Study on the characteristics of PCBN materials at home and abroad

, , ,

(1. China University of Mining and Technology (Beijing), Beijing 100083, China)(2. Henan Huanghe Whirlwind Co., Ltd., Changge 461500, Henan, China)

The automotive and aerospace industries generally use polycrystalline cubic boron nitride (PCBN) cutting tools to achieve higher productivity. PCBN has lower affinity to iron and high hardness properties means that it delivers a superior cutting performance especially during high speed machining of hardened steel, cast iron and sintered alloys etc[1-2].

PCBN material is produced by mixing CBN (cubic boron nitride), whose hardness is second only to diamond, with a special binder, such as ceramic, metal or both. It is then sintered at 5-6 GPa and 1300-1500 ℃. PCBN material is divided into high and low content categories according to CBN content, which has different applications. Also, the dense microstructure of PCBN material with different CBN granularity is often obtained by sintering in a certain proportion. At present, Dinger-Funk equation[3]is the optimum theory that describes the continuous grain size distribution compared to that of real particle size distribution, which is applicable only to PCBN material with high CBN content.

Another factor that affects the quality of PCBN is the type of binder. As a binding phase, composite metals of the elements in groups IV-VI of the periodic table, or their compounds, are most frequently used.

The main objective of this study was to evaluate the characteristics and trends of PCBN materials with different CBN contents and grains, and different binders.

1 Materials and methods

1.1 PCBN categories

There are many series of different PCBN tools, which are used to meet different application requirements. In Table 1 there list representatives of main manufacturers. It can be seen that most Chinese manufacturers produce solid PCBN tools, which is related with the synthesis equipment i. e. cubic press and the high price of foreign solid PCBN. Other companies mainly produce PCBN composite blade due to two-anvil presses they use, but each company would have one or two solid PCBN products for rough processing or semi-finishing.

In recent years, the manufacturers push out new PCBN products with medium or low content CBN and Ti-based ceramic matrix, which are ideal for finishing hardened steels at high speeds, such as BZN-PM161, BZN-V35, BZN-HPT130, DIA500, DHA650, solid PCBN or composites with cemented carbide substrate.

During the development of Chinese superhard material, the cavity of cubic press is limited, so it is difficult to make larger composite blade. At present, the largest diameter of composite blade in cubic press isφ58 mm[4], which can be madeφ54-φ110 mm by using two-anvil press in foreign manufacturers. Larger diameter blade has higher cutting efficiency, each tool only requiring very small PCBN tip for welding blade. Even though the price of the whole composite is higher, the price of each blade is lower, thus, many PCBN composites from abroad used in Chinese brazing tool industries. Compared to two-anvil press, the cubic press is more applicable to direct synthesis solid PCBN conformity with ISO tool standard, and the price is a quarter of that of foreign products, which contributes to China′s dominant position in solid PCBN tools. But in the case of PCBN composites, things go different. The different hydraulic press used in synthesizing superhard products at home and abroad lead to different ideas of material development, leading to many PCBN composite blades in foreign companies, and fast development of solid PCBN tools in China.

