Failure Modes of Machining Center in Test Run

HAO Si-wen(郝思文), CONG Ming (叢 明), HAN Yu-ting (韓玉婷), LI Yong-yao (李泳耀), ZHANG Jian-rong (張建榮)

1 Dalian Xinyu Science Technology Development Center Co., Ltd., Dalian 116024, China 2 School of Mechanical Engineering, Dalian University of Technology, Dalian 116024, China 3 Faw Jiefang Automotive Co., Ltd., Wuxi 214026, China

Failure Modes of Machining Center in Test Run

HAO Si-wen(郝思文)1,2*, CONG Ming (叢 明)1,2, HAN Yu-ting (韓玉婷)1,2, LI Yong-yao (李泳耀)1,2, ZHANG Jian-rong (張建榮)3

1DalianXinyuScienceTechnologyDevelopmentCenterCo.,Ltd.,Dalian116024,China2SchoolofMechanicalEngineering,DalianUniversityofTechnology,Dalian116024,China3FawJiefangAutomotiveCo.,Ltd.,Wuxi214026,China

To analysis the early failures of machining centers, the failure mode effect and criticality analysis (FMECA) method was used. Based on the failure data collected from production lines in test run, all the failure modes of machining centers were summarized and criticality of all subsystems is figured out. And the process of FMECA was improved. The most critical subsystem was manipulator subsystem. The most critical failure mode was impacted manipulator. Reasons and effect of some important failure modes were analyzed. And some suggestions to solve failures were given.

failuremodeeffectandcriticalityanalysis(FMECA);machiningcenter;failuremode

Introduction

Failure mode effect and criticality analysis (FMECA) method is widely used in engineering now. It is developed from failure mode and effect analysis. Based on the development of failure mode and effect analysis, criticality analysis (CA) method was added into it. In the mid-1980s, FMECA was first used in automobile industry[1]. Many countries had made criteria of FMECA. The Department of Defense of USA issued the criteria of FMECA in 1980. It is called MIL-STD-1629. Now many researchers had improved FMECA[2- 3], and some branches of FMECA had been created[4-5]. Reliability of machining centers was also studied for many years. FMECA is also an effective way to improve reliability of machining centers. FMECA can help users find out the weak parts of machining centers and reasons of failure modes to make maintenance plan[6-7].

The report of FMECA can also be fed back to the designers of machining centers to help improve design scheme. Machining centers are complicated and any failure mode may make serious effect. So analyzing the failure modes in test run is a good way to improve the reliability of machining centers.

1 MDH80 Machining Center

1.1 Failure data collection

Machining center is the most important equipment in production line. In this paper, the research target is the domestic MDH80 machining centers in test run. To analyze the reliability by FMECA, the failure data must be real. In this paper, all failure data are collected from users’ failure report of production line in initial 6 months. It means that these machining centers were just used in this production line for 6 months. In this stage, most of failure modes in machining centers appeared. So it is the best stage to analyze failures of machining centers. By analyzing these failure modes, users of machining centers can make effective solutions and maintenance plans.

In this production line, there are 16 machining centers of MDH80 type. Diesel engine cylinder block and head are the products of this production line.

1.2 Subsystems of machining center

Machining center is a complicated system. Figure 1 is one of the MDH80 machining centers in this production line. According to the requirements of analyzing reliability, the machining center is divided into ten major subsystems[8- 9]. And the frequencies of failures in all subsystems are also written in Table 1. It is shown in Table 1 that the manipulator subsystem and computer number control (CNC) subsystem have seriously negative influences on line pitch. And the failure percentage of spindle and lubrication subsystems are lower than others. However, it doesn’t mean that their failure’s criticality must be lower than others’.

Fig.1 MDH80 machining center

NameofsubsystemsFrequencyPercentage/%Toolmagazinesubsystem910.11Feedingsubsystem77.87Spindlesubsystem44.49Manipulatorsubsystem1921.35Fixturesubsystem1314.61CNCsubsystem1719.10Protectionsubsystem77.87Lubricationsubsystem22.25Coolingandchipremovalsubsystem44.49Hydraulicsubsystem77.87

2 Analysis of Failure Mode

The failure percentage of subsystems cannot show the criticality of subsystems’ failure to machining centers. To quantitatively analyze criticality caused by subsystems’ failure, the FMECA method will be used in this chapter.And failure modes are focused on in this method. Effect and causes of failure modes are also analyzed in this chapter.

