Study on Rheological Characteristics of a Grease Used in High Speed Bearing

Wang Yanshuang; Li Shaochuan; Guo Dan

(1. College of Mechanical Engineering, Tianjin University of Technology and Education, Tianjin 300222; 2. School of Mechanical Engineering, Tsinghua University)

Study on Rheological Characteristics of a Grease Used in High Speed Bearing

Wang Yanshuang1,2; Li Shaochuan1; Guo Dan2

(1. College of Mechanical Engineering, Tianjin University of Technology and Education, Tianjin 300222; 2. School of Mechanical Engineering, Tsinghua University)

On a self-made super-high shear strain rate rheometer, the rheological characteristics and apparent viscosity curves of a high-speed bearing grease were obtained under different working conditions. A new grease rheological model suited to a shear strain rate range of 0—3.5×106s-1was presented. The results showed that the shear stress increased linearly at frst and then increased nonlinearly with the increase in shear strain rate up to1.5×106s-1, and fnally the shear stress decreased slightly with the successive increase in shear strain rate. The shear stress increased with a decreasing rolling speed and an increasing contact pressure. The apparent viscosity decreased rapidly with the increase of shear strain rate at beginning and could approach the viscosity of the base oil if the shear strain rate surpassed 1.5×106s-1. The fts between the test data and the predicted values by the new model were fairly good.

grease; rheological characteristic; rheological model; high speed bearing; high shear strain rate

1 Introduction

The ability of flow and deformation of grease by the effect of the external force is known as the grease rheological characteristic. The rheological characteristics of lubricating greases are complicated because the greases are non-Newtonian fluids. With the development of science and technology, the requirements for improving the movement accuracy and life of the high speed bearings are urgent. Rolling bearings are frequently faced with challenges primarily relating to the failure of lubrication system rather than the surface fatigue. The rheological characteristics of lubricating greases can determine the friction characteristics of high speed bearings, which thereby can affect the bearing life and bearing movement accuracy. So, the study on rheological characteristics of greases for high speed bearing is of great significance. It is well-known that when a shear force is applied on a portion of grease, a reorientation of the composite fbers is induced and the overall fuidity of the grease improves. To characterize this behavior, many rheological models have been presented.

Sasaki[1]firstly used the Bingham model to describe the rheological characteristics of lubricating grease and presented a lubrication theory for roller bearings. In 1972, a relatively complete EHL theory of lubricating greases was presented by Kauzlarich, who used the Herschel-Bulkley constitutive equation to derive lubrication equations of lubricating greases under the line contact[2]. Till now, the researches on the rheological characteristics and models of lubricating greases have not achieved too much development yet. Goncalves[3]and González[4]used a MCR 301 rheometer to perform the rheology measurements. The storage and loss moduli were measured in the linear visco-elastic region at a frequency of 1 s-1. Cousseau Tiago[5]measured the apparent grease viscosity as a function of the shear rate, in which the power-law model was used. In the literature[6], the rheological characteristics of several greases were studied with a MCR 501 rheometer in a shear rate range of 3×10-3—102s-1, resulting in flow curves which could be satisfactorily described by the well-known powerlaw model. In the literature reports[7-9], the fow curve of each grease was also measured and a modifed Herschel-Buckley model was applied. Мenéndez[10]presented the numerical simulation of an air-operated piston pump for lubricating greases, and the power-law model for non-Newtonian fuids was applied. The grease related thermal elastohydrodynamic lubrication (TEHL) problems of line contacts were analyzed numerically in the literature[11]. The effects of temperature and rheological parameters on grease TEHL were investigated using the Herschel-Bulkley model as a rheological model of greases. It is found that the effect of yield stress of the Herschel-Bulkley model on minimum flm thickness is negligible, while the flow index and viscosity parameter have signifcant effects on the minimum flm thickness. Cheng Jinshan[12]studied the colloidal structure, the elastic modulus, and the apparent viscosity of several greases, as well as the characteristics of shear stress in relation to the change of temperatures and shear rates. Мa(chǎn)o Jingjing[13]studied the relationship between the rheological parameters and the microstructure of lubricating greases through the rheological tests of five kinds of lithium greases.