Table 1 Categories of PCBN tools

1.2 Binders

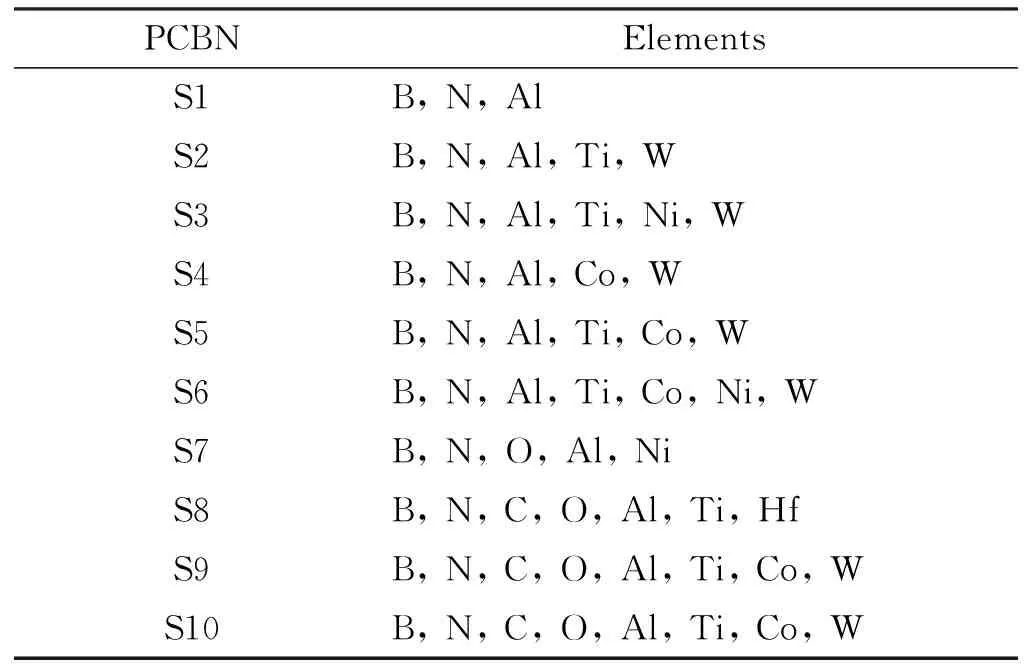

The properties of PCBN materials are closely related to the choice of binders. Several PCBN samples are studied to analyze their element composition through JSM-6390LA scanning electron microscopy and EDS. The results are shown in Table 2.

Table 2 Elements obtained by energy spectrum analysis PCBN samples from abroad

It can be seen that Al, Ti, Co, Ni, W et al. are the common elements in the binder, and C, O elements are also find in the sample. Al, Co, Ni, W are usually used as metallic binder, which provide liquid phase to fill the voids when sintered, such as SUMIBORON BN7000 designed for cast iron and ferrous powder metal machining[5].

Al can easily react with CBN during sintering under high pressure and high temperature, thus generating AlN and AlB2[2, 6-7]. Sometimes AlN or/and Al2O3are chosen as the binder[8-9].

Titanium is often added in the form of nitrides or carbides and was studied with different molar ratio[6, 10-11]. TiN/TiC reacts with BN forming new phase at the BN-binders interface, obtaining the densest microstructure. Hf element was found in the form of HfC for its good properties[12]. With HfC and Al as the binders, CBN reacted with Al and HfC, and produced AlN, AlB2, HfB2and B2C5N2, whose content increased with Al disappearing, and the Vickers hardness of the sintered samples increased with the CBN content. BENKO[13]studied CBN-Ti3SiC2composites with different CBN volume ratio.

1.3 Uniform mixing

The uniform mixing of initial raw materials plays a very important role in the preparation of PCBN materials. Agglomeration microstructural will become a weak point and affect the service life of PCBN cutting tools, especially when the granularity of CBN is finer such as nanostructured. There are more stringent requirements on raw material mixing process.