2.1 Classification of failure modes

One machining center can achieve multiple functions and applications. And there are thousands of components and elements inside a machining center. So machining centers have many types of failure modes. And effects of failure can be reflected from the names of failure modes.

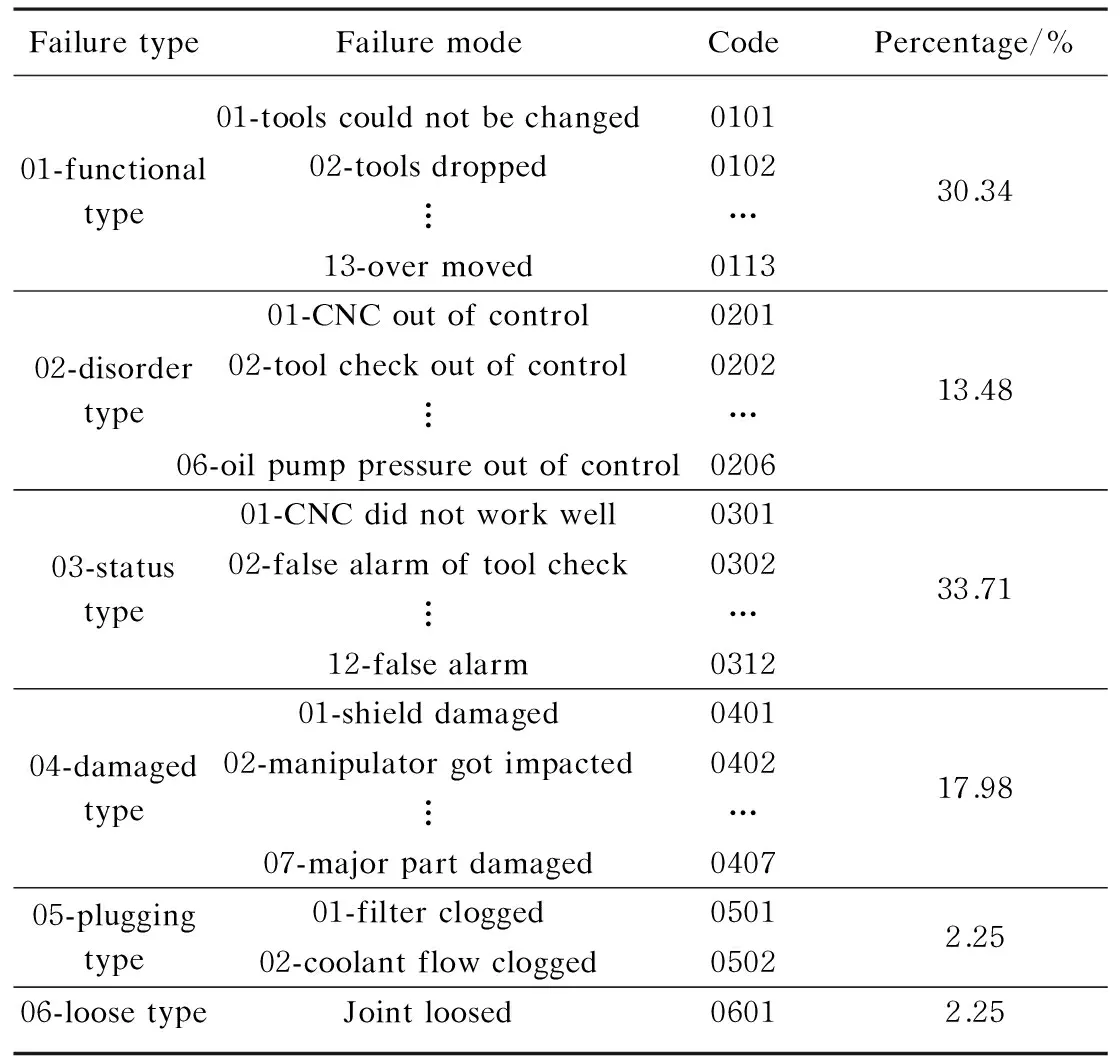

To facilitate machining center’s users and designers to deal with failures, this paper classifies all failure modes.And criteria for failure modes classification are also summarized as the following six types[10].

(1) Failure mode of functional type meant that the subsystems could not implement its function. And it also meant that the mechanism could not complete the requested action.

(2) Failure mode of disorder type meant that the subsystem was temporarily out of control and it was not damaged.

(3) Failure mode of status type meant that the subsystems were in bad status. For example, missing signal and false alarm can be included into this type.