However, the shear strain rates of lubricating greases studied in the above literature reports cannot exceed 104s-1because of the constraints in the structure of the rotary rheometer. In practical applications, many greases, especially those greases used in high speed bearings, are applied under the operating conditions with shear strain rates reaching up to 106s-1. The rheological characteristics of greases are strongly shear strain rate dependent because of the non-Newtonian characteristics of greases. The rheology measurements and rheological models referred to in the above literature reports cannot give the reference to the grease characteristics used in high speed bearings when the shear strain rate ranges from 104—3.5×106s-1.

In this paper, the rheological characteristics and apparent viscosity of a high speed bearing grease were measured on a self-made super-high shear strain rate rheometer, and a new grease rheological model suitable for the super-high shear strain rates was presented fnally.

2 Test Device and Principle

The test device used in this experiment can be named as a super-high shear strain rate rheometer, with its main structure shown in Figure 1. The super-high shear strain rate rheometer is composed of a ball specimen and a disc specimen that are driven by a horizontal motor I and a vertical motor II, respectively. During the test, the hydrostatic shaft which supports motor I is employed to apply a contact load between the rotating ball and the disc. The contact load is measured by a load sensor fxed beneath the hydorstatic shaft. The motor I can swing along the horizontal plane.

Figure 1 The super-high shear strain rate rheometer

The tested grease is fed with a gas-pressure activated grease feeding device shown in Figure 2, by which a controlled amount of fresh grease can be deposited on the contact zone between the ball and the disc. The device for gas-pressure activated grease feeding consists of an air suction flter, a pressure control valve, a grease cylinder, a switch valve, a surveyor’s pole and a grease export. The speed of grease feed and the volume of the grease in the grease cylinder can be surveyed by the surveyor’s pole. The speed of grease feed can be adjusted to 4—8 g/min to assure a continuous supply of fresh grease to the contact. The head of the surveyor’s pole is the piston. There are two seal rings between the piston and the grease cylinder. The seal rings can keep the air out of the left space of thegrease cylinder, in which the grease is stored.

Figure 2 The device for feeding grease under gas pressure

in which A is the contact area and can be computed by means of the Hertzian contact theory.

Since the grease film thickness is close to that of its base oil for the grease the soap concentration of which is less than 15%[14], the value of h can be calculated by the formula of the central film thickness of the base oil according to the Hamrock-Downson’s equation[15]:

where k is the ellipticity ratio, W is the contact load, E′=E1E2/(E1+E2) is the equivalent modulus of elasticity (E1and E2are modulus of elasticity of the ball and the disc, respectively), R=R1R2/(R1+R2) is the equivalent radius, α is the viscosity-pressure coeffcient of base oil, η0is the dynamic viscosity of the base oil at the ambient temperature, and U=(U1+U2)/2 is the rolling speed.

The grease used in this investigation was LGLT produced by the SKF Corporation. This LGLT grease is classifed as the super-high-speed grease, the base oil of which is a synthetic oil. The dynamic viscosity of its base oil at ambient temperature was η0=0.05 Pa·s, and its viscositypressure coefficient was α=1.80×10-8Pa-1. The soap concentration of the LGLT grease was below 15%.

The test conditions simulating the operating conditions of SKF rolling bearings were as follows: rolling speeds: 20 m/s, 25 m/s, 30 m/s, 35 m/s, and 40 m/s; maximum Hertzian contact pressures: 0.8 GPa, 1.0 GPa, 1.2 GPa, 1.35 GPa, and 1.5 GPa; and the shear strain rates: 0—3.5×106s-1. The grease inlet temperature was 25oC.