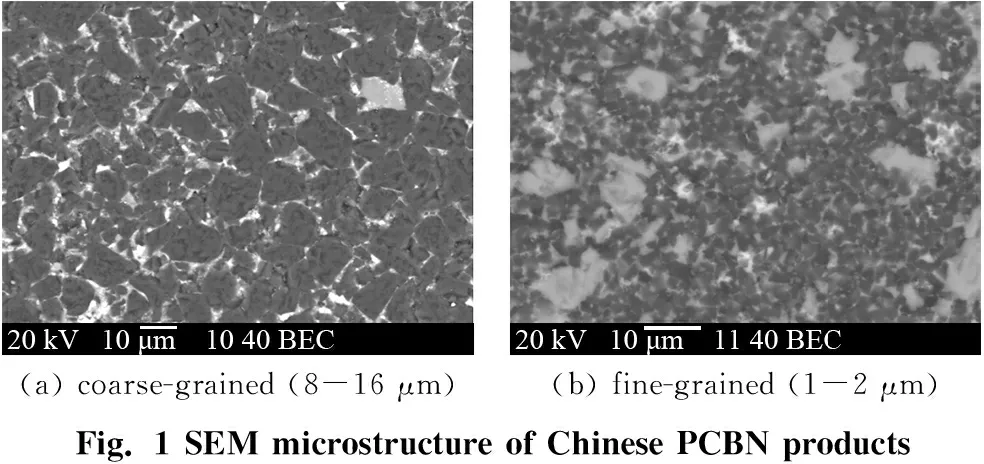

Fig. 1 shows SEM microstructure of some PCBN products from China. It can be seen that the overall distribution of coarse grains is relatively uniform, but there are still some binder agglomerations (Fig. 1a). The microstructure distribution of fine grains is uneven, and there are more binder agglomerations (Fig. 1b).

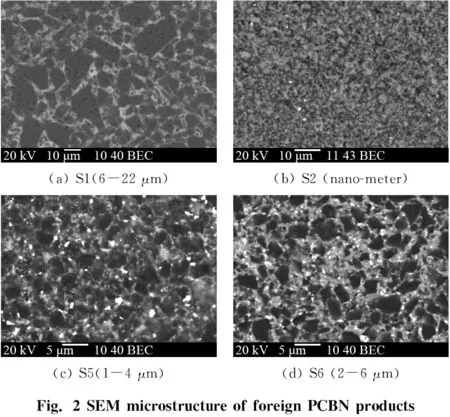

The microstructure of foreign PCBN products are shown in Fig. 2. It is found that they are uniformly distributed, even at nanometer size as shown in Fig. 2b. Uniform and dense microstructure distribution effectively ensures the stability of the products.

(a) coarse-grained (8-16 μm) (b) fine-grained (1-2 μm) Fig. 1 SEM microstructure of Chinese PCBN products

(a) S1(6-22 μm)(b) S2 (nano-meter)(c) S5(1-4 μm)(d) S6 (2-6 μm)Fig. 2 SEM microstructure of foreign PCBN products

Three-dimensional mixer, roller ball mill, and planetary ball mill are always chosen as mixing equipment to meet the requirements for uniform mixing powder. Vacuum and ultrasonic are also used in mixing equipment. The parameters, such as ratio of grinding media to material, rotational speed and mixing time in mixing process, are strictly controlled to obtain uniform sintered microstructure. In most case, dry mixing are used for coarse-grained powders and wet mixing for fine-grained powders. The binders are pre-milled in ethanol in ceramic ball mill tank, and then fine-grained powders were added to the slurries milling to the required time[14-15].

1.4 High toughness PCBN

The impact toughness of PCBN is particularly concerned when used as cutting tools. It is expected that PCBN tools has high abrasion and high impact toughness. In actual cutting process, CBN abrasive grain on the cutting edge of PCBN tools drastically contacts with the machined components at a very high speed, which would impose a heavy shock load on the CBN grains, especially in intermittent cutting. Under the joint action of internal stress and finally result in grain shedding and macro-fracture. HUANG et al[16]indicate that elongated microcrystalline CBN particles and crack branching contribute to the effect of size distribution of the contained microcrystalline CBN particles on the bulk toughness of the PCBN abrasive grains, by using the theory of Voronoi Diagram. LIU et al[17]sintered PCBN compact with CBN grain sized 1-2 μm on WC-16wt%Co substrates without any sintering agent, which indicated that liquid substance infiltrated from the substrates and chemically reacted with CBN powder, therefore forming plenty of direct BN-BN bondings. The hardness of the product was 38.5 GPa, which ensures the comprehensive properties of PCBN material. When the CBN size is 10-14 μm, by using the infiltrating method in situ, the workpiece surface has a good finish after cut by PCBN tool, which has a dense concrete microstructure and the Vickers hardness of 29.3 GPa[18]. Furthermore, the addition of lanthanon can make the sintered material with compact-grain structure, which can improve the wear resistance and impact toughness of PCBN[19-21]. The SiC whiskers mix in the microstructures as a strip can effectively improve the strength and fracture toughness of PCBN materials[22-23].