(4) Failure mode of damaged type meant that some parts of machining centers had been damaged. If the operators improperly used machining center, the number of damaged type would increase.

(5) Failure mode of plugged type appeared when the liquid in machining center was plugged.

(6) Failure mode of loosed type often appeared when assembly workers did not tighten joints well.

It can be seen that effects of failures have been reflected from the names of failure modes. Effect of most failure modes is that some parts of machining centers cannot work. Because machining center is a kind of series system, machining center will not work if any part of it has failure. So effect of most failure modes is increasing the task time of production line. Failures of plugged type and loose type can have a negative effect on the environment of production line.

In Table 2, it can be seen that 33.71% of failure modes are of status type and 30.34% of failure modes are of functional type. Failures of these two types should be paid much attention to in test run. And 17.98% of failure modes are of damaged type. So the machining center can be damaged with a great probability. These failures should be solved immediately in test run.

2.2 Method of CA

CA is a highly significant method of FMECA. Its purpose is to calculate the criticality of each failure mode. And finally, the criticality of each subsystem can also be calculated. By CA method, users of machining centers can find the difference of criticality between each subsystem.

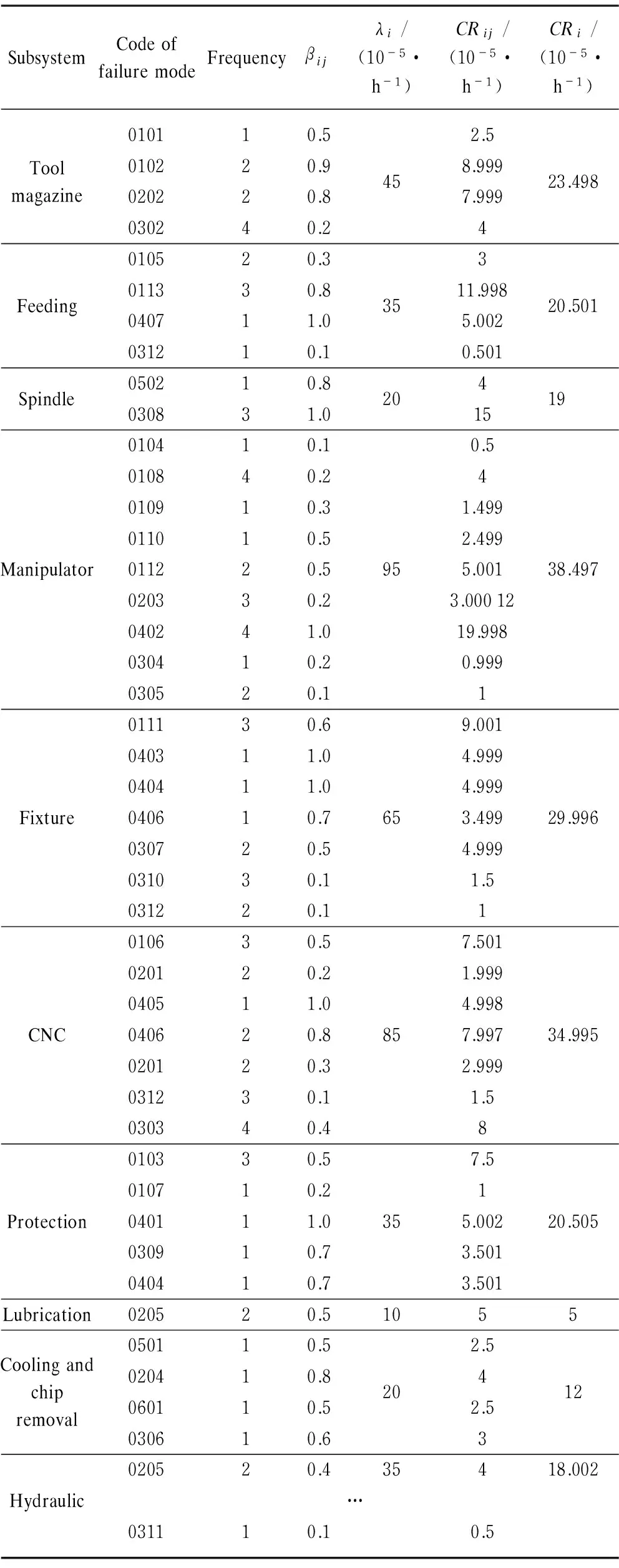

As written in Table 1, the machining center can be divided into 10 subsystems. The criticality of each subsystem is defined asCRi. So the criticality of the ten subsystems can be set as tool magazine subsystem(CR1), feeding subsystem(CR2), spindle subsystem(CR3), manipulator subsystem(CR4), fixture subsystem(CR5), CNC subsystem(CR6), protection subsystem(CR7), lubrication subsystem(CR8), cooling and chip removal subsystem(CR9), and hydraulic subsystem(CR10).

