HEAT TRANSFER OF TiO2/WATER NANOFLUID IN A COILED AGITATED VESSEL WITH PROPELLER*

PERARASU V. T., ARIVAZHAGAN M., SIVASHANMUGAM P.

Heat Transfer Research Laboratory, Department of Chemical Engineering, National Institute of Technology, Tiruchirappalli 620 015, Tamilnadu, India, E-mail: vtparasu@gmail.com

(Received February 21, 2012, Revised May 18, 2012)

HEAT TRANSFER OF TiO2/WATER NANOFLUID IN A COILED AGITATED VESSEL WITH PROPELLER*

PERARASU V. T., ARIVAZHAGAN M., SIVASHANMUGAM P.

Heat Transfer Research Laboratory, Department of Chemical Engineering, National Institute of Technology, Tiruchirappalli 620 015, Tamilnadu, India, E-mail: vtparasu@gmail.com

(Received February 21, 2012, Revised May 18, 2012)

An attempt is made to investigate heat transfer enhancement using nanofluid in a coiled agitated vessel fitted with propeller agitator. The heat transfer coefficient in coiled agitated vessel for water and TiO2/water nanofluid of 3 different volume concentrations (0.10%, 0.20% and 0.30%) are estimated and compared. The heat transfer coefficient for nanofluid is found to be higher than that for water and also found to increase with increasing volume concentrations. The enhancement in the convective heat transfer using nanofluid is found to be a maximum of 17.59%. Empirical correlations are separately formed for water and TiO2/water nanofluid as well as found to fit the experimental data within ±5% for water and within ±10% for nanofluid.

coiled agitated vessel, heat transfer enhancement, Nusselt number, TiO2/water nanofluid

Introduction

Heat transfer has broad application in processing industries and also in the functioning of various devices and systems. In a wide variety of situations, heat transfer principles are used to increase, decrease or preserve temperature to achieve desired process at a controlled rate. Out of many heat transfer processes in practice, agitation is one of the important chemical engineering operations and together with material transport and heat transfer, it is probably the most universally employed operation in almost all chemical industries. Many chemical processing industries involve the operation of mixing or interpenetration of one substance with another. The most commonly-used equipment for the purpose is a vessel fitted with agitator called agitated vessels, which are extensively used in all chemical process industries. Agitated vessels are often also used as mixers, aerators and reactors. Agitated vessels are suitable for carrying out reactions under isothermal conditions where the heat of reaction is high. Heating or cooling of the reaction system toconduct the reaction at desired temperature is affected either by jacketing the vessel or by introducing a heat transfer surface inside the vessel in the form of helical coil. In some cases, both the jacket and helical coil are used for enhancing the rate of heat transfer. In most of the cases the use of immersed helical coil is more suitable than the use of jackets as the heat transfer coefficient is high in the coil than in jacket and also coil provides large surface area in a relatively small reactor volume for heat transfer.

There have been many investigations on heat transfer coefficients in a coiled agitated vessel for different type of impellers and less work has been devoted to study the effect of impeller position in the tank on heat transfer. In most of the reported works, heat transfer studies were conducted by varying agitator speed and arbitrarily fixing the flow rates of cooling or heating medium without changing the heat input. Recently, Triveni et al.[1]studied heat transfer of few industrially important systems and Perarasu et al.[2]presented a descriptive report on the effect of varying heat input to the agitated medium on heat transfer performance in a coiled agitated vessel. All the earlier works in coiled agitated vessels carried out so far, have used various Newtonian and non Newtonian fluids (single/two phase liquids, solid-liquid, gas-solid and gas-solid suspensions) for heat transfer experi-mentation.

An innovative way of improving the heat transfer performances by means of improving thermal conductivities of fluids is to suspend small solid particles of high thermal conductivity in the fluids. The idea of bringing millimeter- or micrometer-sized particles in suspension with conventional fluids for the increased heat transfer rate is a common technique and attempted many years ago. But such suspensions bear major disadvantages like settling[3], clogging flow channels[4], erosion to heat transfer devices and increased pressure drop[5]. Hence, the enhancement mechanism of heat transfer using different techniques has attracted wide interest in the recent years. Out of many devoted efforts, the use of energy efficient heat transfer fluids, which are engineered by suspending nano sized particles in conventional heat transfer fluids, has created considerable interest for their improved heat transfer capabilities.

Nanofluid (liquid suspensions containing particles with dimensions significantly smaller than 100 nm) is the term coined by Choi and Eastman to describe this new class of nanotechnology-based heat transfer fluids. The potential advantages of properly engineered nanofluid include: (1) higher thermal conductivities than that predicted by currently available macroscopic models, (2) excellent stability, and (3) little penalty due to an increase in pressure drop and pipe wall abrasion than experienced by suspensions of millimeter or micrometer particles.