2 New PCBN materials

2.1 Nano - polycrystalline cubic boron nitride

Nano-polycrystalline CBN is expected to replace single crystal CBN as a superhard and superstiff material for it has higher hardness and transverse rupture strength than single crystal even when exposed to high temperatures. So nano-polycrystalline CBN tools not only have excellent wear resistance and thermal conductivity, but also have excellent impact resistance, suitable for applications at high speed under heavy load impact. Fig. 3 shows the synthesis regions of nano - polycrystalline CBN which are always synthesized in the pressure range of 8-20 GPa and temperature range of 1300-2400 ℃ without using any binder that lies on the boundaries of CBN grains and significantly affects the mechanical properties and thermal stability of the sintered compact[24-25].

Fig. 3 Nano-polycrystalline diamond / CBN synthesis regions[25]

It was suitable for the determination of nano-PCBN with Knoop hardness. Nano-polycrystals consisting of smaller CBN grains increase the elastic recovery of indentations during unloading of the indenters and the diagonal of Vickers indentations, and the minor diagonal of Knoop indentations significantly decrease in length. The Vickers hardness significantly increased as the grain size decreased, while the Knoop hardness remained nearly unchanged through measured the longitudinal-wave elastic constant and Vickers and Knoop hardness of nano-PCBNs[26]. SUMIYA, et al[27]found that incorrect Vickers hardness values in excess of 80 GPa were obtained from nano-polycrystalline CBN with a grain size of 50 nm or less, while the hardness of each type of CBN was around 45 GPa by using a Knoop indenter ensures an accurate hardness evaluation. The Knoop hardness of the single-phase nano-PCBN with a uniform microstructure increased with decreasing mean grain size, which complied with the Hall-Petch relationship[28].

2.2 Non-binder PCBN

The non-binder PCBN avoids the influence of binders, and has excellent higher hardness, heat resistance, and thermal conductivity performance than conventional sintered PCBN, which was sintered with binder in the CBN powder and the binder affected the mechanical properties of CBN. Cutting tools made using non-binder PCBN exhibit superior performance in high-speed and high efficiency machining of ferrous materials[29]. However, the sintering of non-binder PCBN needs higher pressure and higher temperature as described in Fig. 2. OHASHI, et al[30]using HBN disks treated under ultra high pressure of 6.8 GPa and at temperature of 2100 ℃ to get non-binder PCBN directly, and the tools exhibited better wear resistance in cutting of Co base super alloy and cemented carbide. When the fine-grained (<0.5 μm) and high purity (CBN mass fraction>99.9%) polycrystalline sintered body synthesized at 7.7 GPa, 2200-2400 ℃, it has highest hardness and TRS at any temperature[31]. If the pressure is increased to 25 GPa[32], a mean grain size smaller than 100 nm nano-polycrystalline CBN could be synthesized at temperature of 1950 ℃ or lower, and the single-phase non-binder PCBN was harder than 53.5 GPa in Knoop hardness. Similarly, sintering pure diamond compacts with submicron grain size have the same situation[33]. Non-binder PCBN will be a very promising new material based on suitable synthesis conditions and lower cost.

3 Conclusions

(1)The application of PCBN has strong pertinence with material and machining technic of workpiece, the series of different PCBN tools are needed to meet the application requirements according to contents and particle size of CBN, binder category and so on. Foreign manufacturers have formed a relatively complete series of PCBN materials applied in different fields, but different condition in domestic manufacturers whose product category is relatively single, and lack of R&D and tools application service.

(2)The uniform mixing of initial raw materials plays a very important role in the preparation of PCBN material. Agglomeration microstructural will become a weak point and affect the service life of PCBN cutting tools, especially when the granularity of CBN is finer as nanostructure, there are more stringent requirements for the raw material mixing process. Another important factor is the binder, which often chooses the metallic phase such as Al, Co, W and Ti-based cermet matrix with appropriate proportion, according to the actual cutting requirements.