If failure modejhappens in subsystemi, the criticality of failure modejto the machining center can be defined asCRi j. The calculation formula is shown in Eq.(1).

CRi j=αi jβi jλi.

(1)

The criticality from overall failures of subsystemIto the machining center can be calculated as follows[11]:

(2)

All failure modes are listed in Table 2. The percentage of failures in all failure types is also shown in Table 2.

Table 2 All failure modes

Adding Eq.(1) into Eq.(2), theCRican also be calculated as follows:

(3)

In Eqs. (1)-(3),nis the amount of failure modes in subsystemi,αi jis the rate of failure modejin subsystemi. It can be calculated as follows:

(4)

wherenjis the frequency of failure modejin subsystemiandniis the total frequency of failures in subsystemi.

βi jis the probability of damage when failure modejoccurs in subsystemi. In traditional FMECA method, theβi jusually has four kinds of values[12]. Whenβi jis 0, it means that there will not be damage to subsystems or the whole machining center. Whenβi jis 1, it means that the machining center must be damaged by this failure mode. Whenβi jis 0.1, it means that the machining center has a very small possibility to be damaged. And in traditional method whenβi jis 0.5, it means that the machining center has a certain possibility to be damaged. However, machining center is too complicated. The difference between 0.5 and 1 is obviously too much here. And if failure modeais more likely to damage machining centers than failure modeb, theβi jcannot reflect the difference when theβi jis 0.5. So in this paper, theβi jcan be any value between 0.1 and 0.9 when the machining center has a certain possibility to be damaged. The higher value of theβi jmeans the more possibility of being damaged.

(5)

whereNiis the frequency of failure in subsystemi. ∑tis the total running time of machining center. In this research the machining centers run 20000 h.

Then the calculating results for all the failure modes are shown in Table 3.

Table 3 Calculation of criticality

2.3 Results for CA

From Table 3, the code of failure modes has a very high criticality is 0402 and 0113. These failures should be solved immediately and the fundamental cause of these failures should be found out to prevent recurrence of similar incidents after test run.

From Table 1, it can be found that manipulator and CNC subsystems are much higher than others. So the users of machining center must pay much attention to these two subsystems. The frequencies of feeding subsystem, protection subsystem and hydraulic subsystem are the same. However, the criticality value of hydraulic subsystem is lower than the other two.

Thus the frequency of manipulator subsystem’s failures is 3.76 times higher than that of spindle subsystem. But the criticality of manipulator subsystem is only one times higher than the criticality of spindle subsystem. It means that when spindle subsystem has failure, the machining center will also have a large probability of being damaged.

So only comparing the frequencies of subsystems as Table 1 shows cannot reflect the criticality of each subsystem. And CA is a more scientific method for analyzing the failures of the machining centers.

2.4 Analysis for the causes of failure

In manipulator subsystem, most failure modes were caused by imperfect procedure. When some emergencies happened in production line, the procedure had no plan to deal with it. So the users and designers must improve the procedure of control. They should consider all kinds of emergencies when they are making procedure in manipulator subsystem.

Most failures of CNC subsystem is caused by sensors’ problem. The sensors of CNC subsystem also need to be paid much attention to. Assembly of sensors should be supervised. And the signal transmission route should be protected.

Gas detectors in fixture subsystem need to be reset. Dropping tool is a serious failure in tool magazine subsystem.The cause of this failure was mainly due to problems of the control and electrical system. Improving procedures and carrying out maintenance of electrical equipment are important measures to protect the tool magazine. Adjusting the detection sensors in the right position and making sure the reliability of the sensor are the keys to solve the failures of tool detection.

The failures of feed subsystem mainly occurred inX/Y/Zfeed axis and rotary table. Protecting the signal transmission process is an important measure to reduce the failures of rotary table.

The causes of failure modes in spindle subsystem were complicated. And it is very hard to find the reasons. Users must pay a lot of attention to avoiding this failure.

Most failures happened in protection subsystem were caused by assembly. And most failure happened in hydraulic subsystem were caused by purchased parts.