The incredible increase in the use of nanofluids for heat transfer applications in the recent years envisage this work to use nanofluid as agitated medium in a coiled agitated vessel. The earlier investigations for heat transfer investigations using nanofluids have been carried out only in heat exchangers of various forms: (1) circular tubes (horizontal/vertical, heated/ unheated)[6-14], (2) double pipe[15-17], (3) shell and tube[18], (4) multi channel heat exchangers[19]), (5) others (radial flow cooling device[20,21]and rectangular micro channels[22,23]). The outcome of all these investigations showed that the inclusion of nanoparticles to a base fluid improves the convective heat transfer compared to the base fluid and the enhancement of heat transfer coefficient increases with the nanoparticle concentration.

Most of the experiments reported in the literature for heat transfer enhancements using nanofluid are confined only with heat exchangers of various forms. The outcome of literature leads to a novel perspective of using nanofluids as heat transfer fluids in agitated vessel, which has not been reported in the literature. Hence, this paper is aimed at presenting the heat transfer characteristics of TiO2/water nanofluid in agitated vessel using propeller agitator.

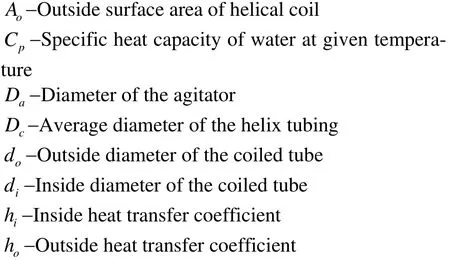

1. Development of TiO2/water nanofluid

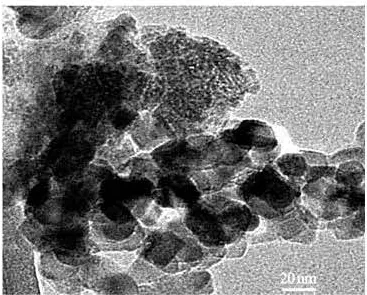

Generally, the preparation of nanofluids is an important step in experiments on nanofluids. To achieve a stable nanofluid that exhibits true nano behavior, the particles should be dispersed with no or very little agglomeration. This can be achieved by various methods and the most commonly used dispersion technique namely ultrasonication was adopted in this study. The TiO2nanoparticles used for this study were supplied by M/s Evonik Degussa India Ltd., with average diameters of 21 nm. The Transmission Electron Microscope (TEM) image of TiO2nanoparticles shown in Fig.1, which reveals an almost spherical shape with average diameter of 21 nm, the same as the particle size given by the manufacturer.

Fig.1 TEM image of TiO2nanoparticles

The TiO2nanoparticles for the specified volume fraction in distilled water base fluid along with 0.1 mg/liter of sodium dodecyl sulfate[24,25]dispersant were subjected to ultrasonication for 8 h to distribute the nanoparticles evenly. The stability of nanofluid was assessed by visual inspection of fluid sample over an extended period of time[7,26]. The density measurements suggested by Hojjat et al.[13]was also adopted to ensure the stability of the nanofluid dispersions. The density of some nanofluid samples was measured before and after the experimental run and no significant changes were observed in density.