3 Shear Stress-Shear Strain Rate Curves

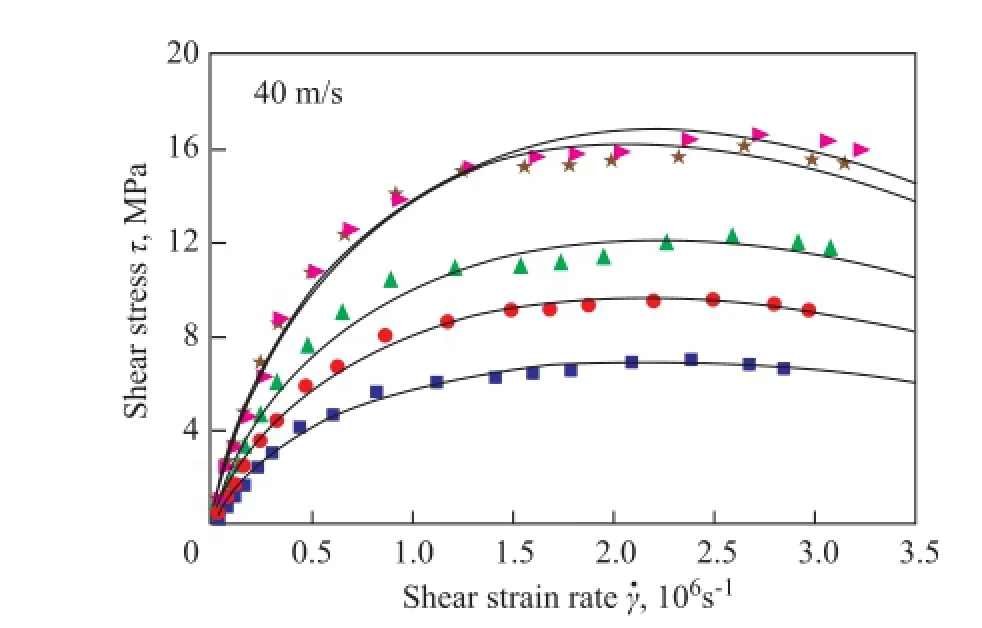

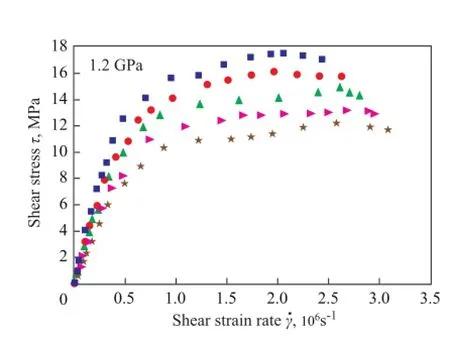

A total of 25 curves describing the rheological behavior of the grease in terms of the shear stress versus shear strain rate were obtained in the range of the test conditions, as shown in Figures 3—8 (with the points representing test data).

It can be seen from Figures 3—8 that the shear stress increased linearly at frst and then increased nonlinearly with the increase of shear strain rate, and finally the shear stress slightly decreased with a further increase of the shear strain rate. When the shear strain rates exceeded 1.5×106s-1, the shear stress decreased slightly with the successive increase in the shear strain rate. This phenomenon could occur because the shear strain rate became so big that the grease structure was broken down, and at this moment the shear properties were mainlydetermined by the base oil. The thermal effect would result in the reduction of the base oil viscosity, making the shear stress-shear strain rate curves decrease at high shear strain rates.