It can be summarized that most failures were caused by sensors and imperfect procedure. So making measures to protect sensors and improving procedures of control will be effective ways to improve the reliability of machining centers.

3 Conclusions

The failure modes of MDH80 machining centers in test run are deeply analyzed by FMECA. This machining center is divided into ten subsystems. The failure modes are divided into six types and all failure modes are summarized. The effect of some failure modes is introduced. The calculation method of CA is introduced and improved. Theβi jin CA is redefined to be any value between 0.1 and 0.9 when machining centers have certain possibility to be damaged. The criticality value of all failure modes and subsystems are figured out. The most critical failure mode is code 0402. And the most critical subsystem is the manipulator subsystem. Through comparing with the criticality value of all subsystems, it can be found out that spindle subsystem also has a large probability to make damage. By analyzing failure modes, reasons of some important failure modes are introduced and maintenance suggestions are given. To improve the reliability of machining center, protecting sensors and improving procedure of control will be effective ways in test run. By analyzing failure modes, FMECA is proved to be a scientific method to improve the reliability of machining center.

[1] Chen Y, Ye C, Liu B D,etal. Status of FMECA Research and Engineering Application [C]. Proceedings of the IEEE 2012 Prognostics and System Health Management Conference(PHM 2012), Beijing, 2012: 1-9.

[2] Mauri F, Garetti M, Gandelli A. A Structured Approach to Process Improvement in Manufacturing Systems [J].ProductionPlanning&Control, 2010, 21(7): 695-717.

[3] Pillay A, Wang J. Modified Failure Mode and Effects Analysis Using Approximate Reasoning [J].ReliabilityEngineering&SystemSafety, 2003, 79(1): 69-85.

[4] Kim J H, Jeong H Y, Park J S. Development of the FMECA Process and Analysis Methodology for Railroad Systems [J].InternationalJournalofAutomotiveTechnology, 2009, 10(6): 753-759.

[5] Johnson K G, Khan M K. A Study into the Use of the Process Failure Mode and Effects Analysis(PFMEA) into the Automotive Industry in the UK [J].JournalofMaterialsProcessingTechnology, 2003, 139(1): 348-356.

[6] Ahmad R, Kamaruddin S, Azid I A,etal. Failure Analysis of Machinery Component by Considering External Factors and Multiple Failure Modes a Case Study in the Processing Industry [J].EngineeringFailureAnalysis, 2012(25): 182-192.

[7] Jia Z C, Yang Z C, Shen G X. Early Failure Mode Effect and Oriticality Analysis for CNC Machining Tools [J].AppliedMechanicsandMaterials, 2013, 303/304/305/306: 1653-1656.

[8] Wang Y Q, Yam R C M, Zuo M J,etal. A Comprehensive Reliability Allocation Method for Design of CNC Lathes [J].ReliabilityEngineering&SystemSafety, 2001, 72(3): 247-252.

[9] Tinga T. Principles of Loads and Failure Mechanisms [M]. London: Springer, 2013: 14-27.

[10] Wang Y H, Deng C, Wu J,etal. A Corrective Maintance Scheme for Engineering Equipment [J].EngineeringFailureAnalysis, 2014(36): 269-283.

[11] Manzini R, Regattieri A, Pham H,etal. Maintenance for Industrial Systems [M]. Berlin: Springer, 2010: 1-127.

[12] Lu X H, Jia Z Y, Gao S G,etal. Failure Mode Effects and Criticality Analysis (FMECA) of Circular Tool Magazine and ATC [J].JournalofFailureAnalysisandPrevention, 2013, 13(2): 207-216.

Foundation item: National Science and Technology Major Project of China (No. 2013ZX04012071)

1672-5220(2014)06-0835-04

Received date: 2014-08-08

* Correspondence should be addressed to HAO Si-wen, E-mail: haosiw6reliability@163.com

CLC number: TH137 Document code: A

Journal of Donghua University(English Edition)2014年6期

Journal of Donghua University(English Edition)2014年6期

- Journal of Donghua University(English Edition)的其它文章

- Stress-Strength Structural Reliability Model with a Stochastic Strength Aging Deterioration Process

- Settlement Prediction of Dredger Fill with the Optimal Combination Model

- Condition-Based Maintenance Decision-Making for Equipment

- Identification of the Credit Guarantee Network of Steel Trade Enterprises in China

- Methods for Reliability Assessment under Irregular Time-Varying-Stress Degradation Testing

- Efficient Method for Accelerated Reliability Qualification Testing