2. Experimental setup

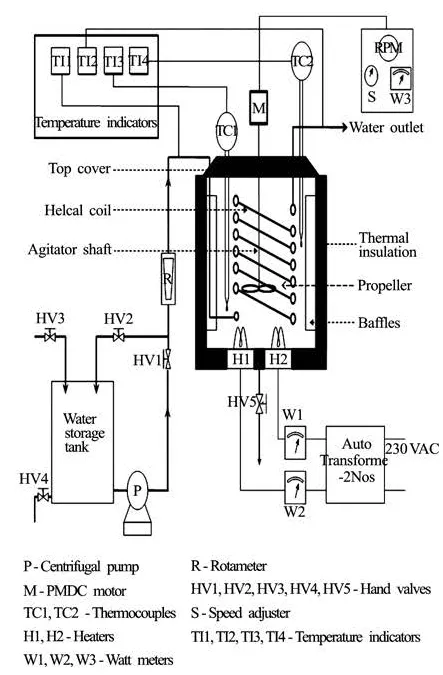

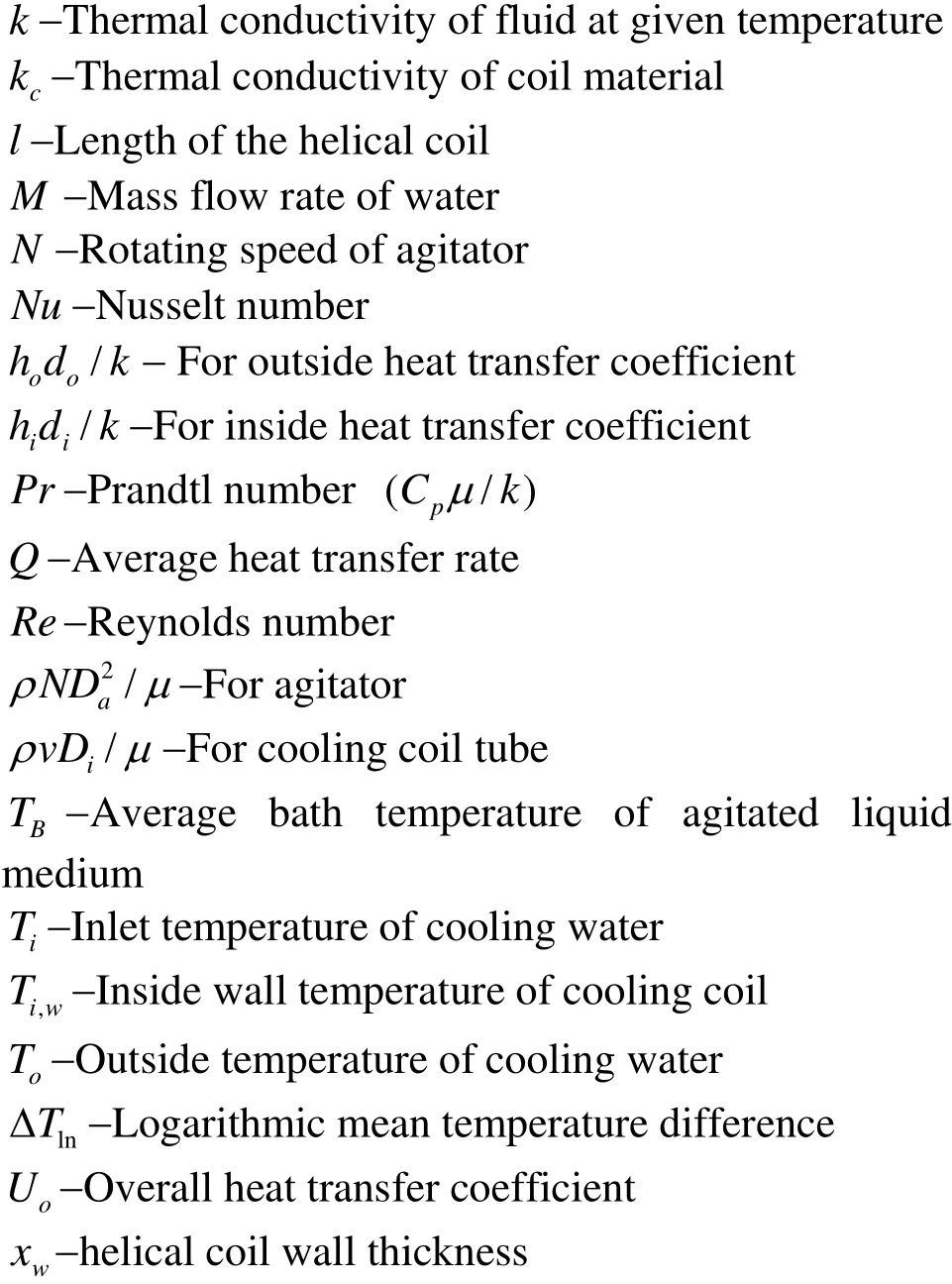

A schematic diagram of the experimental set up is shown in Fig.2. A flat bottomed cylindrical vessel of stainless steel of 0.3 m inner diameter and 0.45 m height with ellipsoidal lid was used as test vessel. Openings were provided at the top cover for insertion of two digital temperature sensors, an impeller shaft of 0.01 m diameter and the cooling water inlet and outlet. Agitation is carried out by propeller agitator of diameter 0.1 m (i.e., 1/3 of tank diameter) with 3 numbers of blades having thickness 0.003 m.

Fig.2 Experimental set up

Propeller agitator speed is varied from 1.667 to 11.667 revolutions per second (rps) by means of variable speed Permanent Magnet Direct Current (PMDC)-type motor. The heat input is varied from 400 Watts to 2 200 Watts and the range of temperature observed during experimentation was between 303.15 K and 328.15 K

Swirling and vortex formation inside the liquid pool can be prevented by using four baffles, each of them having width equal to 0.025 m (1/12 of tank diameter) and height equal to 0.42 m. These baffles were welded to the inside wall of the test vessel by dividing the periphery into four equal segments.

Two immersion heaters of 2 KW each were fitted at the bottom of the vessel to provide heat input to the medium being agitated inside the vessel. Heat input to these heaters was controlled by two autotransformers and measured with the help of digital Watt meters. A helical coil of 7.5 turns was fabricated out of the copper tube of 0.0115 m in inner diameter, 0.013 m in outer diameter and 6.2 m in length. Average outside coil diameter was 0.25 m with 0.028 m spacing between two consecutive coil turns. The helical coil was submerged in the pool of liquid medium being agitated up to a height of 0.3 m (3/4 of tank diameter) and water as cooling medium was circulated through the helical coil with the help of centrifugal pump and the flow rate was measured by means of a calibrated rotameter. The test vessel was fully covered with asbestos rope followed by a layer of glass wool to prevent heat loss to surroundings to the value smaller than 7%. Four digital temperature indicators (PT 100) with the accuracy of 0.1oC were used to note the temperatures of cooling water at the inlet and outlet respectively, and the agitated liquid medium temperatures at the top and bottom locations.