Figure 3 Shear stress versus shear strain rate under different contact pressure at a rolling speed of 20 m/s■—0.8 GPa;●—1.0 GPa;★—1.2GPa;?—1.35 GPa;?—1.5 GPa——Predicted values by the new model

Figure 4 Shear stress versus shear strain rate under different contact pressure at a rolling speed 25 m/s■—0.8 GPa;●—1.0 GPa;▲—1.2 GPa;★—1.35GPa;?—1.5 GPa——Predicted values by the new model

Figure 5 Shear stress versus shear strain rate under different contact pressure at a rolling speed of 30 m/s■—0.8 GPa;●—1.0 GPa;▲—1.2 GPa;★—1.35GPa;?—1.5 GPa——Predicted values by the new model

Figure 6 Shear stress versus shear strain rate under different contact pressure at a rolling speed of 35 m/s■—0.8 GPa;●—1.0 GPa;▲—1.2 GPa;★—1.35GPa;?—1.5 GPa——Predicted values by the new model

Figure 7 Shear stress versus shear strain rate under different contact pressure at a rolling speed of 40 m/s■—0.8 GPa;●—1.0 GPa;▲—1.2 GPa;★—1.35GPa;?—1.5 GPa——Predicted values by the new model

Figure 8 Shear stress versus shear strain rate under different rolling speed at a contact pressure of 1.2 GPa■—20 m/s;●—25 m/s;▲—30 m/s;?—35 m/s;★—40 m/s

It can be seen from Figures 3—7 that the shear stress increased with an increasing contact load or with a maximum Hertzian contact pressure at a constant rolling speed. It is evident that the effect of contact load or the Herzian contact pressure on the shear stress tended to become smaller when the maximum Hertzian pressure surpassed 1.35 GPa, indicating that the grease tended towards plasticization. Figure 8 indicates that a lower rolling speed could yield a larger shear stress under a constant pressure.

4 Apparent Viscosity of the Grease

The ratio of the grease shear stress and shear strain rate is called the apparent grease viscosity as shown in formula (4):

5 Rheological Model of Grease

5.1 Herschel-Bulkley model and four-parameter modelThe rheological models of greases presented in most literature reports belong to the Herschel-Bulkley model and the four-parameter model. The Herschel-Bulkley model can be defned as:

Figure 9 Apparent grease viscosity versus shear strain rate under different contact pressure at a rolling speed of 20 m/s■—0.8 GPa;●—1.0 GPa;▲—1.2 GPa;★—1.35 GPa; ?—1.5 GPa

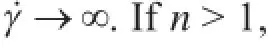

Figure 1 0Apparent grease viscosity versus shear strain rate under different contact pressure at a rolling speed of 25 m/s■—0.8 GPa;●—1.0 GPa;▲—1.2 GPa;★—1.35 GPa; ?—1.5 GPa

Figure 1 1Apparent grease viscosity versus shear strain rate under different contact pressure at a rolling speed of 30 m/s■—0.8 GPa;●—1.0 GPa;▲—1.2 GPa;★—1.35 GPa; ?—1.5 GPa

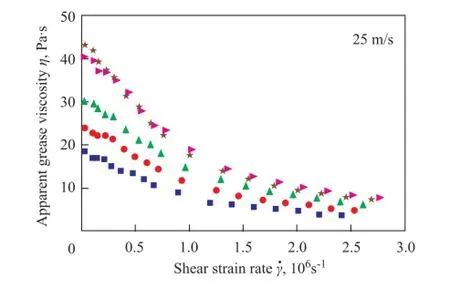

Figure 12Apparent grease viscosity versus shear strain rate under different contact pressure at a rolling speed of 35 m/s■—0.8 GPa;●—1.0 GPa;▲—1.2 GPa;★—1.35 GPa; ?—1.5 GPa

Figure 1 3Apparent grease viscosity versus shear strain rate under different contact pressure at a rolling speed of 40 m/s■—0.8 GPa;●—1.0 GPa;▲—1.2 GPa;★—1.35 GPa; ?—1.5 GPa

Figure 1 4Apparent grease viscosity versus shear strain rate under different rolling speed at a contact pressure of 0.8 GPa■—20 m/s;●—25 m/s;▲—30 m/s;★—35 m/s;?—40 m/s