(3)The impact toughness of PCBN is particularly concerned when used as cutting tool in the industries, In order to obtain high impact toughness based on higher hardness of PCBN, the PCBN composite can be sintered on cemented carbide substrates by using the infiltrating method in situ. Furthermore, the addition of lanthanon and SiC whiskers can improve the strength and fracture toughness of PCBN materials.

(4)Nano-polycrystalline CBN has higher hardness and transverse rupture strength than single crystal even when exposed to high temperatures. Non-binder PCBN has excellent higher hardness, heat resistance, and thermal conductivity performance. There will be very promising new materials based on more suitable synthesis conditions and lower cost.

[1] MCKIE A, WINZER J, SIGALAS I. Mechanical properties of CBN-Al composite materials [J]. Ceram. Int., 2011, 37(1): 1-8.

[2] BENKO E, WYCZESANY A, BARR T L. CBN-metal/metal nitride composites [J]. Ceram. Int., 2000, 26(6): 639-644.

[3] DINGER D R, FUNK J E. Particle-packing phenomena and their application in materials processing [J]. MRS Bulletin, 1997, 22(12): 19-23.

[4] LI S, QU J, FANG H. Synthesis and characterization of φ58 mm polycrystalline diamond compact [J]. Dia. Abra. Eng., 2016, 36(1): 38-42.

[5] MATSUDA Y, OKAMURA K, UESAKA S, et al. Development of new grade "SUMIBORON BN7000" for cast iron and ferrous powder metal machining [J]. SEI Technical Review, 2012(75): 13-17.

[6] YANG L, YUE Z, GONG J, et al.compositions, mechanical properties and microstructures of CBN-based composites sintered with Al or TiC [J]. Adv. Appl. Ceram., 2017, 116(5): 1-6.

[7] SITHEBE H S L, MCLACHLAN D, SIGALAS I, et al. Pressure infiltration of boron nitride preforms with molten aluminum [J]. Ceram. Int., 2008, 34(6): 1367-1371.

[8] LV R, LIU J, LI Y, et al. High pressure sintering of cubic boron nitride compacts with Al and AlN [J]. Dia. & Relat. Mater., 2008, 17(12): 2062-2066.

[9] ZHANG M, SUN X, XIU Z, et al. Influences of sintering temperature on chemical reaction and microstructure in Al2O3-Ti(C0.7N0.3)-CBN composite [J]. J. Nanoelectron. Optoe., 2017, 12(7): 701-705.

[10] RONG X, TSURUMI T, FUKUNAGA O, et al. High-pressure sintering of CBN-TiN-Al composite for cutting tool application [J]. Dia. Relat. Mater., 2002, 11(2): 280-286.

[11] BENKO E, STANISLAW J S, KROLICKA B, et al. CBN-TiN, CBN-TiC composites: chemical equilibria, microstructure and hardness mechanical investigations [J]. Dia. Relat. Mater., 1999, 8(10): 1838-846.

[12] ZHANG L, LIN F, LV Z, et al. CBN-Al-HfC composites: Sintering behaviors and mechanical properties under high pressure [J]. Int. J. Refract. Met. H., 2015, 50: 221-226.

[13] BENKO E, KLIMCZYK P, MACKIEWICZ S, et al. CBN-Ti3SiC2composites [J]. Dia. Relat. Mater., 2004, 13(3): 521-525.

[14] MAWEJA K, CORNISH L A, CAN N. Effects of tungsten and aluminum on the oxidation and phase formation in mechanically alloyed Ti(C,N)-W-Al systems [J]. J. Eur. Ceram. Soc., 2012, 32(13): 3583-3592.

[15] LINDGREN K E, KAUPPI A, FALK L K L. Development of matrix microstructure in polycrystalline cubic boronnitride ceramics [J]. J. Eur. Ceram. Soc., 2017, 37(9): 3017-3026.

[16] HUANG X, DING W, ZHU Y, et al. Influence of microstructure and grinding load on the bulk toughness and fracture behavior of PCBN abrasive grains [J]. Int. J. Adv. Manuf. Tech., 2017, 94(3): 1-12.

[17] LIU G, KOU Z, YAN X, et al. Sintering of fine grained polycrystalline cubic boron nitride compacts without binder [J]. Appl. Mech. Mater., 2014, 665: 79-84.