3. Experimental procedure

The experiments were conducted using distilled water at first and later with TiO2/water nanofluid of different concentrations as working fluids. The following sequences of procedure were maintained during experimentation.

(1) The agitated vessel is filled with working fluid to a height of 0.3 m in the vessel.

(2) Stabilizer is switched on and the power input to the heaters is set at a particular value using the autotransformers.

(3) Speed of the agitator is adjusted by means of the variable speed PMDC motor at a particular value.

(4) Centrifugal pump is switched on and the flow rate of cooling water through the helical cooling coil is fixed at 0.00003 m3/s using a rotameter to cool the heat supplied by heaters in the liquid being agitated and the experiment is allowed to run till steady state is attained.

(5) After attaining steady state, the temperatures of the medium inside the vessel at top and bottom and of the cooling water at the inlet and outlet are noted.

(6) At a particular heat input, the speed of the agitator is varied and the readings were taken after attaining steady state.

(7) The heat input to the heater is varied and the rotational speed of the agitator is also varied for each input and the readings are taken.

4. Models for the calculation.

4.1 Thermo physical properties of nanofluid

The thermophysical properties, namely density, viscosity, specific heat and thermal conductivity of the TiO2/water nanofluid, are calculated using different formulae available in literature and are given below

The density of the nanofluid is calculated according to Pak and Cho’s equation and is given as

Renowned Einstein equation is used for the calculation of viscosity of a fluid containing spherical particle in volume concentrations smaller than 5% andis given by

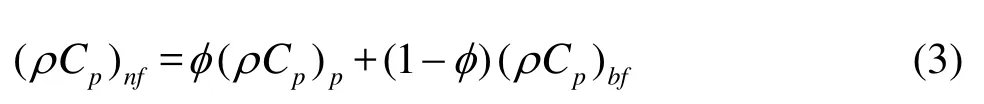

Specific heat of nanofluid is calculated using Xuan and Roetzel’s equation as follows

The Maxwell model applicable to statistically homogeneous and low volume concentration liquid-solid suspensions with randomly dispersed, uniformly sized and non-interacting spherical particles, which was the first model developed to determine the effective electrical or thermal conductivity of liquid-solid suspensions. The Maxwell equation is

If the thermal conductivity of the particles is much higher than that of the liquid, then from the conduction point of view, for very small volume concentration φ, the thermal conductivity of nano fluid can be given as

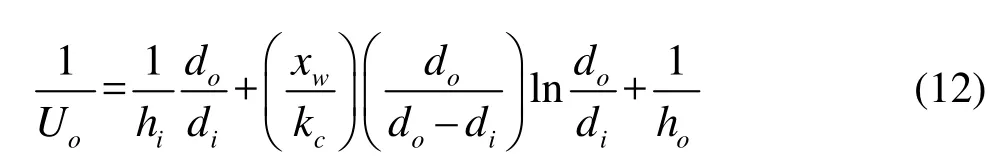

4.2 Models for the calculation of heat transfer coefficient

The heat transfer rate between cooling water flowing inside the helical coil and an agitated fluid depends on many parameters, namely the geometry, the agitated liquid properties, and the mixing intensity, which is influenced by the type of agitator and its revolution.

The transfer of heat in the present study is occurring from the hot fluid in the agitated vessel to the cooling water flowing in the helical coil by convection heat transfer mode. The thermophysical properties of cooling water were evaluated at average temperature measured by temperature indicators TI 1 and TI 2 whereas the thermo physical properties of agitated fluid were evaluated at average temperature (bath temperature) measured by temperature indicators TI 3 and TI 4.

At steady state, the heat transfer rate is calculated by the following equation

whereoA is given by

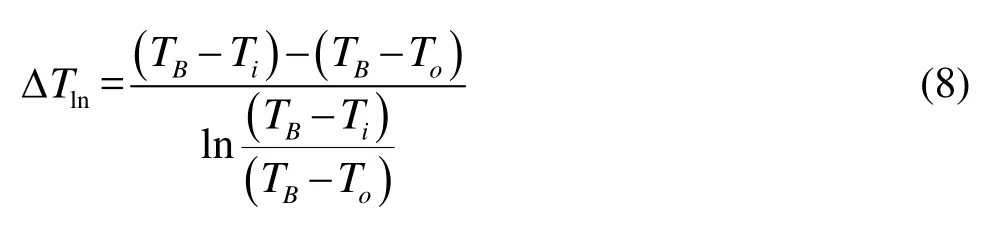

AndlnTΔ is given by

As the vessel is well-insulated to minimize the heat loss less than 7%, the actual rate of heat transfer Qinvolved during agitation is taken as average of heat supplied by heaters and heat gained by the cooling medium and is given as

where Q1is the heat supplied to the agitated medium by immersion heaters measured using digital watt meters W1 and W2, Q2is the heat gained by cooling medium and given by