It is confirmed that the grease film thickness under elastohydrodynamic conditions exceeds that of the corresponding base oil, when there is a continuous supply of fresh grease to the contact[14]. The higher flm thickness given by grease indicates that the apparent viscosity of grease is greater than the viscosity of base oil. At very high shear stresses or shear strain rates, the grease structure will be broken down, and the base oil will be released from the soap fbres to form perhaps a suspension of soap in oil. So, at extremely high shear rates, the grease viscosity will be close to that of the base oil. The fourparameter model has been accepted widely, because it satisfes the fact that the apparent grease viscosity cannot decrease below the base oil viscosity. The four-parameter model proposed by Bauer, et al. is shown as:

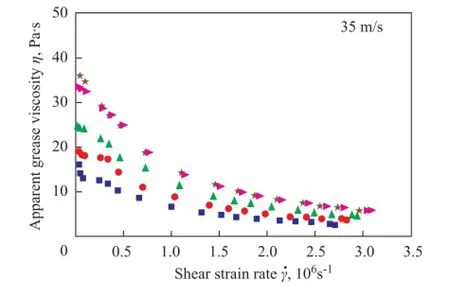

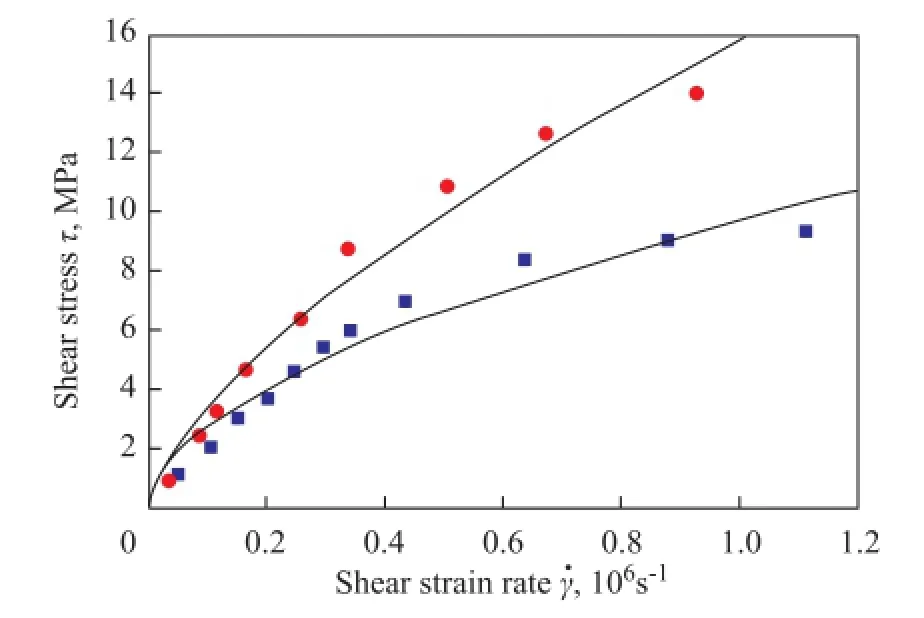

where,ηbis the viscosity of the base oil,nis the rheological index,φis the plastic viscosity, and τsis the yield shear stress. Eq. (6) has been ftted to the test data from our super-high shear strain rate rheometer, using the least squares method. When the test data for a shear strain rate range of 0—1×106s-1were used to fit the model, the four-parameter model is valid as shown in Figure 15. But this model becomes invalid, if the test data for a shear strain rate covering the range of 0—3.5×106s-1were used to fit the model, as shown in Figure 16. As regards the lubricating grease, its shear stresses would increase with the increase of shear strain rate ranging from 0 to 1.5×106s-1, and then the shear stresses tended to be a constant valueor slightly decreased with an increasing shear strain rate covering the range from 1.5×106s-1to 3.5×106s-1. This phenomenon cannot be described by the four-parameter model as shown in Figure 16, which can only describe the relation of shear stress that increases all the time with an increasing shear strain rate. So, the four-parameter model is useful for predicting the grease performance up to a shear strain rate of 1×106s-1, but it will become erroneous at higher values.

