of the graphical diagnostic tool is to monitor the working status of the electrical components of the machine tool.This function provides a powerful help for machine tool users to quickly diagnose electrical faults of machine tools,and presents the I/Ostatus of different parts visually by means of graphics.Users can easily diagnose the corresponding electrical fault,Figure 4 is the CNC lathe top graphical diagnostic tool.

Figure 4 Graphical Diagnosis

(ii)Intelligent Spindle Set le Set

The characteristics that an intelligent spindle should have are as follows:it can automatically detect and optimize its own running conditions,and have the number of process,operation status of selfstudy ability.

The related technologies included in the intelligent spindleset areasfollows:

1.Spindle temperature on-line monitoring,thermal error compensation and intelligent control of coolingsystem;

2.On-line detection technology of spindle turningprecision;

3.Spindle vibration on-line detection,filter analysisand activebalancecontrol strategy.

IV.Conclusion

The intelligent numerical control machine tool has a very broad development prospect,it represents further promotion and development of the efficiency,automation, intellectualization, network, and integration.In the future,the more intelligent CNC machine tools,high-precision parts manufacturing process will be more simple,which is the new trend of the development of the manufacturing industry,Chinese machine tool industry in the development and industrialization of intelligent machine tool link hasalot of roomfor progress.

- 中阿科技論壇(中英文)的其它文章

- Study on Broad Spectral Properties of K 9 Glass Substrate by Ellipsometry

- Mathematical Modeling and Solution of 2K-H Planetary Gear Transmission Optimization Design

- Innovative Customer Service System Design Based on NB-IOT Filter Press

- Application of New Regenerative Braking Energy Absorption Device in Subway

- Literature Review on Entrepreneurial Intention of Chinese College Students Based on Literature Measurement Method

- Design of Power Supply and Distribution System in Residential Buildings