The overall heat transfer coefficient is then calculated using the relation

And

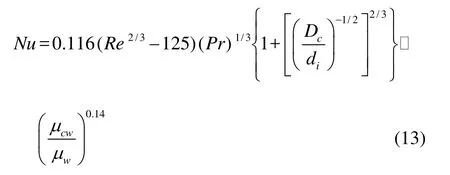

As the coolant flow rate is fixed at 0.00003 m3/s and the Reynolds number for this flow rate based on inside diameter of the cooling coil is around 5 000, the following empirical equation (see Perry’s “Chemical Engineers’ Handbook”) is used for calculating inside heat transfer coefficient

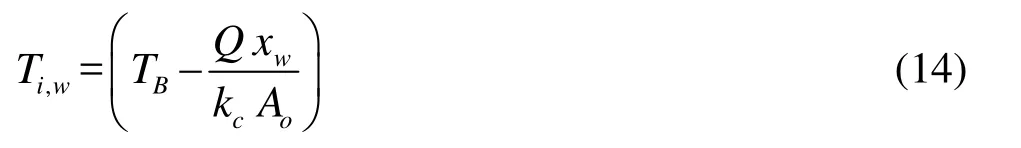

Viscosity simplex is calculated by calculating inside wall temperature of the cooling coil by the following relation

The inside film heat transfer coefficient is then calculated by using the following relation

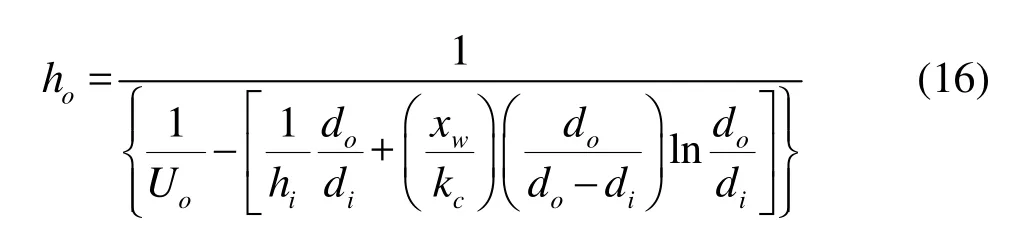

Knowing Uoand hi, the outside heat transfer coefficient is calculated using the relation The Nusselt number for outside heat transfer coefficient is calculated using the relation

Experimental uncertainty was calculated following the Coleman-Steele method and ANSI/ASME standard, and the calculation showed that maxima of ±3.39% and ±1.78% for the Reynolds number and Nusselt number respectively.

5. Results and discussions

5.1 Experimental analysis

Initially experiments were conducted with water which forms the basis for comparison of results with nanofluid. The heat transfer is taking place from the agitated liquid mass to the cooling water flowing in helical cooling coil which is submerged in the pool of agitated liquid. Agitation provides increased rate of heat transfer by dissipating the heat uniformly throughout the vessel. Nanoparticles suspended in a base fluid provide large surface area which allows for more heat transfer. Particles around 20 nm carry 20% of their atoms on their surface, making them instantaneously available for thermal interaction[27]. Another advantage is the mobility of the particles, which may bring about micro-convection of fluid which in turn increase the heat transfer.

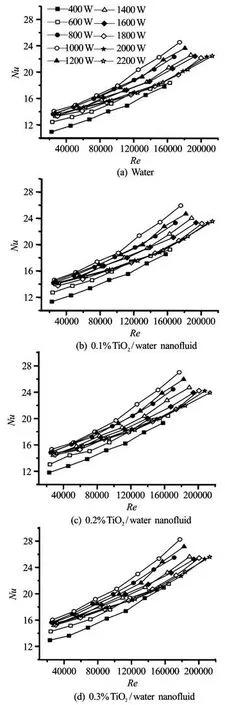

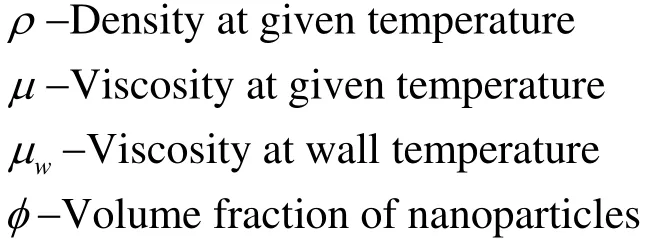

The experimental results of the effect of propeller speed on heat transfer for water and TiO2/water nanofluid of three different volume concentrations using propeller agitator are presented in Fig.3. It is observed from Fig.3 that the Nusselt number increases with increasing speed of agitation. This is due to the reason that the intensity of mixing increases with increasing speed of propeller agitator, as the mixing intensifies turbulence in the medium leading to effective heat transfer. It is also seen from Fig.3 that as the heat input increases, the bath temperature increases. This increase in bath temperature offers higher temperature difference and hence the higher driving forces for heat transfer. This phenomenon results in higher heat transfer coefficient.