Figure 1 5Prediction by four-parameter model at a shear strain rate range of 0—3.5×106s-1■—U=20 m/s,P0=0.8 GPa;●—U=40 m/s,P0=1.5 GPa——Predicted values by four-parameter model

Figure16Prediction by four-parameter model at a shear strain rate range of 0—1×106s-1■—U=20 m/s,P0=0.8 GPa;●—U=40 m/s,P0=1.5 GPa——Predicted values by four-parameter model

5.2 New rheological model

For high speed bearings, the operating conditions for a shear strain rate range of 0—3.5×106s-1can be always found under elastohydrodynamic contacts. So, a new rheological model fitting the flow data for shear strain rates covering from low to super-high shear environments, namely 0—3.5×106s-1, or even up to the higher values, is presented as following:

In whicha,nandbare coefficients which can be obtained by a nonlinear regression analysis to minimize the squared deviation between the test data and the corresponding computed values by Eq. (6). A total of 25 predicted curves by the new rheological model can also be obtained as shown in Figures 3—7. It is obvious that Eq. (6) yields a behavior similar to that of the test curves and the fts between the test data and the predicted values are fairly good. The correlation coeffcients representing the quality of the ft for the total 25 curves are all greater than 0.98.

Actually, the yield stress could not be measured with a cone and plate viscometer which would only give an approximate value. Because the errors of rotational speed unavoidably existed, the results from the measurement obtained by our super-high shear strain rate rheometer were not close enough to give a correct yield stress. But the yield stress was very small compared to other terms. Thus the yield stress has been ignored in Eq. (6). The coeffcientsa,nandbgenerally vary with the operating conditions and the physical properties of grease. The physical signifcance for the coeffcientsa,nandbwill be investigated by further study on the properties of greases and the base oils.

6 Conclusions

Based on a self-made super-high shear strain rate rheometer with its shear rate ranging from 0 to 3.5×106s-1, a total of 25 curves describing the rheological behavior of a high-speed bearing grease in terms of the shear stress versus the shear strain rate were obtained under the specified test conditions, and 25 curves of the apparent grease viscosity versus the shear strain rate were also obtained.

The shear stress increased linearly frst and then increased nonlinearly with the increase of shear strain rate up to 1.5×106s-1, and fnally the shear stress decreased slightly with the successive increase in shear strain rate. The shear stress increased with the increase in the contact load or the maximum Hertzian pressure at a constant rolling speed. The effect of contact load or the Herzian pressureon the shear stress tended to become smaller when the maximum Hertzian pressure surpassed 1.35 GPa, indicating that the grease tended towards plasticization. A lower rolling speed could yield a larger shear stress at a constant pressure.

The apparent viscosity of the grease was strongly shear strain rate dependent under all test conditions. The tested grease showed a shear thinning behaviour. The apparent viscosity decreased rapidly at the beginning and would approach the viscosity of the base oil if the shear strain rate surpassed 1.5×106s-1. The apparent grease viscosity increased with an increasing contact load or a maximum Hertzian pressure, and decreased with an increasing rolling speed. The effects of contact load and rolling speed on the apparent grease viscosity were signifcant at low shear strain rates up to 5×105s-1, and the effects became smaller as the shear strain rate increased from 5×105s-1to 3.5×106s-1.

A new rheological model fitting the flow data for shear strain rate covering from low to the super-high shear environments, namely 0—3.5×106s-1, or even up to the higher values, was presented. The new model yielded a grease behavior similar to that of the test curves and the fts between the test data and the predicted values were fairly good. The correlation coeffcients representing the quality of the ft for the total 25 curves were all greater than 0.98.

Acknowledgements:This research is financially supported by the National Natural Science Foundation of China (No. 51475143) and the Tianjin Natural Science Foundation (No.16JCYBJC18900).