[18] JIA H S, LE Y, LI J, et al. Preparation of polycrystalline cubic boron nitride compact by high-pressure infiltration using cemented carbide [J]. Int. J. Refract. Met. H., 2013, 41(4): 138-142.

[19] ERASMUS R M, COMINS J D, FISH M L. Raman and photoluminescence spectra of indented cubic boron nitride and polycrystalline cubic boron nitride [J]. Dia. Relat. Mater., 2000, 9(6): 600-604.

[20] SIGALAS I, DAVIES, GEOFFREY J. Ulna-hard WC-diamond and WC-BN composite materials for abrasive tools: WO, 2004040029 [P]. 2004-05-28.

[21] ZANG J, WANG M, WANG Y, et al. Structure and properties of Si3N4bond polycrystalline cubic boron nitride toughened with ZrO2(Y2O3) [J]. Chin. J. Mater. Res., 2000, 14(6): 595-598.

[22] DOGAN C P, HAWK J A. Influence of whisker toughening and microstructure on the wear behavior of Si3N4- and Al2O3-matrix composites reinforced with SiC [J]. J. Mater. Sci., 2000, 35(23): 5793 - 5807.

[23] DONG Q, WEI X, PENG J, et al. Study of micro-structure of PCBN with Si3N4whisker binders [J]. Dia. Abra. Eng., 2010, 30(1): 50-52.

[24] SUMIYA H, HARANO K, ISHIDA Y. Mechanical properties of nano-polycrystalline CBN synthesized by direct conversion sintering under HPHT [J]. Dia. Relat. Mater., 2014, 41(1): 14-19.

[25] SUMIYA H, HARANO K. Innovative ultra-hard materials: binderless nano-polycrystalline diamond and nano-polycrystalline cubic boron nitride [J]. Sei Technical Review, 2016(82): 21-26.

[26] NAGAKUBU A, OGI H, SUMIYA H, et al. Elasticity and hardness of nano-polycrystalline boron nitrides: The apparent Hall-Petch effect [J]. Appl. Phys. Lett., 2014, 105(8): L9.

[27] SUMIYA H, ISHIDA Y, ARIMOTO K, et al. Real indentation hardness of nano-polycrystalline CBN synthesized by direct conversion sintering under HPHT [J]. Dia. & Relat. Mater., 2014, 48(3): 47-51.

[28] ICHIDA Y, OHFUJI H, IRIFUNE T, et al. Synthesis of coarse-grain-dispersed nano-polycrystalline cubic boron nitride by direct transformation under ultrahigh pressure [J]. Dia. Relat. Mater., 2017, 77: 25-34.

[29] UESAKA S, SUMIYA H. Mechanical properties and cutting performances of high purity polycrystalline CBN compact [J]. ASME Manuf. Sci. Eng. Med., 1999, 10: 759-766.

[30] OHASHI T, YAMAMOTO K, HAMADA Y, et al. Some properties and cutting performance of polycrystalline cubic boron nitride with no additives [J]. Int. J. Refract. Met. H., 1998, 16: 403-407.

[31] SUMIYA H, UESAKA S, SATOH S. Mechanical properties of high purity polycrystalline CBN synthesized by direct conversion sintering method [J]. J. Mater. Sci., 2000, 35(5): 1181 - 1186.

[32] ICHIDA Y, OHFUJI H, IRIFUNE T, et al. Synthesis of coarse-grain-dispersed nano-polycrystalline cubic boron nitride by direct transformation under ultrahigh pressure [J]. Dia. Relat. Mater, 2017, 77: 25-34.

[33] LU J, KOU Z, LIU T, et al. Submicron binderless polycrystalline diamond sintering under ultra-high pressure [J]. Dia. Relat. Mater., 2017, 77: 41-45.

Author introduction

XIE Hui, male, born in 1983. Mainly engaged in the research and development of high-pressure synthesis of PCBN, PDC and diamond-related new materials and their applications.E-mail: xiehui9019@126.com