Fig.3 Effect of impeller speed on heat transfer performances for water and TiO2/water nanofluids

It is also observed that the Nusselt number increases with heat input up to 1 000 Watts and then decreases for both water and TiO2/water nanofluid. Above this value of heat input, the Nusselt number increases with increasing speed of propeller, but thevalues are found to be smaller. This may be due to the reason that propeller agitator induces axial mixing of fluid and this axial movement of fluid aids heat transfer up to a particular value and becomes insignificant beyond this value.

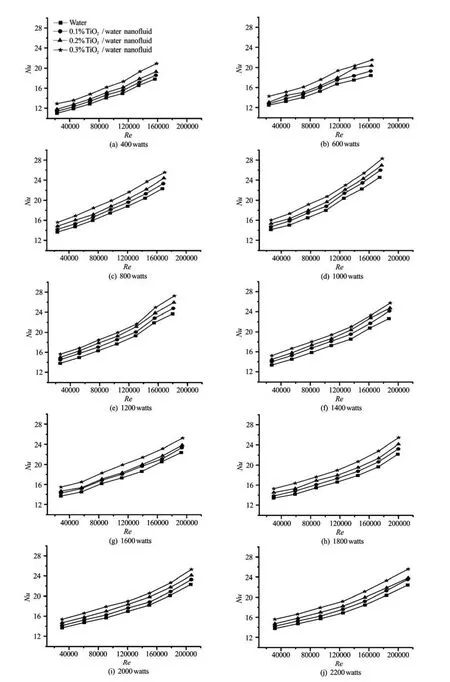

Fig.4 Comparison of heat transfer characteristics of TiO2/water nanofluids with water

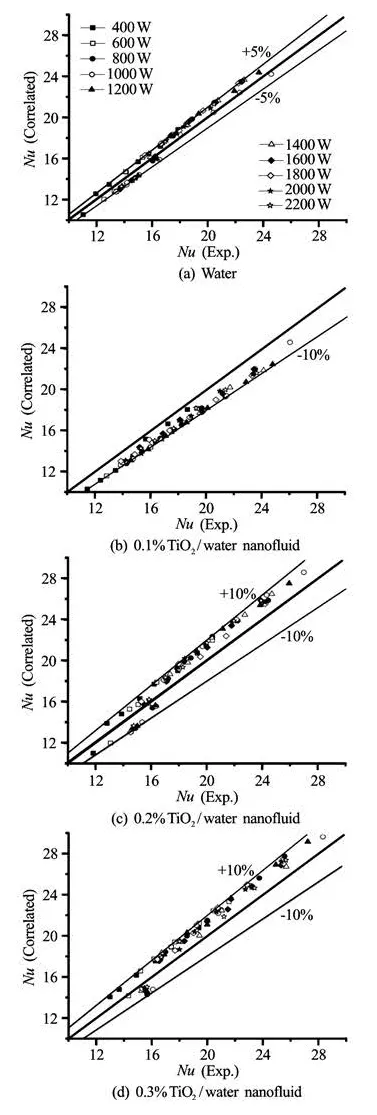

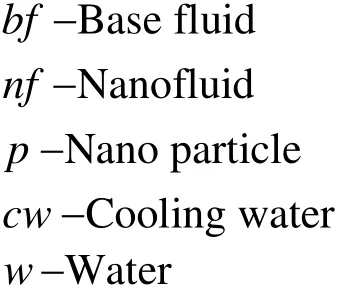

Fig.5 Comparison of experimental and correlated Nusselt number for water and TiO2/water nanofluids

Figure 4 illustrates the variation of convective heat transfer coefficients with the Reynolds number for water and three different volume concentrations of TiO2nanoparticles respectively. It is seen from Fig.4 that the Nusselt number of TiO2/water nanofluid increases gradually with the increase in the Reynolds number (agitator speed). It is also evident that the trend of increase rate of the Nusselt number with the Reynolds number of nanofluid is similar to that trend observed for water. As is shown in Fig.4 addition of nanoparticles has strong influences on the convective heat transfer coefficient of nanofluid, and the increasing pattern of heat transfer coefficient (the Nusselt number) with increasing volume concentration of nanofluid is observed with increasing agitator speed.

The mechanism behind this increasing behavior of heat transfer is as follows: (1) increased mixing intensity due to turbulence created with increasing speed of propeller attributing enhanced heat uniformity throughout the agitated vessel, (2) increased surface area with increasing volume concentration of nanoparticles and hence significant improvement in the effective thermal conductivity of nanofluids which results in enhanced heat transfer rate.

The heat transfer enhancements using TiO2/water nanofluid are found to be in the ranges of 2.82% to 6.51% for 0.10% concentration, 5.86% to 13.74% for 0.20% concentration and 13.23% to 17.59% for 0.30% concentration compared to water. The nanofluid increases the thermal conductivity of the medium and hence the improved heat exchange causes this enhancement. It is believed that the enhancement in the thermal conductivity of nanofluid is mainly responsible for the improvement in the convective heat transfer coefficient of nanofluids[16].