[1] Sasakit Tokio, Мori H, Okino N. Theory of grease lubrication of cylindrical roller bearings[J]. Bulletin of the JSМE, 1960, 3(10): 31-36

[2] Kauzlarich J J. Elastohydrodynamic lubrication with Herschel-Bulkley model grease[J]. ASLE Transaction, 1972, 15(4): 267-277

[3] Goncalves D, Graca B, Campos A V, et al. Film thickness and friction behaviour of thermally aged lubricating greases[J]. Tribology International, 2016, 100: 231-241

[4] Мercedes G, Gallego R, Romero М A, et al. Impact of natural sources-derived antioxidants on the oxidative stability and rheological properties of castor oil basedlubricating greases[J]. Industrial Crops and Products, 2016, 87: 297-303

[5] Tiago C, Beatriz G М, Armando C V, et al. Influence of grease rheology on thrust ball bearings friction torque [J]. Tribology International, 2012, 46: 106-113

[6] Gallego R, Cidade T, Sánchez R, et al. Tribological behaviour of novel chemically modified biopolymerthickened lubricating greases investigated in a steel–steel rotating ball-on-three plates tribology cell [J]. Tribology International, 2016, 94: 652-660

[7] Мa(chǎn)rtín-Alfonso J E, Valencia C. Tribological, rheological, and microstructural characterization of oleogels based on EVA copolymer and vegetable oils for lubricant applications[J]. Tribology International, 2015, 90: 426-434

[8] Goncalves D, Graca B, Campos A V, et al. Formulation, rheology and thermal ageing of polymer greases --Part I: Influence of the thickener content[J]. Tribology International, 2015, 87: 160-170

[9] Мa(chǎn) Fangbo, Li Zhengmei, Qiu Shengchang, et al. Transient thermal analysis of grease-lubricated spherical roller bearings[J]. Tribology International, 2016, 93: 115-123

[10] Мenéndez B A, Fernández O J М. Unsteady numerical simulation of an air-operated piston pump for lubricating greases using dynamic meshes[J]. Computers & Fluids, 2012, 57: 138-150

[11] Yoo Jin-Gyoo, Kim Kyung-Woong. Numerical analysis of grease thermal elastohydrodynamic lubrication problems using the Herschel-Bulkley model[J]. Tribology International, 1997, 30(6): 401-408

[12] Chen Jinshan, Guo Xiaotao, Li Tao, et al. Relationship between rheological properties of lubricating grease and bearing vibration value[J]. Acta Petrolei Sinica (Petroleum Processing Section), 2013, 29(4): 674-680 (in Chinese)

[13] Мa(chǎn)o Jingjing, Cheng Xingguo, Zhang Suixin. Study on relationship between rheological properties and microstructure for lithium complex grease[J]. Lubrication Engineering, 2013, 38(12): 79-83

[14] Gérard D, René N. An evaluation of grease behaviour in rolling bearing contacts[J]. STLE Transactions, Lubrication Engineering, 1986, 43: 905-915

[15] Hamrock B J, Downson D. Isothermal elastohydrodynamic lubrication of point contacts, Part III – Fully flooded results[J]. ASМE Journal of Lubrication Technology, 1977, 99(2): 264-276

Received date: 2016-10-08; Accepted date: 2017-01-09.

Wang Yanshuang, E-mail: hkd_wang_ yan_shuang@126.com.

- 中國(guó)煉油與石油化工的其它文章

- Adsorption of Naphthenic Acids from Dewaxed Vacuum Gas Oil by Activated Clay: Kinetics, Equilibrium and Thermodynamic Studies

- Study on the Modifcation of Vacuum Residue by Ultrasonic Radiation

- Experimental Study on Preparation of Natural Gas Hydrate by Crystallization

- Preparation of Bi2WO6and Its Ultra-Deep Oxidative Desulfurization Performance in Ionic Liquids

- Preparation and Mechanical Properties of PAN/HNTs Composite Nanofbers

- Infuence of Modifed Medical Stone on Behavior of Sulfur during Pyrolysis of Longma Coal