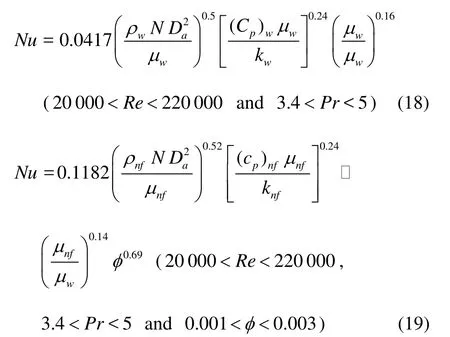

5.2 Empirical correlations

The following empirical correlations are formulated from experimental data using the multiple linear regression analysis for water and TiO2/water nanofluid respectively:

The values obtained from correlation are compared with the experimental values and the deviations are found to fall within ±5% for water and ±10% fornanofluid. Figure 5 presents the comparison of correlated and experimental Nusselt number for water and nanofluid of varying concentrations.

6. Conclusions

(1) Heat transfer in a coiled agitated vessel using water and TiO2/water nanofluid has been studied using a propeller agitator.

(2) The influence of agitation speed on heat transfer coefficient has been studied, concluding that the heat transfer coefficient increases with increasing speed of agitator.

(3) The heat transfer behavior of TiO2/water nanofluid follows the same trend as water with significant enhancement in the heat transfer rate.

(4) The heat transfer characteristics has been observed to increase with increasing particle volume concentration of up to 0.30%

(5) The use of TiO2/water nanofluid as agitated liquid instead of water yields a maximum enhancement of 6.51% for 0.10% concentration, 13.74% for 0.20% concentration and 17.59% for 0.30% concentration.

(6) Empirical correlations for both TiO2/water nanofluid and water have been formed separately based on experimental data and found to fit the experimental values within the range of ±5% for water and within the range ±10% for nanofluid.

Acknowledgements

The authors would like to express their thanks to M/s Evonik Degussa India Ltd, Mumbai for the valuable donation of the TiO2nanoparticles used in the present study.

[1] TRIVENI B., VISHWANADHAN B. and VENKATESHWAR S. Studies on heat transfer to Newtonian and non-Newtonian fluids in agitated vessels[J]. Heat Mass Transfer, 2008, 44(11): 1281-1288.

[2] PERARASU V. T., ARIVAZHAGAN M. and SIVASHANMUGAM P. Heat transfer studies in coiled agitated vessel with varying heat input[J]. International Journal of Food Engineering, 2011, 7(4): Article 3.

[3] LIN J., LIN P. and CHEN H. Research on the transport and deposition of nanoparticles in a rotating curved pipe[J]. Physics of Fluids, 2009, 21(12): 1-11.

[4] YU M., LIN J. and CHAN T. A new moment method for solving the coagulation equation for particles in Brownian motion[J]. Aerosol Science and Technology, 2008, 42(9): 705-713.

[5] YU Ming-Zhou, LIN Jian-Zhong and CHAN Tat-Leung. Effect of precursor loading on non-spherical TiO2nanoparticle synthesis in a diffusion flame reactor[J]. Chemical Engineering Science, 2008: 63(9): 2317-2329.

[6] CHANDRASEKAR M., SURESH S. and CHANDRA BOSE A. Experimental studies on heat transfer and friction factor characteristics of Al2O3/water nanofluid in a circular pipe under laminar flow with wire coil inserts[J]. Experimental Therm Fluid Science, 2010, 34(2): 122-130.

[7] AMROLLAHI A., RASHIDI A. M. and LOTFI R. et al. Convection heat transfer of functionalized MWNT in aqueous fluids in laminar and turbulent flow at the entrance region[J]. International Communications in Heat Mass Transfer, 2010, 37(6): 717- 723.

[8] XIE H., LI Y. and YU W. Intriguingly high convective heat transfer enhancement of nanofluid coolants in laminar flows[J]. Physics Letters A, 2010, 374(25): 2566-2568.

[9] FOTUKIAN S. M., NASR ESFAHANY M. Experimental investigation of turbulent convective heat transfer of dilute γ-Al2O3/water nanofluid inside a circular tube[J]. International Journal of Heat Fluid Flow, 2010, 31: 606-612.

[10] FOTUKIAN S. M., NASR ESFAHANY M. Experimental study of turbulent convective heat transfer and pressure drop of dilute CuO/water nanofluid inside a circular tube[J]. International Communications in Heat Mass Transfer, 2010, 37(2): 214-219.

[11] SURESH S., CHANDRASEKAR M. and CHANDRA SEKHAR S. Experimental studies on heat transfer and friction factor characteristics of CuO/water nanofluid under turbulent flow in a helically dimpled tube[J]. Expimental Thermal Fluid Science, 2010, 35(3): 542-549.

[12] BIANCO V., MANCA O. and NARDINI S. Numerical investigation on nanofluids turbulent convection heat transfer inside a circular tube[J]. Internatinal Journal of Thermal Sciences, 2011, 50(3): 341-349.

[13] HOJJAT M., ETEMAD S. Gh. and BAGHERI R. et al. Convective heat transfer of non-Newtonian nanofluids through a uniformly heated circular tube[J]. Internatinal Journal of Thermal Sciences, 2011, 50(4): 525-531.

[14] SURESH S., VENKITARAJ K. P. and SELVAKUMAR P. Comparative study on thermal performance of helical screw tape inserts in laminar flow using Al2O3/ water and CuO/water nanofluids[J]. Superlattices Microstructures, 2011, 49(6): 608-622.

[15] CHUN Byung-Hee, KANG Hyun Uk and KIM Sung Hyun. Effect of alumina nanoparticles in the fluid on heat transfer in double-pipe heat exchanger system[J]. Korean Journal of Chemical Engineering, 2008, 25(5): 966-971.

[16] DUANGTHONGSUK W., WONGWISES S. Heat transfer enhancement and pressure drop characteristics of TiO2-water nanofluid in a double-tube counter flow heat exchanger[J]. International Journal of Heat Mass Transfer, 2009, 52(7-8): 2059-2067.

[17] DUANGTHONGSUK W., WONGWISES S. An experimental study on the heat transfer performance and pressure drop of TiO2-water nanofluids flowing under a turbulent flow regime[J]. International Journal of Heat Mass Transfer, 2010, 53(1-3): 334-344.

[18] FARAJOLLAHI B., ETEMAD S. Gh. and HOJJAT M. Heat transfer of nanofluids in a shell and tube heat exchanger[J]. International Journal of Heat Mass Transfer, 2010, 53(1-3): 12-17.

[19] JWO Ching-Song, JENG Lung-Yue and TENG Tun-Ping et al. Performance of overall heat transfer in multichannel heat exchanger by alumina nanofluid[J].Journal of Alloys Compounds, 2010, 504(Suppl.1): S385-S388.

[20] NGUYEN C. T., ROY G. and GAUTHIER C. et al. Heat transfer enhancement using Al2O3-water nanofluid for an electronic liquid cooling system[J]. Applied Thermal Engineering, 2007, 27(8-9): 1501-1506.

[21] GHERASIM I., ROY G. and NGUYEN C. T. et al. Experimental investigation of nanofluids in confined laminar radial flows[J]. International Journal of The- rmal Sciences, 2009, 48(8): 1486-1493.

[22] JUNG Jung-Yeal, OH Hoo-Suk and KWAK Ho-Young. Forced convective heat transfer of nanofluids in microchannels[J]. International Journal of Heat Mass Transfer, 2009, 52(1-2): 466-472.

[23] MOHAMMED H. A., BHASKARAN G. N. and SHUAIB H. et al. Numerical study of heat transfer enhancement of counter nanofluids flow in rectangular microchannel heat exchanger[J]. Superlattices Micro- structures, 2011, 50(3): 215-233.

[24] HWANG Yunjun, LEE Jae-Keun and LEE Jong-Ku et al. Production and dispersion stability of nanoparticles in nanofluids[J]. Powder Technology, 2008, 186(2): 145-153.

[25] FEDELE L., COLLA L. and BOBBO S. et al. Experimental stability analysis of different water based nano- fluids[J]. Nanoscale Research Letters, 2011, 6: 300.

[26] TORII S., YANG W. J. Heat transfer augmentation of aqueous suspensions of nanodiamonds in turbulent pipe flow[J]. Journal of Heat Transfer, 2009, 131(4): 043203.

[27] WANG X. Q., MUJUMDAR A. S. Heat transfer characteristics of nanofluids: A review[J]. International Journal of Thermal Sciences, 2007, 46(1): 1-19.

Notations

Greek letters

Subscripts

10.1016/S1001-6058(11)60322-3

* Biography: PERARASU V. T. (1981-), Male, Master Candidate

ARIVAZHAGAN M.,

E-mail: ariva@nitt.edu

- 水動力學(xué)研究與進(jìn)展 B輯的其它文章

- DIFFUSING OF AN AMMONIA MOLECULE IN WATER IN A VERY SHORT TIME PERIOD*

- 3-D VARIABLE PARAMETER NUMERICAL MODEL FOR EVALUATION OF THE PLANNED EXPLOITABLE GROUNDWATER RESOURCE IN REGIONAL UNCONSOLIDATED SEDIMENTS*

- NUMERICAL STUDY OF THE PITCHING MOTIONS OF SUPERCAVITATING VEHICLES*

- A FAST LAGRANGIAN SIMULATION METHOD FOR FLOW ANALYSIS AND RUNNER DESIGN IN PELTON TURBINES*

- TRANSPORT OF BICOMPONENT CONTAMINANT IN FREE-SURFACE WETLAND FLOW*

- RESERVOIR SEDIMENTATION AND TRANSFORMATION OF MORPHOLOGY IN THE LOWER YELLOW RIVER DURING 10 YEAR’S INITIAL OPERATION OF THE XIAOLANGDI RESERVOIR*